Feeding box and slicing machine

A feeding box and box body technology, which is applied in metal processing and other directions, can solve problems such as low slicing efficiency, unfavorable slicing quality, and mismatched bottom shape and shape, and achieve the effects of improving slicing efficiency, simple transmission structure, and guaranteed slicing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

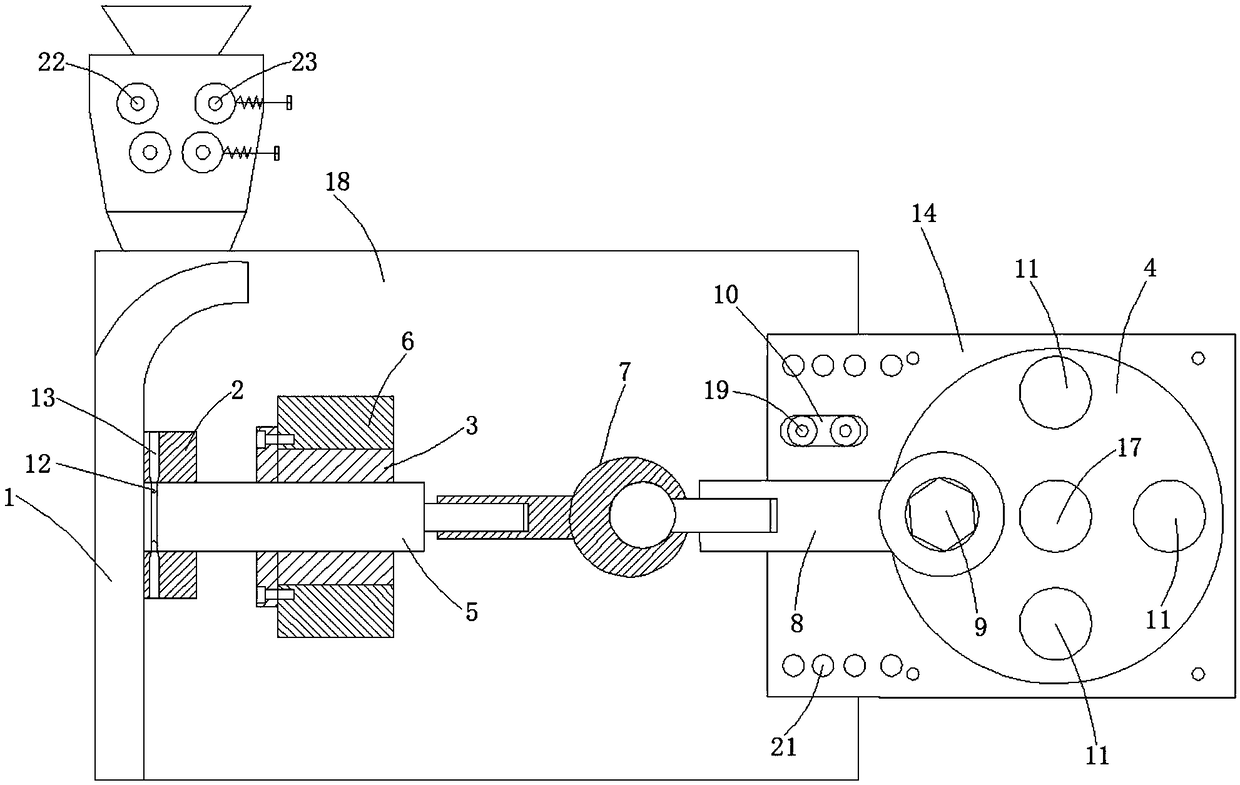

[0038] This embodiment provides a feeding box, which has the advantages of high slice quality and high efficiency, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, specifically set to the following structure:

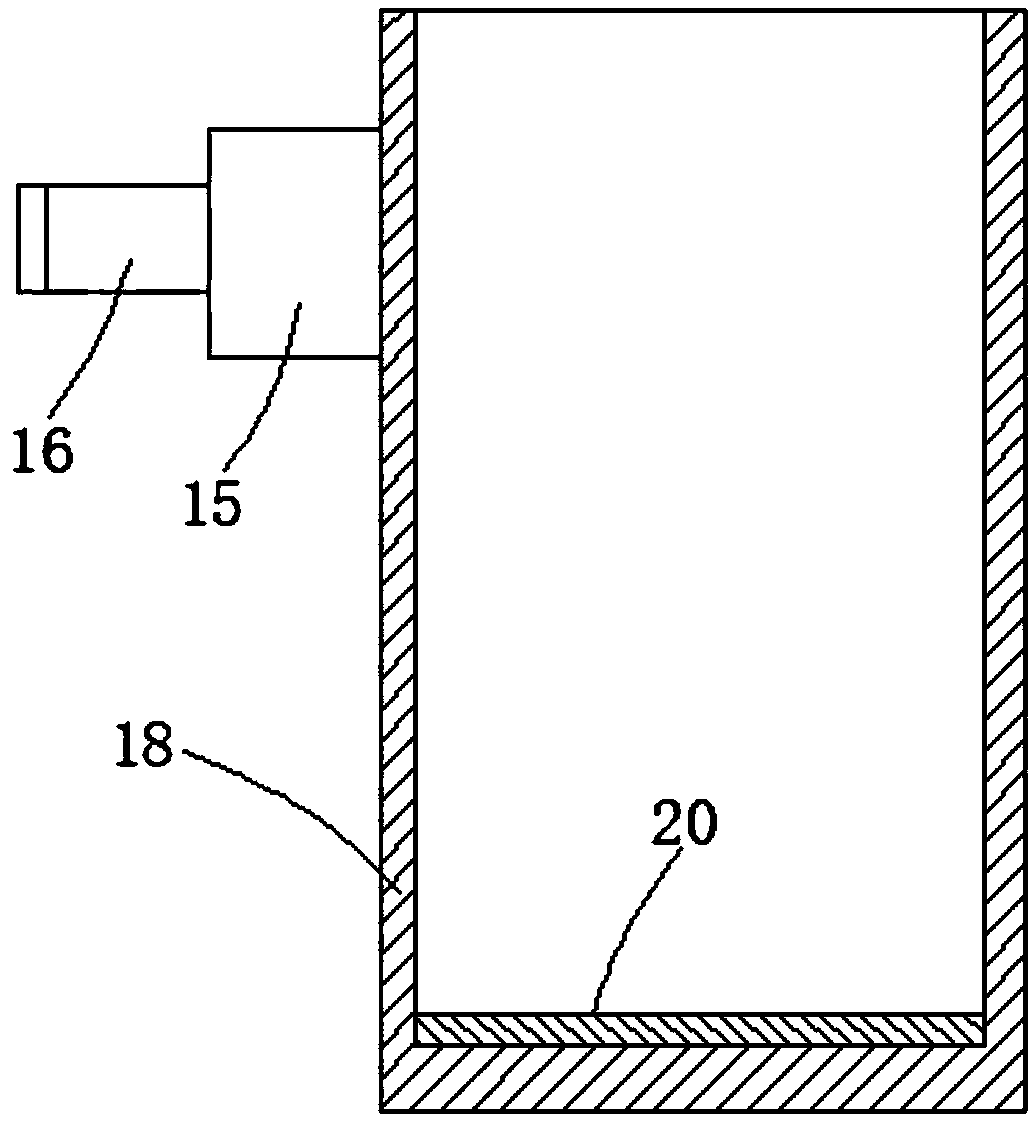

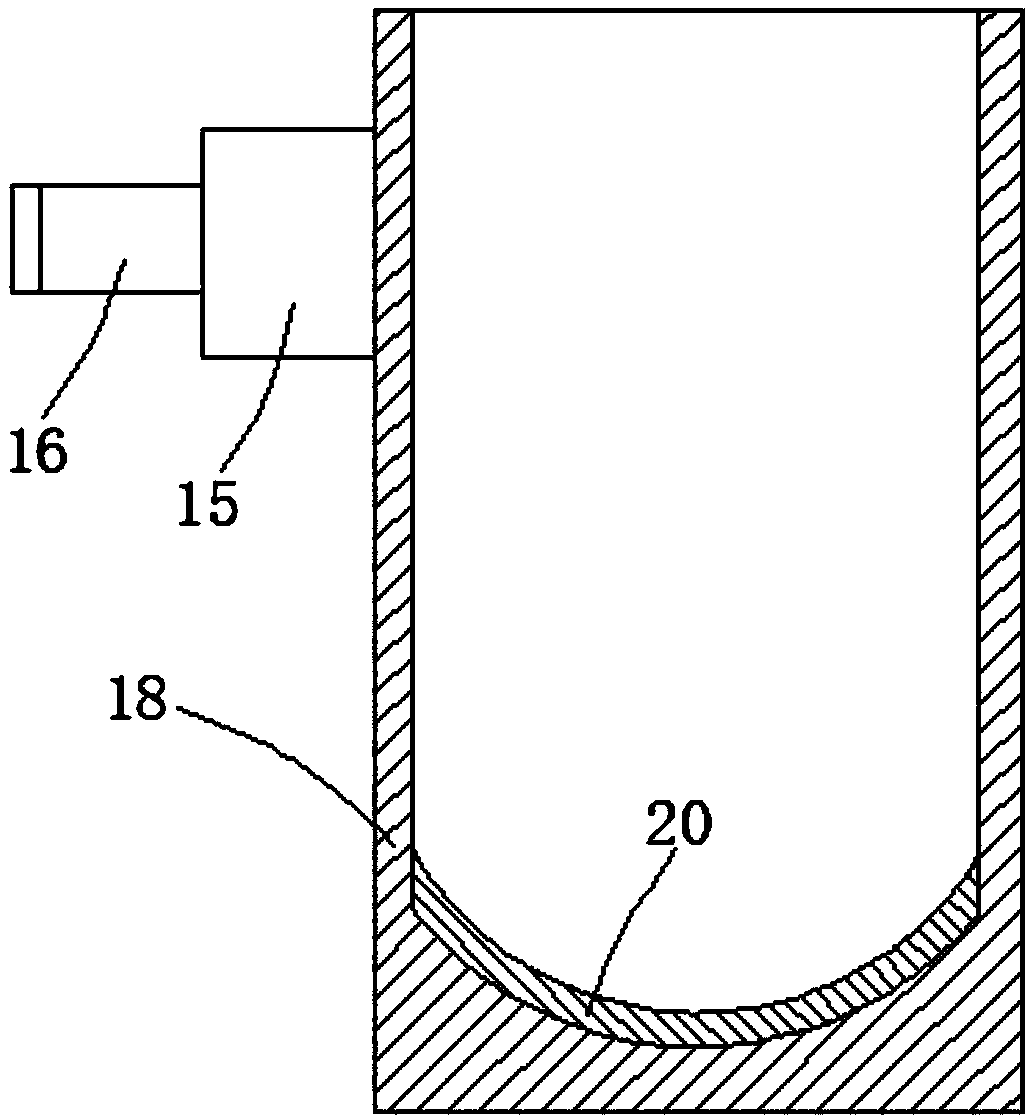

[0039] Including the box body, the box body is a U-shaped box body with front, rear and top openings, mainly composed of a bottom plate and side plates 18 on the left and right sides of the bottom plate, the length direction of the box body is the conveying direction of the plants to be cut, the feeding box One side near the cutterhead is the feed port, and the side plate 18 can be inlaid with hard alloy strips near the feed port on the side plate 18 in order to be wear-resistant. The box body is provided with a push plate 1, a linear motion mechanism, and a crank connecting rod mechanism. The push plate 1 is vertically arranged and arranged near the feeding port, the left and right sides of the push plate 1 are respectively in sliding friction fit with...

Embodiment 2

[0050] The present invention further optimizes on the basis of above-mentioned embodiment:

[0051] The feeding box also includes a crushing device installed on the top of the box body. The crushing device includes a housing and at least one pair of crushing wheels arranged in the housing. The housing is connected to the top of the side plate 18, and the crushing wheels It includes a flattening wheel 22 and an adjusting wheel 23 capable of adjusting the pitch. The flattening wheel 22 is connected with a motor to provide rotational power. One end of the adjusting wheel 23 is connected with an adjusting pull rod, which slides and fits with the housing and can be pulled The adjustment pull rod pulls back or pushes the adjustment wheel 23 forward to realize the adjustment of the flattened thickness. The top of the housing has a material inlet, the material inlet is provided with a hopper, the bottom of the housing is provided with a material outlet, and the material outlet faces t...

Embodiment 3

[0054] The invention provides a slicer, especially adopts the following setting structure:

[0055]The slicer slices rhizomes and tubers, including the feed box in Embodiment 2, and the outer surface of the push plate 1 in the box body of the feed box faces the cutter head of the slicer. After adopting the feeding box, the slicing machine can ensure the slicing quality and improve the slicing efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com