Betel nut centering slicing device

A slicing device and betel nut technology, applied in metal processing and other directions, can solve the problems of wasteful process, high equipment cost, low production efficiency, etc., and achieve the effects of improving product qualification rate, accurate centering and cutting, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

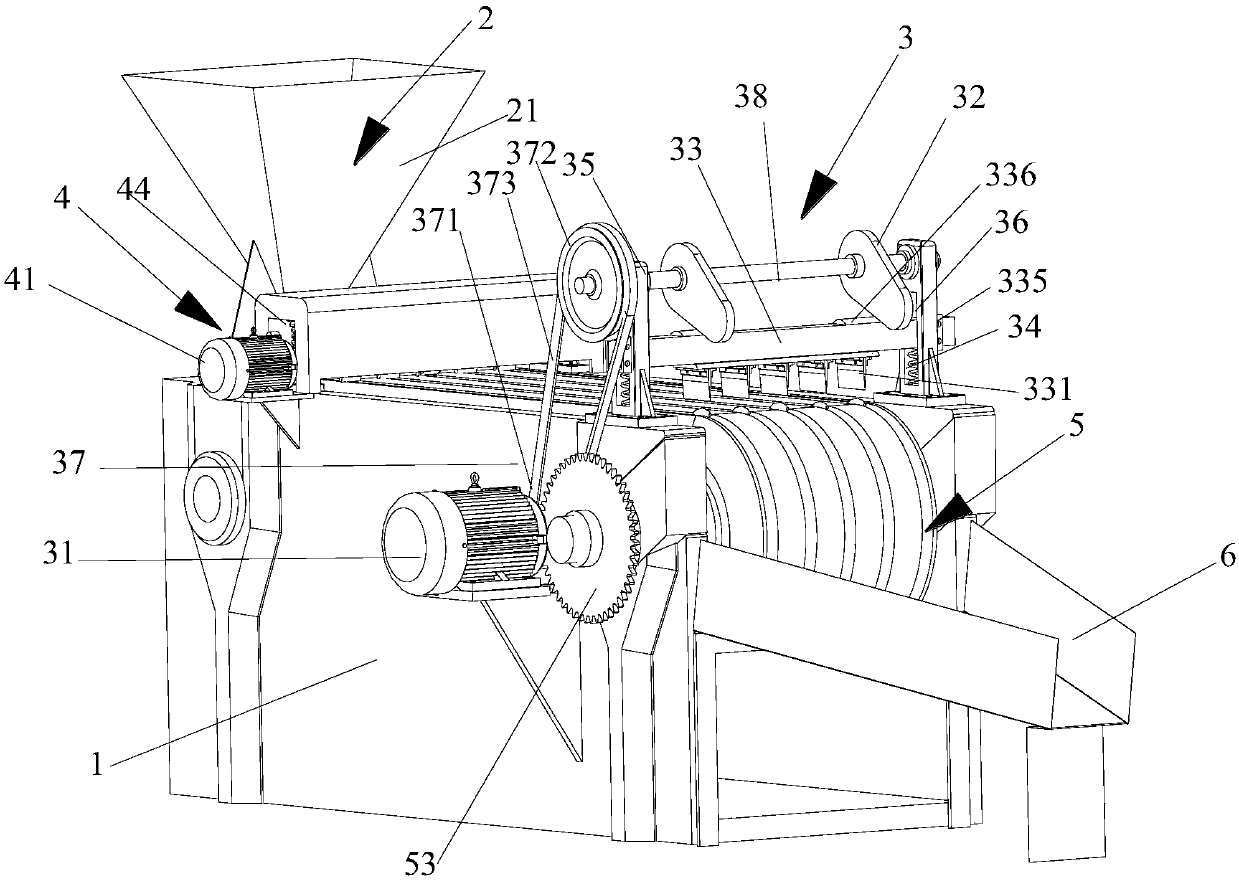

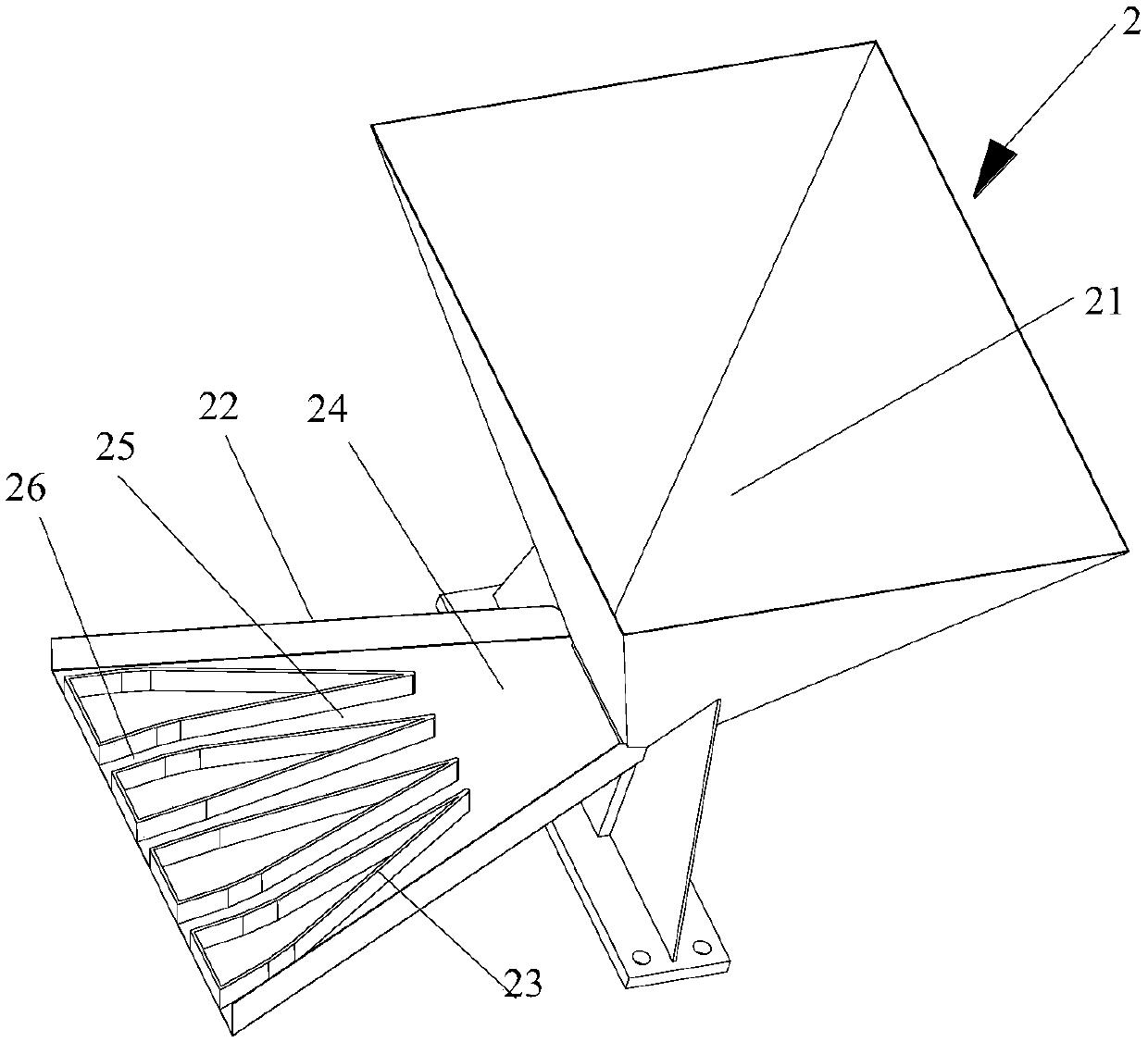

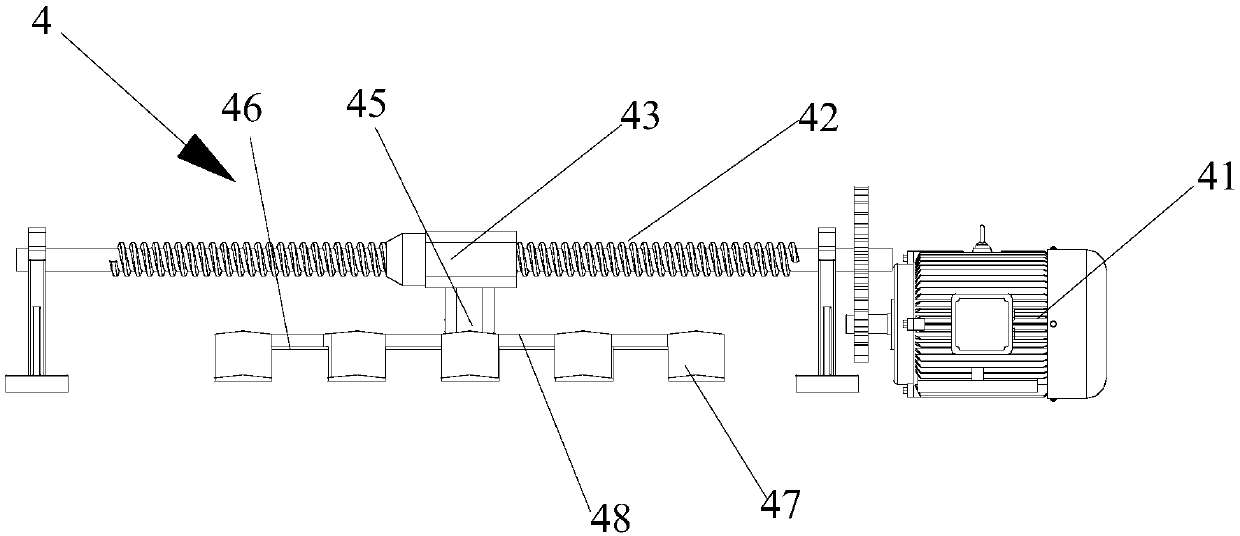

[0027] Depend on Figure 1 to Figure 4 It can be seen that a betel nut centering slicing device includes a box base 1, a feed system 2 fixed on the box base 1, a conveyor belt 5 that receives and transmits materials from the feed system 2, and a section that slices the materials. System 3, by figure 2It can be seen that the feeding system 2 includes a hopper 21, a feeding chute 22 that is connected to the outlet of the hopper 21 and is inclined downwards, and the lower part of the feeding chute 22 is provided with an isolation belt 23, and the isolation belt 23 is an irregular polygon to move the feeding chute 23 from top to bottom Sequentially divided into splitter grooves 24, tapered grooves 25 and parallel grooves 26; tapered grooves 25 are connected with diverter grooves 24 and parallel grooves 25 up and down, and the width of the paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com