Slicing device with positioning structure

A technology of positioning structure and slicing device, which is applied in metal processing and other directions, can solve problems such as the inability to ensure uniform slice thickness and personal safety, low quality of finished products, and heavy workload, so as to reduce labor intensity of workers, long service life, and easy feeding. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

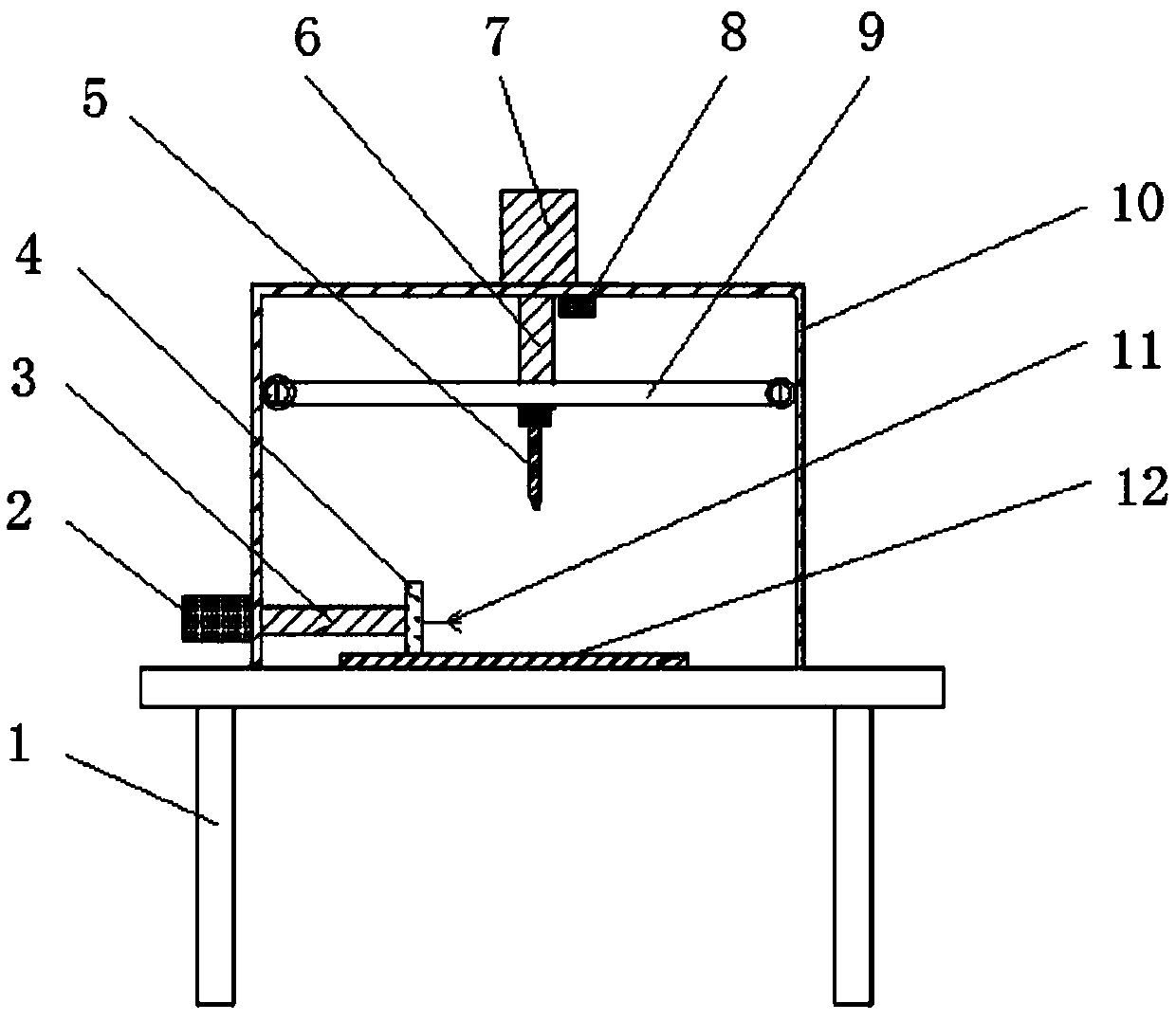

[0022] Such as figure 1 As shown, a slicing device with a positioning structure includes a lower bracket 1, an upper bracket 10 and an automatic cutting device placed on the upper bracket 10, the upper bracket 10 is placed on the top of the lower bracket 1, and the top of the lower bracket 1 is placed. platform; automatic cutting equipment includes a cutting device and a feeding device, the cutting device is composed of a vertical electric cylinder 7 and a blade 5 placed on the top of the upper support 10, the body of the vertical electric cylinder 7 is vertically arranged on the top of the upper support 10, and the blade 5. Fixed on the lower end of the telescopic rod 6 of the vertical electric cylinder 7, the lower end of the telescopic rod 6 is also equipped with a positioning support 9, and a sliding structure is provided between the two ends of the positioning support 9 and the upper bracket 10; Composed of electric cylinder 2 and push plate 4, the horizontal electric cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com