Slicing device

A technology of slicing device and cutting device, which is applied in metal processing and other directions, can solve the problems of inability to ensure uniform slice thickness and personal safety, low quality of finished products, poor appearance, etc., and achieves outstanding practicability, labor saving, and convenient feeding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

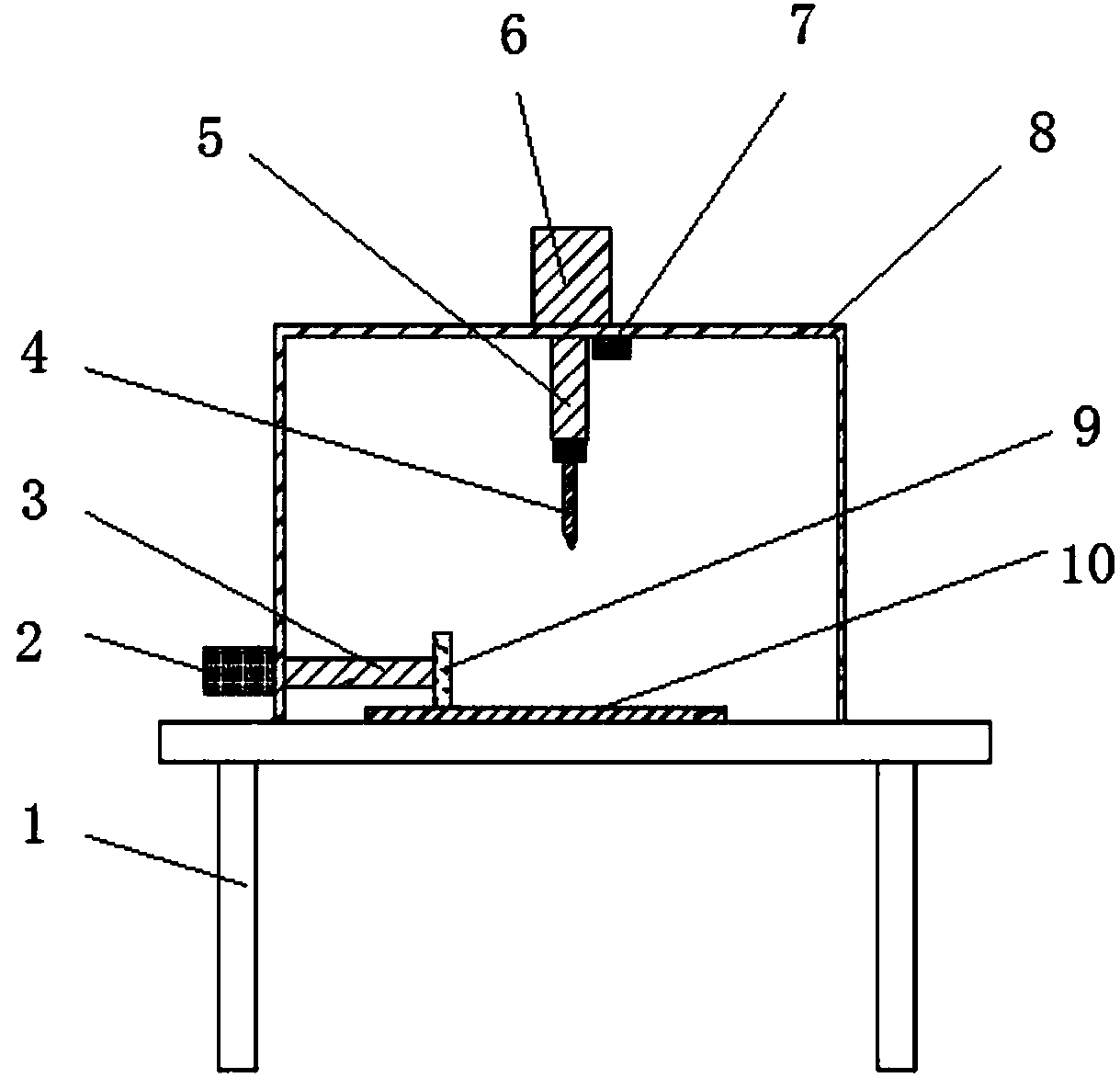

[0021] Such as figure 1 As shown, a slicing device comprises a lower support 1, an upper support 8 and an automatic cutting device arranged on the upper support 8, the upper support 8 is placed above the lower support 1, and a workbench is placed above the lower support 1 for automatic cutting The equipment includes a cutting device and a feeding device; the cutting device is composed of a vertical electric cylinder 6 and a blade 4 placed on the top of the upper bracket 8, the body of the vertical electric cylinder 6 is vertically arranged on the top of the upper bracket 8, and the blade 4 is fixed on the vertical To the lower end of the telescopic rod 5 of the electric cylinder 6; the feeding device is composed of a horizontal electric cylinder 2 and a push plate 9. The end of the rod 3; the cutting device and the feeding device are controlled by the same controller, and an infrared positioning device 7 is arranged beside the cutting device. Blade 4 is fixed on the lower end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com