Glazing device for building cup manufacturing

A technology for making and functioning a lamp, which is applied in the field of glazing devices, and can solve the problems of difficulty in fixing the lamp, insufficient glazing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A glazing device for making Jianzhan, such as Figure 1-5 As shown, it includes a first support frame 1, a loading frame 2, a placement assembly 3 and a clamping assembly 4. There are two first support frames 1, and a loading frame 2 is arranged between the top of the first support frame 1. A supporting frame 1 is provided with a placing component 3 on the top, and a clamping component 4 is provided on the top of the placing component 3 .

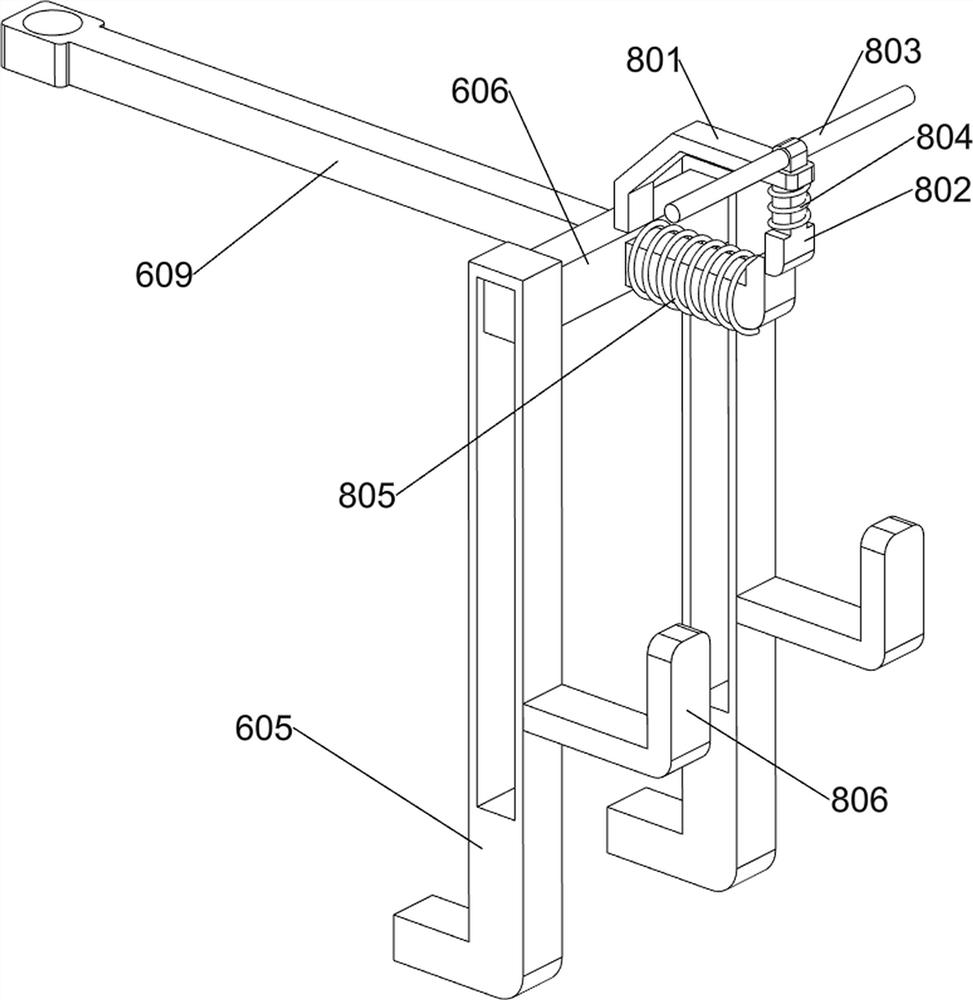

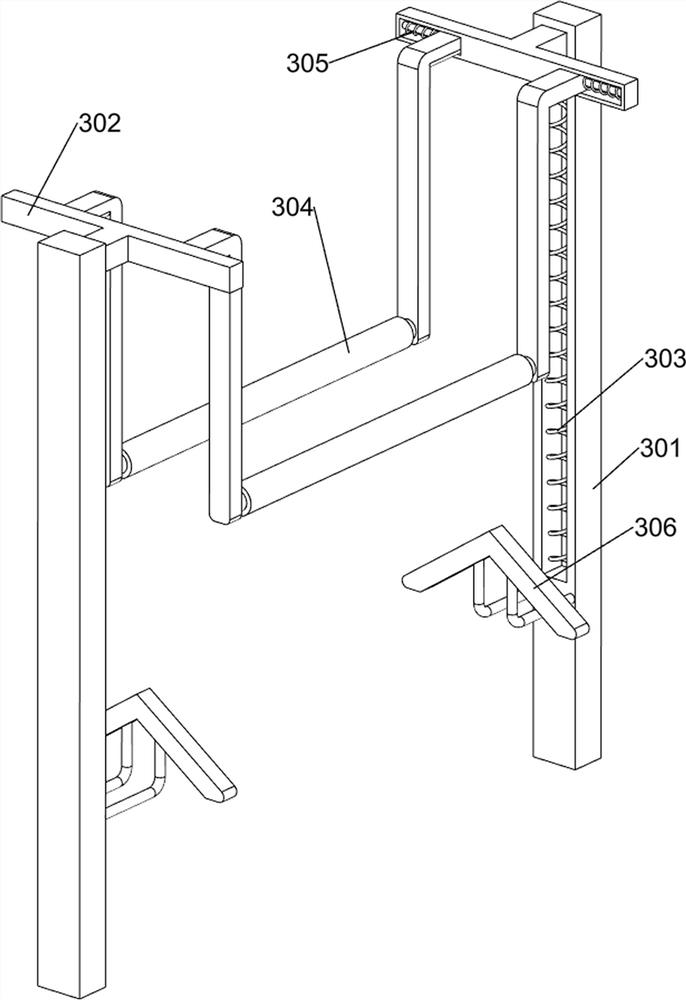

[0032] The placement assembly 3 includes a first support rod 301, a first sliding rod 302, a first spring 303, a placement rod 304, a second spring 305 and a wedge rod 306, and the first support frame 1 is provided with a first support rod on the middle side of the top. 301, the upper side of the first support bar 301 is slidingly provided with a first slide bar 302, and the first slide bar 302 and the first support bar 301 on the same side are connected with a first spring 303, and the inside of the first slide bar 302 The front an...

Embodiment 2

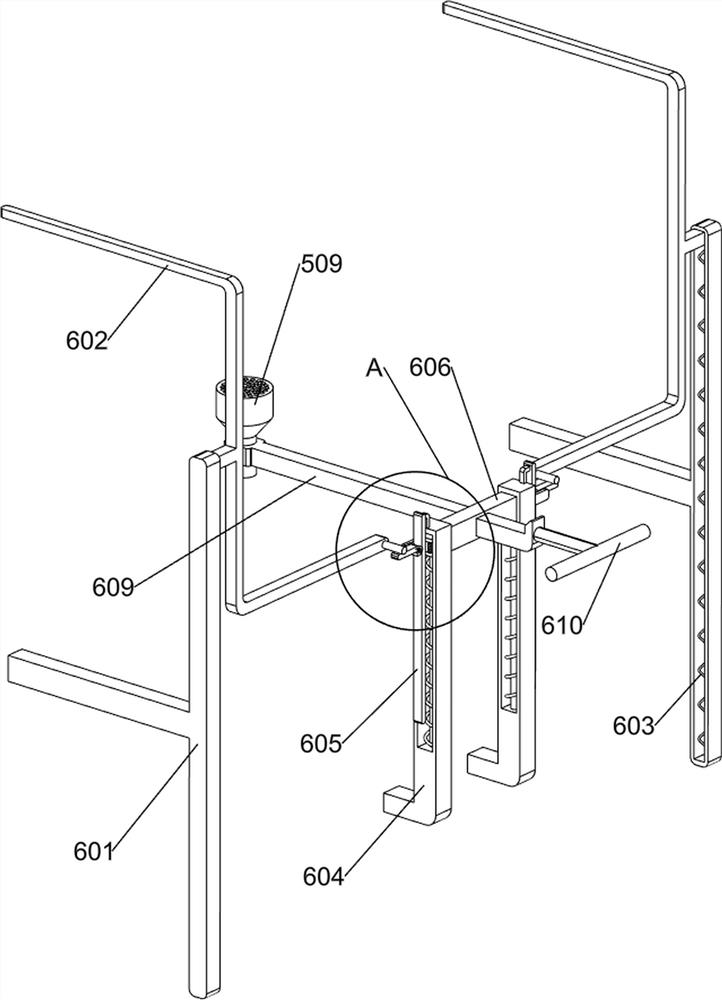

[0036] On the basis of Example 1, such as Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, it also includes a spraying assembly 5, and the spraying assembly 5 includes a second support rod 501, a piston cylinder 502, a feed pipe 503, a first piston 504, a first support block 505, a first pressing rod 506, a first torsion Spring 507, discharge pipe 508 and nozzle 509, the second support rod 501 is arranged between the front side of the first support frame 1 top, the middle part of the front side of the second support rod 501 is provided with a piston cylinder 502, the bottom of the piston cylinder 502 is connected with the loading material A feed pipe 503 is connected between the frames 2, a first piston 504 is slidably provided inside the piston cylinder 502, a first support block 505 is provided on the rear side of the top of the piston cylinder 502, and a first support block 505 is provided with a rotating type on the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com