Board-side net-hauling tension testing device

A technology of testing device and power device, applied in fishing nets, fishing boats, fishing and other directions, can solve the problems of lack of basic basis for device design, lack of basic experimental research, drum structure and net difficulty, etc., and achieves simple structure and high measurement accuracy. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

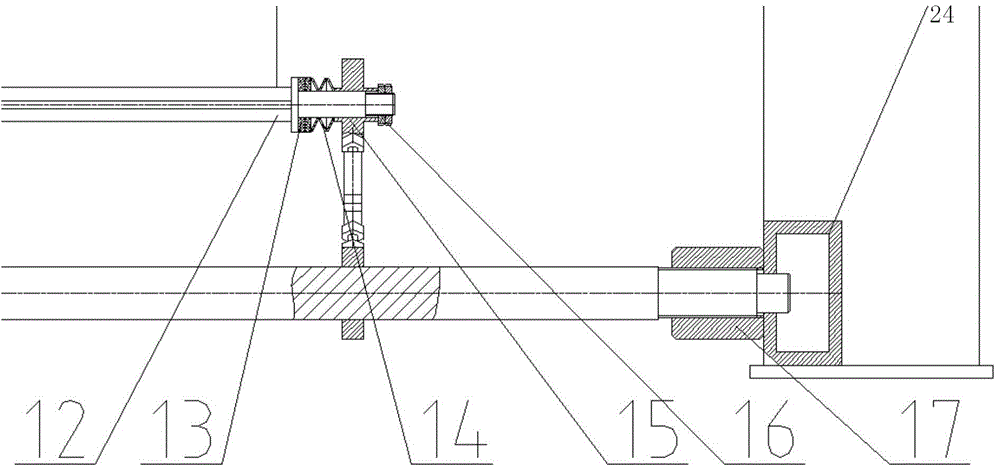

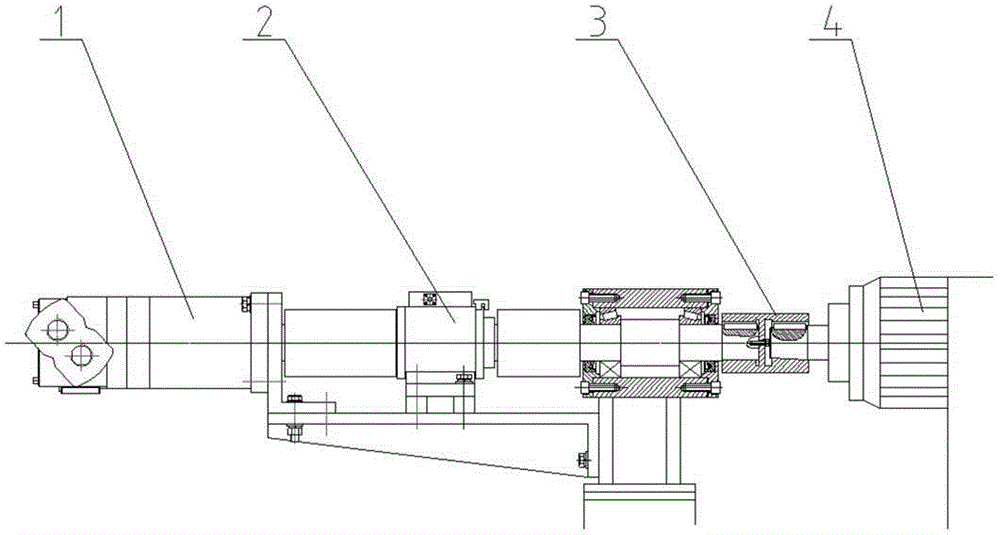

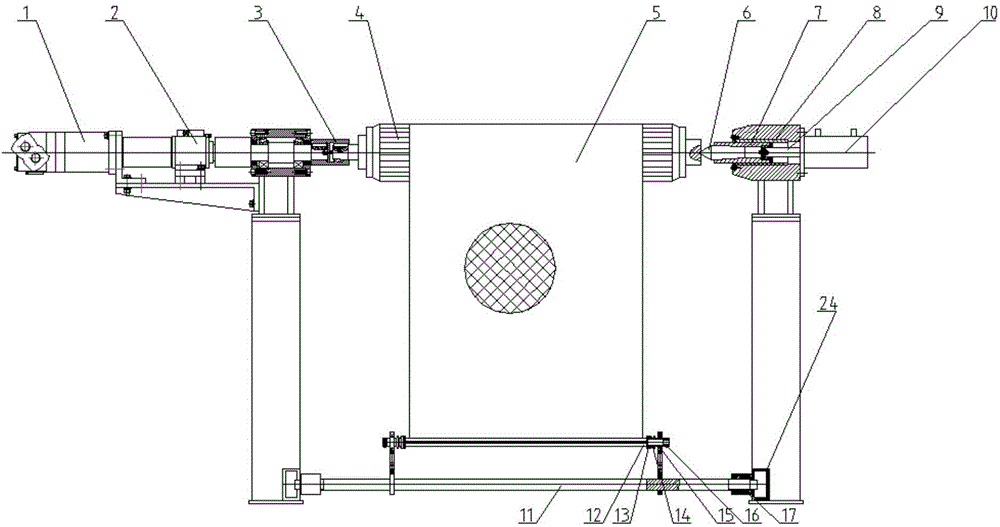

[0031] see Figure 1-7 , according to the requirements for measuring the friction force between the side drum and the mesh and the tension of the mesh, the present invention uses the torque meter 2 and the tension and pressure sensor 21 to work together to accurately measure the dynamic and static friction between the roller and the mesh , the tension of the elastic side mesh. When carrying out friction and tension measurement operations, if it is necessary to replace the side roller, it is only necessary to open the cylinder 10, so that the piston 9 drives the thimble sheath 7 and the thimble 6 to move backward along the sliding bearing 8, so that the thimble and the side roller shaft Port hole disengages. The side roller can be separated from the connection sleeve 3. Then insert the new side roller under test into the taper hole of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com