Large-breadth laser cutting machine

A laser cutting machine and large-format technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems that affect the final quality of the product and easily produce deviations, and achieve light weight, small load, and high processing speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

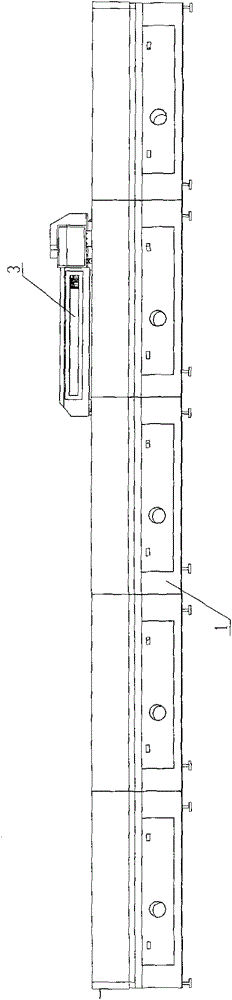

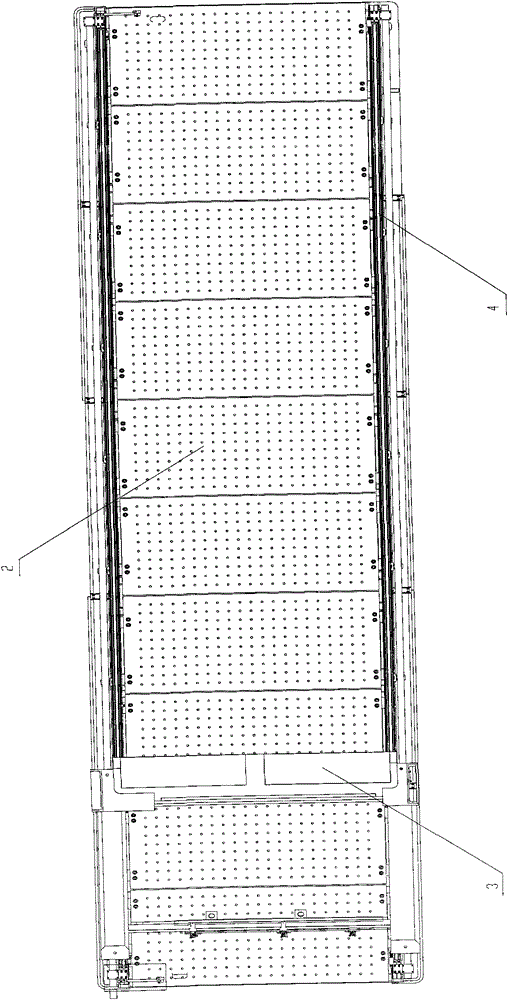

[0027] Please refer to figure 1 and figure 2 As shown, the large-format laser cutting machine of the present invention includes a support body 1, the support body 1, and the support body 1 is a metal frame. A workbench 2 is installed on the support body 1, and the workbench 2 is used for carrying materials to be processed. Two first guide rails 4 are arranged on both sides of the workbench 2 , and the two first guide rails 4 are fixed on the support body 1 and installed on both sides of the workbench 2 respectively.

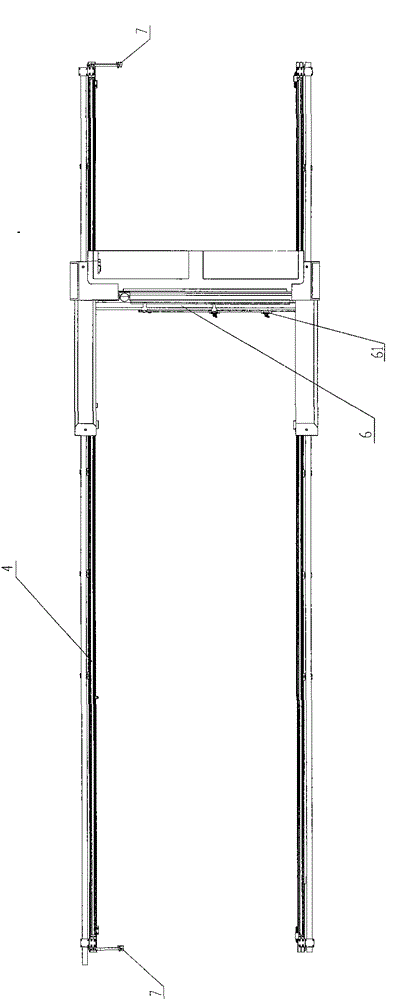

[0028] Please continue to refer image 3 , The two ends of the first guide rail 4 are respectively provided with a feeding positioning device 7, and the feeding positioning device includes a rotating head and an indicating light emitting device (not shown) fixed on the rotating head. Whether the feeding is accurate is determined by the red ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com