Monocrystalline silicon high-efficient composite cutting method and cutting system thereof

A cutting method, single crystal silicon technology, applied in the direction of fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of wire life limitation, poor cutting quality, low cutting efficiency, etc., to reduce processing costs, cut Good effect, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for high-efficiency composite cutting of single crystal silicon, which will be to clamp the single crystal silicon rod to be cut on the feed table of the improved (see Embodiment 2 for specific improvements) wire electric discharge machine tool, and use solid The metal wire bonded with diamond abrasive is used as the cutting wire for wire electric discharge cutting, and the advantages of fast wire electric discharge cutting processing speed and good cutting effect of diamond abrasive on the bonded abrasive metal wire are fully utilized to achieve fast and efficient processing of single crystal silicon rods. The purpose of cutting is to make the surface of the cut single crystal silicon naturally form a textured structure with anti-reflection effect. The metal wire bonded with diamond abrasives of the present invention can be a commercially available product, and the wire electric discharge machine tool can also be a commercially available common electric dischar...

Embodiment 2

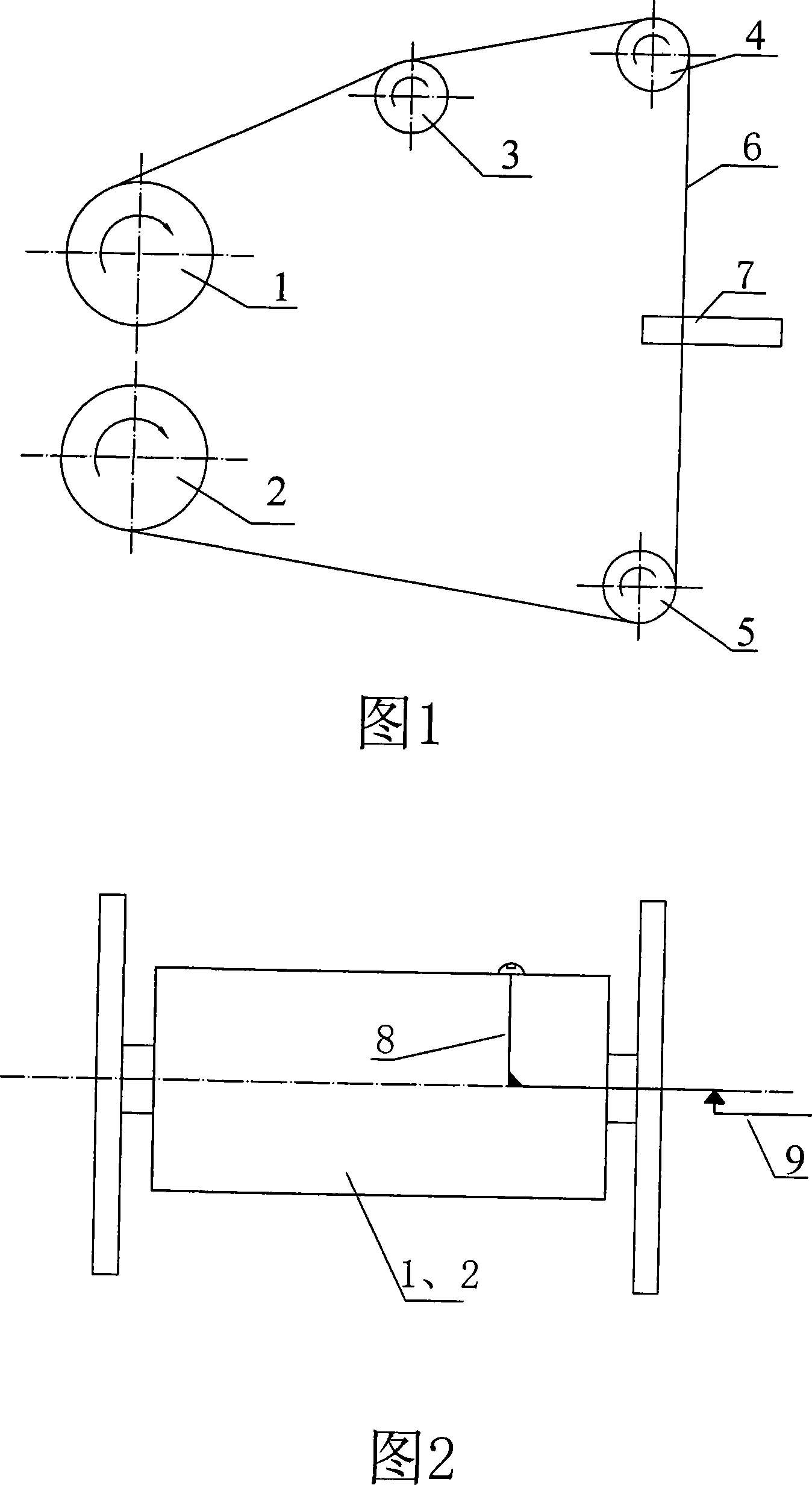

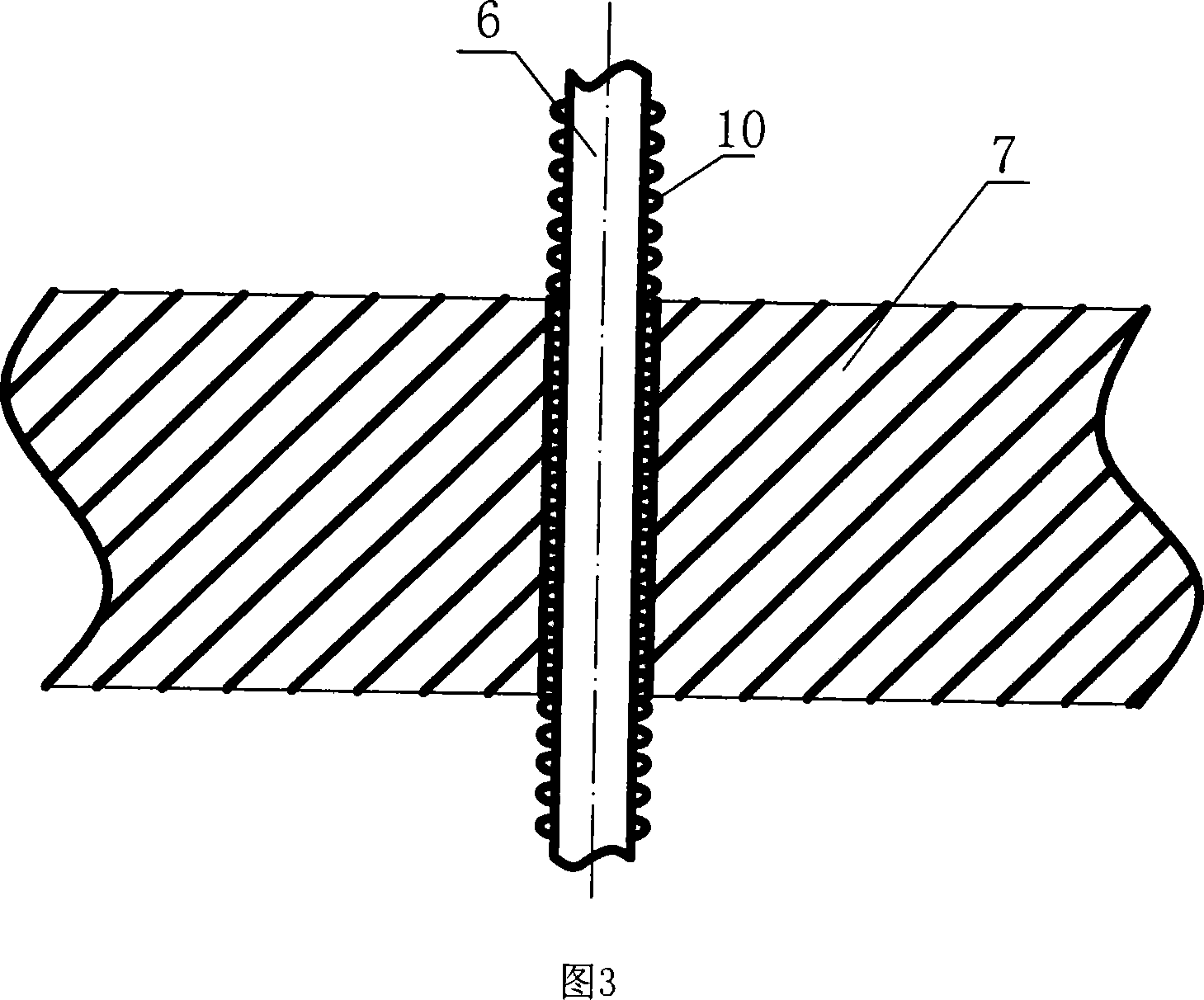

[0023] As shown in Figures 1, 2, and 3.

[0024] A high-efficiency composite cutting system for monocrystalline silicon, including a wire electric discharge machine tool and a metal cutting wire 6 consolidated with diamond abrasives, and a single crystal silicon rod 7 is installed on the feed workbench of the wire electric discharge machine tool, said Working wheels 4, 5, tensioning wheels 3 and two bobbins 1, 2 are also installed on the workbench, and the two working wheels 4, 5 are respectively installed on both sides of the monocrystalline silicon rod 7, and the tensioning wheel 3 Installed between the bobbin 1 and the working wheel 4 and / or between the bobbin 2 and the working wheel 5, one end of the metal cutting wire 6 consolidated with diamond abrasive is fixed on the bobbin 1, and the other end is bypassed The working wheels 4, 5 and the tensioning wheel 3 are fixed on the bobbin 2, as shown in Figure 1. The fixed points of the metal cutting wire 6 on the bobbins 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com