Ampoule laser automatic opening device and method thereof

A technology of automatic opening and ampoule loading, which is applied to manual cutting devices and other directions, can solve the problems of high labor intensity, contamination of liquid medicine or samples, and falling in, and achieve the effect of reasonable structural design and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

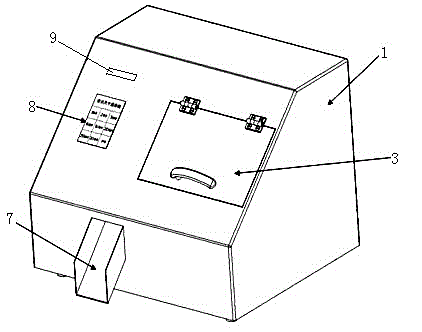

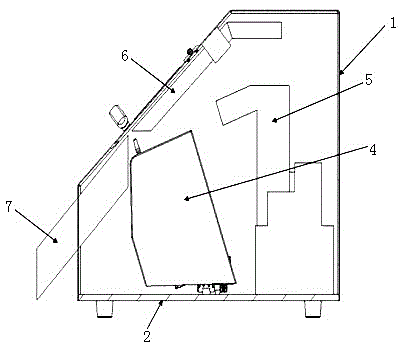

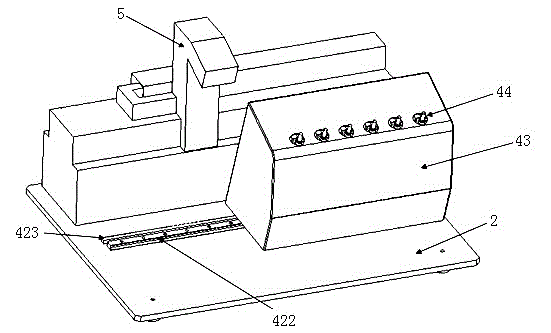

[0040] one sight figure 1 , figure 2 , image 3 , an ampoule laser automatic opening device, including a housing 1 with a window door 3, an ampoule clamping mechanism 4 located in the housing 1 and slidably arranged on the bottom plate 2 of the housing, and an ampoule clamping mechanism 4 located in the housing 1 and fixedly arranged on the bottom plate of the housing 2 relative to the ampoule clamping mechanism 4, the laser cutting machine 5 is disposed in the housing 1 and is located above the ampoule clamping mechanism 6, and is disposed on the housing 1 The chute 7 arranged on an upward slope, the keyboard operating device 8 and the signal indicator light 9 arranged on the outer wall of the housing, the safety self-locking switch 10 arranged on the window door 3, and the driving ampoule card loading mechanism 4, laser cutting Machine 5, vacuum tube 6, keyboard operating device 8, signal indicator light 9 and safety self-locking switch 10 are connected and have the singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com