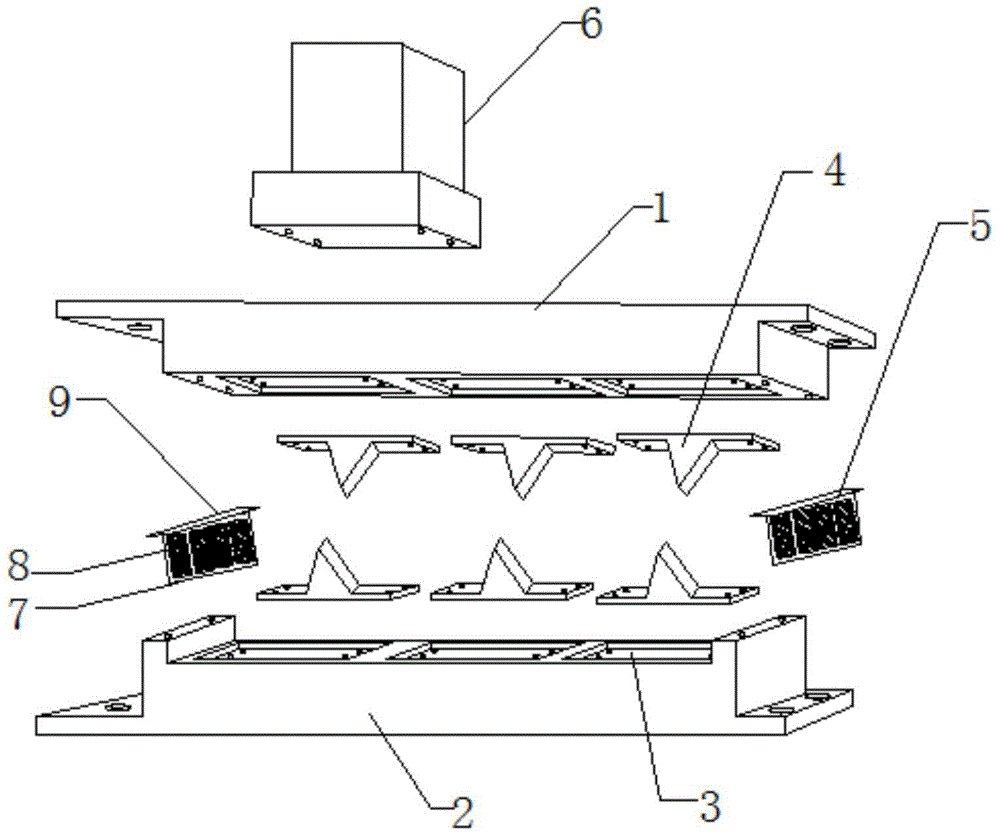

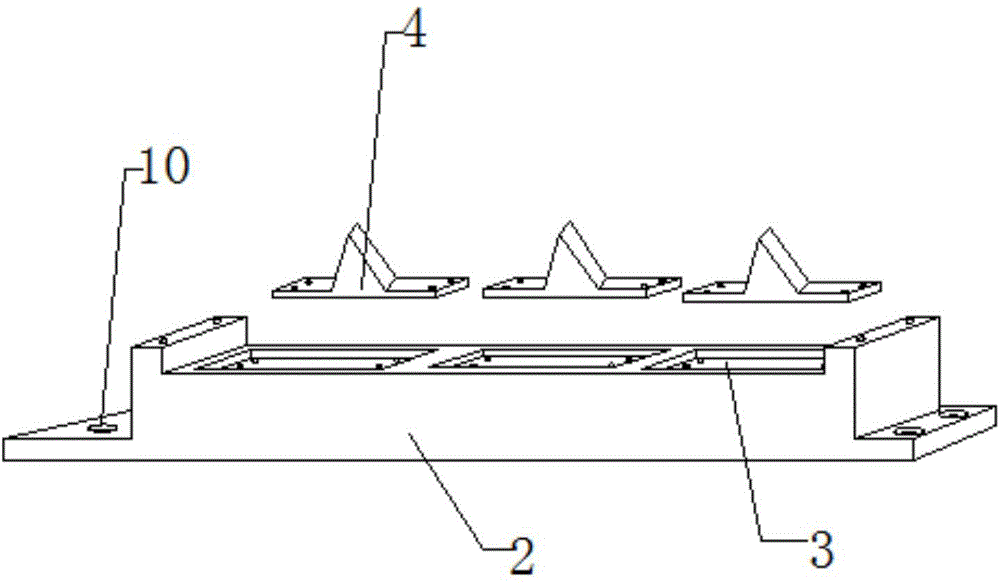

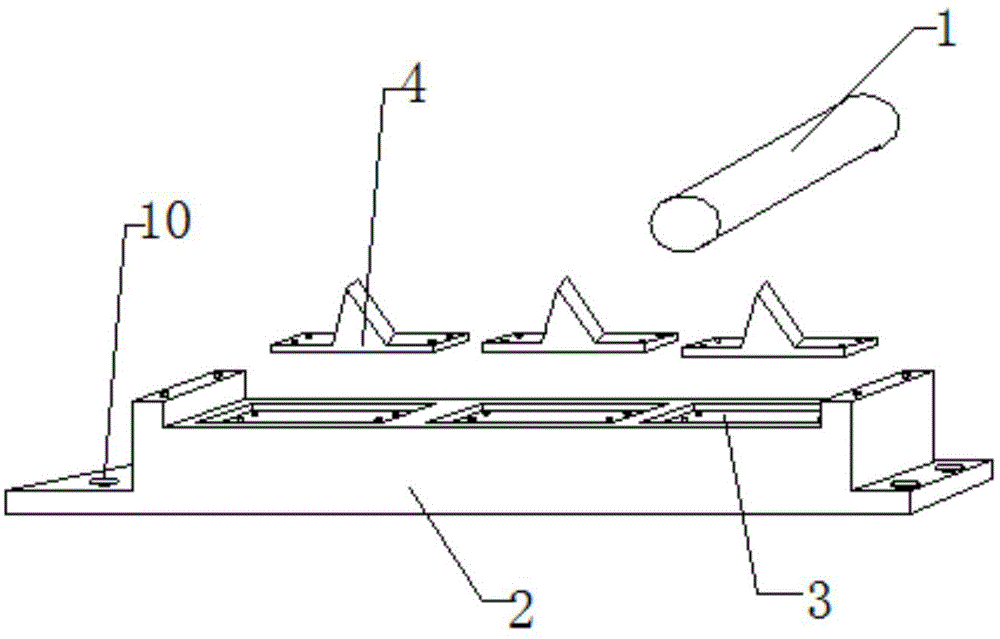

Sliding knife device for automobile inner tire open mill or internal mixer

A technology of open mill and internal mixer, which is applied in the field of automobile inner tube production equipment, can solve the problems of low efficiency, sticking, increasing labor intensity of staff, etc., and achieve the effect of ensuring cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 2:

Embodiment 2

[0019] Example 3:

Embodiment 3

[0021] The above-mentioned embodiments are only descriptions of preferred implementations of the present invention, and are not intended to limit the concept and scope of the present invention. Under the premise of not departing from the design concept of the present invention, various modifications and improvements made by ordinary persons in the art to the technical solution of the present invention shall fall within the scope of protection of the present invention, and the technical content claimed in the present invention has been fully described in the claims.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com