Multi-wire cutting machine guide wheel wire groove and its processing method

A multi-wire cutting machine and guide wheel technology, applied in stone processing equipment, working accessories, manufacturing tools, etc., can solve the impact of the overall slicing quality of crystal slices, the surface grooves, line marks or steps on the wafer surface, which affect the quality of crystal rod slicing and other problems, to achieve the effect of reducing the axial width, reducing line marks, and avoiding "jumping lines"

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

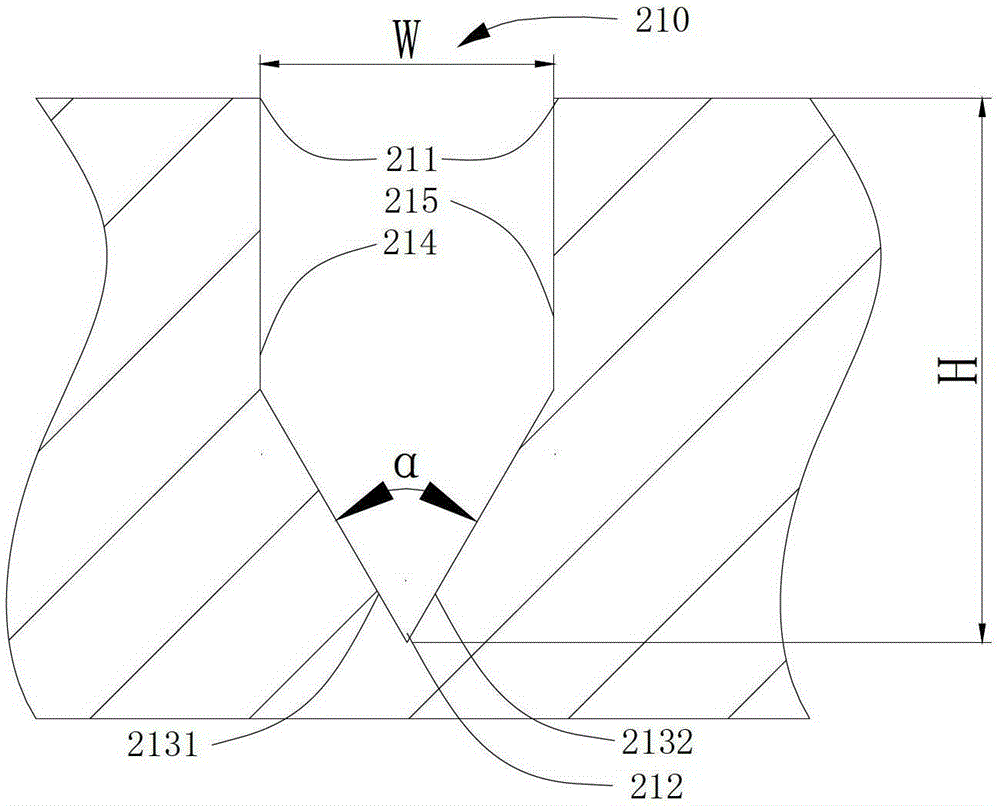

[0043] Please refer to image 3The structure of the first embodiment of the multi-wire cutting machine guide wheel 100 wire groove 210, the wire groove 210 in this embodiment has a groove top 211 close to the outer diameter of the guide wheel 100 and a groove bottom 212 opposite to the groove top 211; the wire groove 210 is in the A V-shaped groove is formed on the axial section of the guide wheel 100. The V-shaped groove has a left side portion 2131 and a right side portion 2132. The left side portion 2131 and the right side portion 2132 are symmetrical to the center line of the wire groove 210 . In addition, a left straight side 214 is connected between the groove top 211 and the left side 2131 , and a right straight side 215 is connected between the groove top 211 and the right side 2132 . Wherein, the left straight portion 214 and the right straight portion 215 are parallel to the center line of the wire groove 210 .

[0044] With this structural design, the axial width ...

Embodiment approach 2

[0049] Please refer to Figure 4 The structure of the second embodiment of the wire groove 310 of the guide wheel 100 of the multi-wire cutting machine. The wire groove 310 in this embodiment has a groove top 311 close to the outer diameter of the guide wheel 100 and a groove bottom 312 opposite to the groove top 311; the wire groove 310 is in the A V-shaped groove is formed on the axial section of the guide wheel 100. The V-shaped groove has a left side portion 3131 and a right side portion 3132. The left side portion 3131 and the right side portion 3132 are symmetrical to the center line of the wire groove 310 . In addition, a left straight portion 314 is connected between the groove top 311 and the left side portion 3131 , and a right straight portion 315 is connected between the groove top 311 and the right side portion 3132 . Wherein the left straight edge portion 314 and the right straight edge portion 315 are parallel to the center line of the trunking. The difference...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com