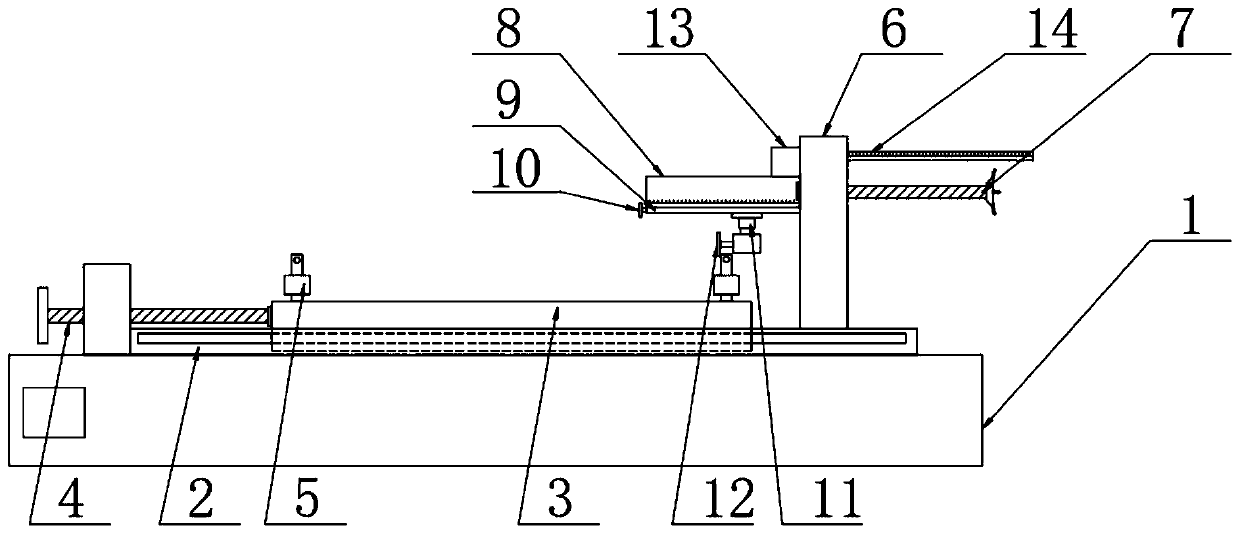

Convenient-to-use drum type brake production device

A production device and drum-type technology, which is applied in the direction of sawing machine, metal sawing equipment, measuring/indicating equipment, etc., can solve problems affecting processing and use, and achieve the effect of avoiding misalignment, ensuring stability and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

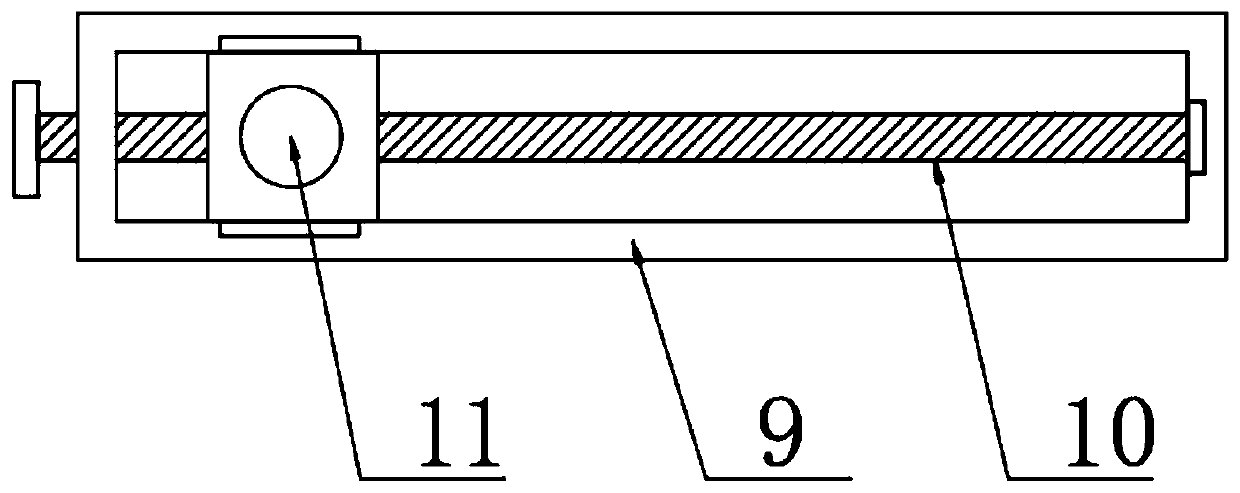

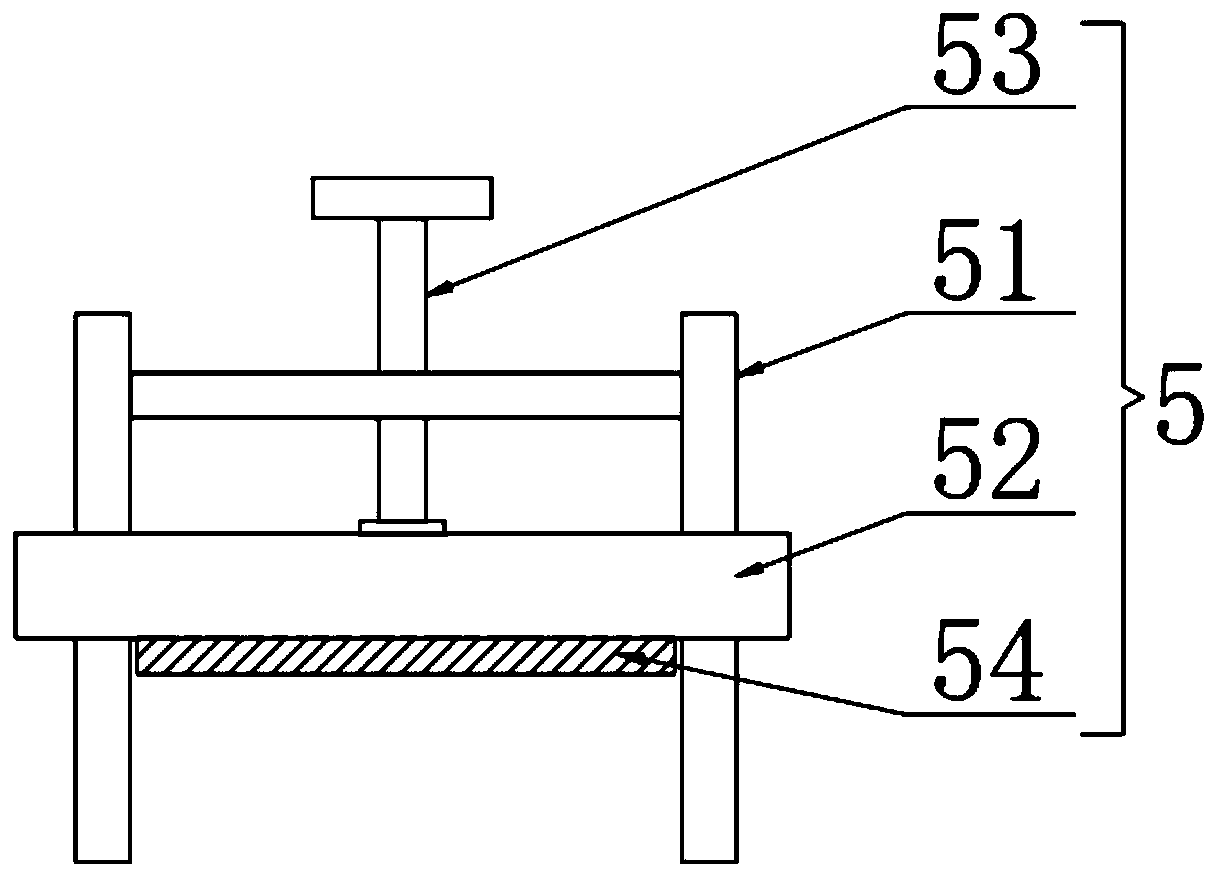

[0022] Embodiment: When in use, two sets of compression screws 53 are turned to drive the pressing block 52 to move upward, and at the same time, the brake pad to be sliced is placed on the top of the placement plate 3, and the left and right ends of the brake pad are located on the left and right sides of the pressing block 52 bottom, and make the brake pads flush with the right side of the placement plate 3, reversely rotate two sets of compression screw rods 53 to drive the pressing block 52 to fix the brake pads downward, and turn the screw rod 4 to make the placement plate 3 face the limit plate Move at 6 places and fit with the limit plate 6, turn the adjusting screw 7 according to the length to be measured to drive the installation block 8 to move to the left, the installation block 8 moves to the left, and the measuring rod 14 also moves to the left, and then Turn the fine-tuning screw 10 to make fine-tuning, the fine-tuning screw 10 drives the receiving block to move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com