Full-automatic foam thin cutting device

A fully automatic, foam technology, applied in other manufacturing equipment/tools, grinding machines, metal processing, etc., can solve the problems of inability to achieve thin cutting, low cutting efficiency, large tool loss, etc., to achieve stability and precision control, Improves cutting stability and uniformity, avoiding jitter or offset effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

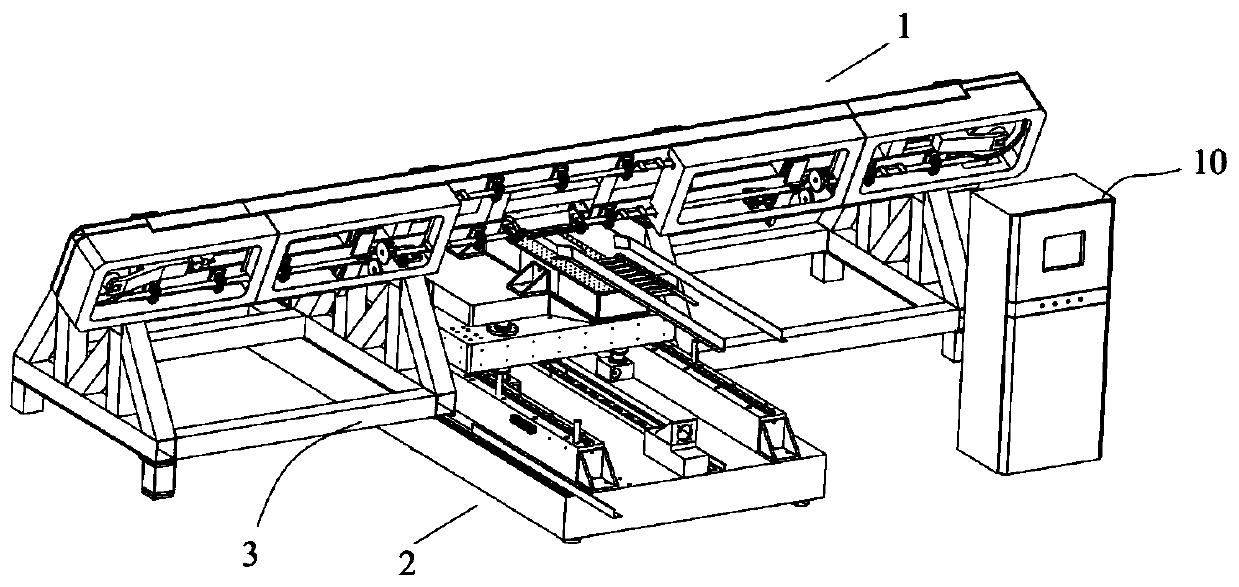

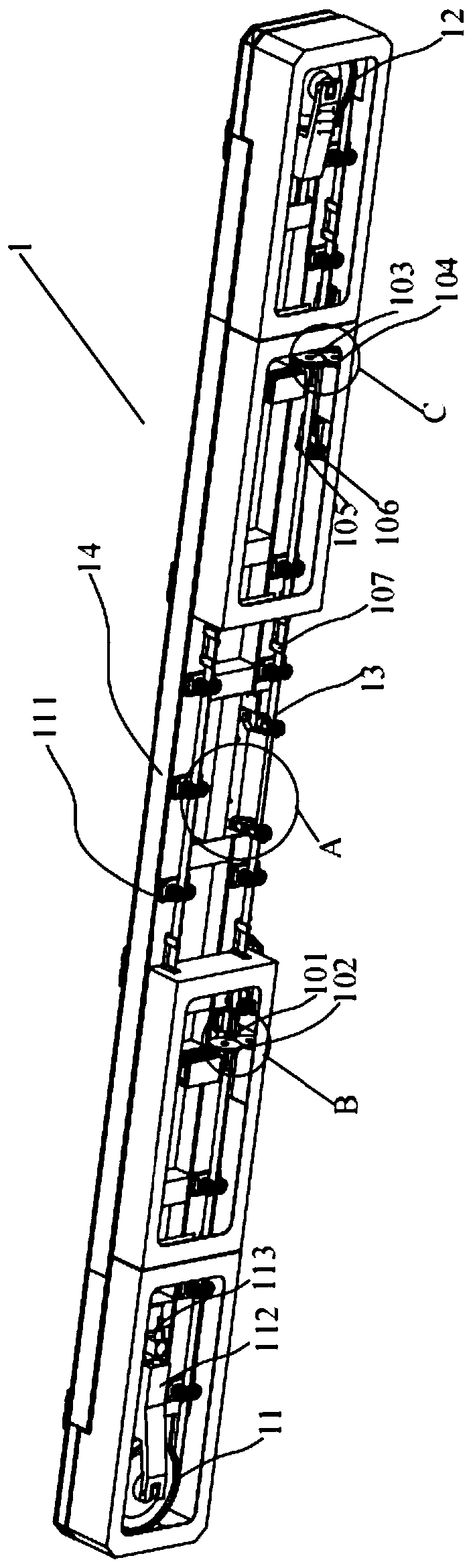

[0077] like figure 1 As shown in the figure, the fully automatic foam thinning device disclosed by the present invention includes a frame 3, a cutting mechanism 1 arranged on the frame 3, a foam feeding mechanism 2, and a control cabinet 10, which is used to control Operation of cutting mechanism 1 and foam feeding mechanism 2.

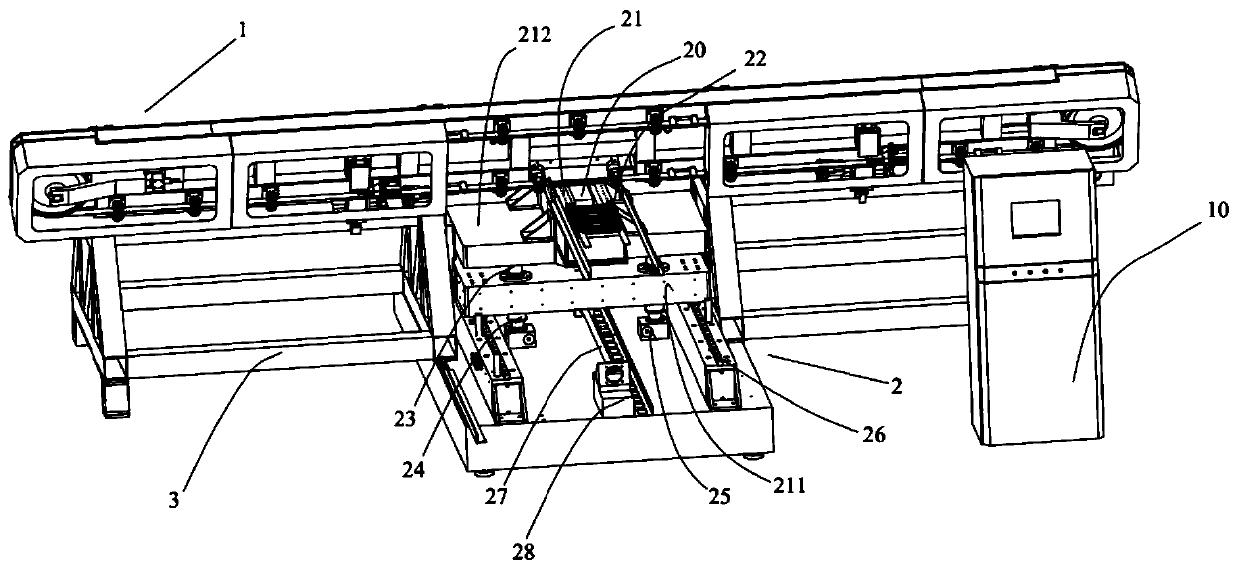

[0078] Further, such as figure 2 As shown in the figure, the foam feeding mechanism 2 of the fully automatic foam thinning device includes a feeding base 21 and a driving device that drives the feeding base 21 to move; specifically, the feeding base 21 has a vacuum adsorption end to form a vacuum adsorption work A table is used to absorb and position the foam piece 20 placed on the feeding base 21; in order to facilitate the cutting of foam pieces with higher thickness and hardness, a preheating device 22 is provided above the feeding base 21. The heat device 22 includes several infrared heating tubes arranged side by side.

[0079] The driving de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com