A kind of air energy decompression membrane distillation device and distillation method

A technology of vacuum membrane distillation and membrane still, which is applied in the direction of chemical instruments and methods, total evaporation, membrane technology, etc., can solve the problems of membrane fouling, hydrophobicity, degradation, etc., achieve high mass transfer efficiency, reduce consumption, and occupy small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

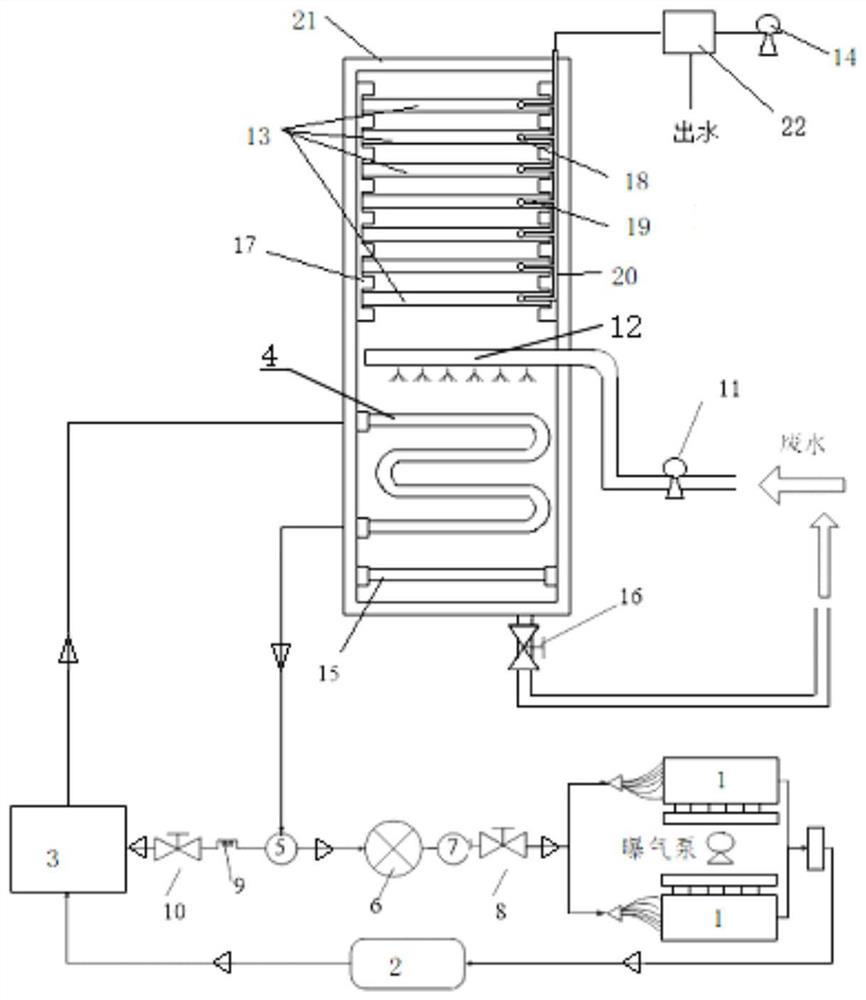

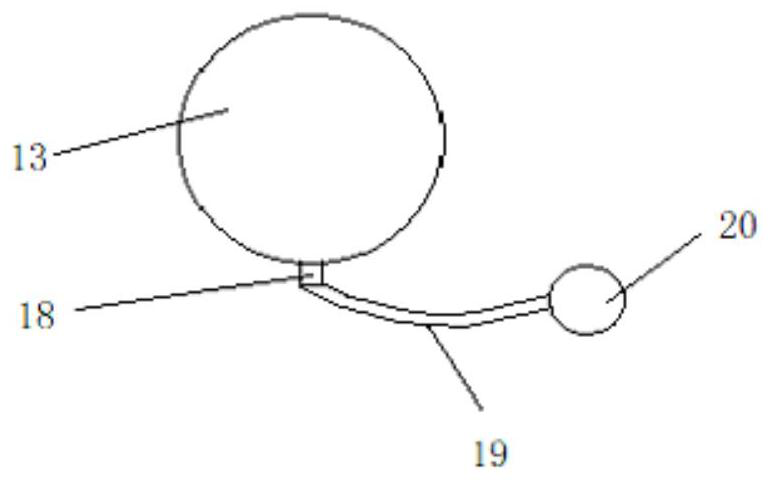

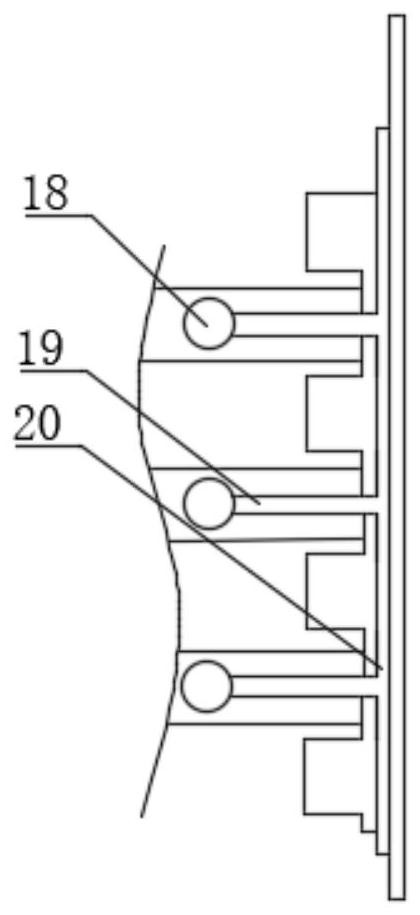

[0022] An air energy decompression membrane distillation device includes an air source heat pump system and heat transfer equipment. In this embodiment, the heat transfer equipment is a membrane distillation device.

[0023] The air source heat pump system is used to realize energy acquisition and conversion, and convert the low-grade heat energy in the air into heat energy for heating wastewater after multi-layer conversion. The air source heat pump system includes an air heat exchanger 1. The air heat exchanger is placed near equipment that can generate hot air, such as an aeration pump, so that the heat in the air is transferred to the working medium in the air heat exchanger. After the working medium absorbs heat, it Gasification: In this embodiment, the working fluid is any one of the heat pump working fluids such as Freon 142b, R227ea, and R407C. The output end of the air heat exchanger 1 is connected to a gas-liquid separator 2, and the gas-liquid separator 2 is used to...

Embodiment 2

[0028] An air energy decompression membrane distillation method, comprising the steps of: the air heat exchanger 1 absorbs heat, the working medium in the air heat exchanger 1 is vaporized, and is input into the gas-liquid separator 2; the gas-liquid separator 2 converts the working medium gas Liquid separation, the low-temperature and low-pressure gas is input into the compressor 3, and the compressor 3 compresses the low-temperature and low-pressure gas into a high-temperature and high-pressure liquid; the liquid is input into the heat transfer tube bundle 4 of the membrane distiller, and the heat transfer tube bundle 4 receives the high temperature and high pressure output from the compressor 3 The liquid is heat-exchanged with the high-salt wastewater. At this time, the temperature of the working medium in the heat transfer tube bundle 4 is reduced to a low-temperature condensed liquid. The low-temperature condensed liquid is input into the drying filter 5 and dried, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com