Numerical control forming machine for integrated circuit pin

An integrated circuit and molding machine technology, applied in the field of integrated circuit pin numerical control molding machine, can solve the problems of differences in molding height and length of molding pins, and achieve the goal of ensuring molding accuracy and consistency, simplifying process, and improving safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

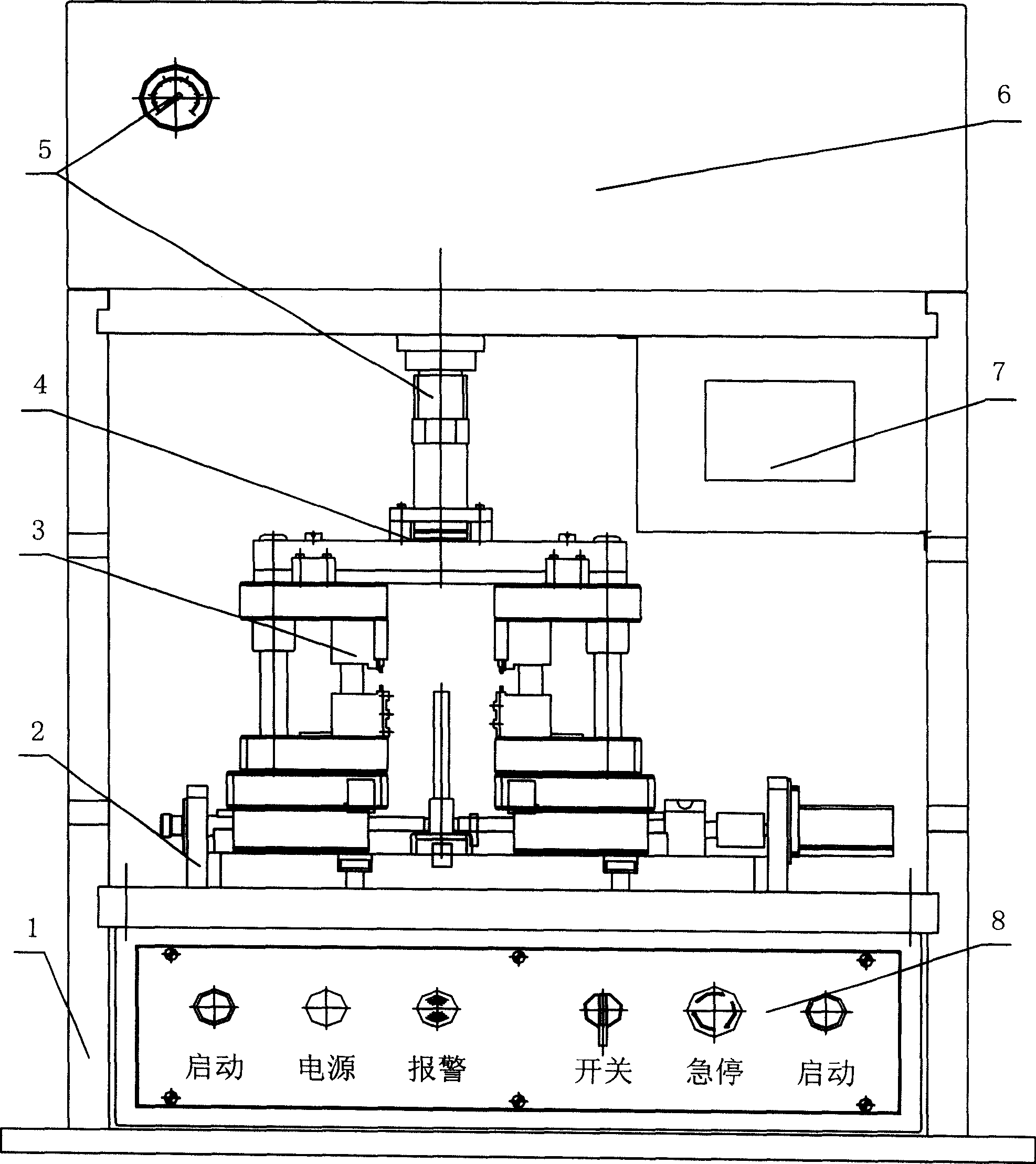

[0030] Such as figure 2 Shown is a schematic structural view of the forming machine of the present invention, which has a frame 1, a control system 8, a pneumatic device 5, a guide mechanism 4, a bidirectional mobile platform 2 and a double-sided composite mold forming mechanism 3 with a nested structure. The frame is divided into three layers by three platforms, the control system 8 is placed on the lower layer of the frame 1, and the top of the control system 8 is fixed on the bottom surface of the middle platform by screws; the two-way mobile platform 2 and the double-sided composite mold forming mechanism 3 Placed on the second layer of the frame, the base 17 of the two-way mobile platform 2 is fixedly connected to the middle platform of the frame 1, and the left and right half molds of the bilateral composite mold forming mechanism 1 of the nested structure are correspondingly fixed on the left and right sides of the two-way mobile platform. On the right slider 14, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com