Cutting equipment for aerated block

A gas-filled block and cutting machine technology, applied in stone processing equipment, stone processing tools, manufacturing tools, etc., can solve the problems of difficult production process, complex manufacturing process, and large equipment investment, so as to reduce the cost of human resources, The effect of reducing operating costs and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

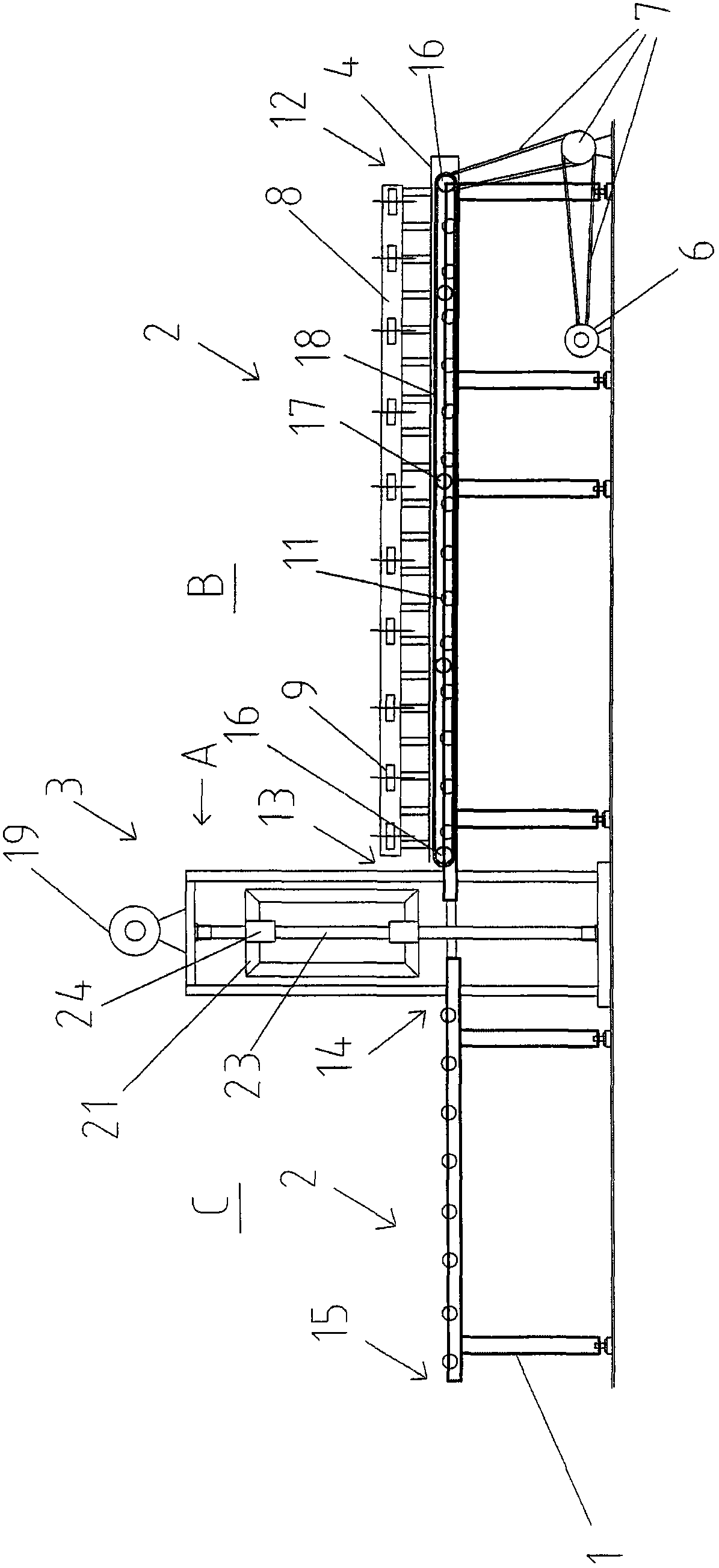

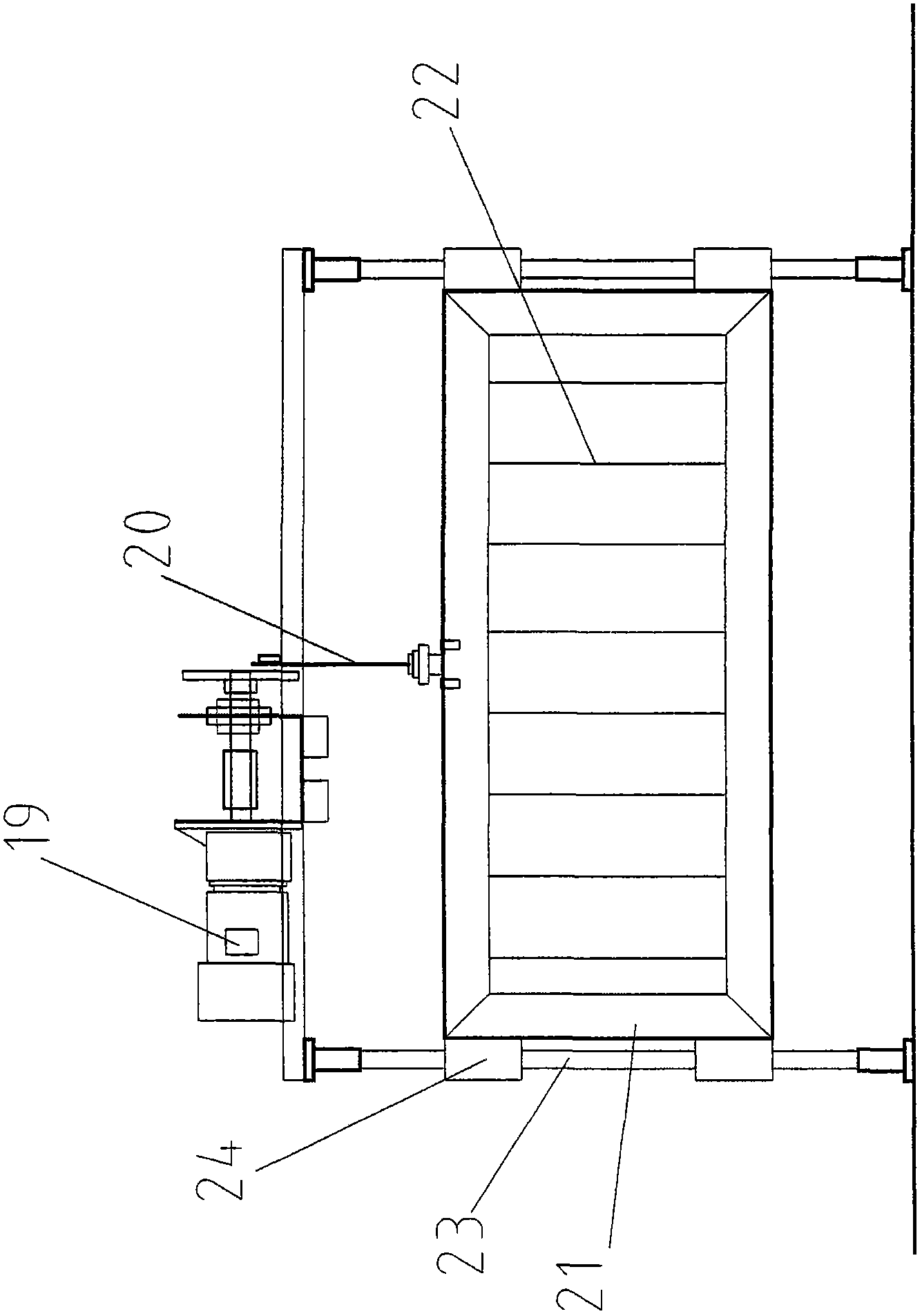

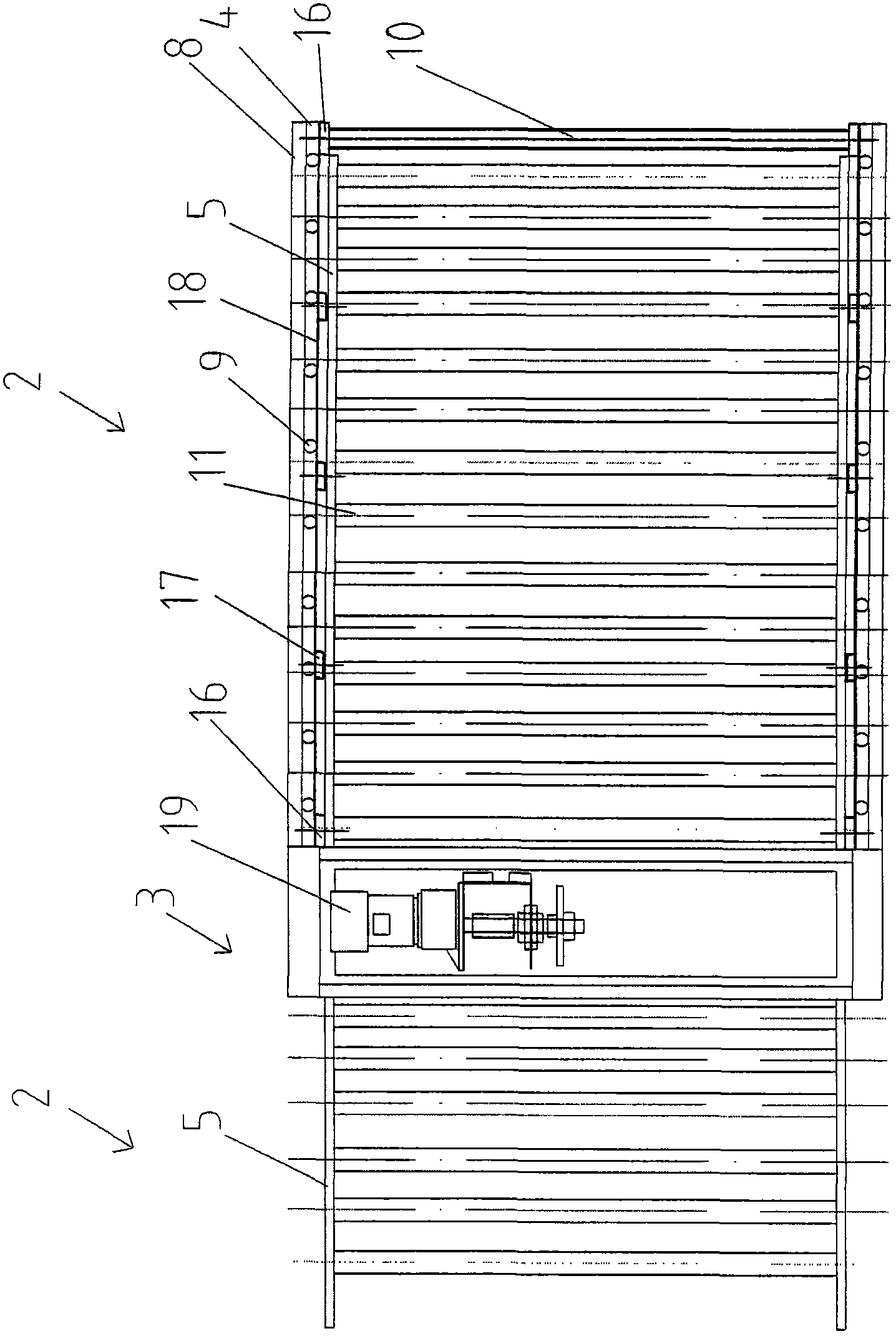

[0011] The cutting equipment of aerated block of the present invention is made up of frame 1, plane conveyer 2 installed on the frame, cutting machine 3 installed on the frame and control system (not shown); The machine 2 is located at the front part B and the rear part C of the cutting machine 3, and the plane conveyor includes a side frame 4, a middle frame 5, a first reduction motor 6, a first transmission mechanism 7, a second transmission mechanism, guide Wheel frame 8, guide wheel 9, feeding push rod 10, roller 11, described plane conveyor is successively provided with feeding end 12, cutting machine inlet end 13, cutting machine outlet end 14 and The discharge end 15, the side frame 4 is located on the left and right sides of the frame 1 and extends between the feed end and the inlet end of the cutting machine, and the second transmission mechanism is composed of a sprocket 16, a driven guide Wheel 17 and chain 18 are formed, on the inside surface of described side fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com