Laser cutting device for battery pole piece

A battery pole piece, laser cutting technology, applied in the direction of electrode manufacturing, battery pack parts, laser welding equipment, etc., can solve the problems of increased equipment maintenance costs, more burrs on the pole piece, powder off the cutting edge, etc., to achieve cutting quality and The effect of high efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

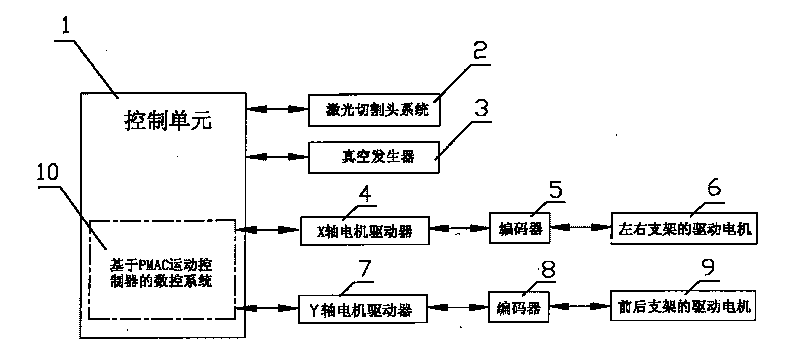

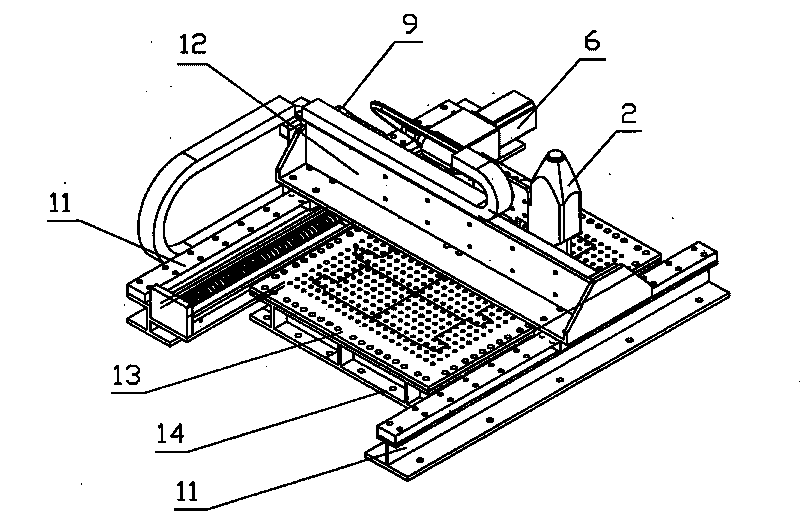

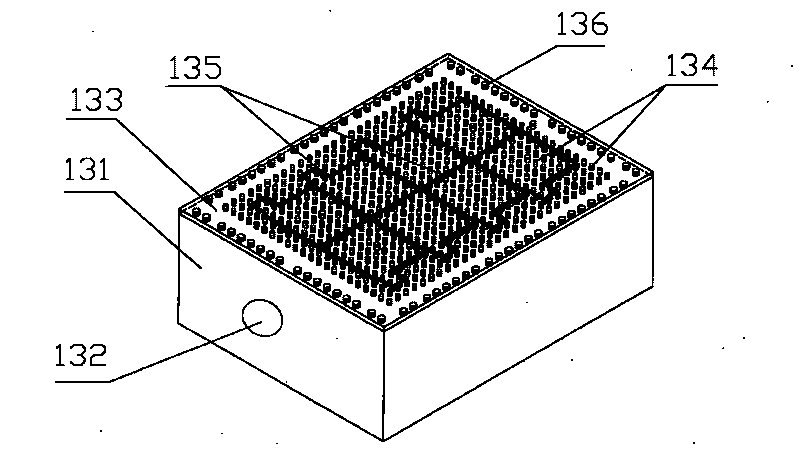

[0022] As shown in the figure, the battery pole piece laser cutting device of this embodiment includes a control unit 1 composed of an industrial computer and a laser cutting head system 2 composed of a laser generator and a laser cutting head. The laser cutting head system 2 is provided with a The vacuum suction device 13, the laser cutting head system 2 and the vacuum suction device 13 can relatively move horizontally. Its specific structure is as follows: the battery pole piece laser cutting device includes left and right brackets 11 and front and rear brackets 12 erected on the left and right brackets 11, the left and right brackets 11 are provided with a platform 14 that can move along the left and right brackets, and the vacuum adsorption device 13 is fixed on the platform 14; the laser cutting head system 2 is arranged on the front and rear brackets 12 and can move along the front and rear brackets 12.

[0023] Described left and right support 11 is provided with leadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com