Main spindle transmission control system of economy type numerically controlled lathe

A CNC lathe and spindle transmission technology, applied in metal processing equipment, etc., can solve the problems of inconsistent roughness of the processed surface, the inability of stepless speed regulation of the spindle, and the inability of wide-range speed regulation of the spindle to achieve simple operation and automation High, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

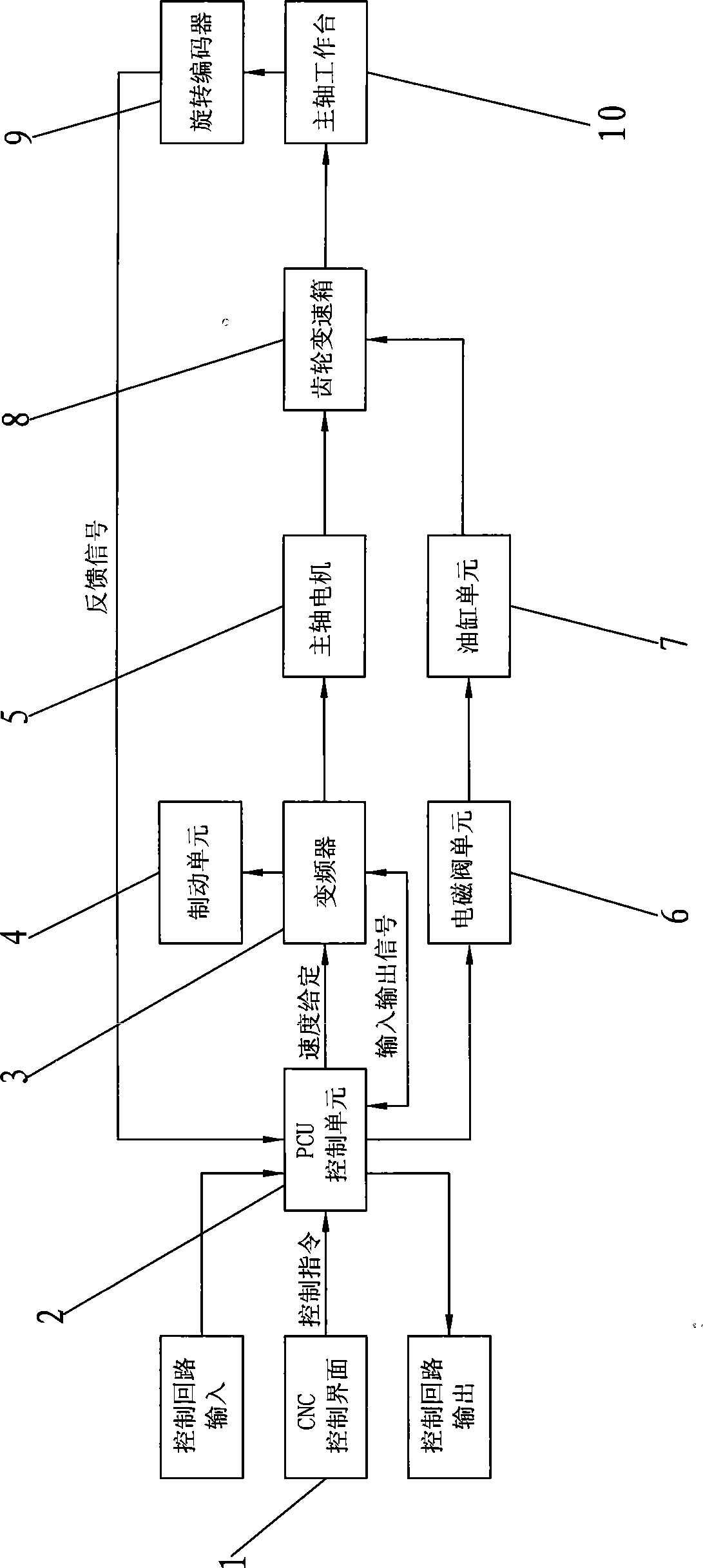

[0009] The spindle drive control system of the economical CNC lathe of the present invention, such as figure 1 As shown, it includes CNC control interface 1, PCU control unit 2, frequency converter 3, braking unit 4, spindle motor 5, solenoid valve unit 6, oil cylinder unit 7, gear box 8 and rotary encoder 9. The CNC control interface 1 is connected to the setting input terminal of the PCU control unit 2, and the control output terminal of the PCU control unit 2 is connected to the frequency converter 3, the spindle motor 5 and the gear box 8 in turn, and the brake unit 4 (the brake unit mainly starts the spindle stop energy consumption braking) is connected to the brake control output terminal of the inverter 3, and the analog output terminal of the PCU control unit 2 is bidirectionally connected with the analog input terminal of the inverter 3 to realize the input and output of control signals; the PCU control unit The other output end of 2 is connected to the solenoid valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com