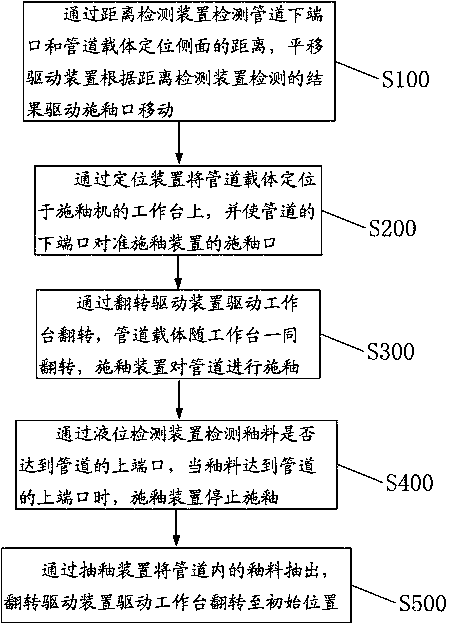

A method for automatic glazing of pipelines

A pipeline and automatic technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of inaccurate control of glaze amount, difficult control of glaze amount, increased workload, etc., to improve quality and work efficiency , reduce work costs and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

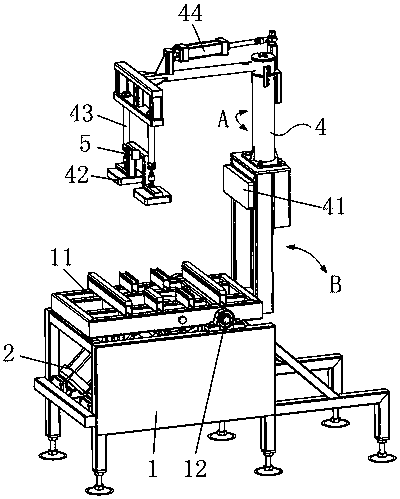

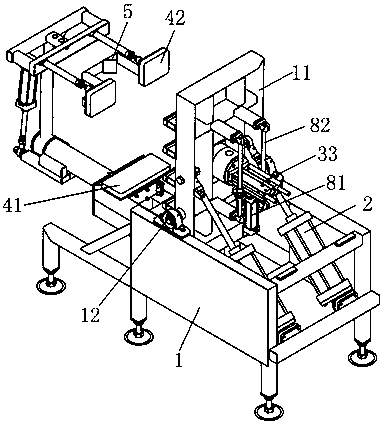

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings. It is only stated here that the words for directions such as up, down, left, right, front, back, inside, and outside that appear or will appear in the text of the present invention are only based on the accompanying drawings of the present invention, and are not specific to the present invention. limited.

[0038] It should be noted that the glazing method of the present invention can be used for ordinary straight pipes and curved pipes, wherein the pipe carrier is the device where the pipe is located. For the convenience of illustration, the pipe carrier of the present invention takes the toilet 9 as an example, wherein the pipe is The sewage pipe 90 of the toilet, the sewage pipe 90 of the toilet 9 is an upwardly convex siphon with a bend, and the lower port 90a a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com