Patents

Literature

33results about How to "Guaranteed slice quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Monocrystalline silicon high-efficient composite cutting method and cutting system thereof

InactiveCN101138869AImprove cutting effectSave the texture processFine working devicesMetalElectric spark

An efficiently composite cutting method of monocrystalline silicon is characterized in that a monocrystalline silicon rod for cutting is installed and nipped at an electric spark linear cutting machine; metallic thread which is concreted with diamond grinding material is used as cutting wire to make the electric spark linear cutting; the advantages that the processing speed of the electric spark linear cutting is high and the cutting effect of the diamond grinding material at the metallic thread of the concreted grinding material is good are completely exerted; the purpose to realize the quickly and efficiently cutting towards the monocrystalline silicon rod is achieved; at the same time the surface of the cut monocrystalline silicon naturally forms a fleece-faced texture which has the effect of anti-reflection. The present invention has a series of advantages of simple method, high efficiency of processing, good quality etc.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

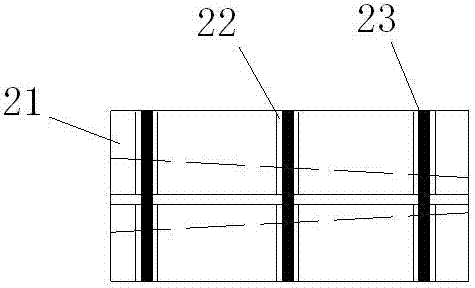

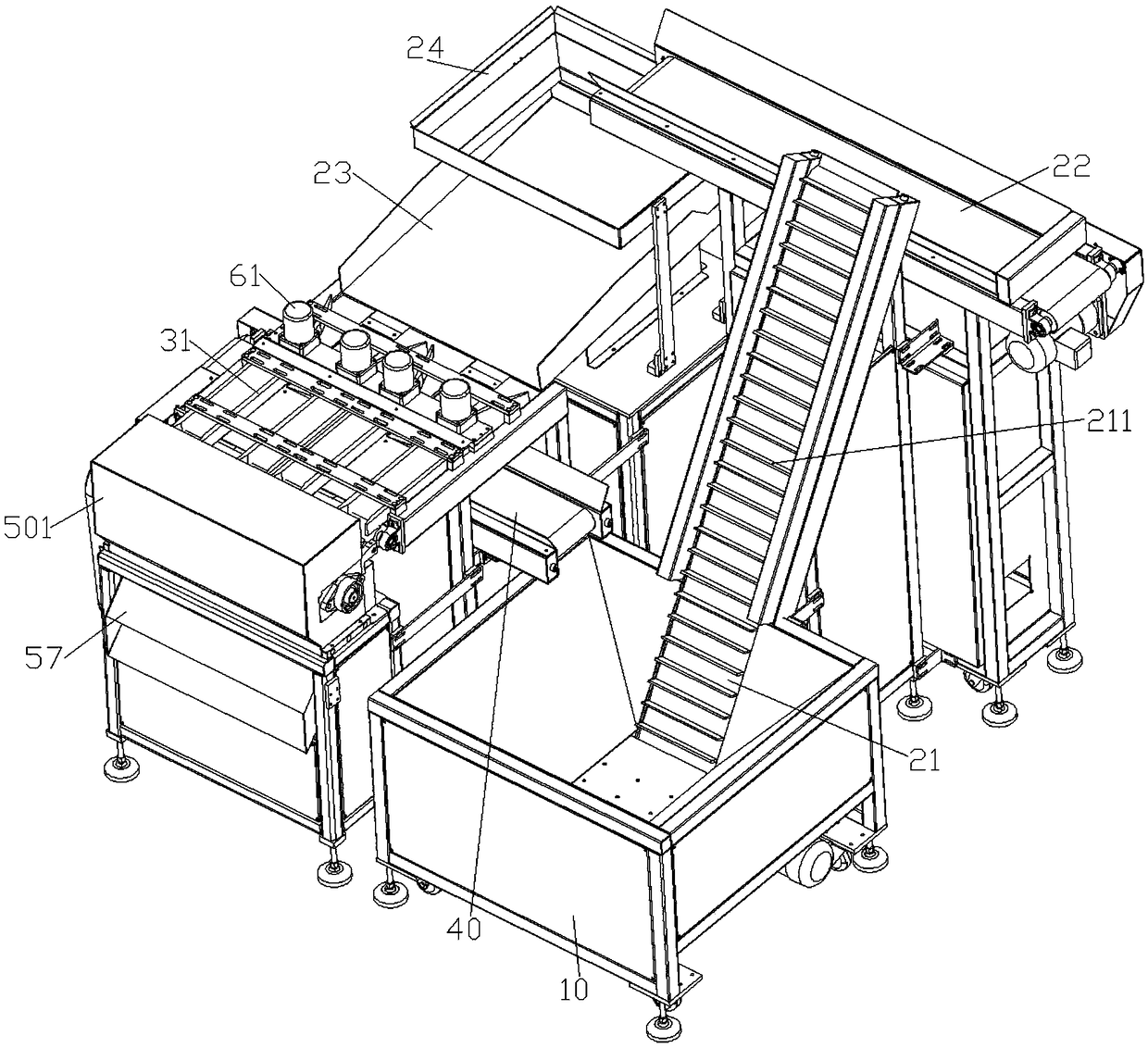

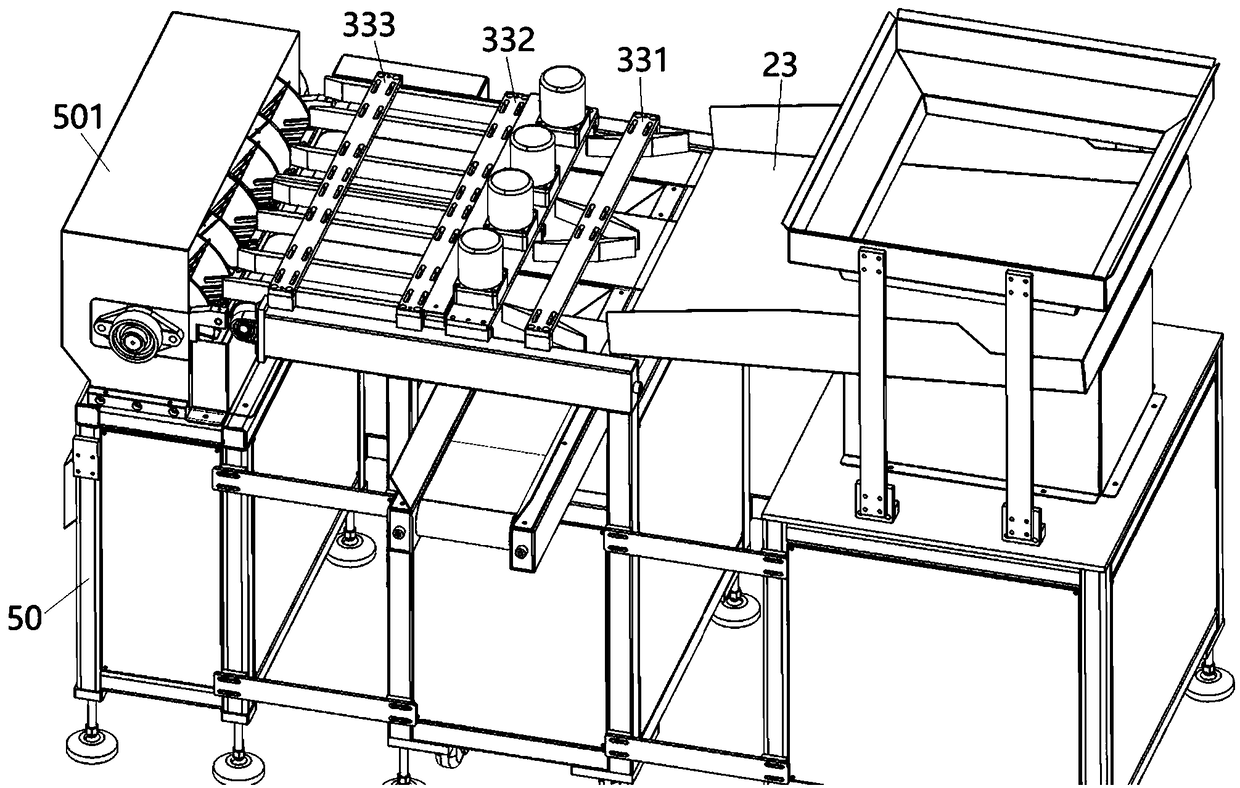

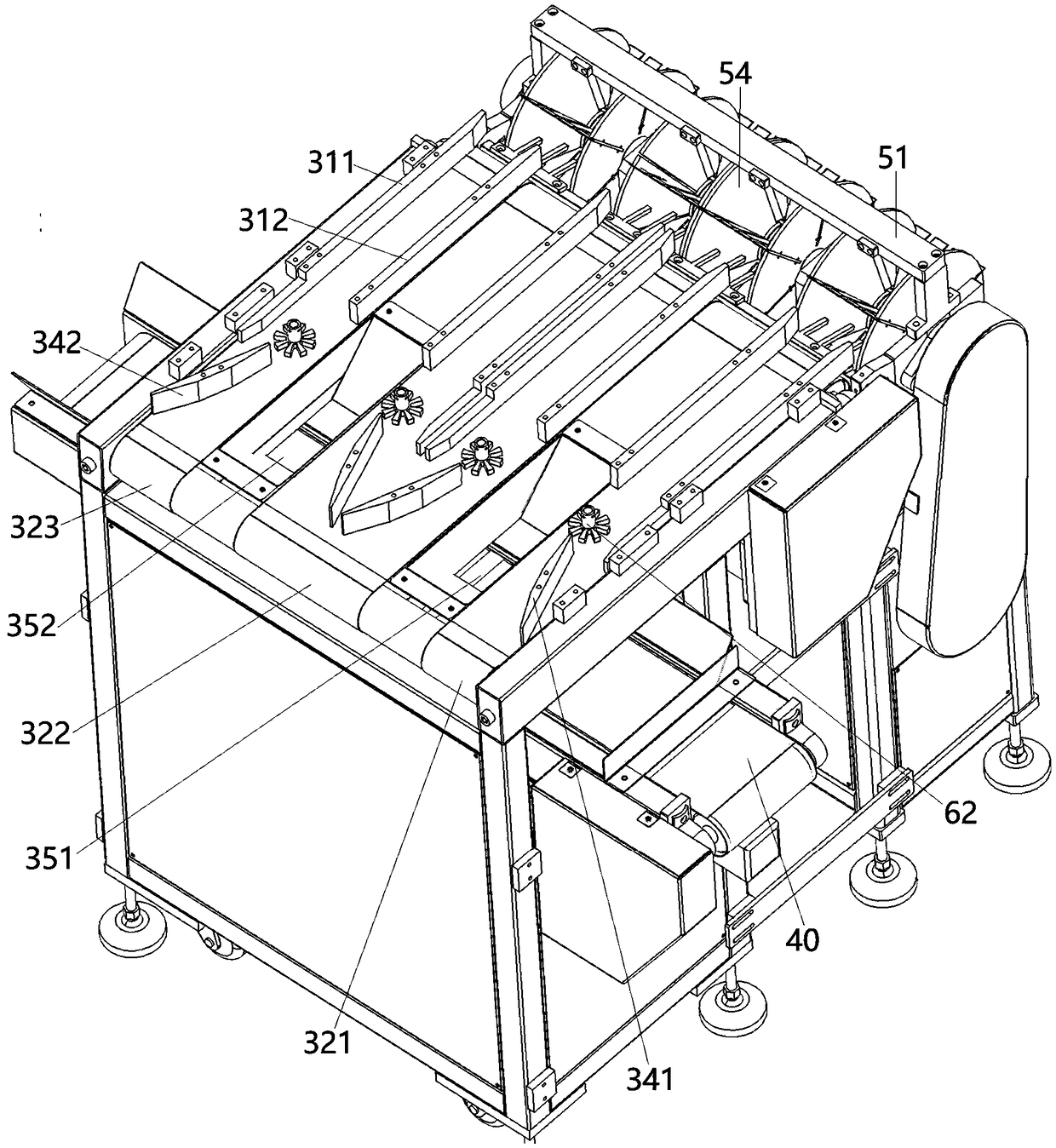

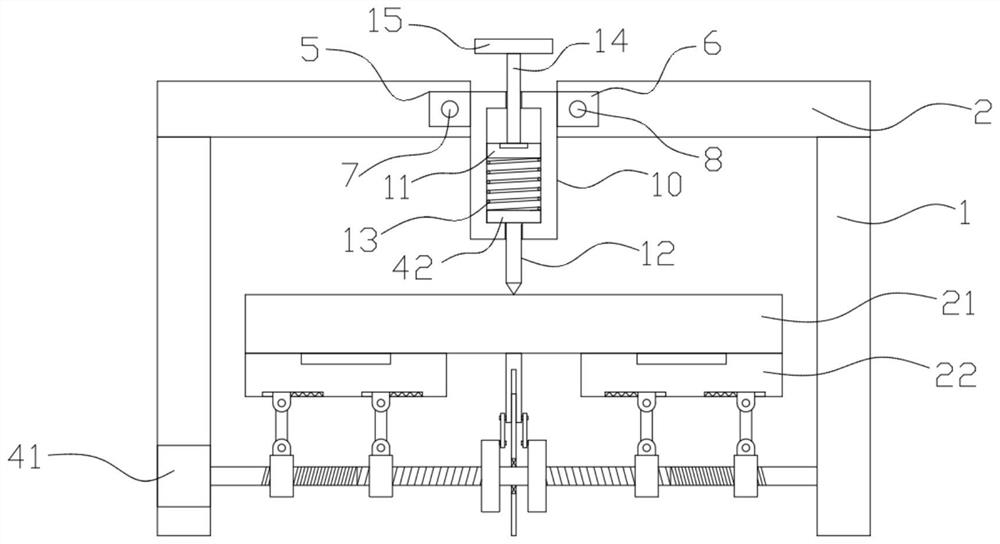

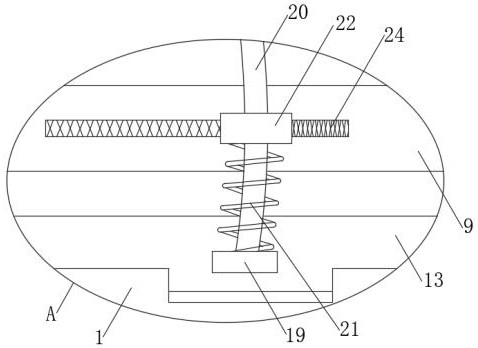

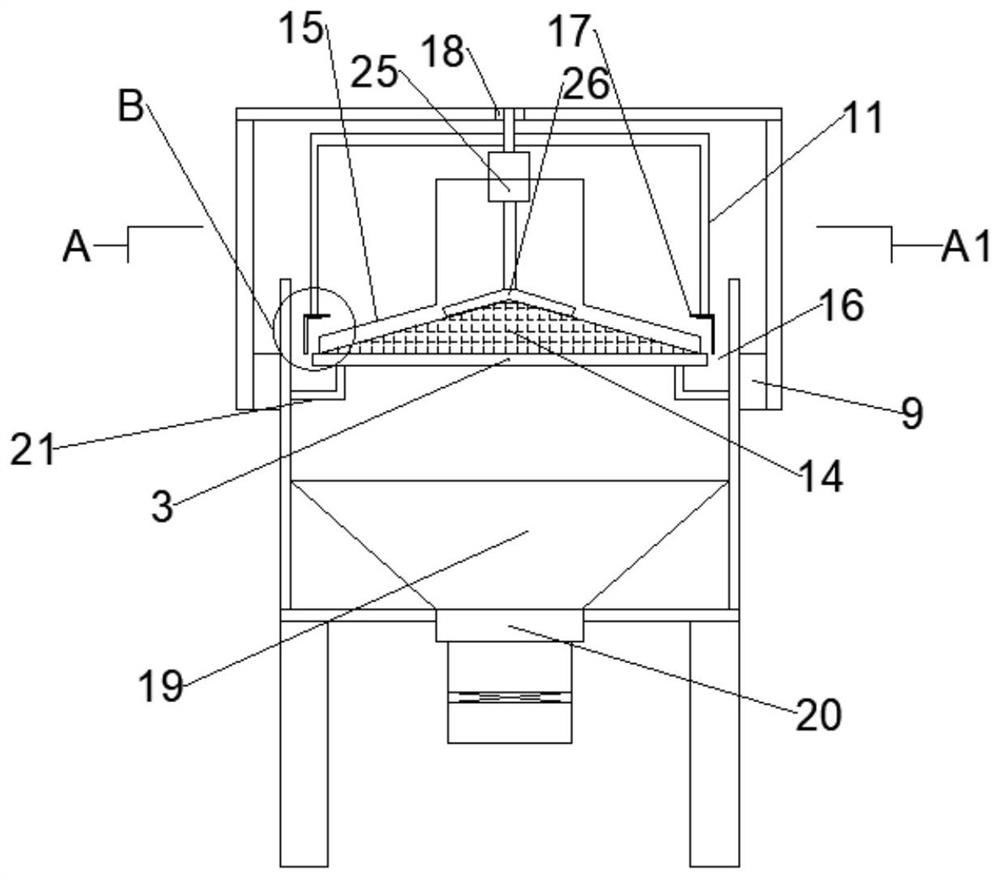

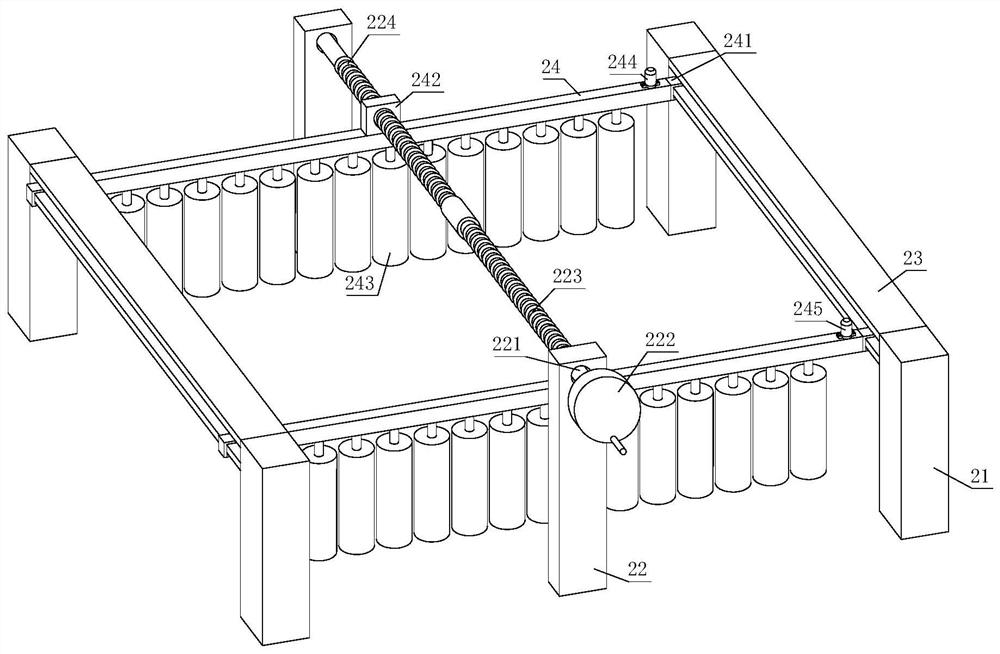

Betel nut centering slicing device

PendingCN107838970AAvoid safety accidents such as cutsPrecise centering and cuttingMetal working apparatusBetel nutsControl system

The invention discloses a betel nut centering slicing device. The centering slicing device comprises a box base, a feeding system fixedly arranged on the box base, a conveying belt used for receivingmaterials of the feeding system and conveying the materials and a slicing system used for slicing the materials, and an automatic feeding speed control system for enabling the betel nut to automatically align is further arranged between the feeding system and the conveying belt; V-shaped groove is designed in the surface of the conveying belt; isolation belts are arranged on the lower part of a feeding groove of the feeding system, the isolation belts are in an irregular polygon shape and divided the feeding groove into a shunting groove, conical grooves and parallel grooves from top to bottomin sequence. According to the betel nut centering slicing device, unique structure of the V-shaped groove is fully utilized to clamp betel nuts, no additional clamping is needed during segmentation,the process of clamping is omitted, conveying and clamping of the betel nuts are integrated, so that slicing efficiency is improved, meanwhile, single-fruit passing is achieved by utilizing the conical grooves and the automatic feeding speed control system, centering slicing is accurate, and product slice quality is improved.

Owner:WUYI UNIV

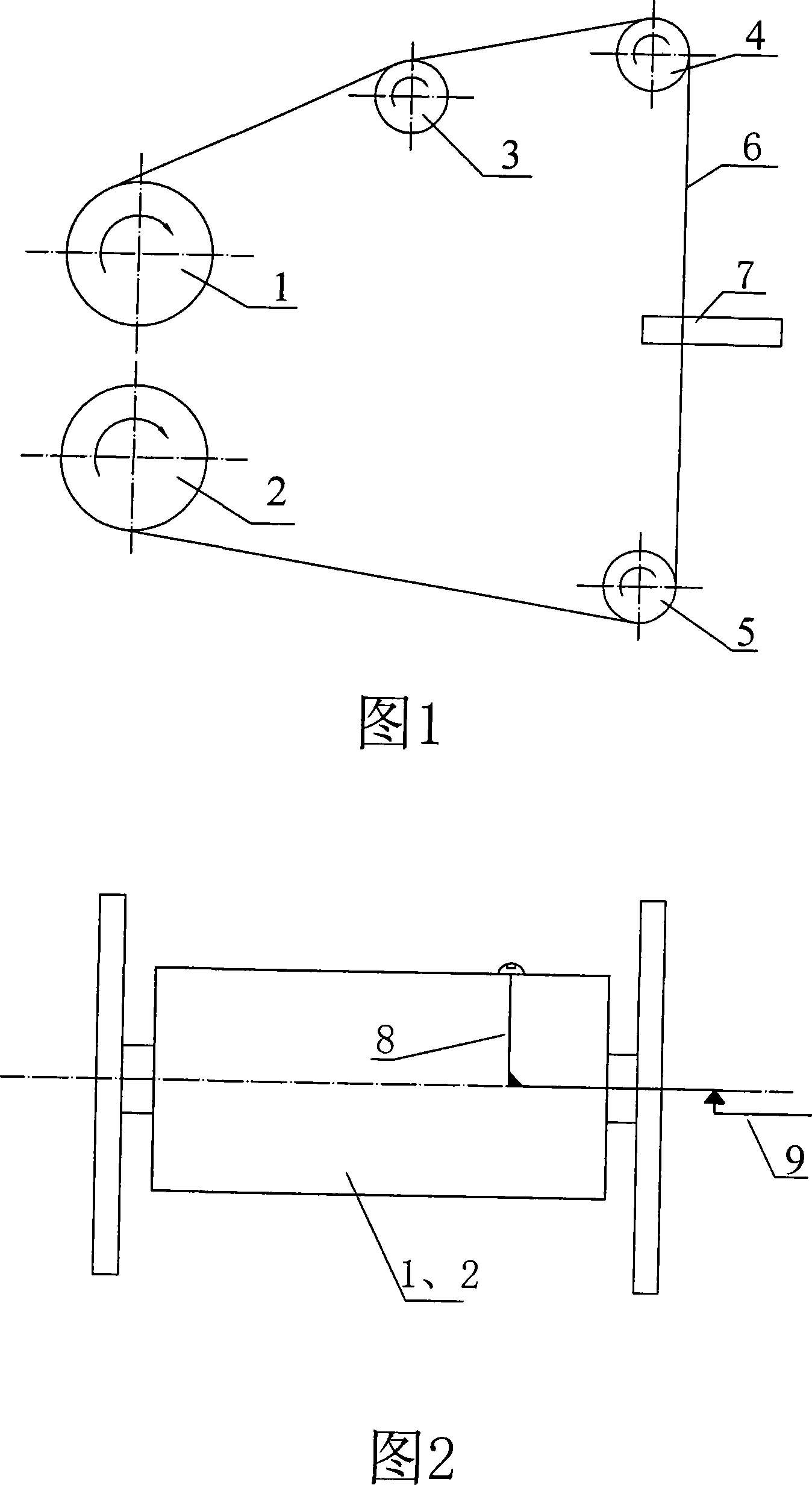

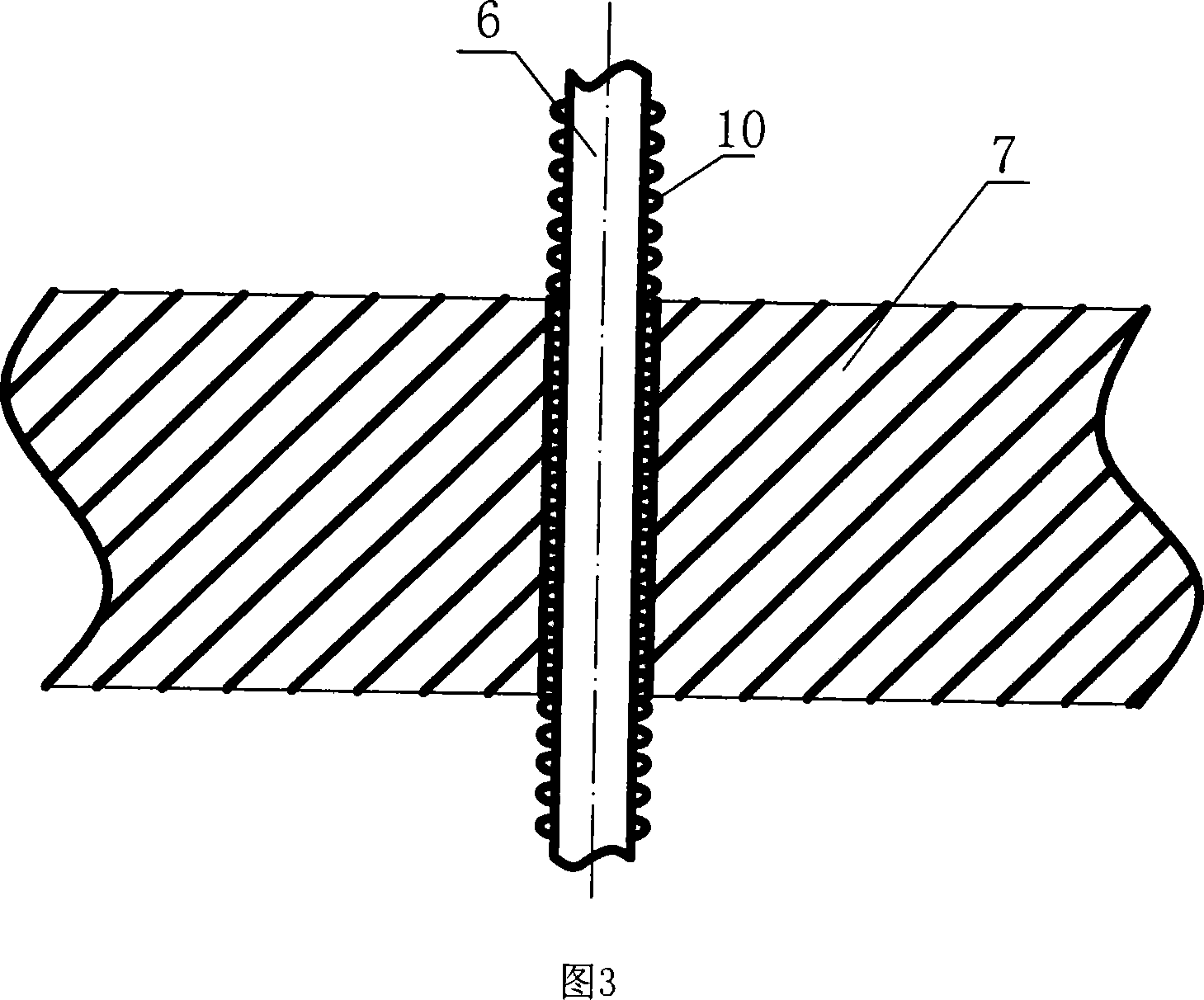

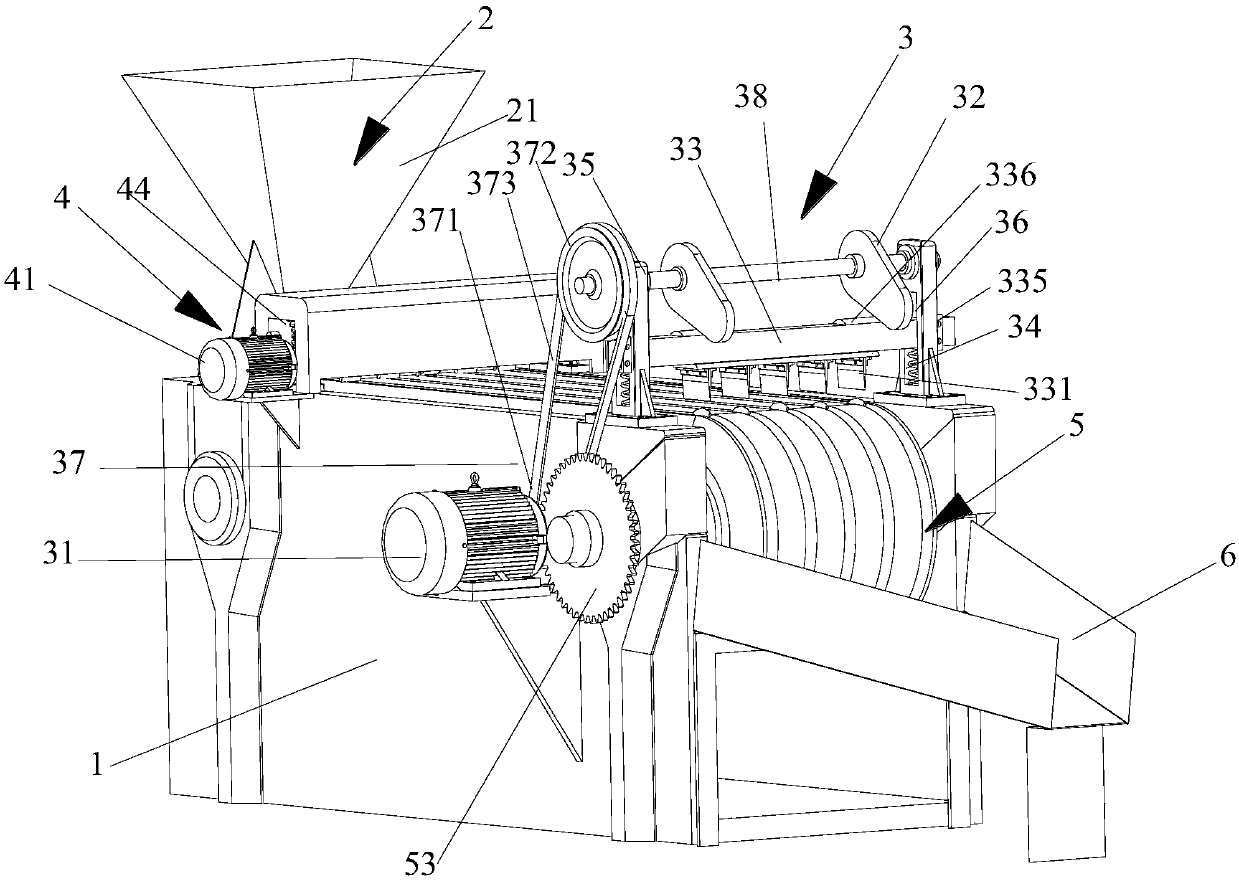

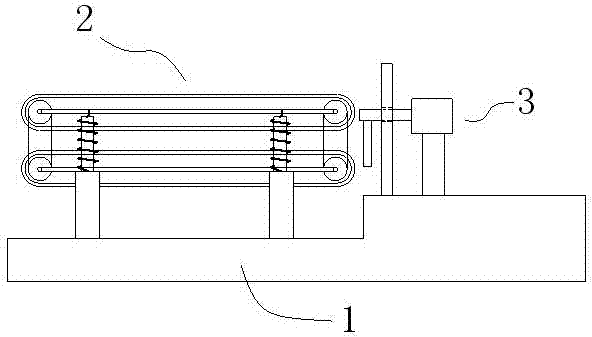

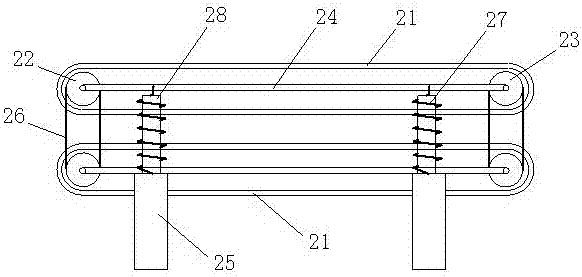

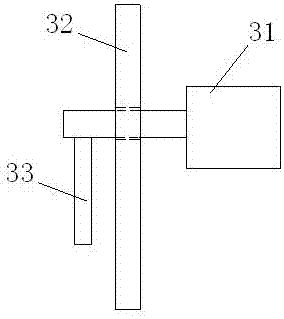

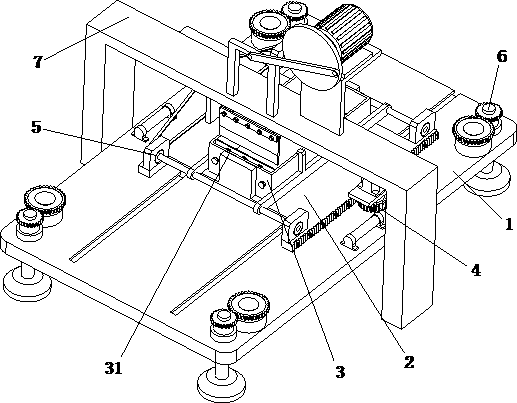

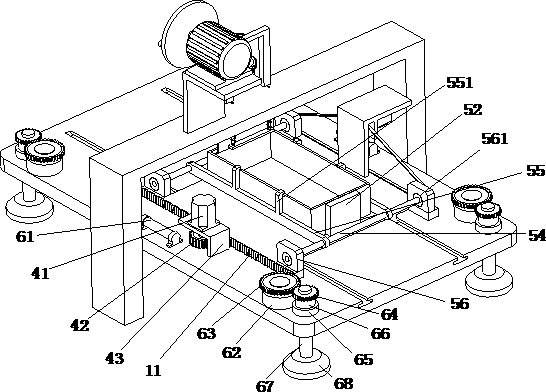

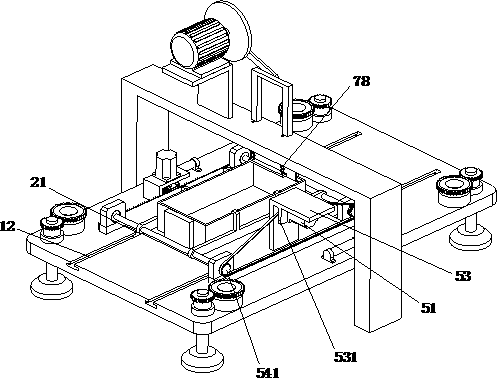

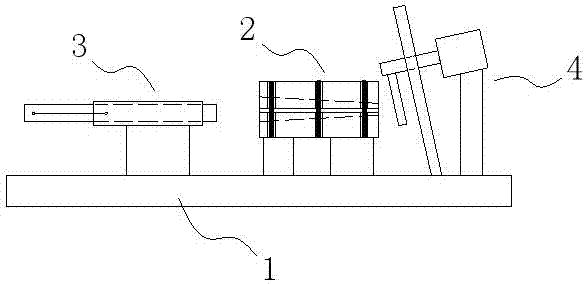

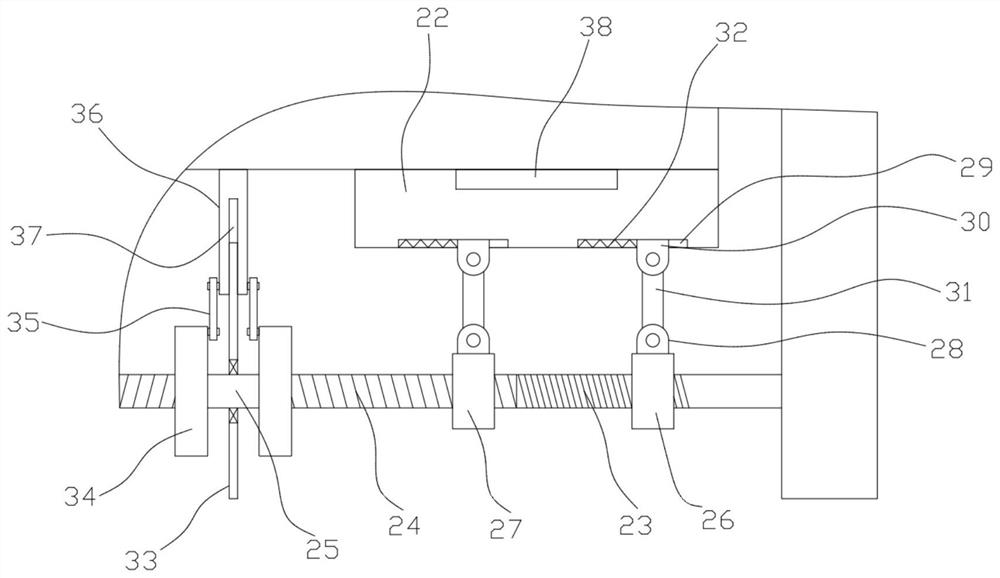

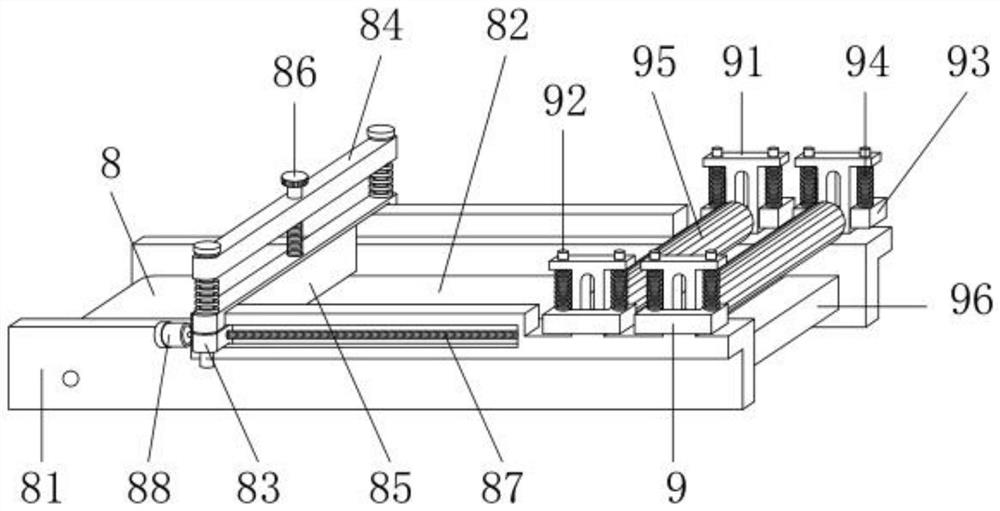

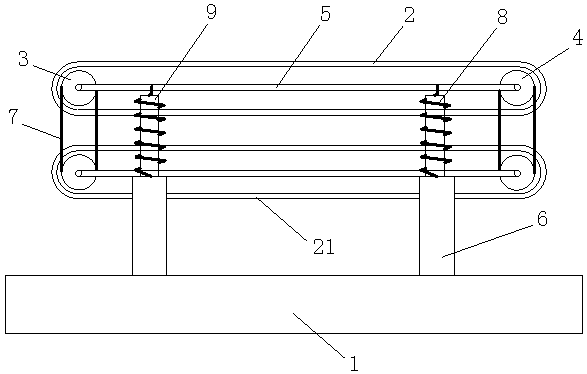

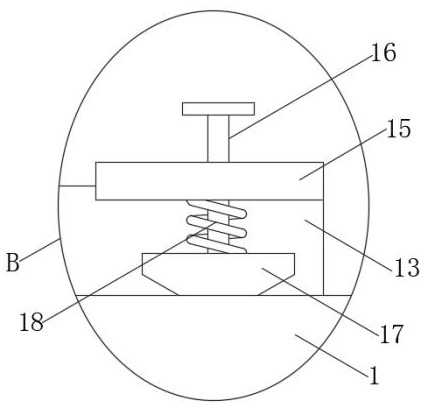

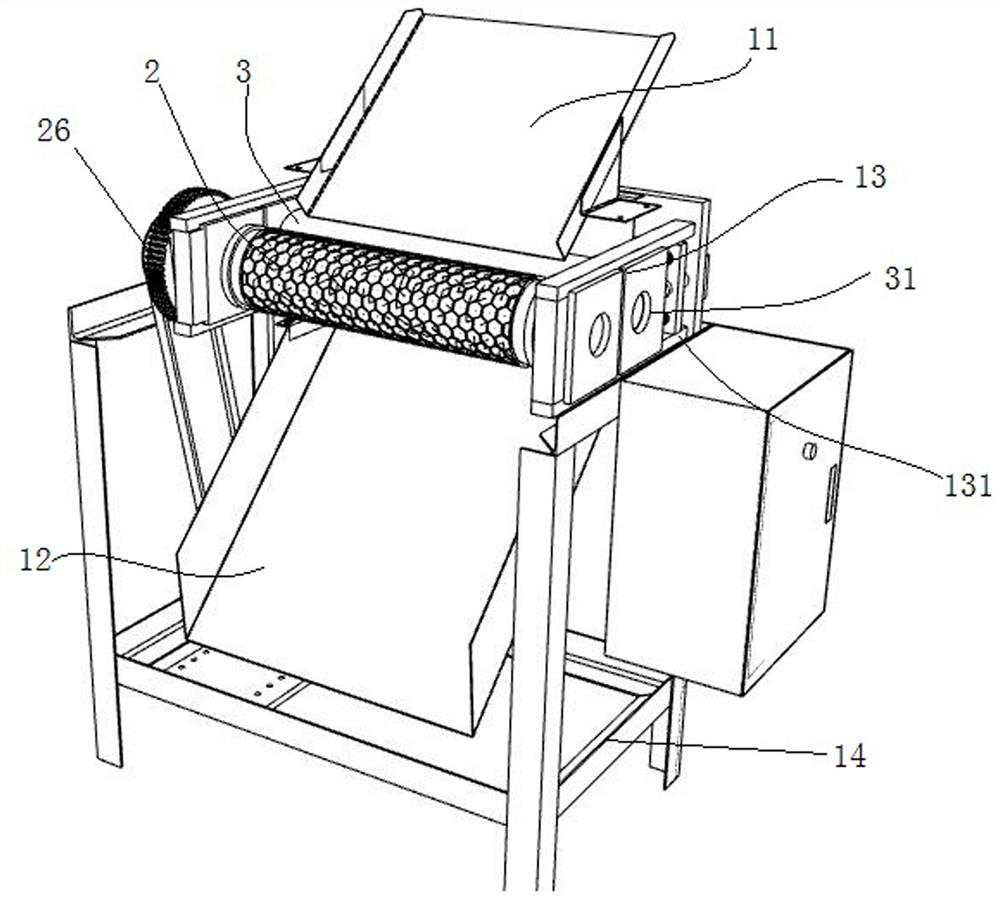

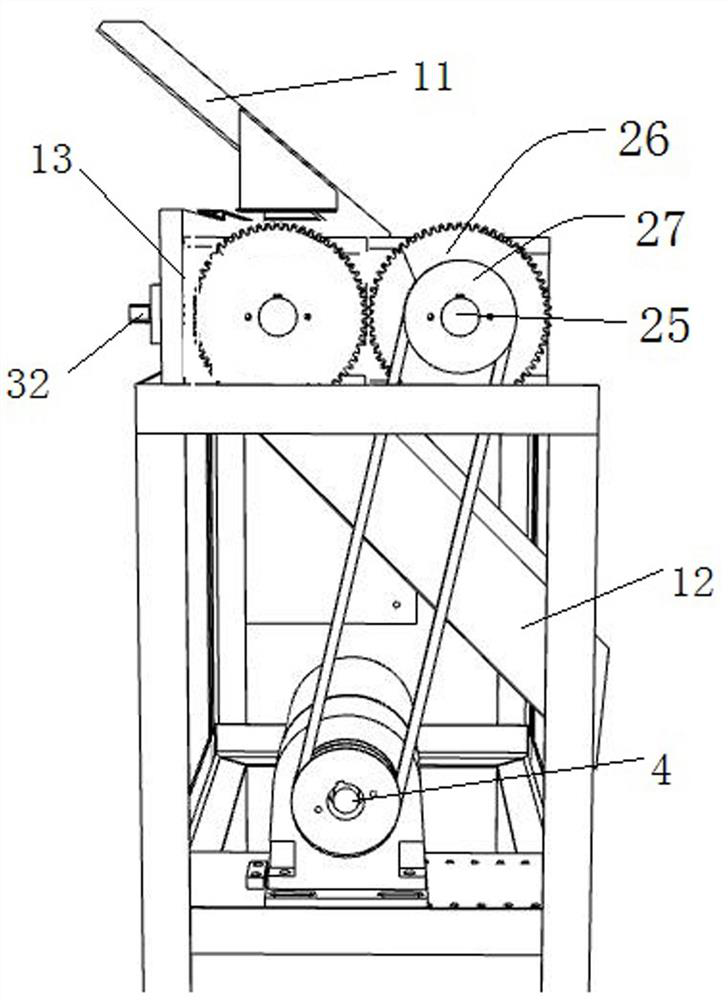

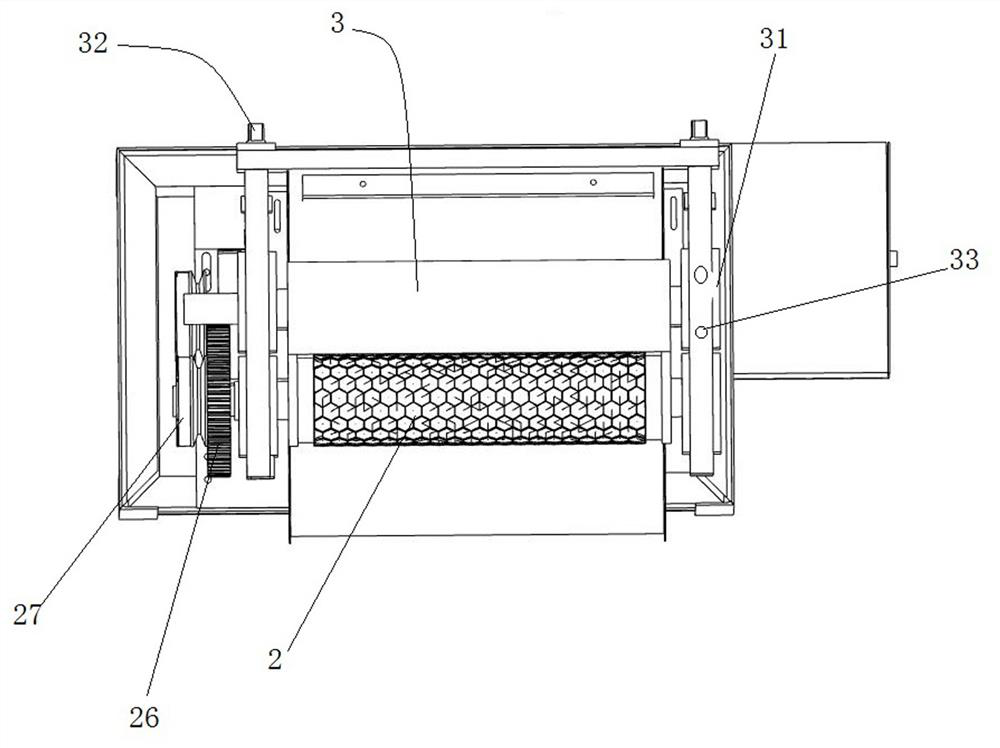

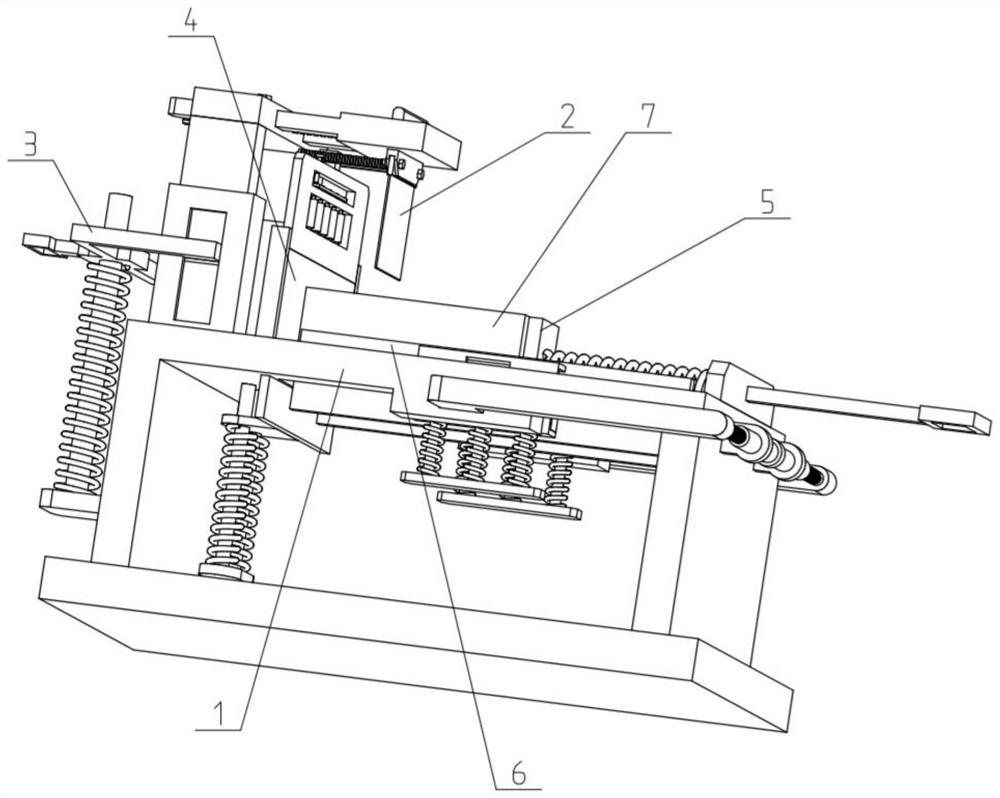

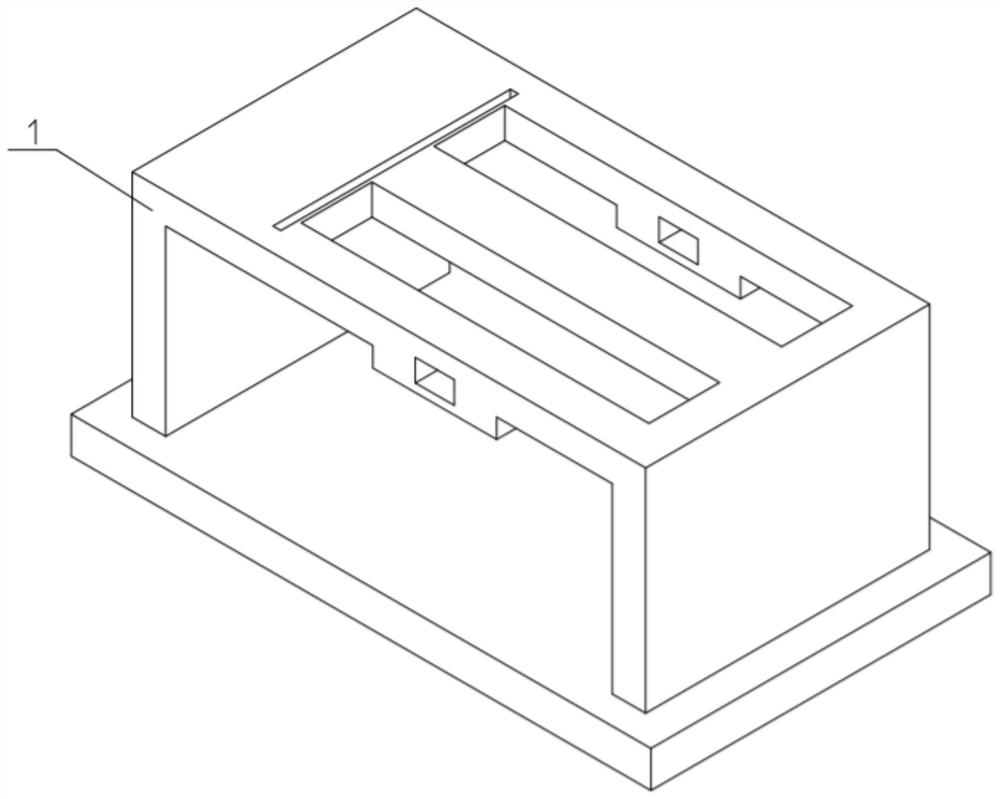

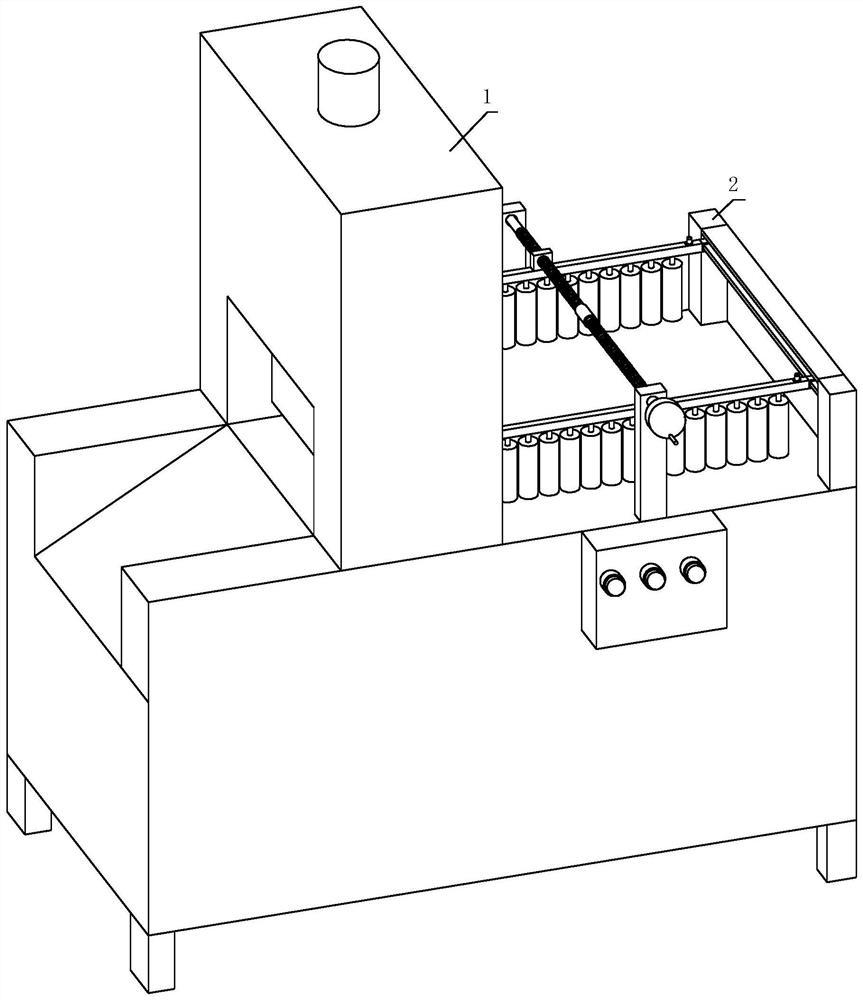

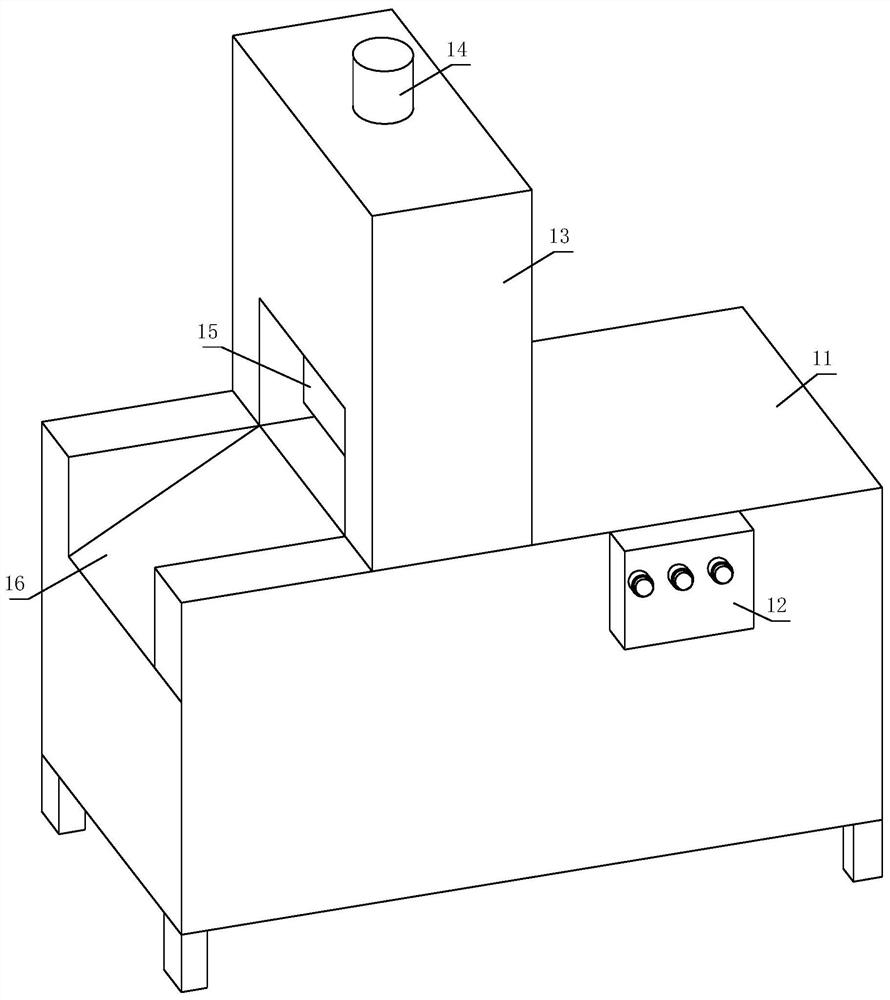

Winding and clamping type feeding slicing machine for traditional Chinese medicines

The invention provides a winding and clamping type feeding slicing machine for traditional Chinese medicines. The slicing machine is used for stably slicing branch-shaped traditional Chinese medicinalmaterials with the toughness. The slicing machine is composed of a machine base, a pushing mechanism and a slicing mechanism, wherein the pushing mechanism and the slicing mechanism are arranged on the machine base; the pushing mechanism is composed of two conveying belts which are vertically and oppositely arranged; driving wheels and driven wheels are arranged at the two ends of the conveying belts separately and are connected through horizontal connecting rods, wherein the horizontal connecting rod of the lower conveying belt is fixed to the machine base through supports, and the horizontal connecting rod of the upper conveying belt is movably arranged on the supports through elastic mechanisms; the elastic mechanisms apply the downward elastic acting force to the upper conveying belt;the slicing mechanism is composed of a motor, a baffle and a cutting blade; the baffle and the motor are both fixed to the machine base; the cutting blade is located on the side, facing a clamping mechanism, of the baffle; a gap is formed between the cutting blade and the baffle; and a motor shaft of a motor penetrates through a through hole formed in the baffle and is connected to the cutting blade so as to drive the cutting blade to rotate.

Owner:信宜市安然中药饮片有限公司

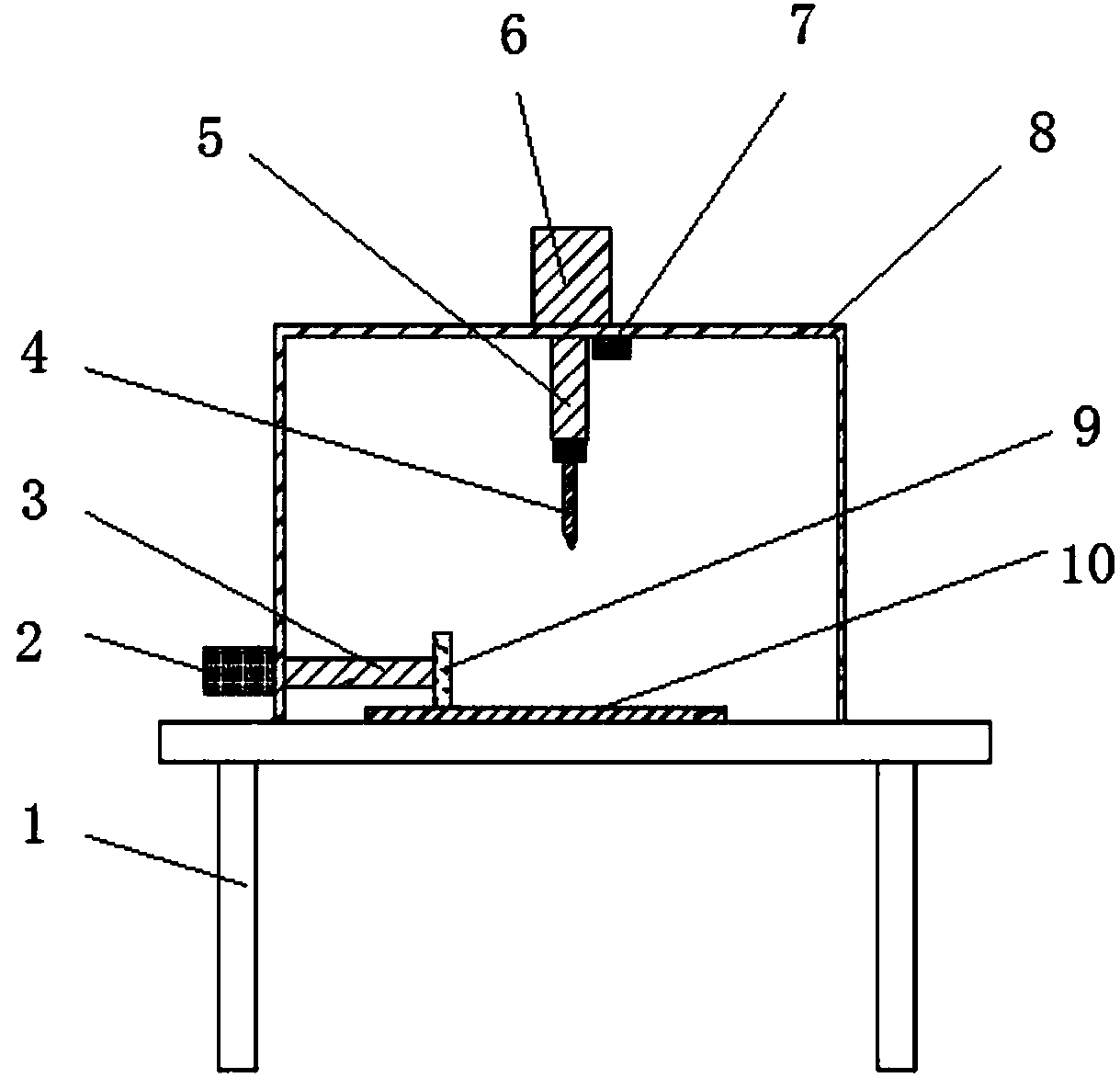

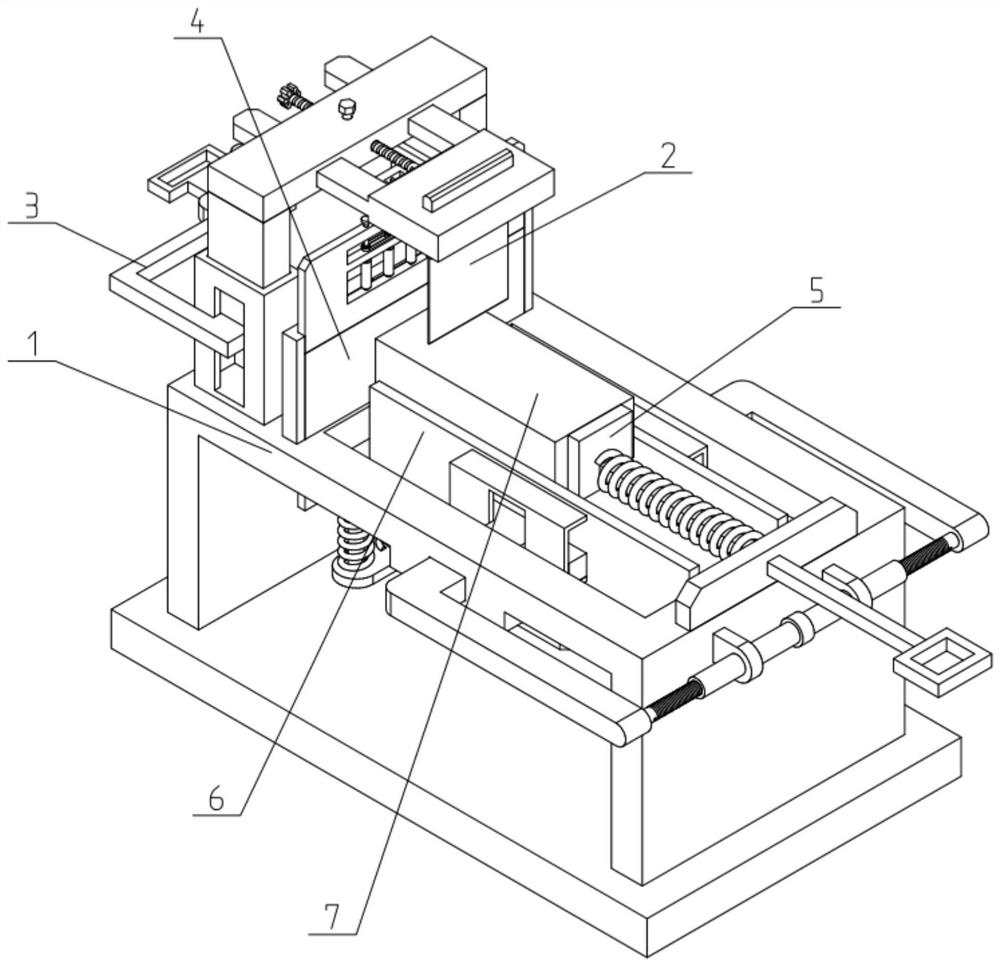

Biomedical medicine slicing device

ActiveCN111086036AAvoid shakingEasy to moveWithdrawing sample devicesPreparing sample for investigationEngineeringMechanical engineering

The invention discloses a biological medicine slicing device, and relates to the technical field of biological medicine. The biological medicine slicing device comprises a support plate, an object carrying plate, a specimen box, a moving mechanism, a limiting mechanism, a height leveling mechanism and a slicing mechanism, wherein the height leveling mechanism is installed on the support plate, thebottom of the object carrying plate is provided with two symmetrically arranged guide blocks, the top of the support plate is provided with two guide sliding grooves which are in guide fit with the two guide blocks one by one, the moving mechanism is installed on the support plate, the moving mechanism is in transmission connection with the object carrying plate, the specimen box is installed onthe object carrying plate, a compensation assembly matched with the slicing mechanism is arranged in the specimen box, the limiting mechanism is installed on the object carrying plate, and the slicingmechanism is positioned above the support plate. According to the invention, shaking during slicing can be avoided, slicing quality is improved, and slicing efficiency is improved.

Owner:金丽素

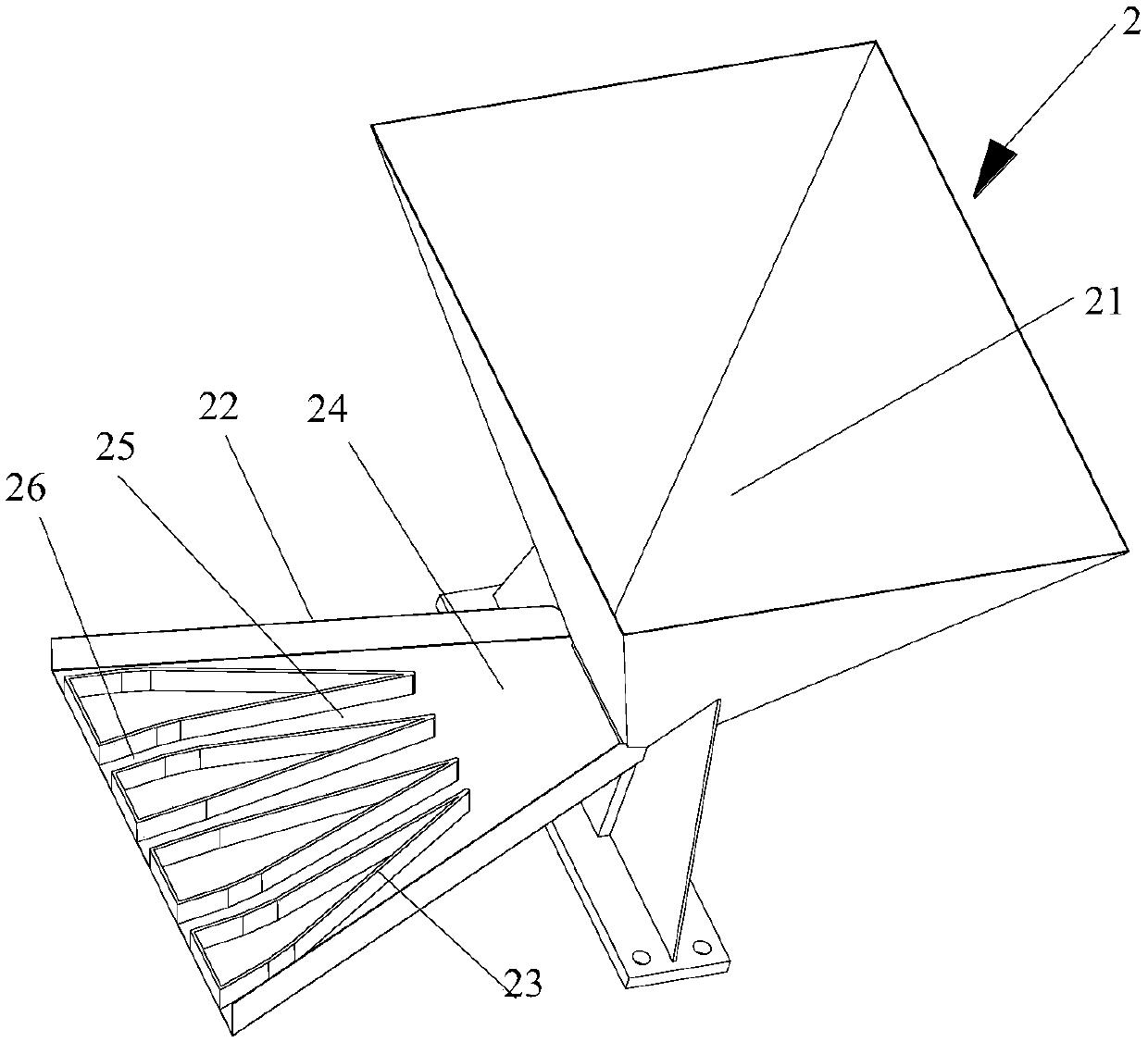

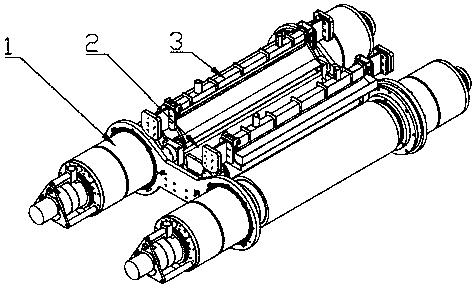

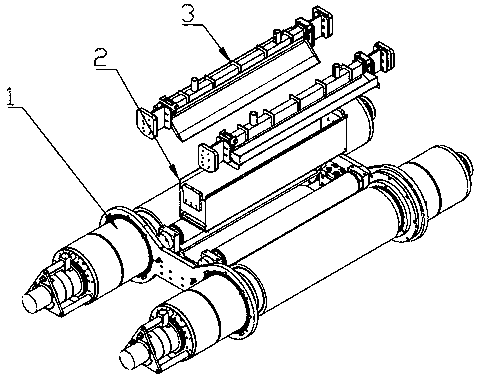

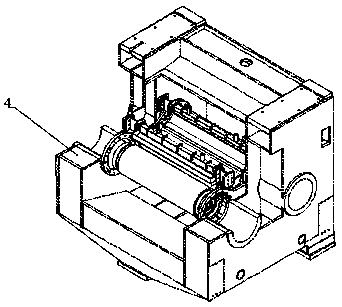

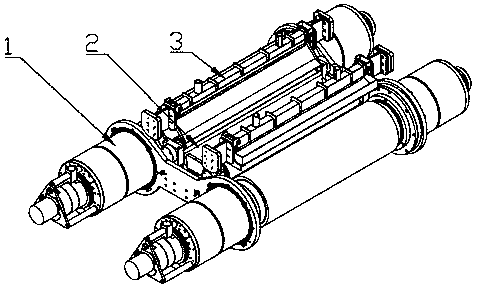

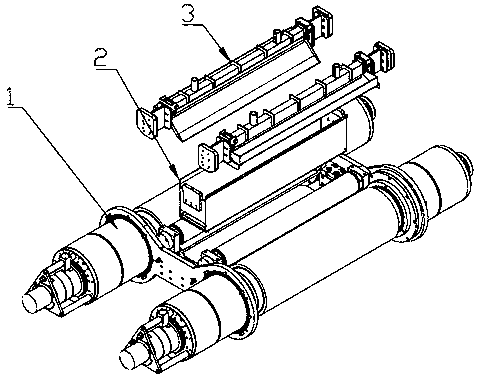

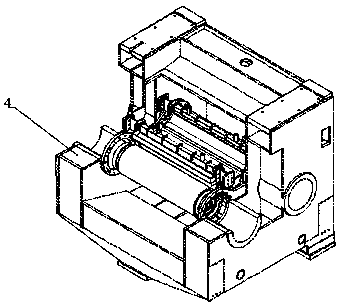

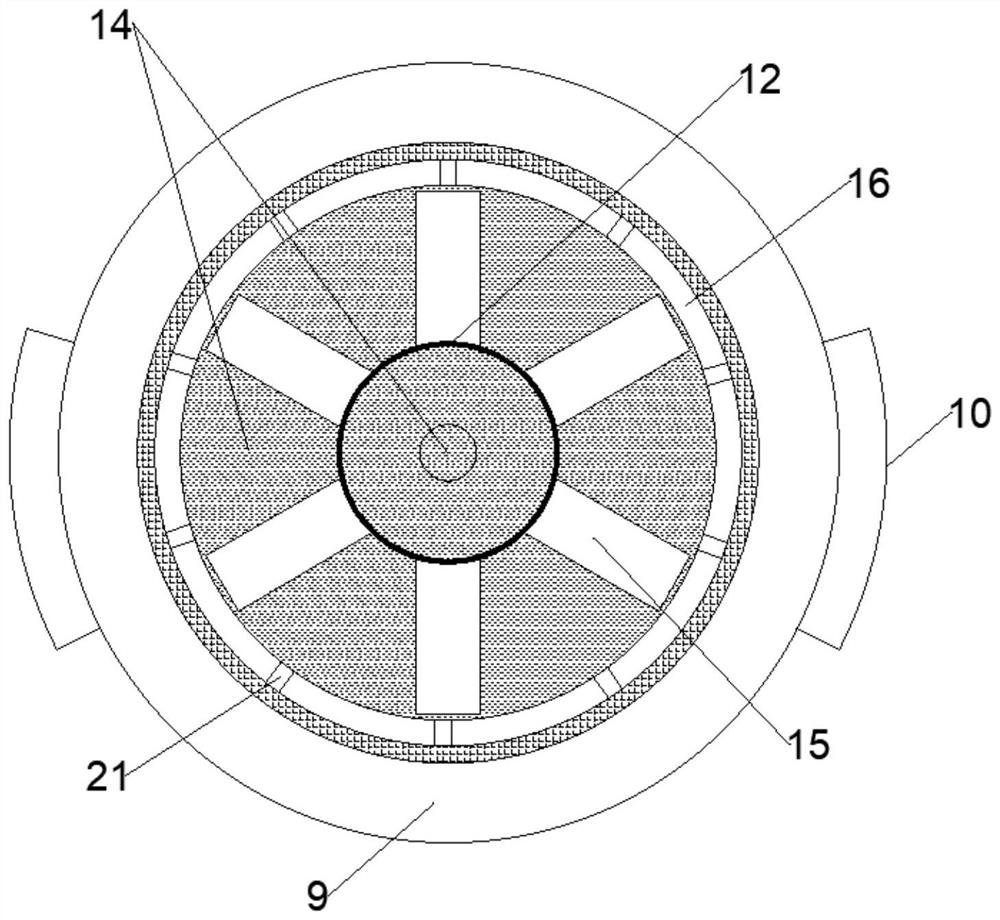

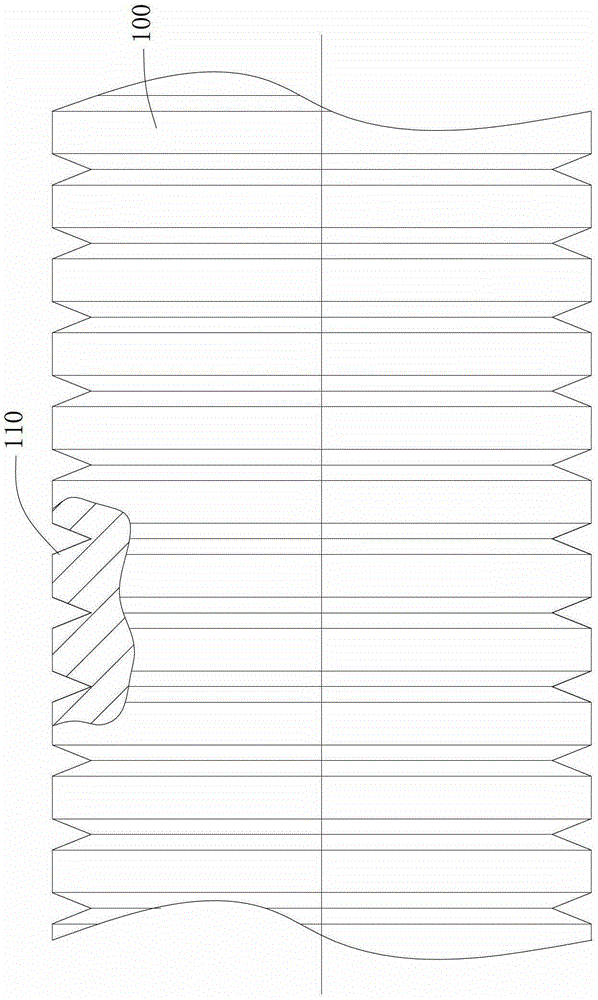

Four-roller main shaft device of multi-wire cutting machine

ActiveCN109176932AImprove rigidityImprove stabilityWorking accessoriesFine working devicesWire cuttingEngineering

A four-roller main shaft device of a multi-wire cutting machine comprises a main shaft system, a material receiving box assembly and a nozzle assembly. The main shaft system and the nozzle assembly are arranged on a cutting chamber. The main shaft system comprises two main roller assemblies, two auxiliary roller assemblies, a front installing support and a rear installing support. The two main roller assemblies are symmetrically arranged on the front installing support and the rear installing support. The two auxiliary roller assemblies are symmetrically arranged on the front installing support and the rear installing support and located between the main roller assemblies. The material receiving box assembly is arranged in limiting grooves of the front installing support and the rear installing support and located between the auxiliary roller assemblies. Each main roller assembly comprises a rotation water cooling device, a driven bearing box, a main roller, a driving bearing box and ahollow locking screw. Each auxiliary roller assembly comprises an auxiliary roller, a bearing block I, a bearing II, a locking nut I, a sealing cover I, a bearing block II, a bearing III, a locking nut II, a sealing cover II, an installing frame, an adjusting screw and a nut. By utilization of the four-roller main shaft device, the requirements for high-speed and high-precision cutting of diamondwires can be met.

Owner:HUNAN YUJING MACHINE

Traditional Chinese medicine slicing machine

The invention aims to provide a traditional Chinese medicine slicing machine used for conducting stable slicing on branch-shaped Chinese medicinal materials with toughness. The traditional Chinese medicine slicing machine is composed of a machine base, a clamping barrel, a pushing mechanism and a slicing mechanism, wherein the clamping barrel, the pushing mechanism and the slicing mechanism are mounted on the machine base; the clamping barrel is located between the pushing mechanism and the slicing mechanism; the slicing mechanism is composed of a motor, a baffle and a cutting blade, the baffle and the motor are fixed to the machine base, the cutting blade is located on the side, facing a clamping mechanism, of the baffle, and a gap is formed between the cutting blade and the baffle; and amotor shaft of the motor penetrates through a through hole formed in the baffle to be connected with the cutting blade, so that the cutting blade is driven to rotate. Compared with a traditional slicing machine, the clamping barrel is additionally arranged on the traditional Chinese medicine slicing machine, good limiting can be conducted on the Chinese medicinal materials in the slicing process,bending of the Chinese medicinal materials is avoided, the slicing quality is ensured accordingly, and the traditional Chinese medicine slicing machine is very suitable for slicing of the branch-shaped Chinese medicinal materials with the toughness.

Owner:信宜市安然中药饮片有限公司

Block cutting device of dried bean curd

InactiveCN109366576APrevent splashAvoid MisdeliveryMetal working apparatusGradingQuality of workEngineering

The invention discloses a block cutting device of dried bean curd. The block cutting device comprises a material storage mechanism, a conveying mechanism, a material guiding mechanism and a slicing mechanism, wherein bean products to be sliced are placed in a storage hopper, a first vibration motor is matched with a material shifting piece on a feeding conveying belt to lift and convey the bean products in the storage hopper to a transfer conveying belt, and the bean products enter a material collecting conveying plate from a material collecting hopper; the material guiding mechanism comprisesa guide frame, a guide conveying belt, a guide strip and a material distributing plate, and the bean products are conveyed to the corresponding feeding channel through the matching of the guide stripand the material distributing plate; the bean products which are fed into the feeding channel are sent back to the storage hopper; and the slicing mechanism comprises a slicing machine frame, cuttingblades, a cutting shaft and a feeding assembly. According to the block cutting device, the bean products can be automatically sliced, the labor intensity of workers is greatly reduced, and the working efficiency and the working quality are improved.

Owner:JIASHAN JIAJIA BEAN PROD

Slicing machine

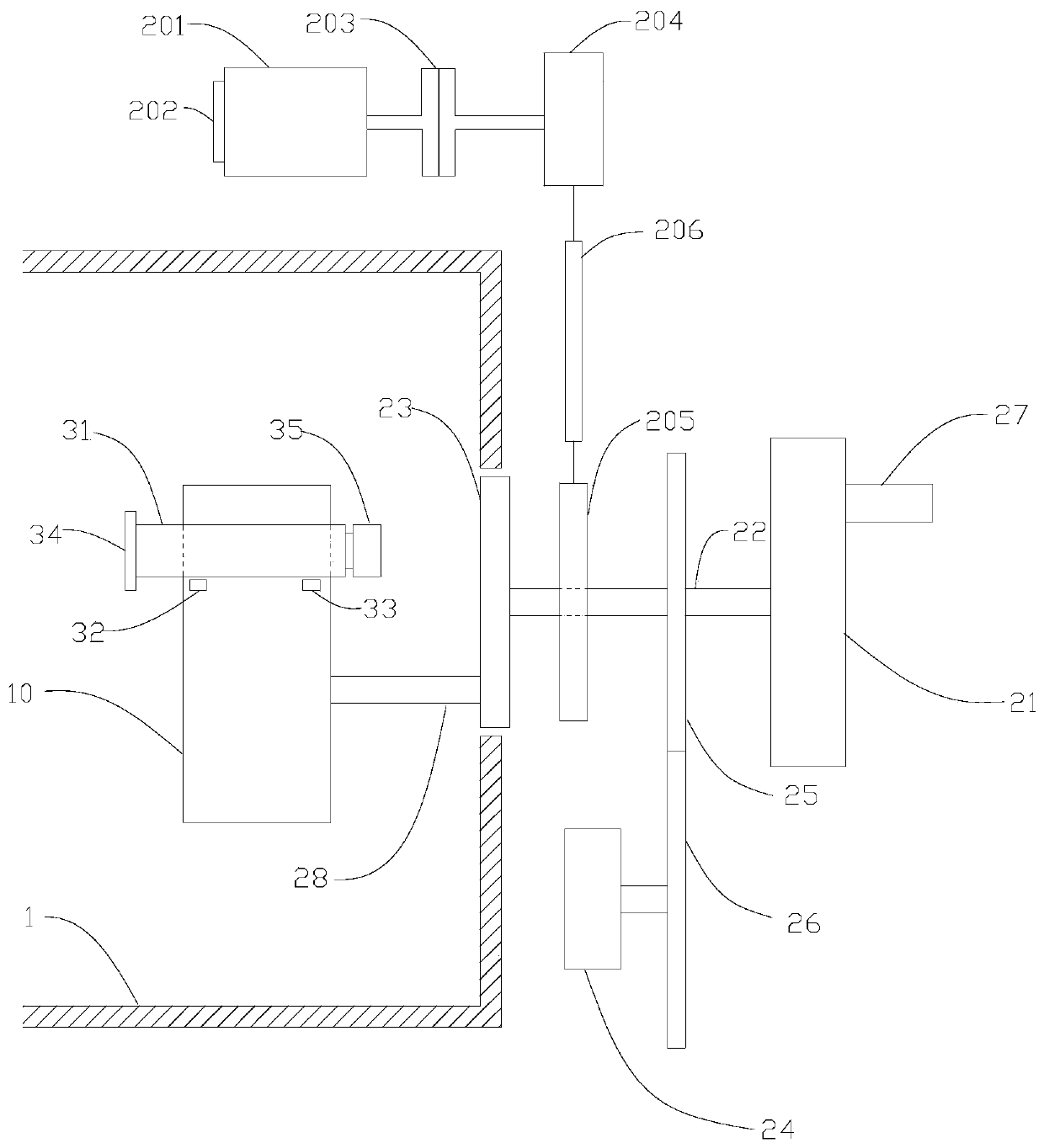

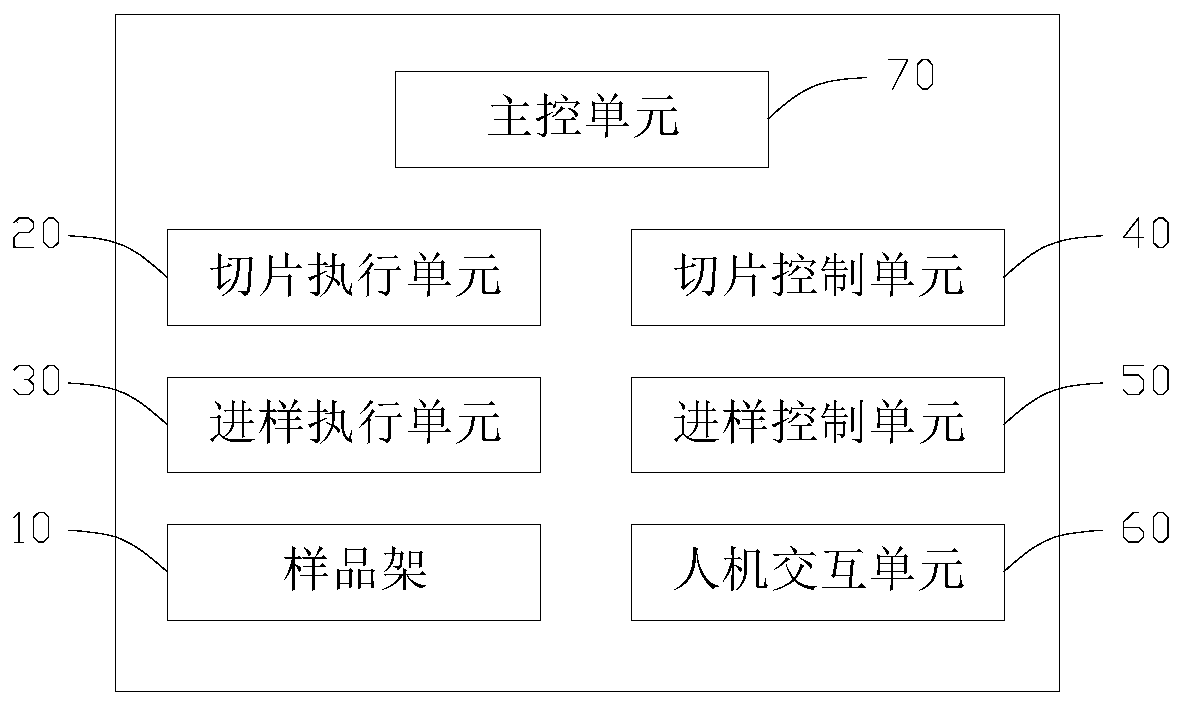

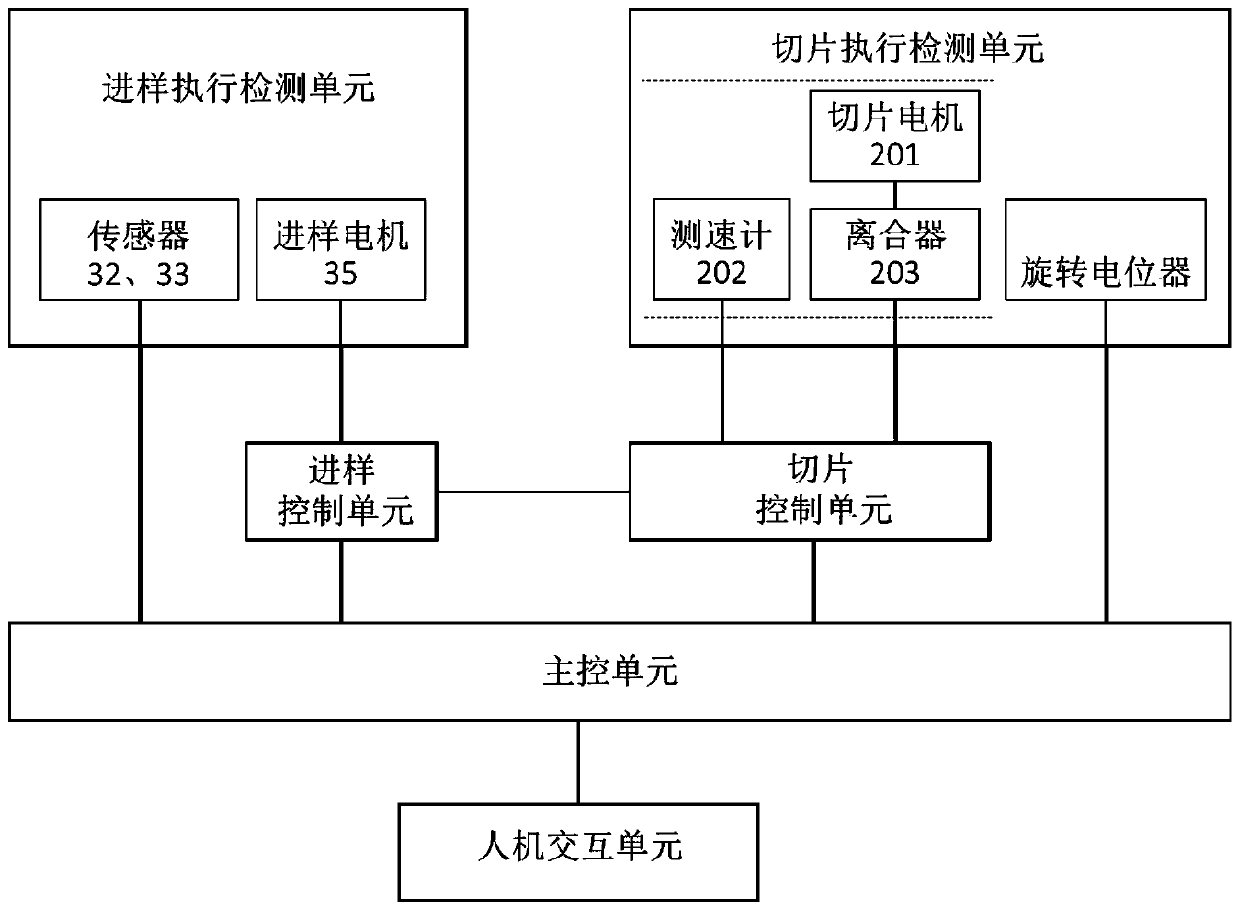

InactiveCN109732673AGuaranteed slice qualityWithdrawing sample devicesPreparing sample for investigationMedical equipmentDrive shaft

The invention relates to the technical field of medical equipment, and provides a slicing machine. The slicing machine comprises a slicing execution unit, a sample feeding executing unit and a sampleframe; the slicing execution unit is connected with the sample frame; the slicing executing unit comprises a hand wheel, a first transmission shaft, an eccentric mechanism and a rotary detecting element; the hand wheel, the first transmission shaft and the eccentric mechanism are connected in sequence; the eccentric mechanism is connected with the sample frame; the rotary detecting element is usedfor detecting rotation of the first transmission shaft to monitor the position of the sample frame; the sample feeding execution unit comprises a sample feeding mechanism, a first sensor and a secondsensor; the sample frame is connected with the sample feeding mechanism; and the first sensor and the second sensor are arranged in the advancing direction of the sample feeding mechanism. The slicing machine can arrange the rotary detecting element outside a cavity without generating the condensation and frosting conditions; and the working state is not limited by wheel rotation slicing or freezing slicing machine types.

Owner:RWD LIFE SCI

Slicing device

InactiveCN109719788AReduce labor intensityLabor savingMetal working apparatusMechanical engineeringEngineering

The invention discloses a slicing device. The slicing device comprises a lower support, an upper support and automatic cutting equipment arranged on the upper support, wherein the upper support is arranged above the lower support, a work table is arranged above the lower support, and the automatic cutting equipment comprises a cutting device and a feeding device; the cutting device is composed ofa vertical electric cylinder arranged at the top of the upper support and a blade, the body of the vertical electric cylinder is vertically arranged at the top of the upper support, and the blade is fixed at the lower end of a telescopic rod of the vertical electric cylinder; the feeding device is composed of a transverse electric cylinder and a push plate, the transverse electric cylinder is transversely arranged below the left side of the upper support, and the push plate is arranged at the end of a telescopic rod of the transverse electric cylinder; and the cutting device and the feeding device are controlled by the same controller to operate, and an infrared positioning device is arranged beside the cutting device. The slicing device can automatically slice agricultural products such as melons, radishes, potatoes and the like, labor is saved, the labor intensity of workers is reduced, the slicing efficiency is improved, and the slicing device has outstanding practicability.

Owner:金晨

Method for freezing and embedding tissue paraffin section

InactiveCN102175508AThere will be no phenomenon of water ingress forming a cavityNo void formationWithdrawing sample devicesPreparing sample for investigationEnvironmental resistanceParaffin oils

The invention discloses a method for freezing and embedding a tissue paraffin section. The method comprises the following steps of: placing a paper embedding frame impregnated with paraffin tissues and molten paraffin into a 4 DEG C refrigerating chamber, standing for 10 minutes, peeling off paraffin blocks from the packet-embedding frame, slicing and dyeing. Compared with the conventional cold water embedding method of the tissue paraffin section, the method disclosed by the invention is simple, fast, environment-friendly and practical; the paper embedding frame can be recycled; cold water is not required, and phenomenon such as the formation of a hollow because water enters the paraffin block is avoided; and the quality of the section is guaranteed. Moreover, the method is wide in application, can be used for tissue sections of animals and plants and pathological sections of human bodies.

Owner:安徽省林业科学研究院

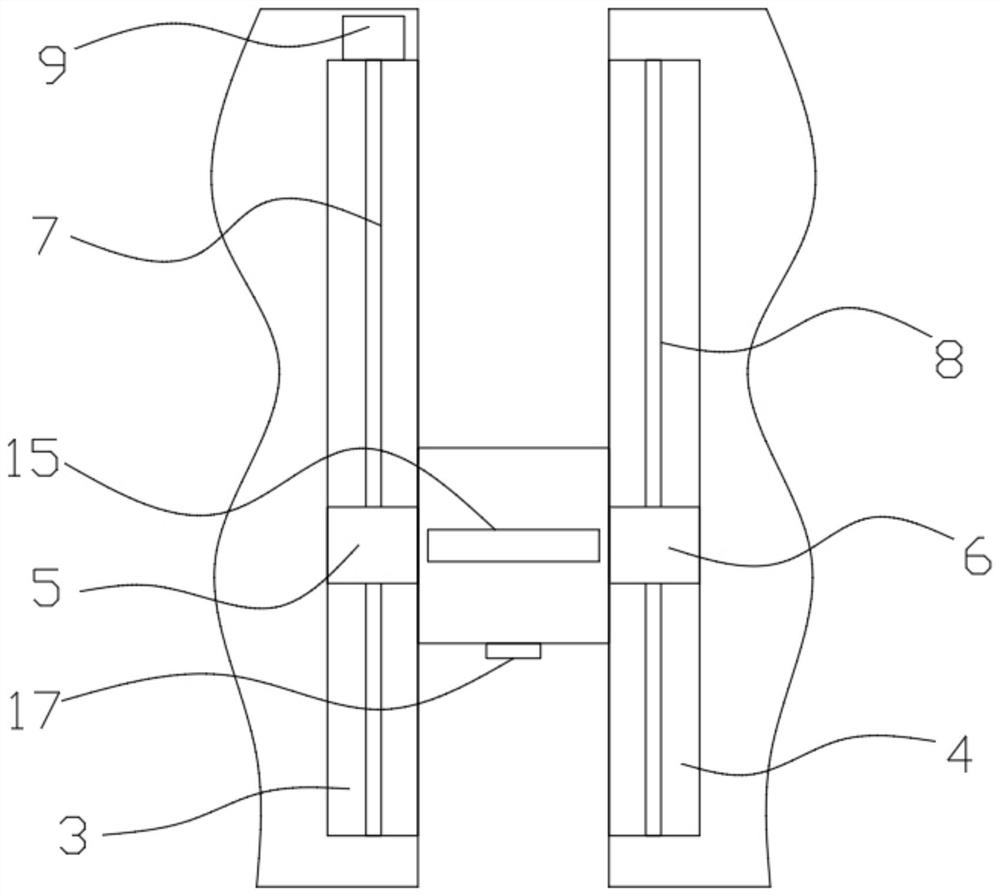

Glass cutting and breaking device

ActiveCN112939438AAvoid manual cutting deflectionHigh breaking qualityGlass severing apparatusGlass productionPhysicsElectric machinery

The invention discloses a glass cutting and breaking device. The device comprises two first vertical plates, top plates are symmetrically and fixedly connected to the upper ends of the two first vertical plates, a first sliding groove and a second sliding groove are formed in the opposite sides of the two top plates correspondingly, a first sliding block and a second sliding block are slidably connected into the first sliding groove and the second sliding groove correspondingly, a lead screw and a guide rod are inserted into the first sliding block and the second sliding block correspondingly, the first sliding block is in threaded connection with the lead screw, a first motor used for driving the lead screw to rotate is embedded in the inner wall of the first sliding groove, the second sliding block is in sliding connection with the guide rod, the guide rod is fixed to the inner walls of the two sides of the second sliding groove, and the opposite sides of the first sliding block and the second sliding block are jointly and fixedly connected with a movable cylinder with two ends closed. The device has the advantages that: manual cutting is replaced by automatic linear cutting, the force of the cutting knife can be adjusted according to the thickness of a glass sheet, the glass sheet is firstly knocked and then broken off, and the cutting efficiency is high.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER COMPANY TAIZHOU POWER SUPPLY

Convenient-to-use drum type brake production device

InactiveCN110193630AGuaranteed stabilityAvoid damageMetal sawing devicesMeasurement/indication equipmentsEngineeringBrake pad

The invention discloses a convenient-to-use drum type brake production device which belongs to the technical field of drum type brake production. The convenient-to-use drum type brake production device comprises a working platform, wherein the position, close to the left side, between two groups of side plates is in sliding connection to a placing plate; fixing parts with the same structure are symmetrically arranged at left and right sides of the top of the placing plate; the right side of the top of the working platform is fixedly equipped with a limiting plate; the top of the outer wall ofthe left side of each side plate is equipped with a mounting block in an adhered mode; the bottom of a bearing block is equipped with an electric telescopic pole; and the output end of a motor passesthrough the left side of a protective housing in a penetrating mode, and is equipped with a saw blade. According to the convenient-to-use drum type brake production device disclosed by the invention,a regulating screw is rotated to drive the mounting blocks to move; when the mounting blocks move, a measuring rod also moves, so that a user conveniently observes a moving distance; and a fine-tuningscrew can be arranged to rotate and finely turn the position of the saw blade, and needed length can be regulated by calculating a position, which corresponds to a graduated bar, of the saw blade anda distance, moving towards the left side, of the measuring rod, so that precision is higher, and slicing quality of a brake pad is guaranteed.

Owner:高邮市宏生制动器厂

Biological medicine slicing device for animals and plants

InactiveCN111941484APrevent movementAvoid dangerMetal working apparatusAnimal scienceElectric machinery

The invention discloses a biological medicine slicing device for animals and plants. A base, a shell, a sliding groove, a first motor, a crankshaft wheel and a cutter are included. Supporting columnsare arranged at the four corners of the upper surface of the base, limiting grooves are formed the right ends of the front side and the rear side of an inner cavity of the base in the vertical direction, and the bottom end of the shell is fixedly connected with the supporting columns on the upper surface of the base; and the sliding groove is formed in the left side of the top end of the shell inthe left-right direction, the first motor is in screw connection with the right side of the top end of the sliding groove in the left-right direction, the crankshaft wheel is in key connection with the right side of the output end of the first motor, and the front end and the rear end of the cutter are connected with the limiting grooves in the front side and the rear side of an inner cavity of the shell in an inserted mode correspondingly. According to the biological medicine slicing device for animals and plants, manual continuous feeding is not needed during slicing work, time and labor aresaved, danger of people is avoided, safety of slicing work is guaranteed, feeding is stable, the slicing thickness is uniform, the slicing thickness is easy to control, and the slicing quality is guaranteed.

Owner:田琳琳

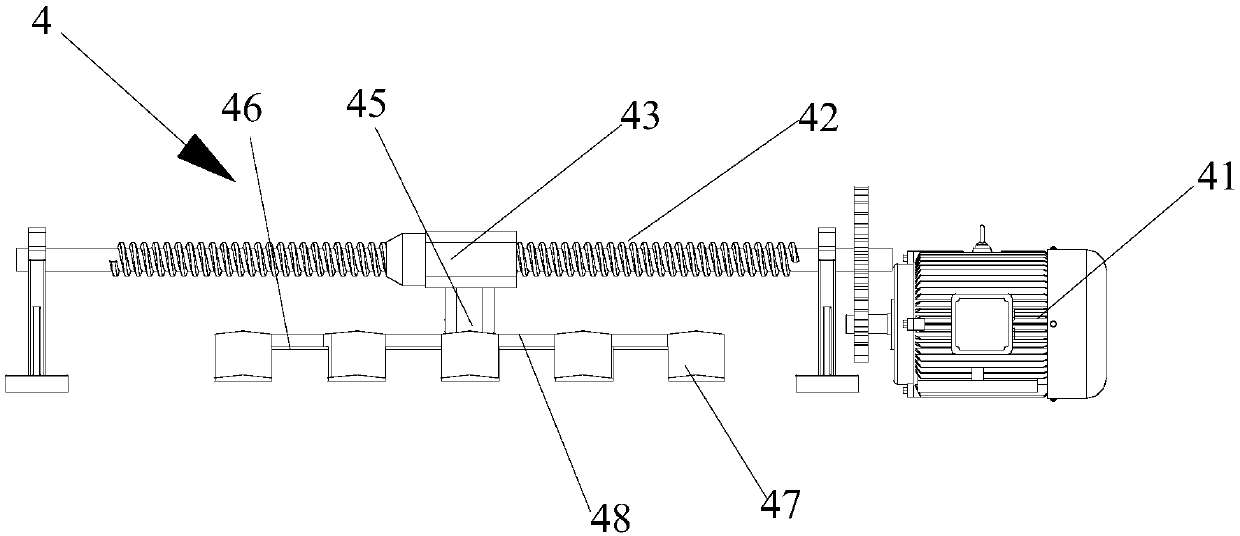

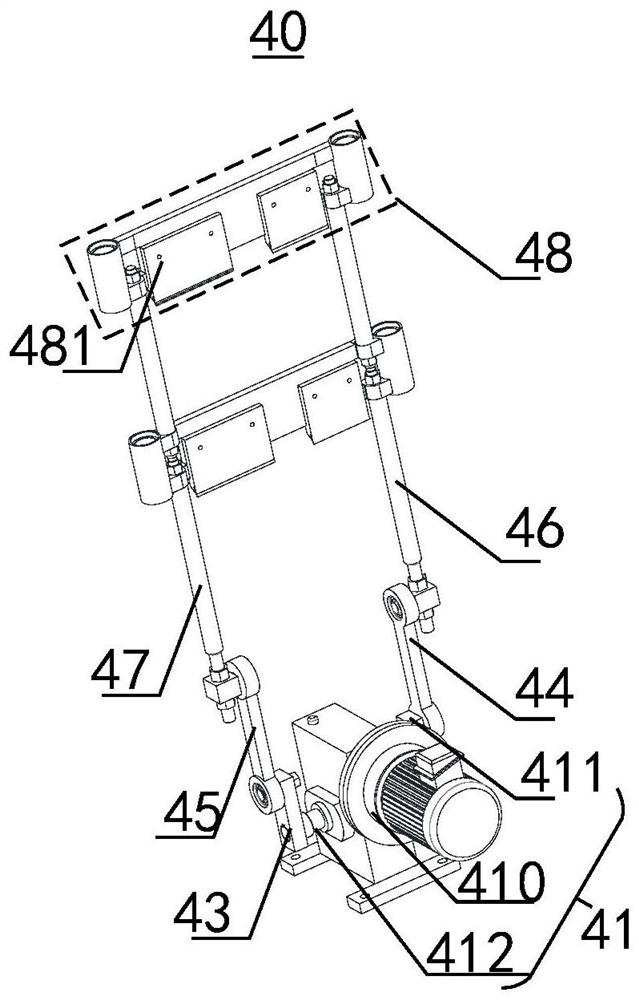

Roll type feeding mechanism

The invention provides a roll type feeding mechanism for feeding branch-shaped Chinese herbal medicines with toughness in a traditional Chinese medicine slicing machine to prevent influence on normalslicing by bending of the Chinese herbal medicines under the acting force of slicing. The roll type feeding mechanism consists of a base, and two conveying belts oppositely arranged up and down; driving wheels and driven wheels are arranged at two ends of the conveying belts, and are connected through horizontal connecting rods; the horizontal connecting rod of the conveying belt on the lower sideis fixed on the base through a bracket; the horizontal connecting rod of the conveying belt on the upper side is movably mounted on the bracket through an elastic mechanism; downwards elastic actingforce is applied to the conveying belt on the upper side by the elastic mechanism, so that the conveying belt on the upper side tends to approach the conveying belt on the lower side; and the two conveying belts are the same in conveying speed.

Owner:信宜市安然中药饮片有限公司

Device used for rat brain tissue slicing and layering

The invention discloses a device used for rat brain tissue slicing and layering. The device comprises a slicing module, wherein the slicing module is provided with a plurality of cutter grooves with equal spacing, and fresh rat brain tissues are placed on the slicing module in slicing operation. The device is characterized in that the slicing module is embedded in a rectangular cavity on an operation desk, a cutter with a tool rest is arranged above the slicing module, two blades which are mutually parallel and vertical downwards are arranged below the tool rest, spacing between the two blades is just equal to distance between two cutter grooves of the slicing module, the cutter is connected with the upper end of a vertical arm, and the lower end of the vertical arm is connected with a mechanism which can move along the front length direction of the operation desk for positioning.

Owner:THE FIRST AFFILIATED HOSPITAL OF MEDICAL COLLEGE OF XIAN JIAOTONG UNIV

Slicing device with positioning structure

InactiveCN109719785AReduce labor intensityLabor savingMetal working apparatusEngineeringMechanical engineering

The invention relates to a slicing device with a positioning structure. The slicing device comprises a lower bracket, an upper bracket and automatic cutting equipment placed on the upper bracket. Theautomatic cutting equipment comprises a cutting device and a feeding device, the cutting device is composed of a vertical electric cylinder and blades placed on the top of the upper bracket, a body ofthe vertical electric cylinder is vertically arranged on the top of the upper bracket, the blades are fixed to the lower end of a telescopic rod of the vertical electric cylinder, a positioning support is also arranged at the lower end of the telescopic rod, and sliding structures are arranged between two ends of the positioning support and the upper bracket in a fit manner; the feeding device iscomposed of a transverse electric cylinder and a push plate, the transverse electric cylinder is transversely placed below the left side of the upper bracket, and the push plate is placed on the endpart of a telescopic rod of the transverse electric cylinder; and the cutting device and the feeding device are controlled by a same controller to operate, and an infrared positioning device is arranged next to the cutting device. The slicing device not only saves the manpower, reduces the labor intensity of workers and improves the slicing efficiency, but also has the advantages of being stable to operate and long in service life.

Owner:金晨

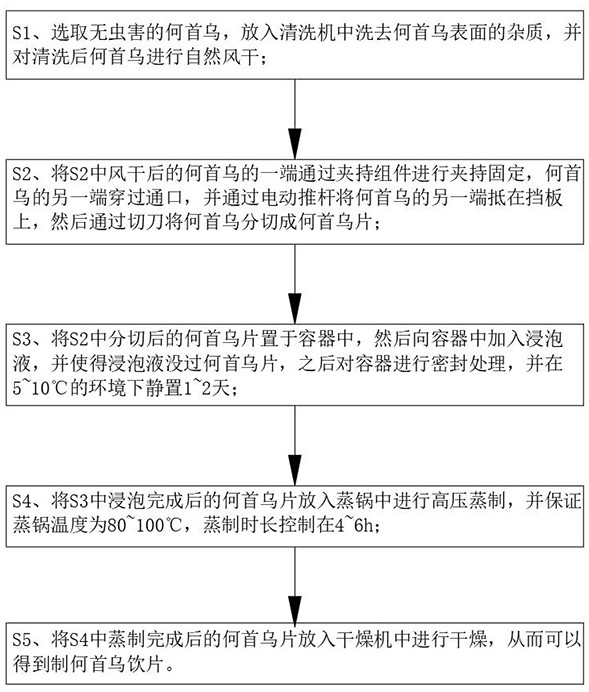

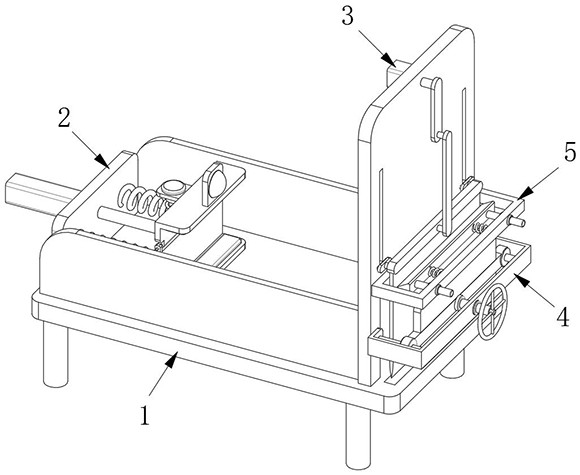

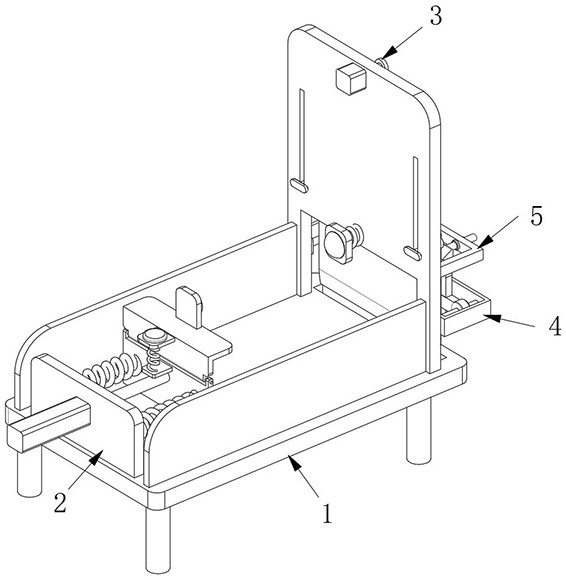

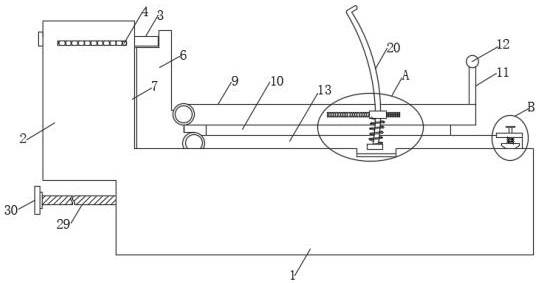

Artificial intelligence-based radix polygoni multiflori preparata decoction piece production equipment and processing method

ActiveCN114010687AEasy to holdEasy to sliceMetal working apparatusPlant ingredientsKnife bladesWorkbench

The invention discloses artificial intelligence-based radix polygoni multiflori preparata decoction piece production equipment and a processing method. The artificial intelligence-based radix polygoni multiflori preparata decoction piece production equipment comprises a supporting mechanism, a pushing mechanism mounted on the supporting mechanism, a slicing mechanism mounted on the supporting mechanism, an adjusting mechanism mounted on the supporting mechanism and an anti-adhesion mechanism mounted on the supporting mechanism, the supporting mechanism comprises a working table. According to the equipment, polygonum multiflorum to be sliced can be conveniently clamped and fixed, the clamped polygonum multiflorum can be conveniently pushed, so that the polygonum multiflorum can be conveniently sliced, the slicing thickness of the polygonum multiflorum can be conveniently adjusted, and the polygonum multiflorum slices with different thicknesses can be cut as required; the practicability of the production equipment is improved, the polygonum multiflorum slices adhered to the blade can be scraped in real time in the cutting process, the polygonum multiflorum slices are effectively prevented from being adhered to the blade, convenience is brought to workers, and the slicing efficiency is improved.

Owner:桂林欧润药业有限公司

Raw material manual slicing device for dried sweet potato processing

PendingCN112792891AUniform thicknessReduce generationMetal working apparatusAgricultural engineeringEngineering

The invention discloses a raw material manual slicing device for dried sweet potato processing. The raw material manual slicing device comprises a placing box, a pushing mechanism is arranged in the placing box, a fixed seat is fixedly arranged on one side of the top end of the placing box, a base is arranged on one side of the fixed seat, a slicing mechanism is arranged on one side of the base, a positioning mechanism is arranged at the bottom of the slicing mechanism, the slicing mechanism comprises a supporting plate, one end of the supporting plate is rotationally connected with one side of the base, a plurality of cutters distributed at equal intervals are fixedly arranged at the bottom end of the supporting plate, the positioning mechanism comprises a pressing plate, one end of the pressing plate is rotationally connected with one side of the base, a plurality of rectangular notches are formed in the top end of the pressing plate and correspond to the cutters in position, connecting mechanisms are arranged on the two sides of the pressing plate, and a pressure buffering mechanism is arranged on one sides of the connecting mechanisms. According to the raw material manual slicing device for dried sweet potato processing, sweet potatoes are positioned through the pressing plate, the positioned sweet potatoes are sliced through the multiple cutters distributed at equal intervals, it is guaranteed that the slicing thickness is uniform, generation of slicing residues is reduced, waste is reduced, and operation is easy.

Owner:赣州市和裕实业有限公司

A four-roller spindle device for a multi-wire cutting machine

ActiveCN109176932BImprove rigidityImprove stabilityWorking accessoriesFine working devicesWire cuttingEngineering

A four-roller main shaft device of a multi-wire cutting machine comprises a main shaft system, a material receiving box assembly and a nozzle assembly. The main shaft system and the nozzle assembly are arranged on a cutting chamber. The main shaft system comprises two main roller assemblies, two auxiliary roller assemblies, a front installing support and a rear installing support. The two main roller assemblies are symmetrically arranged on the front installing support and the rear installing support. The two auxiliary roller assemblies are symmetrically arranged on the front installing support and the rear installing support and located between the main roller assemblies. The material receiving box assembly is arranged in limiting grooves of the front installing support and the rear installing support and located between the auxiliary roller assemblies. Each main roller assembly comprises a rotation water cooling device, a driven bearing box, a main roller, a driving bearing box and ahollow locking screw. Each auxiliary roller assembly comprises an auxiliary roller, a bearing block I, a bearing II, a locking nut I, a sealing cover I, a bearing block II, a bearing III, a locking nut II, a sealing cover II, an installing frame, an adjusting screw and a nut. By utilization of the four-roller main shaft device, the requirements for high-speed and high-precision cutting of diamondwires can be met.

Owner:HUNAN YUJING MACHINE

Slicing device for processing traditional Chinese medicine decoction pieces

PendingCN113276197AUniform thicknessAvoid secondary cuttingMetal working apparatusProcess engineeringMaterials processing

The invention provides a slicing device for processing traditional Chinese medicine decoction pieces, and relates to the technical field of Chinese medicinal material processing equipment. The slicing device comprises a shell, a supporting plate, connecting pieces, a conical guide table, a material barrel, guide grooves, blanking seams, cutter mechanisms, a driving mechanism and a control panel. According to the slicing device, the thickness of decoction pieces can be kept uniform, and the sliced decoction pieces directly fall into a conical blanking bin; secondary cutting is avoided, and raw material medicines are output through the multiple guide grooves simultaneously while the slicing quality is guaranteed; and the multiple material guide grooves work in cooperation with the multiple cutter mechanisms, and the slicing efficiency is effectively improved.

Owner:THE THIRD PEOPLES HOSPITAL OF QINGDAO

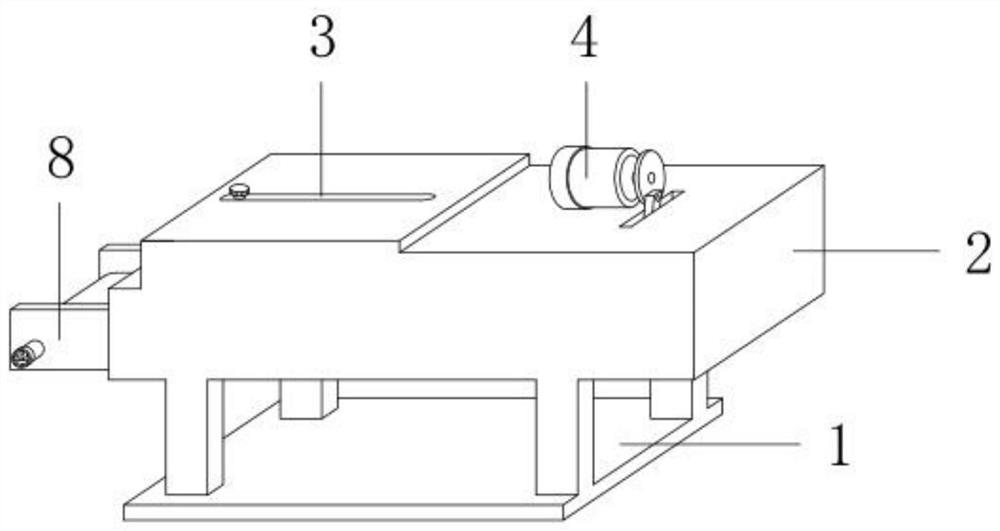

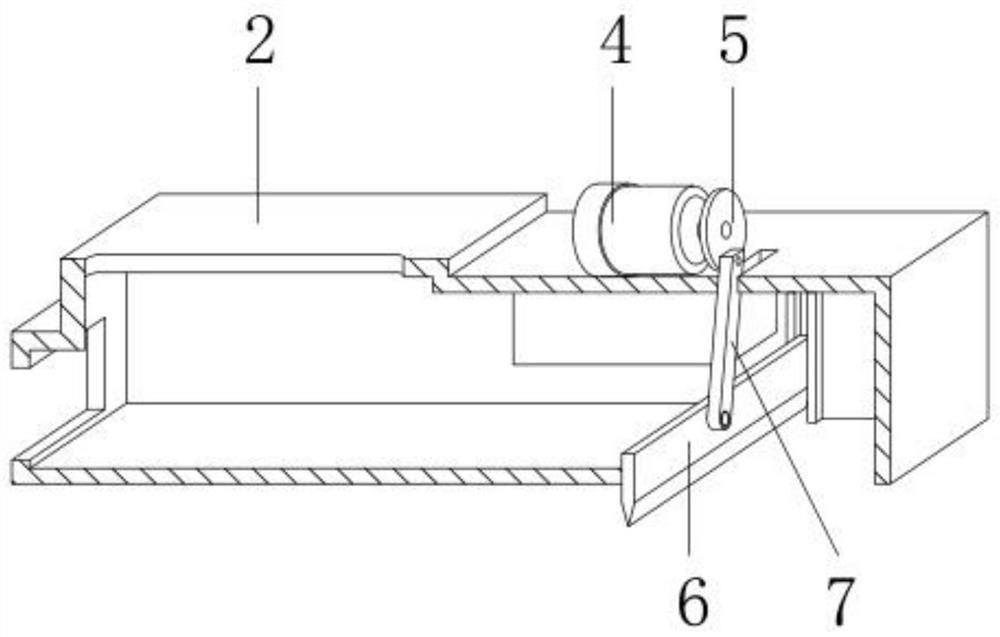

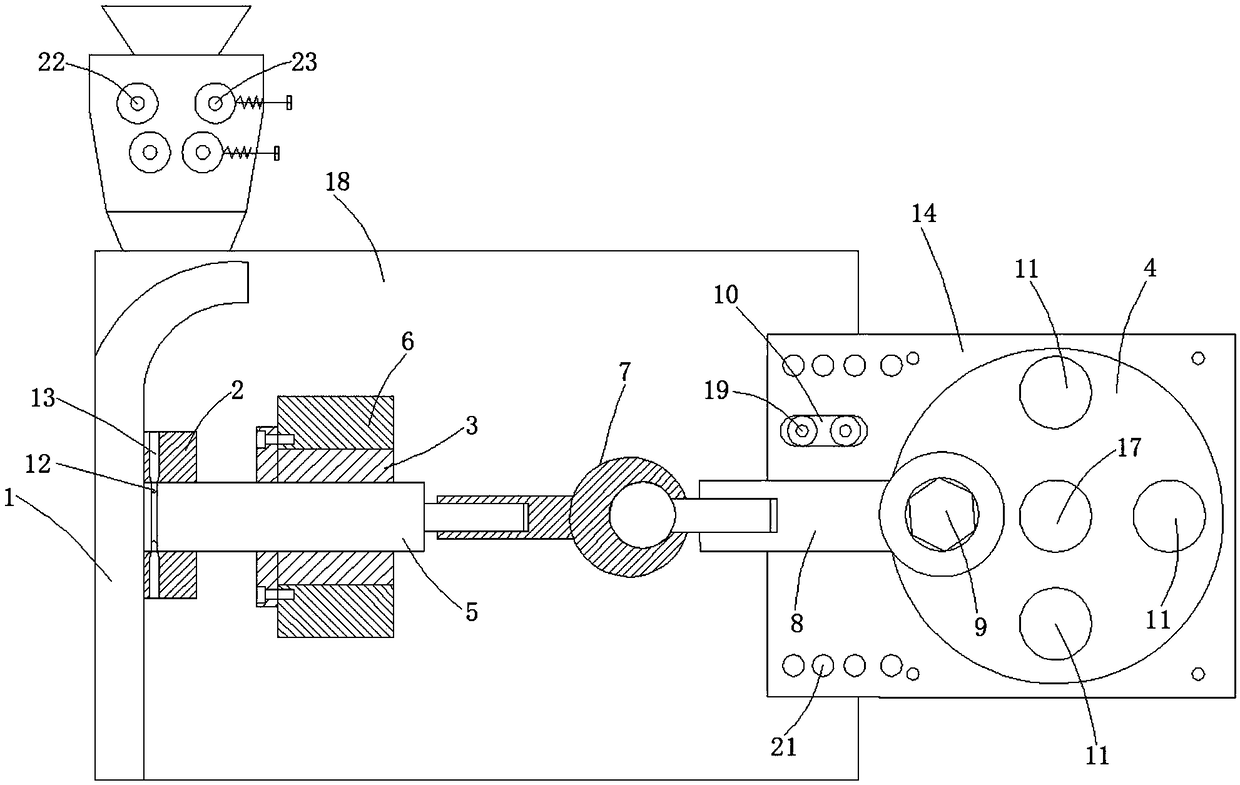

A device for extruding and slicing tobacco leaves

ActiveCN110833203BGuaranteed slice qualitySlicing is fastTobacco treatmentAgricultural engineeringStructural engineering

Owner:HUBEI CHINA TOBACCO IND +1

Slicing machine for columnar food

InactiveCN108858382AEffectively cleans up adhesionsClean up adhesionMetal working apparatusBlade plateFood category

The invention belongs to the technical field of columnar type food category processing equipment, and particularly relates to a slicing machine for columnar food. The distance between two friction blocks is less than the thickness of a blade, when the blade passing between the two friction blocks, the friction blocks can act on both sides of the blade to effectively clean food chippings adhere tothe blade, not only the subsequent stable blade is provided with guarantee, but also the quality of food cutting is greatly improved. The friction blocks are friction blocks manufactured of sponge materials, the blade effectively cleaned is guaranteed, and meanwhile, damage to the blade is avoided. The slicing machine for the columnar food can automatically realize the slicing working of the columnar food, the working efficiency of before manual slicing is effectively improved, and appearing of the condition of blade sticking is avoided. A plurality of blades are uniformly distributed on a blade plate, even though the condition of parts damaged appears, the using of other blades cannot be affected, the maintenance and replacement of the damaged blades are convenient, and thus the efficiency and quality of the slicing are guaranteed.

Owner:孙勇

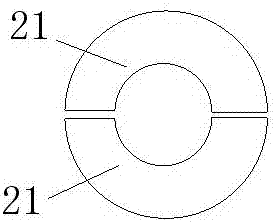

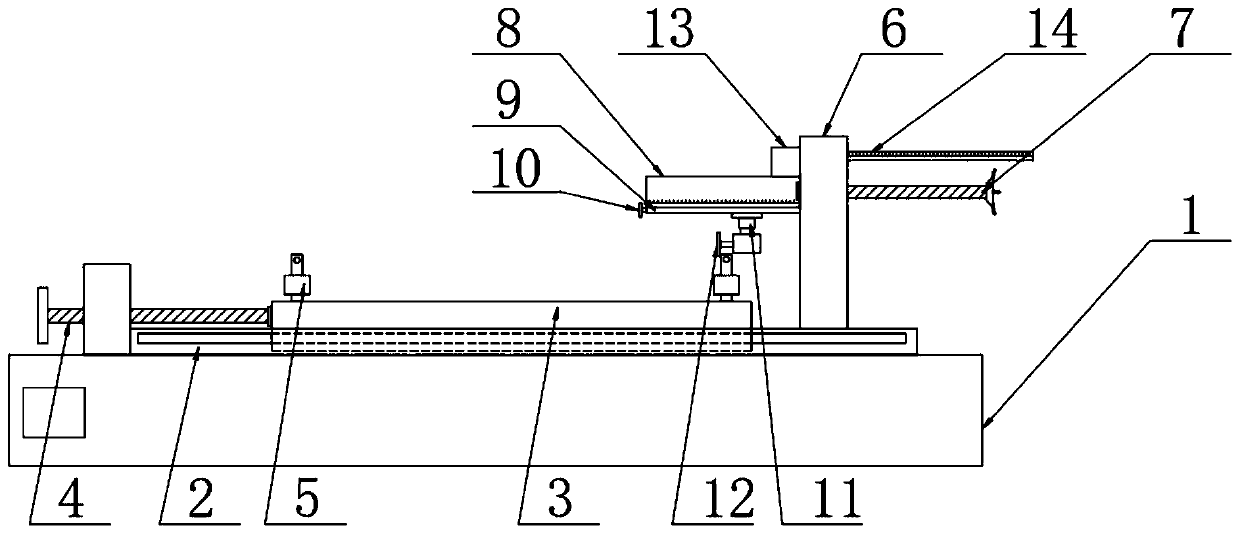

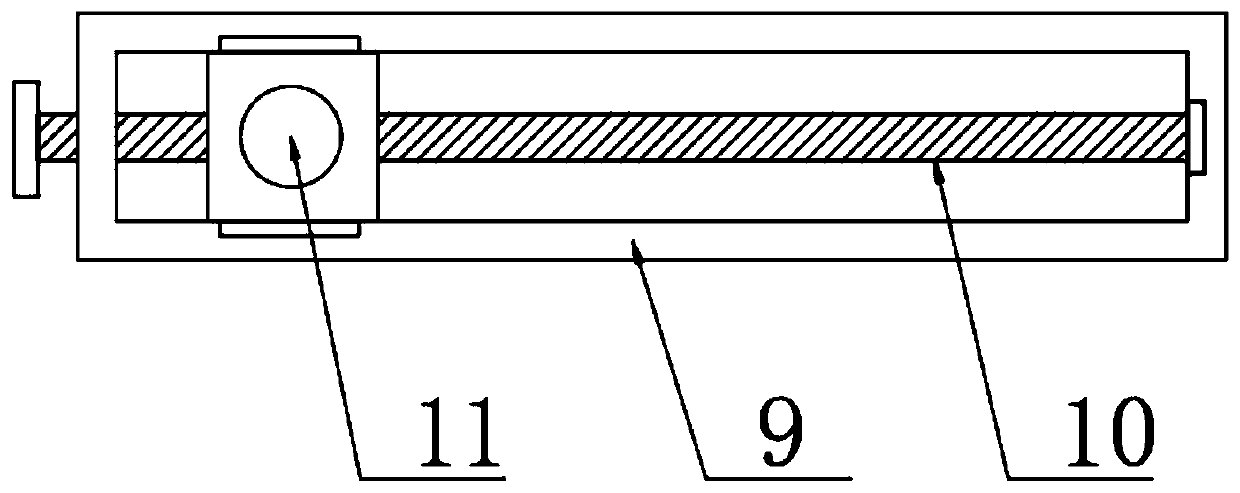

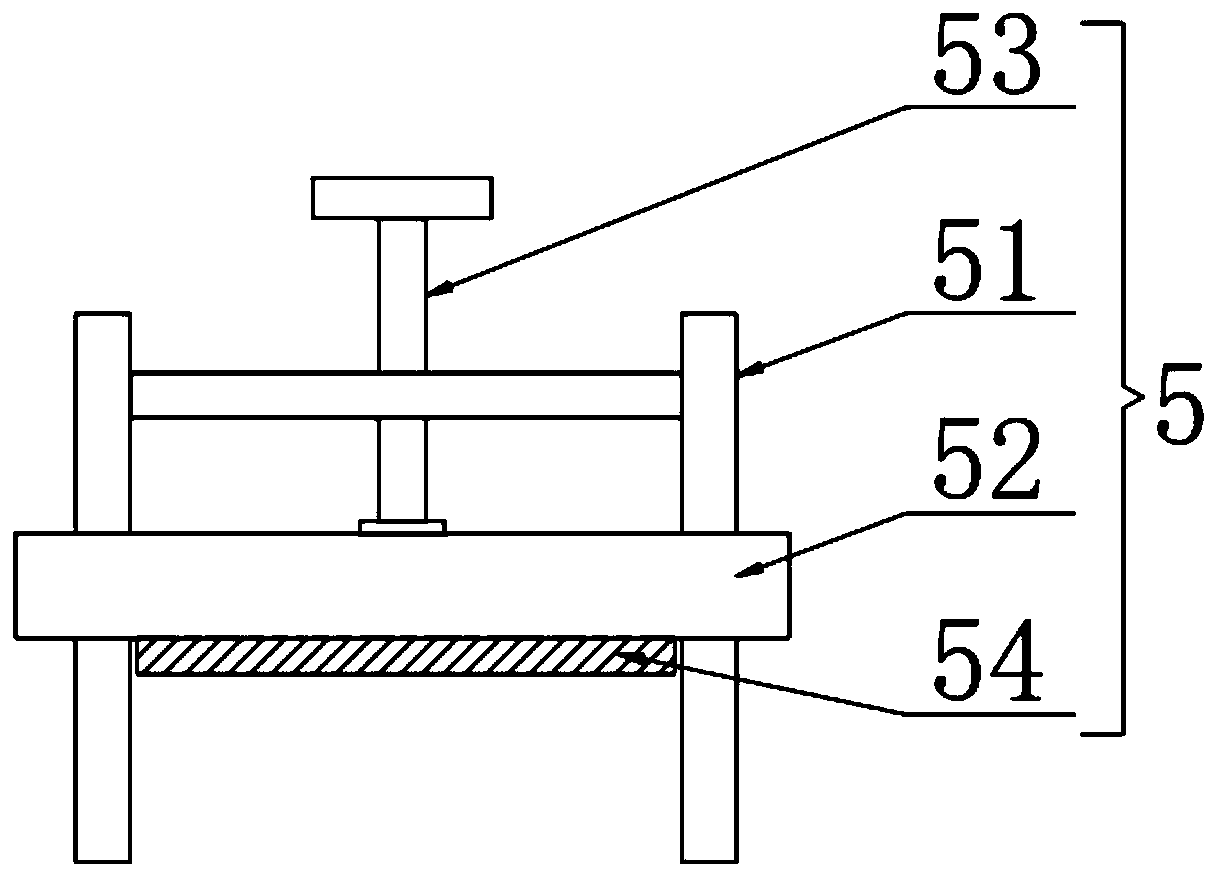

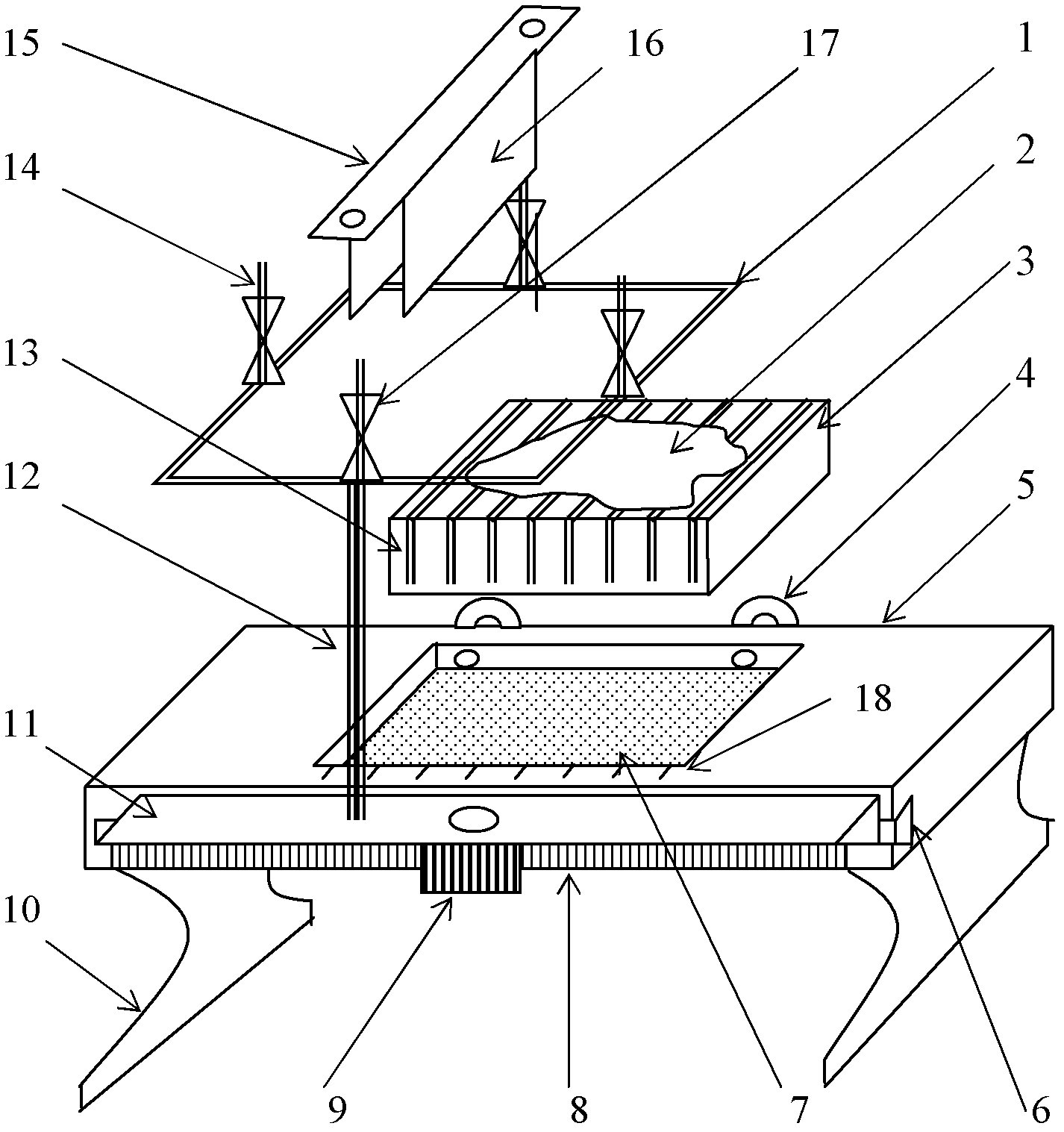

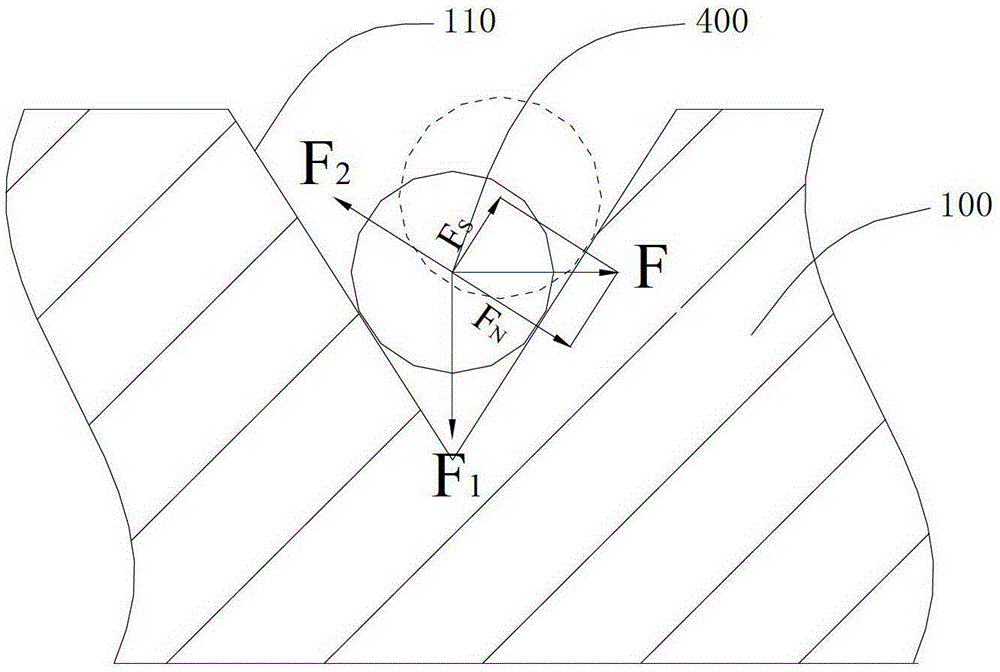

A single crystal silicon rod slicing device

ActiveCN111571833BAvoid displacementGuaranteed slice qualityWorking accessoriesFine working devicesEngineeringCondensed matter physics

Owner:新疆东方希望光伏科技有限公司

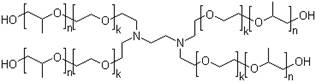

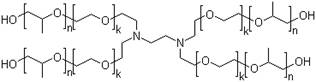

Dicing solution for gold electrode chips

The invention discloses a dicing liquid for gold electrode chips, which is prepared by selecting non-foaming amphoteric surfactant, ethylenediamine ethoxypropoxylate, polyethylene glycol 10000 and water, which not only has dynamic wetting ability It is strong, can quickly wet the blade and cutting channel, and has extremely low foam and fast defoaming. At the same time, because ethylenediamine ethoxypropoxylate has a rich branched chain structure, it forms a local short-range steric hindrance in the solution. It can be filled in the basic frame built by polyethylene glycol, which can significantly improve the steric hindrance density of the solution, enhance the suspension and dispersion ability of the cutting powder, avoid the adhesion of the cutting powder on the chip, and ensure the quality of the slice.

Owner:DALIAN SANDAAOKE CHEM

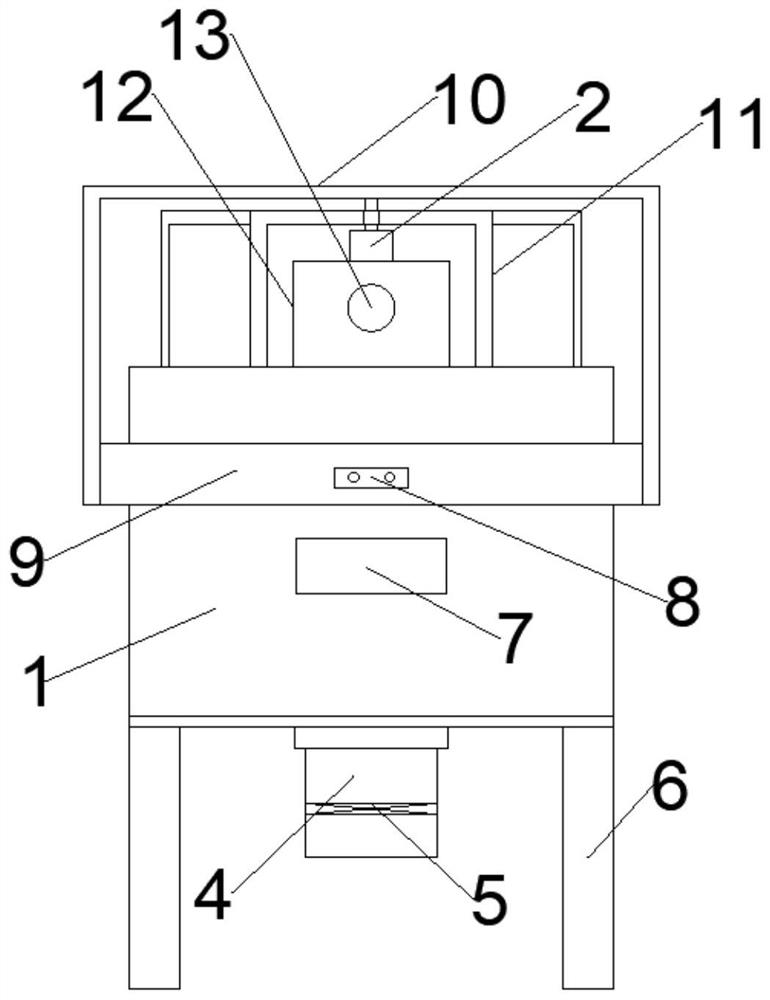

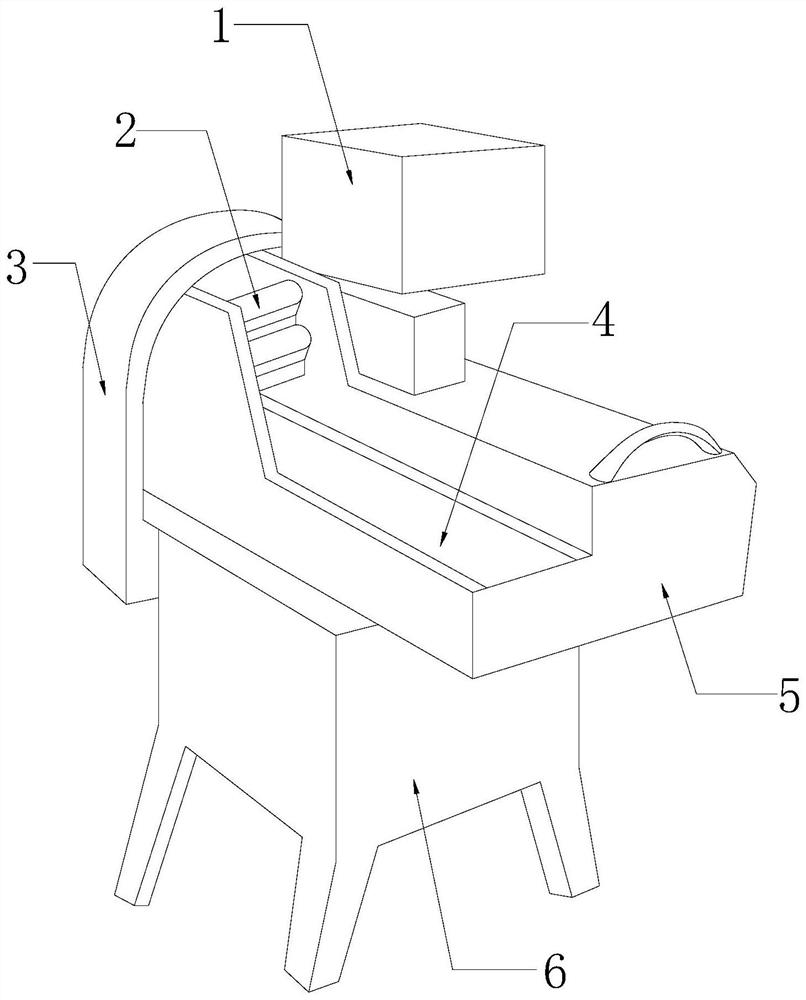

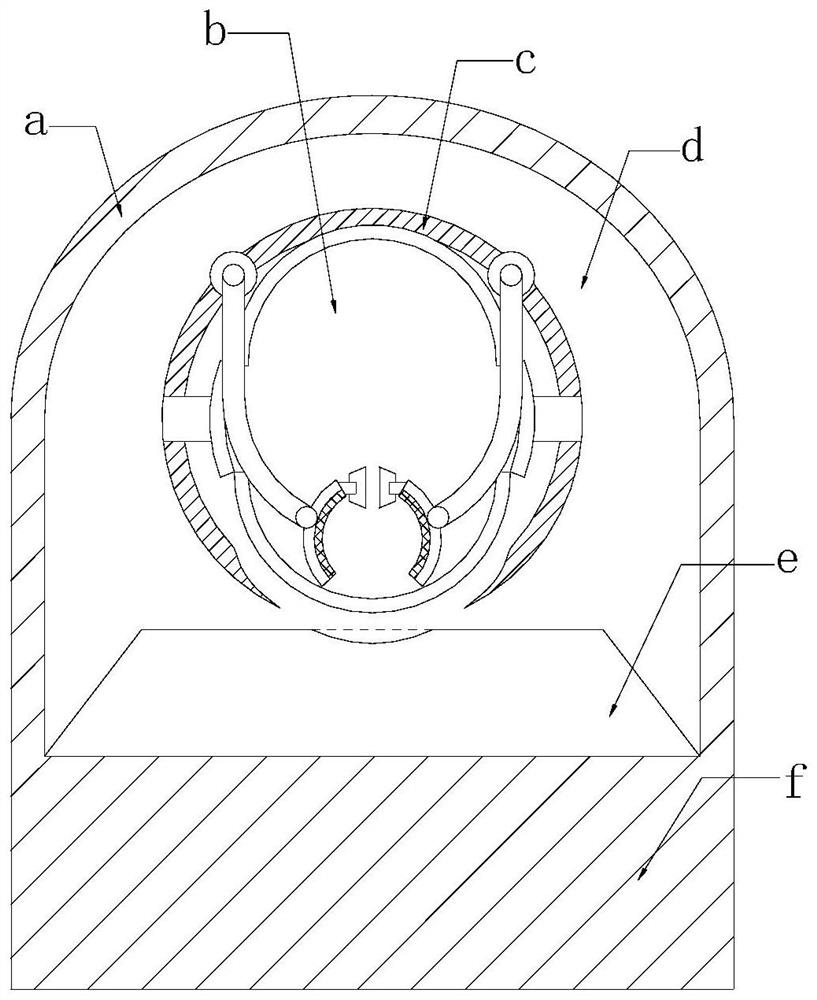

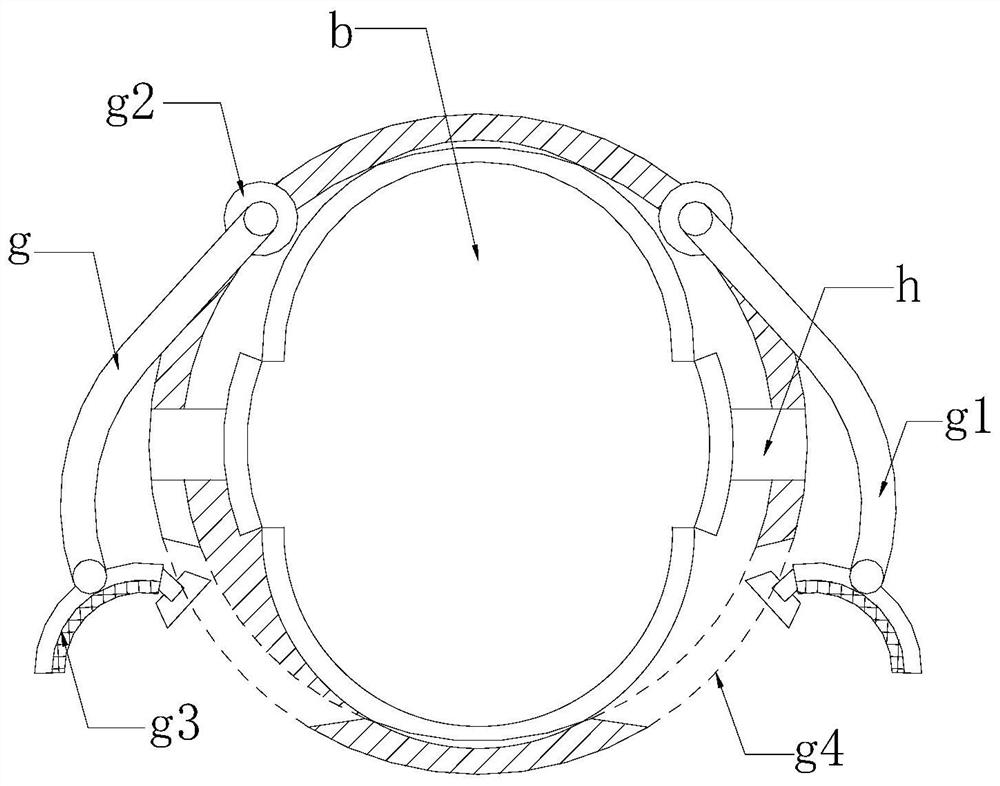

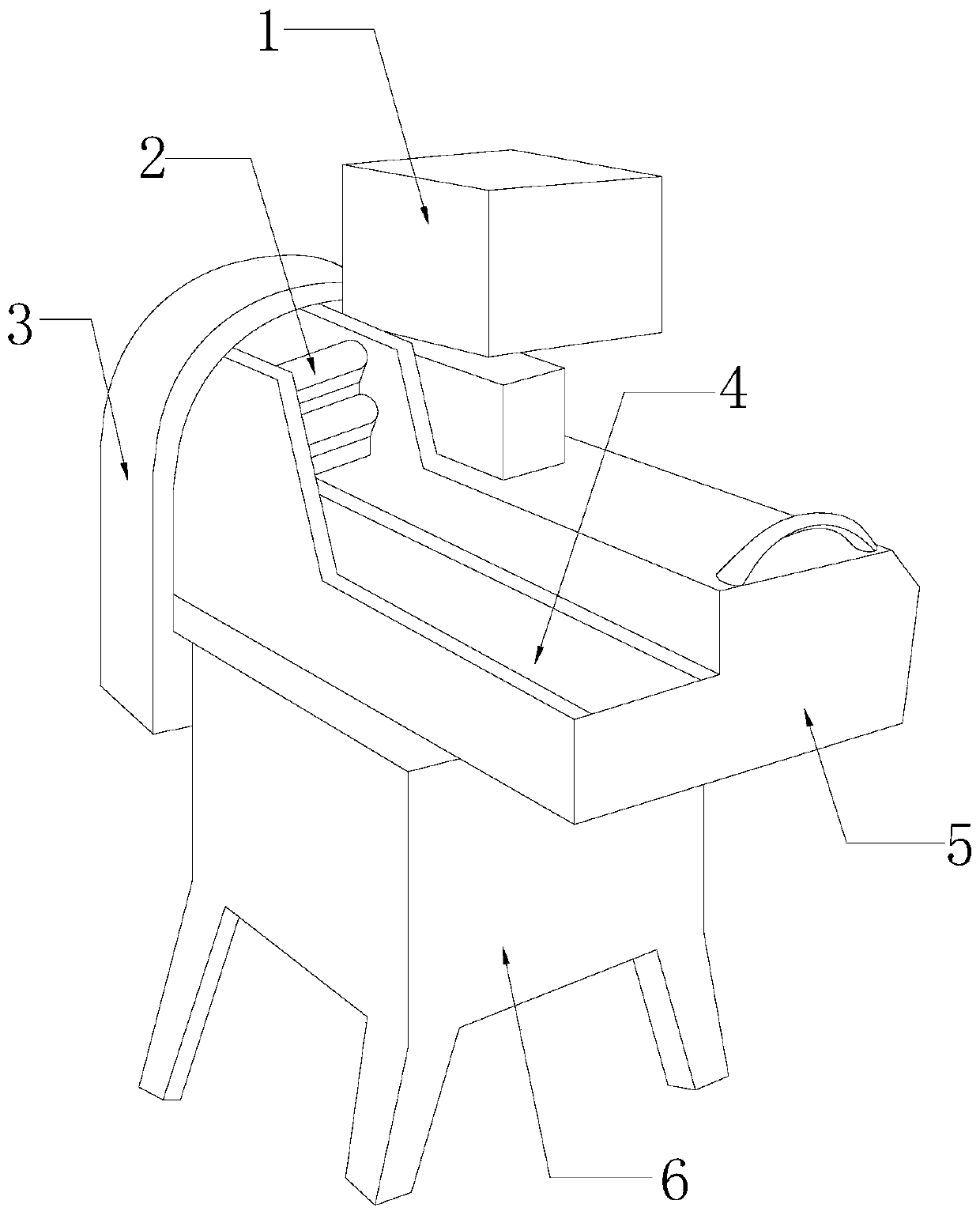

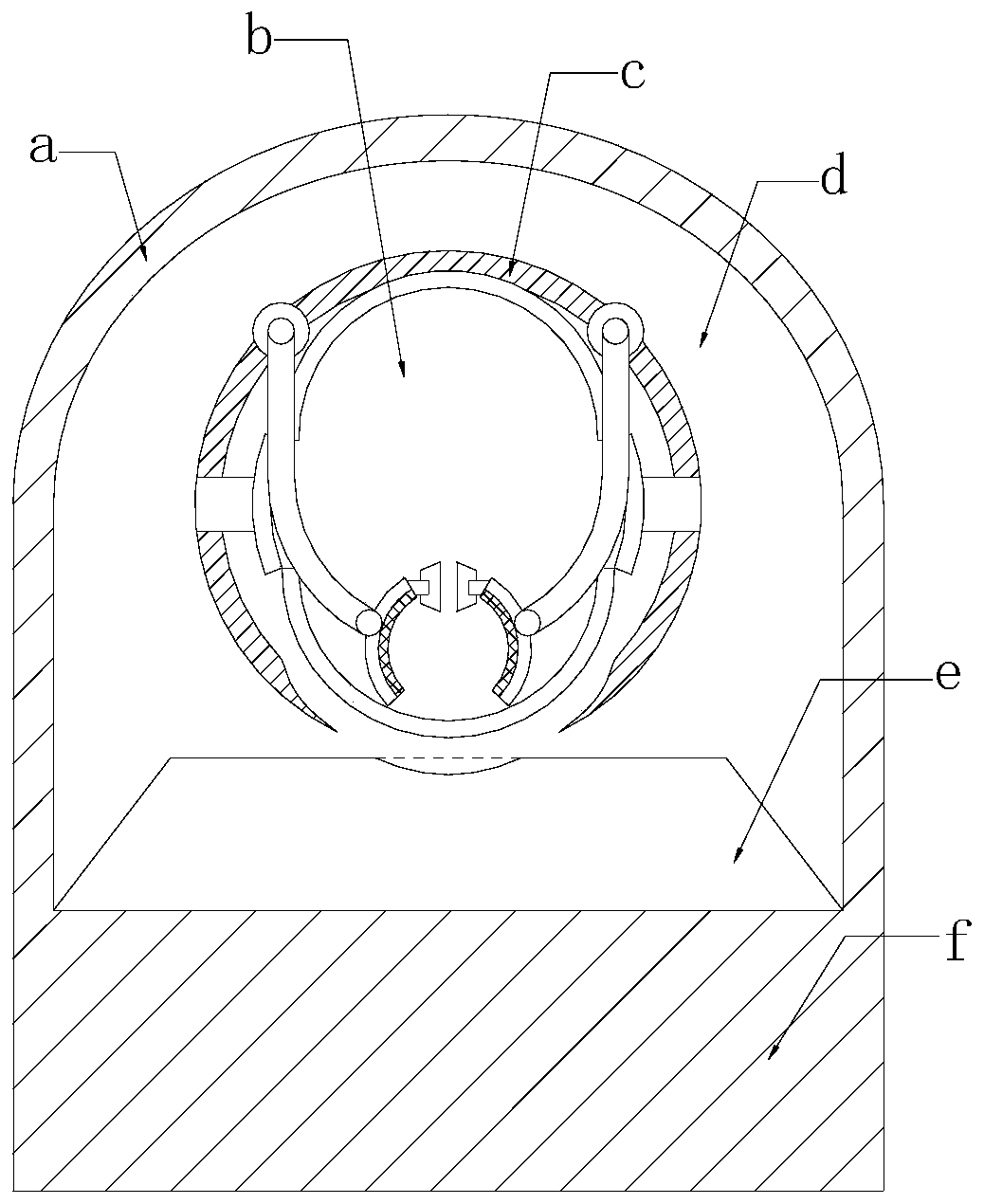

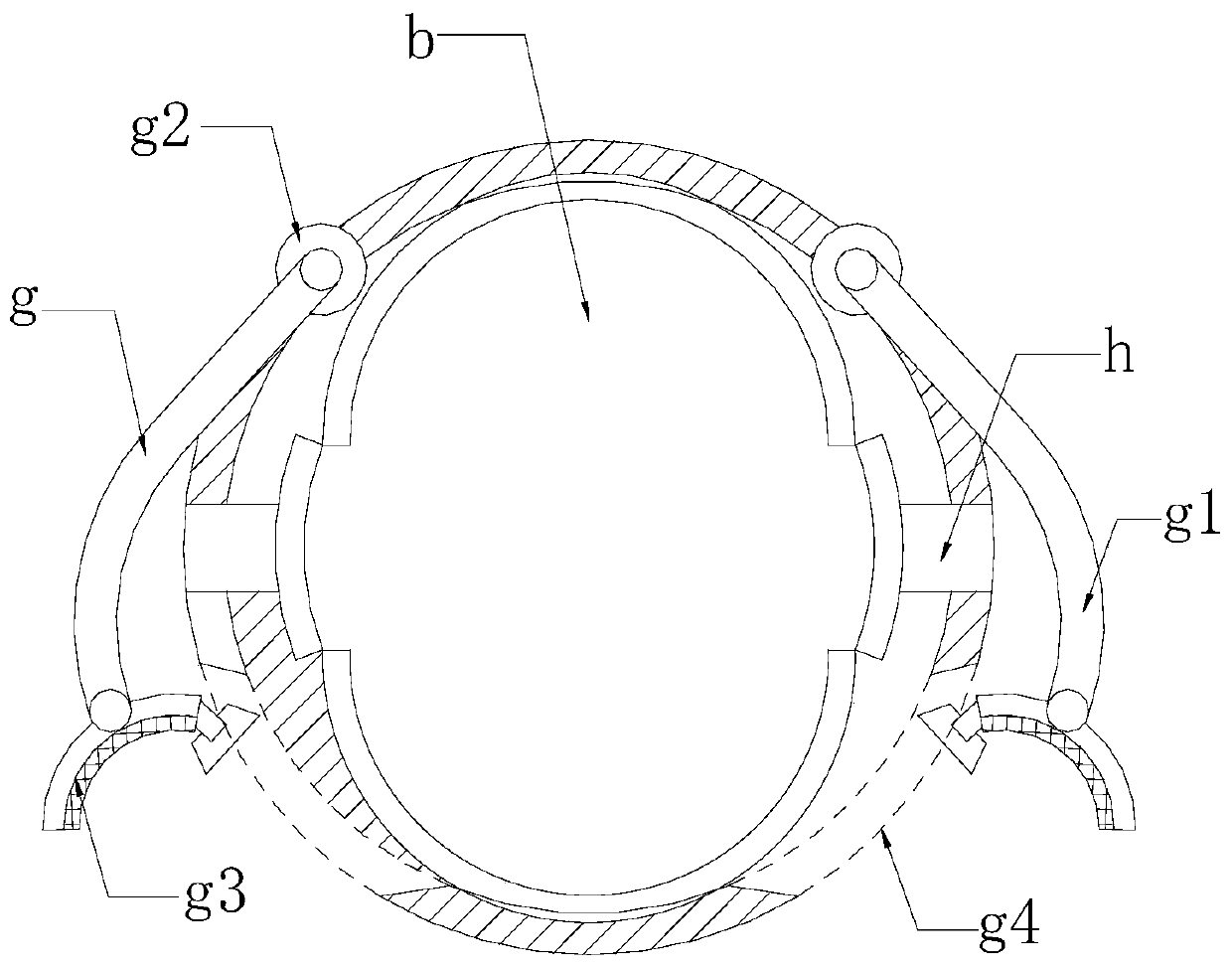

Monocrystalline silicon rod slicing device

ActiveCN111571833AAvoid displacementGuaranteed slice qualityWorking accessoriesFine working devicesStructural engineeringMachining process

The invention discloses a monocrystalline silicon rod slicing device. The monocrystalline silicon rod slicing device structurally comprises a distribution box, a cutting head, a guide-in device, a machining table, a fixing seat and a base, the fixing seat is installed on the base, the machining table is arranged on the fixing seat, and the cutting head is matched with the guide-in device. The monocrystalline silicon rod slicing device has the beneficial effects when a clamping layer on a clamping head makes contact with a monocrystalline silicon rod, the magnetism of two magnetic blocks is different, the two magnetic blocks attract each other to reinforce the clamping force of the clamping head, the clamping head can clamp and fix the monocrystalline silicon rod under the dual action, twomovable grooves can be ejected out along with the diameter of the monocrystalline silicon rod to be replaced and matched with the size of the monocrystalline silicon rod, when the two movable groovesand two fixed grooves are located on the same arc line, outward movement is stopped, and meanwhile force is applied to the monocrystalline silicon rod, so that the monocrystalline silicon rod is fixed, displacement of the monocrystalline silicon rod under the impact force of a wire saw is prevented, relative fixation of the position of the monocrystalline silicon rod in the machining process is guaranteed, and the slicing quality of the monocrystalline silicon rod is further guaranteed.

Owner:新疆东方希望光伏科技有限公司

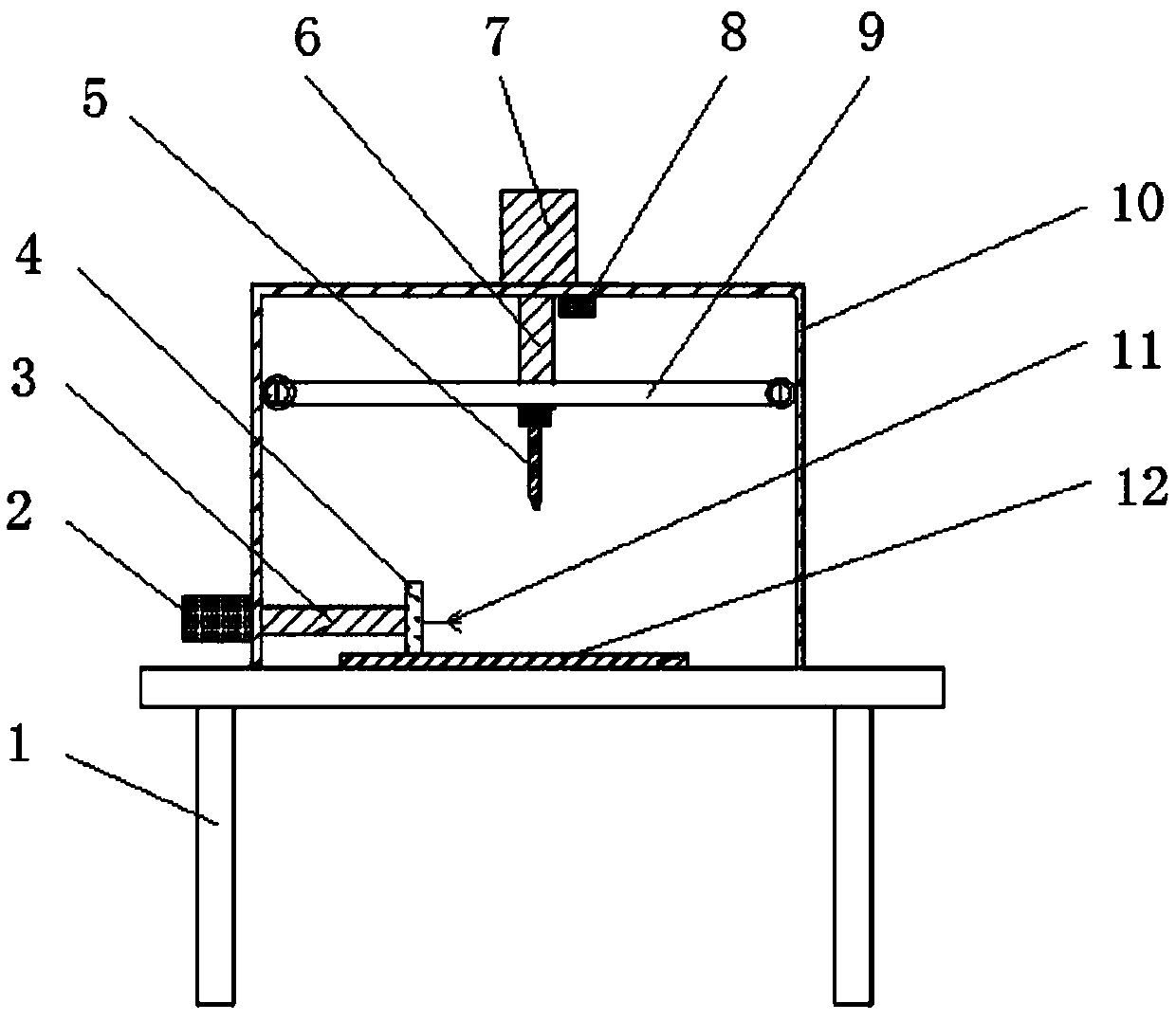

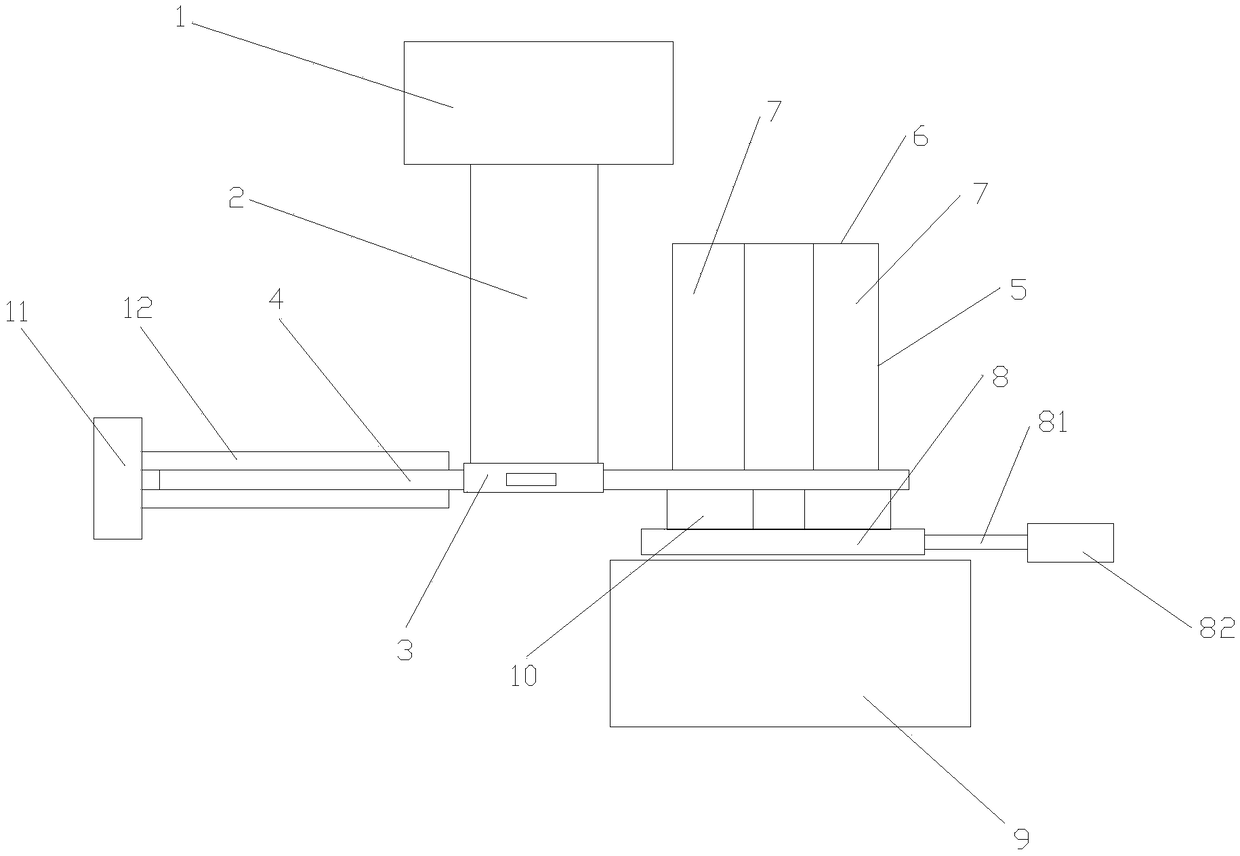

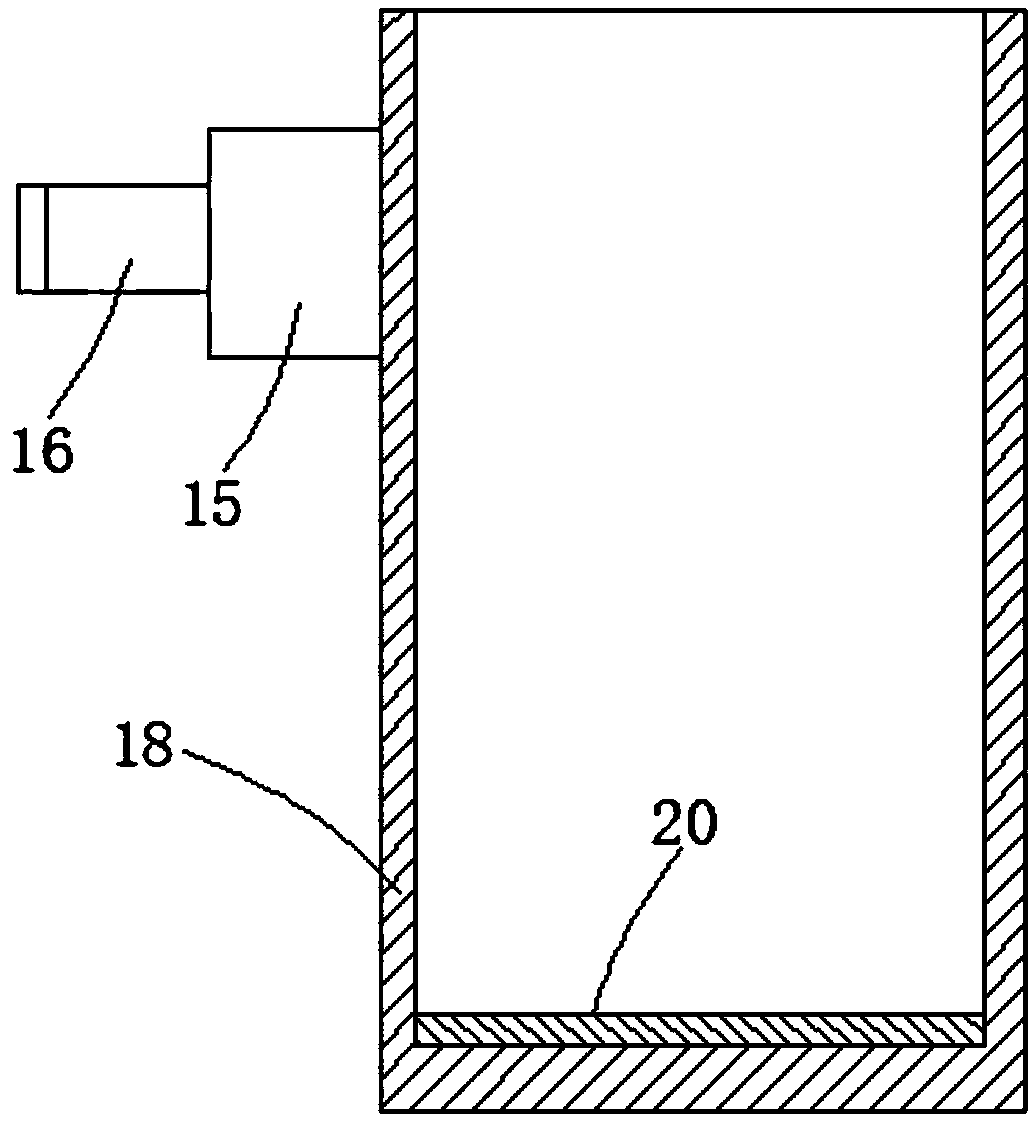

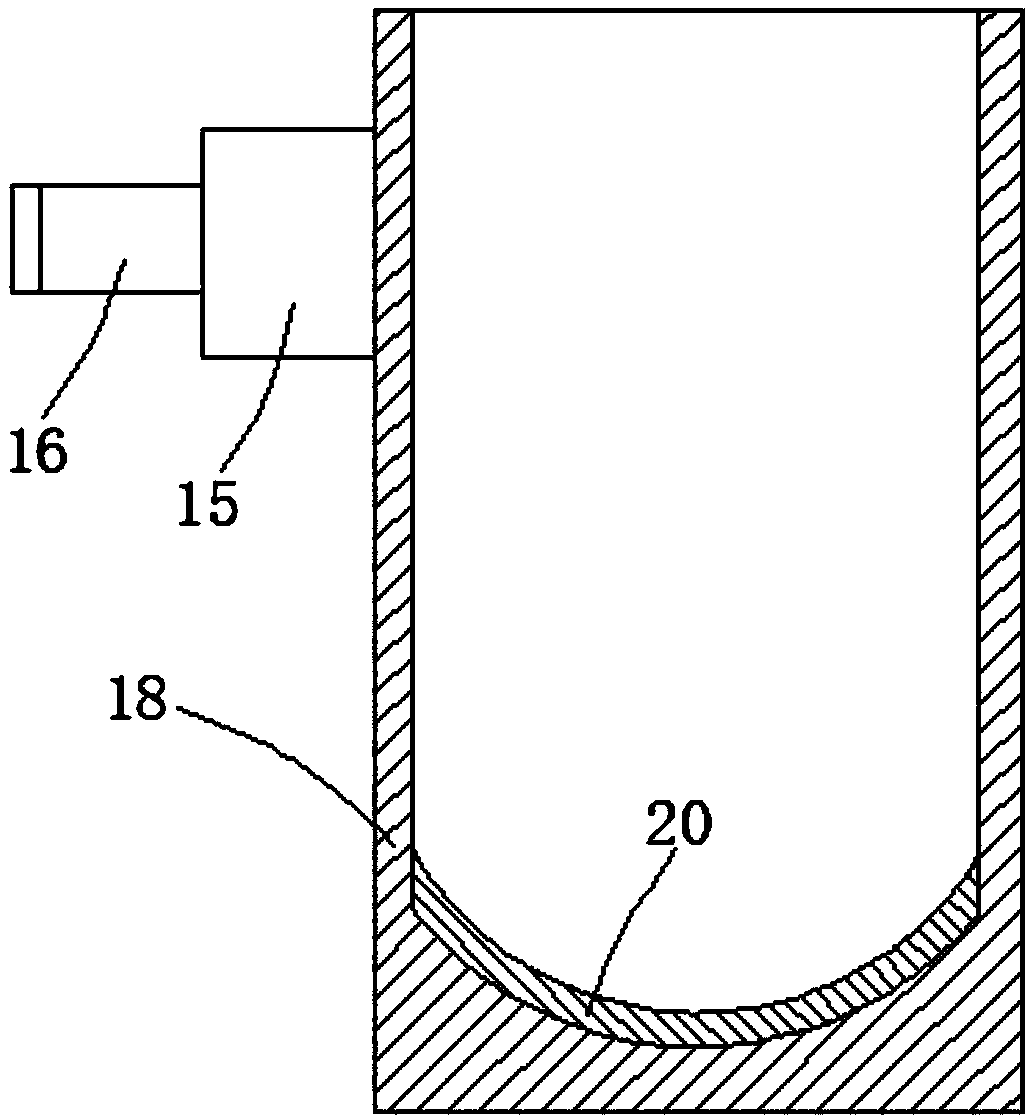

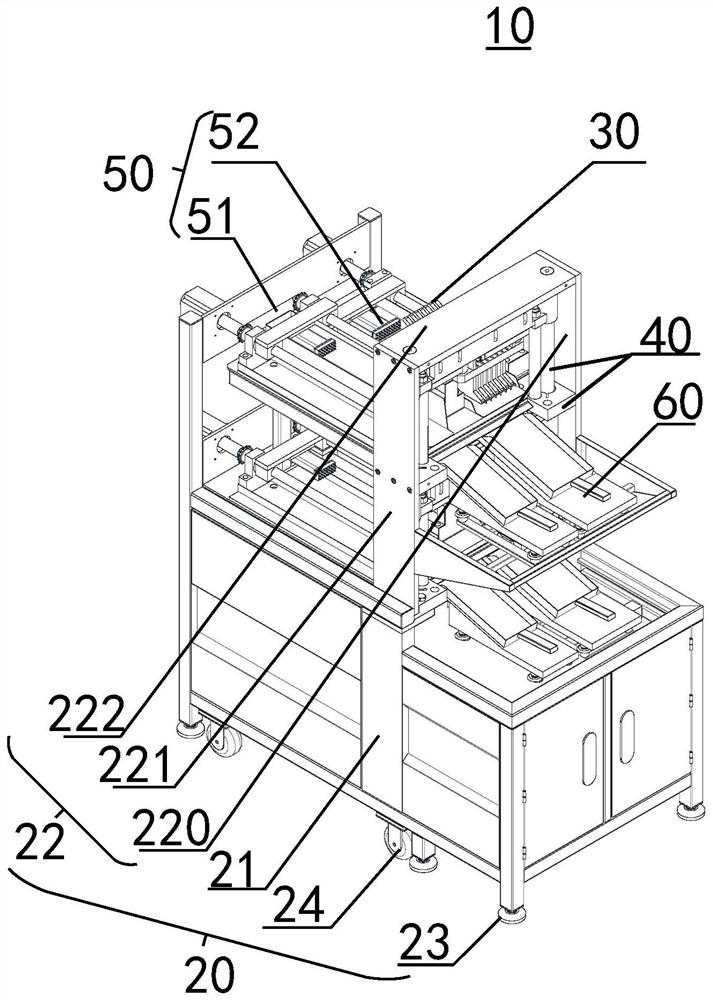

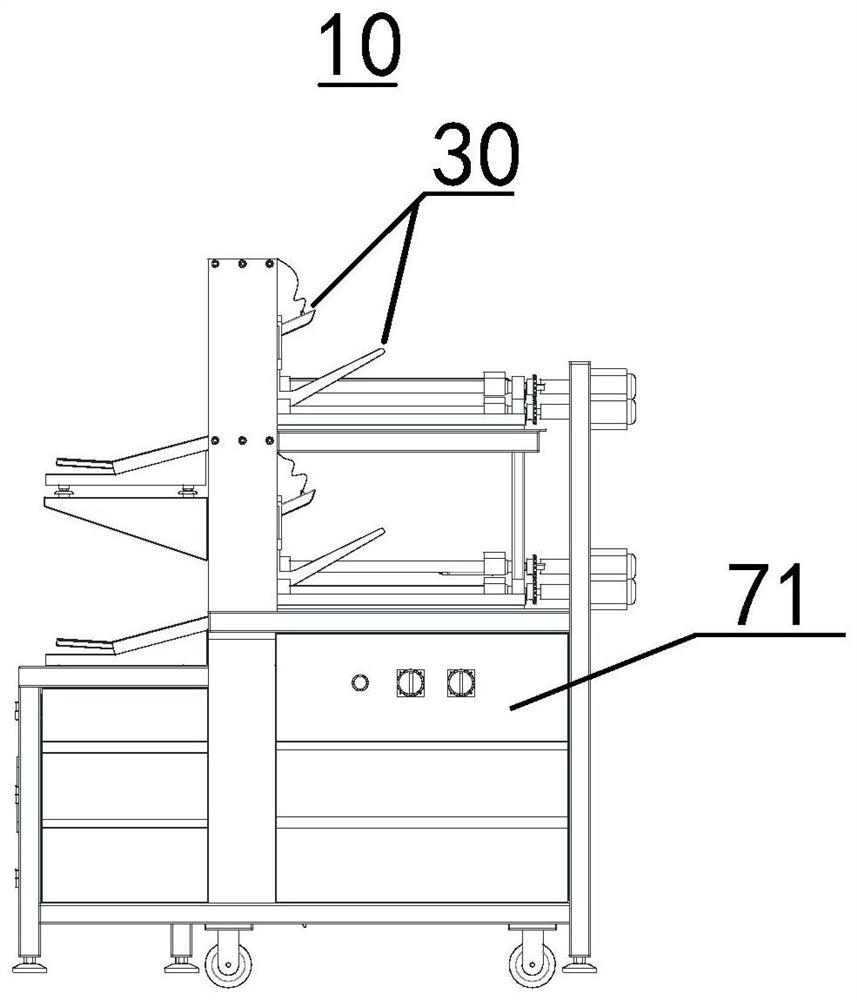

Feeding box and slicing machine

PendingCN109434929AIntermittentAvoid squeezingMetal working apparatusLinear motionReciprocating motion

The invention provides a feeding box and a slicing machine and relates to the technical field of cutting equipment. The problems that in the prior art, slicing quality is low, and slicing efficiency is low are solved. The feeding box provided by the invention comprises a box body, a push plate, a linear motion mechanism and a crank-link mechanism, and the push plate, the linear motion mechanism and the crank-link mechanism are arranged in the box body. The linear motion mechanism is fixed in the box body and can reciprocate front and back. The first end of the linear motion mechanism is connected to the push plate. The second end of the linear motion mechanism is movably connected with the link free end of the crank-link mechanism. The crank free end of the crank-link mechanism is used forbeing connected with a power machine. The crank-link mechanism can drive the push plate to reciprocate linearly in the length direction of the box body through the linear motion mechanism. The advantages of high slicing quality and high efficiency are achieved. The slicing machine provided by the invention adopts the feeding box, and slicing quality and slicing efficiency can be ensured.

Owner:张斌

Sliding Large Slicer

ActiveCN112606062BEasy to slicePrevent the effect of subsequent operation inspection from being affectedWithdrawing sample devicesMetal working apparatusTissue architectureSurgery

The invention relates to the technical field of pathological slicing equipment, and more particularly, to a sliding type large slicer, comprising: a slicing table, a slicing knife mechanism, a slicing control mechanism, a fixed limit mechanism and a push limit mechanism; The control mechanism is matched and connected to the slicing table; the slicing control mechanism is matched and connected with the slicing knife mechanism to drive the slicing knife mechanism to slice the pathological samples placed on the slicing table; the fixing The limit mechanism and the push limit mechanism are relatively matched on the slicing table to limit and fix the pathological sample; the slice knife mechanism is matched with the fixed limit mechanism and the push limit mechanism between. The invention is convenient for cutting pathological samples into pathological slices with clear tissue structure, which is helpful for preserving the complete morphological structure of the pathological slice tissue, and is beneficial to accurate pathological diagnosis.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV +3

A vertical slicer

InactiveCN108858346BImprove slicing efficiencyImprove intelligent controlMetal working apparatusMachine buildingSoftware engineering

The embodiment of the invention provides a vertical type slicer, and relates to the field of machine manufacturing. Through the ingenious design of a slicing system in the vertical type slicer, slicing operation of multiple layers of materials in different channels can be achieved at the same time, the slicing efficiency is effectively improved, and the slicing quality is guaranteed.

Owner:HAI DI LAO HLDG PTE LTD +1

A frozen meat slicer

ActiveCN111716407BEasy to straightenAdaptableMetal working apparatusMeat processing devicesGear wheelElectric machinery

The invention discloses a slicer for frozen meat, which includes a slicing device and a feeding device. The feeding device is installed on the upper end of the slicing device. When the turntable is rotated, the turntable drives a threaded rod to rotate. The outer surface of the threaded rod is provided with a first thread and a The second thread, under the rotation of the first thread and the second thread, the moving assembly can move to the center at the same time, which is convenient for straightening frozen meat of different widths and makes the device more adaptable. Turn the motor, when the forward rotation motor rotates to drive the first gear, the first gear drives the chain, the chain drives the second gear, the second gear rotates to make the roller rotate, which is convenient for feeding frozen meat, and the two rows of rollers can make the frozen meat The meat is fed in a limited width to prevent the feeding from skewing.

Owner:湖南华乐食品有限公司

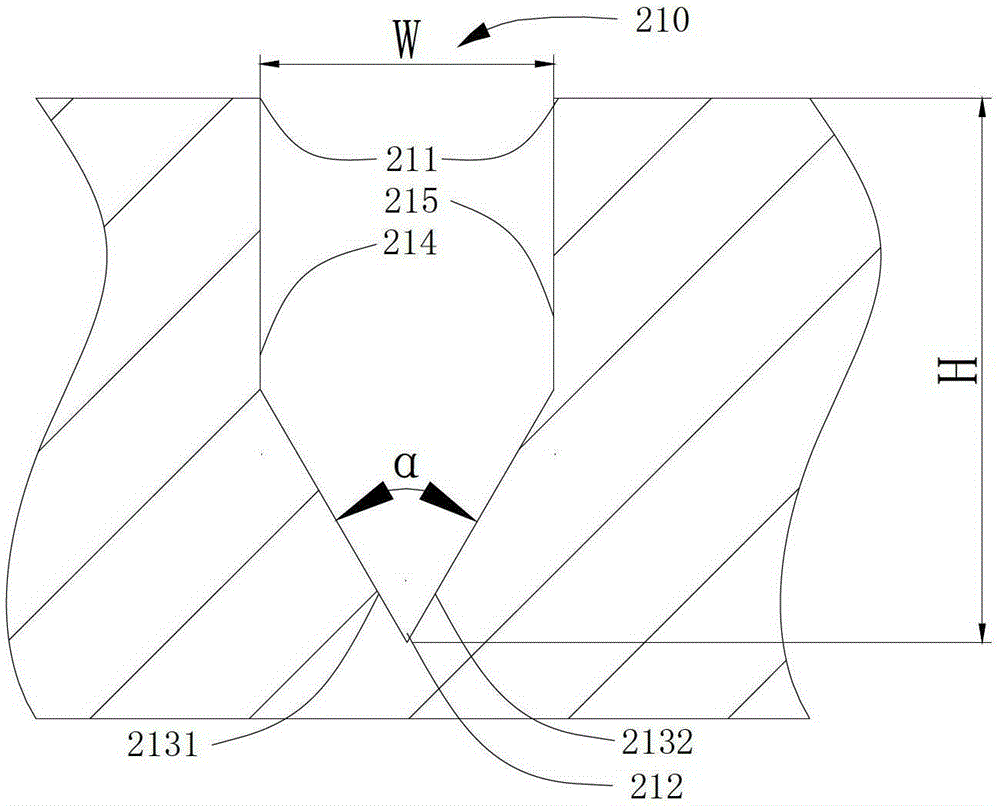

Multi-wire cutting machine guide wheel wire groove and its processing method

ActiveCN103395131BShorten the axial widthAvoid "Jumper" AccidentsWorking accessoriesFine working devicesWire cuttingEngineering

Owner:GCL POLY ENERGY HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com