Dicing solution for gold electrode chips

A technology of gold electrodes and chips, which is applied in lubricating compositions, petroleum industry, etc., can solve the problems of polluting machines in ultra-clean production sites, difficulty in ensuring cutting quality, and insufficient suspension and dispersion capabilities, and achieve enhanced suspension and dispersion capabilities, dynamic lubrication Strong wetting ability and fast wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

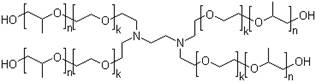

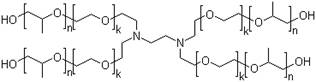

[0010] At room temperature, add 1% non-foaming amphoteric surfactant (Shanghai Fakai Chemical Co., Ltd. FC-39) and 1% polyethylene glycol 10000 to deionized water, stir for 10 minutes, then add 3% ethylenediamine ethoxy propoxy Base compound (Clariant PN30) can be stirred for 20min.

Embodiment 2

[0012] At room temperature, add 5% non-foaming amphoteric surfactant (Shanghai Fakai Chemical Co., Ltd. FC-39) and 0.5% polyethylene glycol 10000 in deionized water, stir for 10 minutes, then add 5% ethylenediamine ethoxypropoxy Base compound (Clariant PN30) can be stirred for 20min.

Embodiment 3

[0014] At room temperature, add 6% non-foaming amphoteric surfactant (Shanghai Fakai Chemical Co., Ltd. FC-39) and 1% polyethylene glycol 10000 to deionized water, stir for 10 minutes, then add 6% ethylenediamine ethoxypropoxy Base compound (Clariant PN30) can be stirred for 20min.

[0015] Commercially available scribing solution (comparative example) and Examples 1, 2, and 3 of the present invention were diluted 5000 times with deionized water and used as scribing solution for gold electrode chips, and the effects are shown in Table 1.

[0016] Table 1

[0017] Example Cutting Powder Retention bubble state 1 The powder is easy to clean, no sticking Less foam, disappears in 20 seconds 2 The powder is easy to clean, no sticking Less foam, disappears in 35 seconds 3 The powder is easy to clean, no sticking Less foam, disappears in 40 seconds comparative example Powder is difficult to clean, a small amount of adhesion A lot of foam, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com