Superhard material nozzle cutting device

A kind of superhard material, cutting device technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

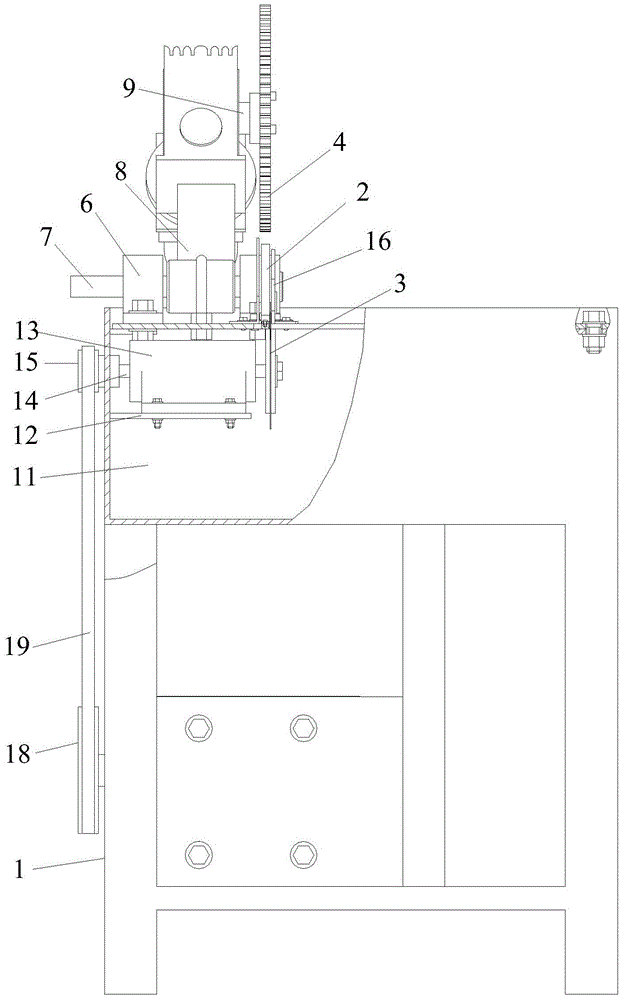

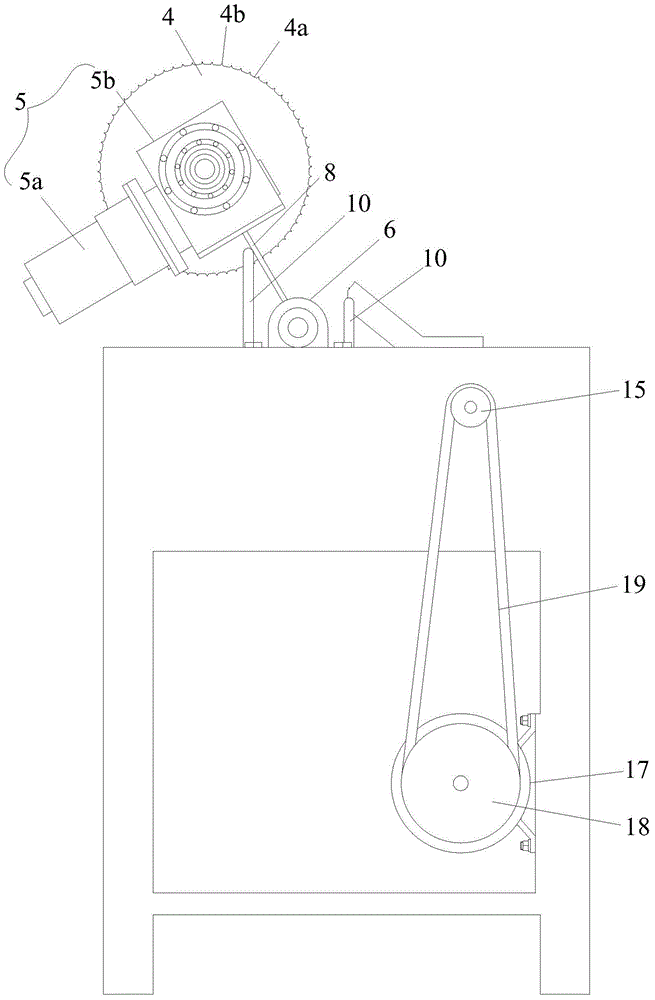

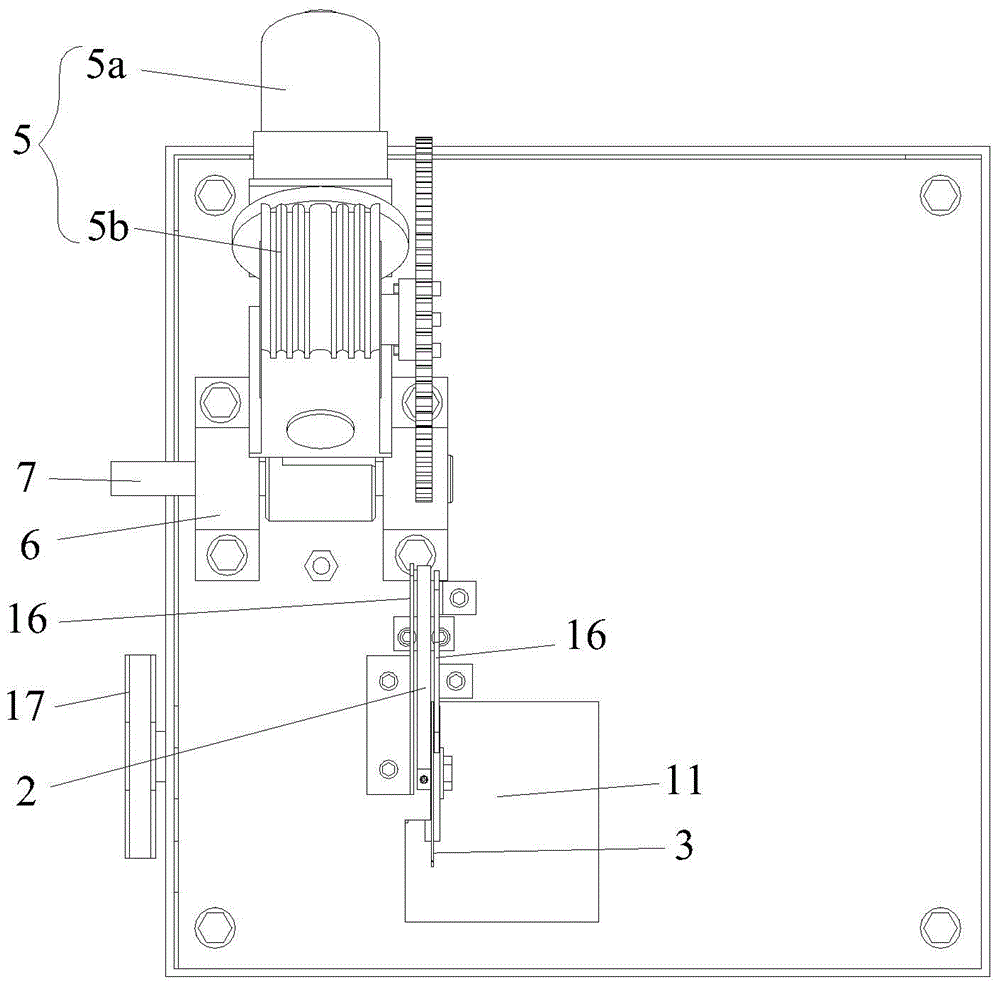

[0017] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

[0018] Please refer to Figure 1-3 , the superhard material nozzle cutting device includes a frame 1, the upper side of the frame 1 is provided with a feeding tray (not shown), a feeding track 2 for transporting superhard workpieces, a cutting blade 3, Feed carousel 4 and first driving device 5. The rear end of the feeding track 2 is connected to the outlet of the feeding tray, and the cutting blade 3 is located at the side of the front end of the feeding track 2 . The feeding track 2 is arranged obliquely, and the front end of the feeding track 2 is lower than the rear end. The feeding turntable 4 can be turned upside down and hinged on the frame 1. The feeding turntable 4 is driven by the first driving device 5 to form a uniform rotation speed. The rotation speed of the feeding turntable 4 is the same as that of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com