Manufacturing method of connecting sheet circuit board

A technology for connecting a circuit board and a manufacturing method, which is applied in the directions of printed circuit manufacturing, printed circuits, electrical components, etc., can solve the problems of circuit board unit positioning shaking, large forming deviation, and non-compliance with forming accuracy requirements, so as to improve the forming process. Accuracy, the effect of ensuring molding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The manufacturing method of the connected circuit board provided by the technical solution will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0041] The embodiment of the technical solution provides a method for manufacturing a continuous circuit board, which includes the following steps:

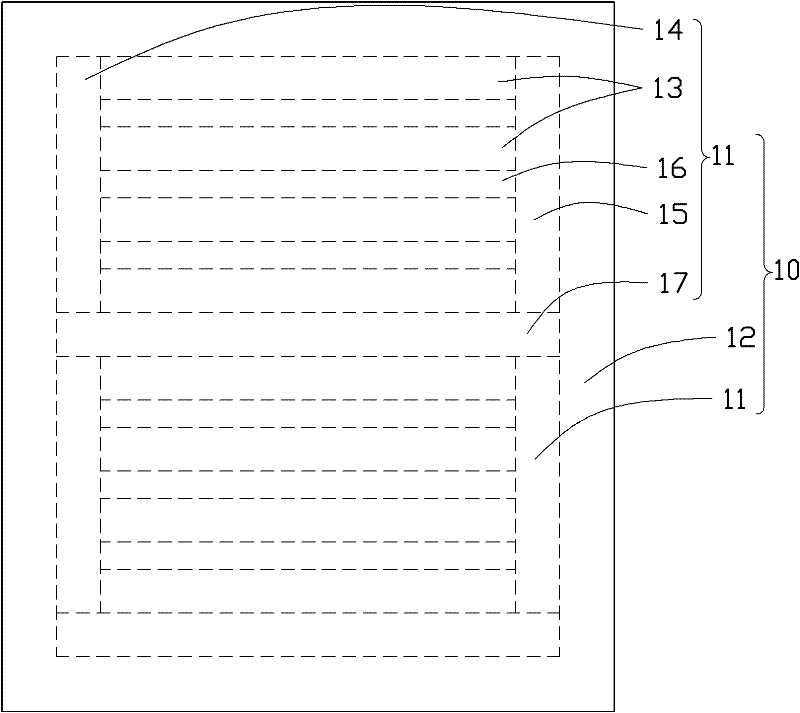

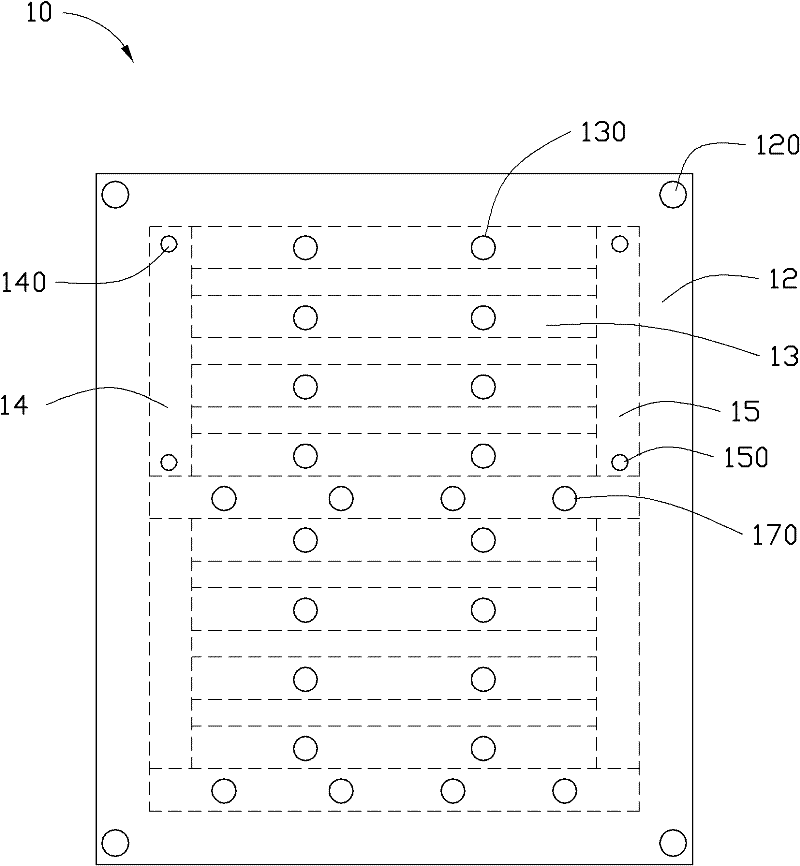

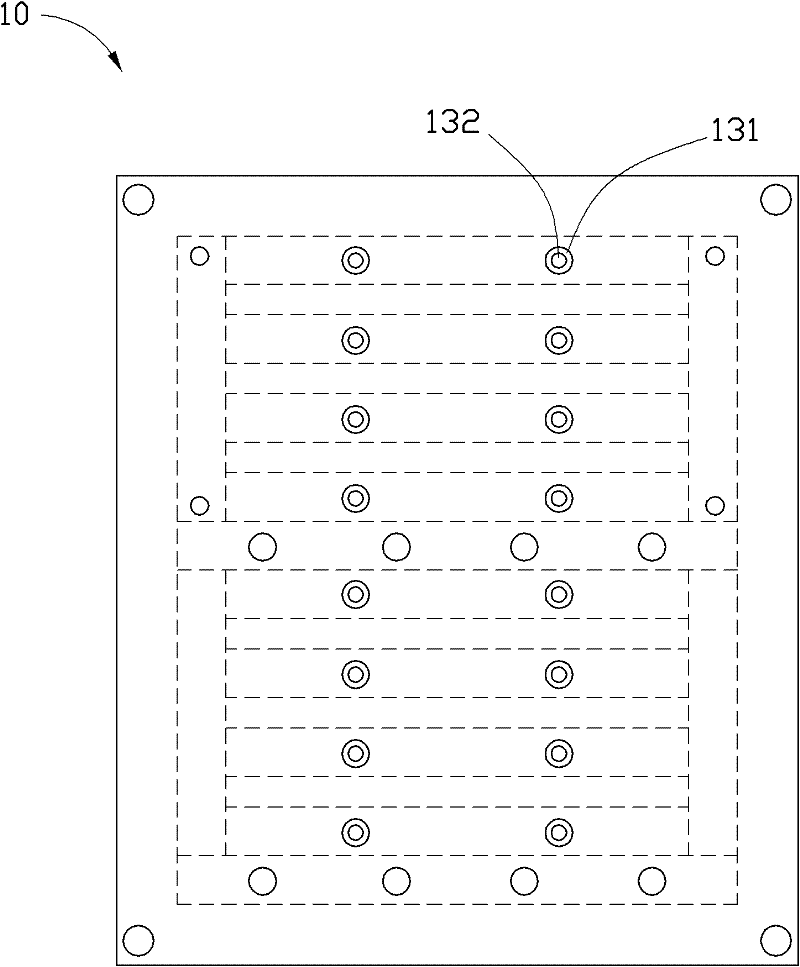

[0042] For the first step, please also refer to figure 1 and figure 2 , provide a copper-clad substrate 10, the copper-clad substrate 10 includes at least one processing area 11 and a first waste area 12 surrounding and connected to the at least one processing area 11. The copper-clad substrate 10 can be a rectangular double-sided copper-clad board, which includes a first conductive layer, an insulating layer and a second conductive layer stacked in sequence. In this embodiment, the processing area 11 is also rectangular, and its length direction is the width direction of the copper clad substrate 10 . The number of the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com