A four-roller spindle device for a multi-wire cutting machine

A technology of multi-wire cutting machine and spindle device, which is applied to fine working devices, manufacturing tools, stone processing equipment, etc., can solve the problems of reduced cutting accuracy, increased thermal deformation of the main roller, and reduced cutting efficiency, achieving rigidity and Improved stability, reduced spindle distance, and reduced consumable costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

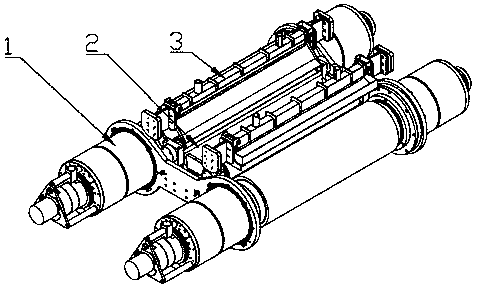

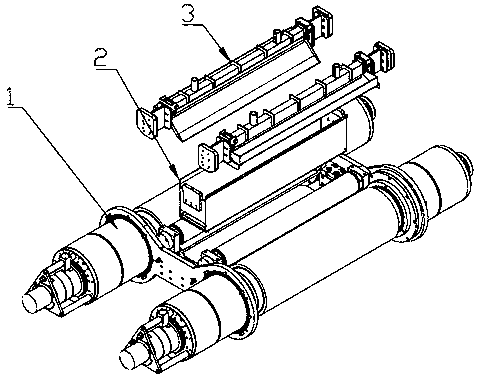

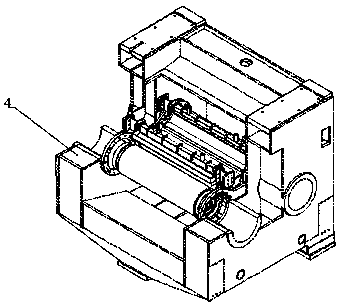

[0030]Referring to the accompanying drawings, a four-roller spindle device of a multi-wire cutting machine includes a spindle system 1, a material receiving box assembly 2 and a nozzle assembly 3, and the spindle system 1 and the nozzle assembly 3 are installed in the cutting chamber 4 of the multi-wire cutting machine Above, the spindle system 1 includes 2 sets of main roller assemblies 1-1, 2 sets of auxiliary roller assemblies 1-2, a front mounting bracket 1-3 and a rear mounting bracket 1-4, and the 2 sets of main roller assemblies 1-1 Symmetrically installed on the front mounting bracket 1-3 and the rear mounting bracket 1-4, the two sets of secondary roller assemblies 1-2 are symmetrically installed on the front mounting bracket 1-3 and the rear mounting bracket 1-4, and are located in two groups In the middle of the main roller assembly 1-1, the material receiving box assembly 2 is installed in the limit groove of the front mounting bracket 1-3 and the rear mounting brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com