Slicing machine for columnar food

A slicing machine and food technology, applied in metal processing and other directions, can solve the problem that the cutter is easy to stick to food debris, and achieve the effect of ensuring the slicing efficiency and quality, improving the quality, and avoiding sticking to the knife

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

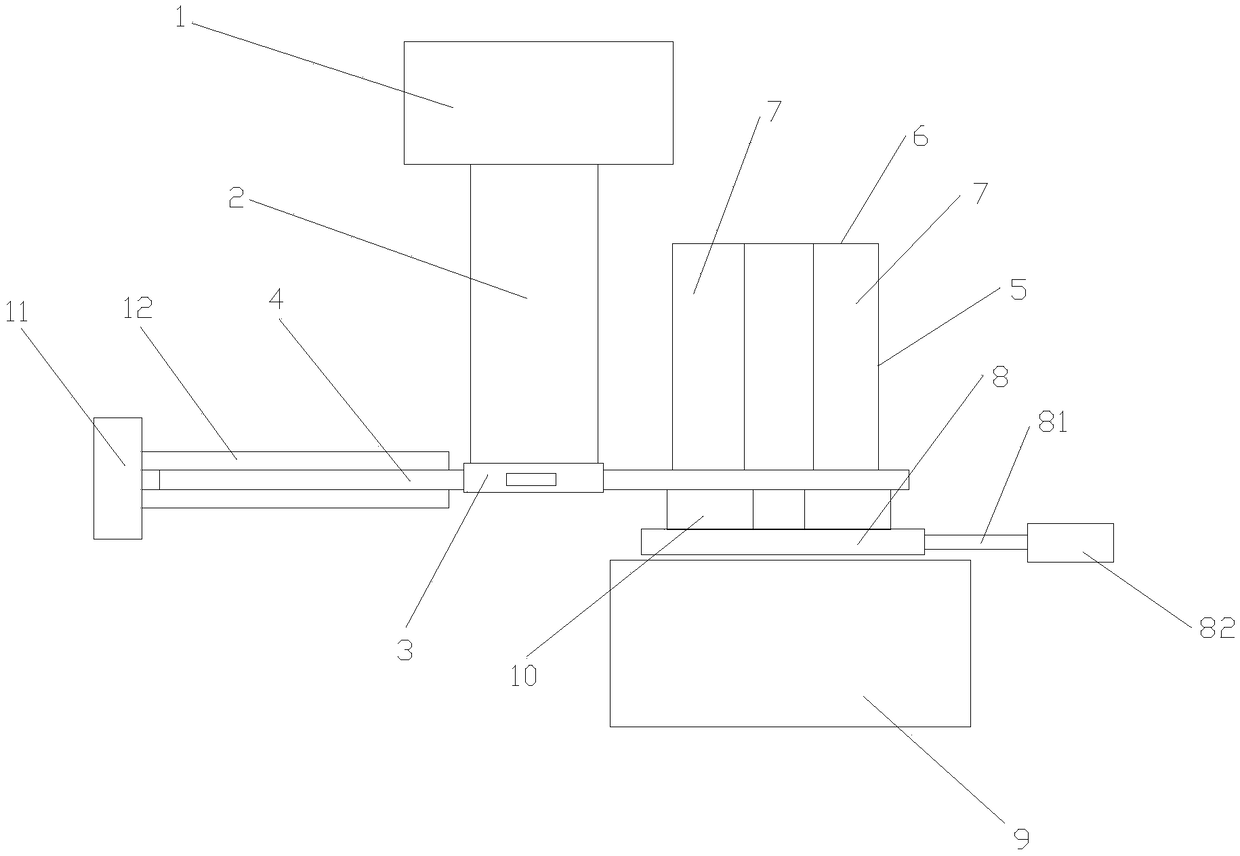

[0027] like figure 1 As shown, a columnar food slicer provided by the present invention includes a rotating shaft motor 1, the output end of the rotating shaft motor 1 is connected to a rotating shaft 2, and a cutter head 3 is sleeved on the bottom of the rotating shaft 2, and the cutter head 3 is provided with several blades 4, and one side of the rotating shaft 3 is provided with a feed box 5, and a guide cylinder 7 is arranged symmetrically in the feed box 5, and a feed inlet 6 is provided at the top of the guide cylinder 7, A blanking hole 10 is provided below the feeding box 5 corresponding to the position of the guide cylinder 7, there is a gap between the guide cylinder 7 and the blanking hole 10, and a stopper is installed below the blanking hole 10. A material plate 8, the side end of the material retaining plate 8 is connected with a motor 82 through a link 81, a support 11 is installed on the other side of the rotating shaft 3, and friction blocks 12 are symmetrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com