Real-time sensing and intelligent monitoring system for 3D-printed sand mold

An intelligent monitoring system and 3D printing technology, applied in the field of sand casting, can solve the problems of inability to real-time control, insufficient control of 3D printing sand molding process, affecting sand molding accuracy, etc., so as to ensure printing accuracy, improve stability, and improve molding accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further explained below in conjunction with the embodiments and accompanying drawings, but this should not be used as a limitation to the protection scope of the present application.

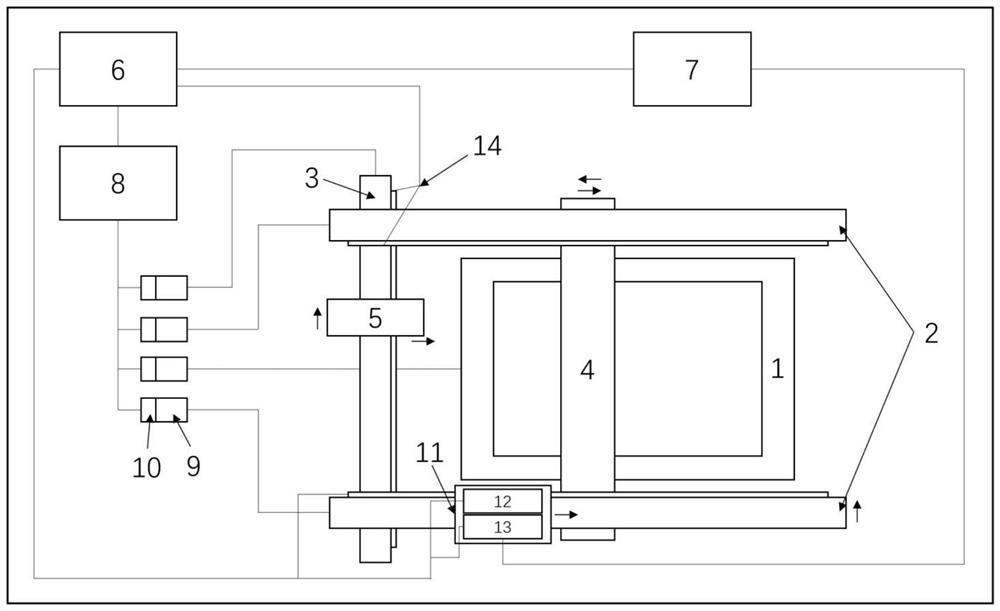

[0036] A 3D printing sand mold real-time perception and intelligent monitoring system of the present invention, comprising:

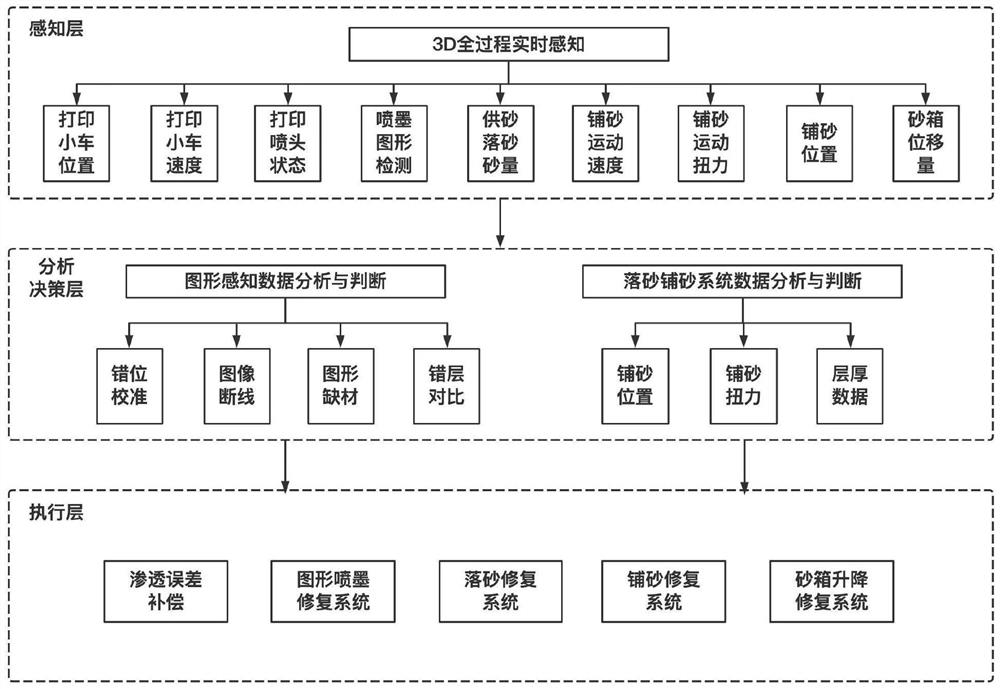

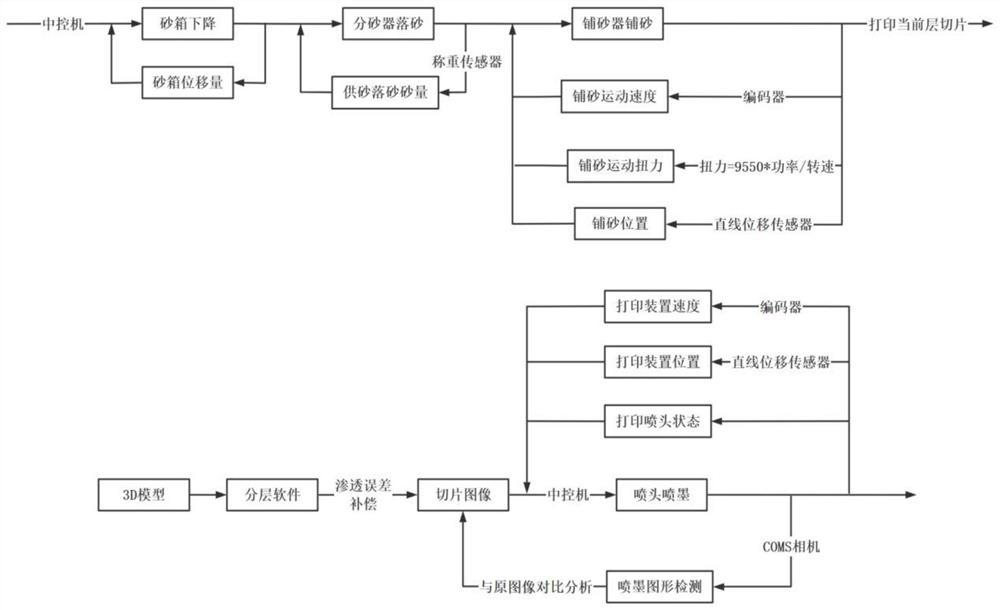

[0037] A perception layer, the perception layer is a 3D whole process real-time perception module, which discretely collects the multi-parameter data of the 3D printing sand mold system. Perception of the entire system in sand printing.

[0038] Analysis and decision-making layer, the analysis and decision-making layer includes a graphic perception data analysis and judgment module, a falling sand sanding system data analysis and judgment module, that is, to analyze and judge discrete data.

[0039] Execution layer, the execution layer includes infiltration error compensation, graphic inkjet repair system, falling sand repair system, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com