3D printer of double cycle heating constant temperature forming space

A 3D printer, dual-cycle technology, applied in the direction of additive processing, etc., can solve the problems of uneven heating and cooling of space, reduced working performance and service life, affecting the printing accuracy of models, etc., to achieve the effect of ensuring molding accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

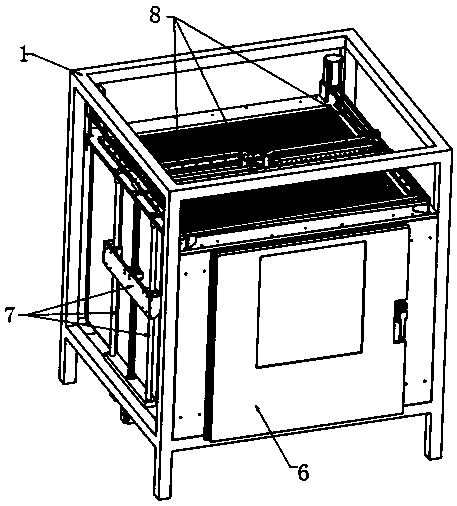

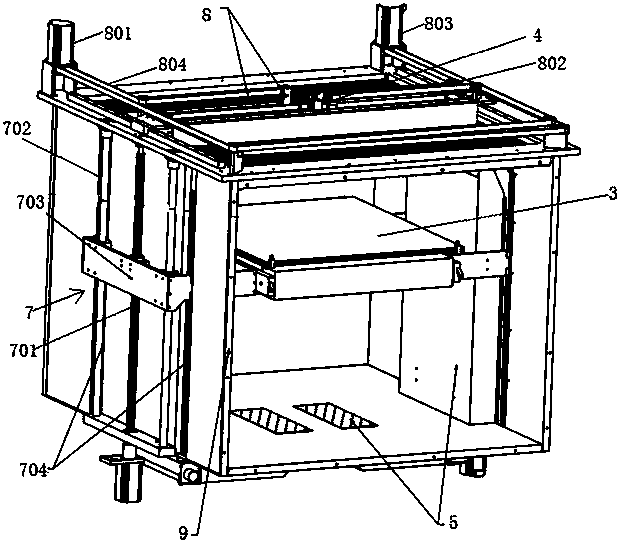

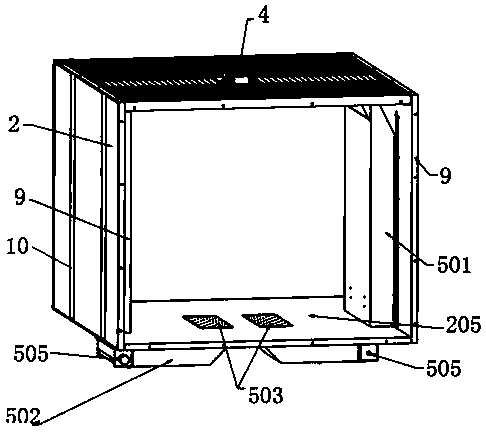

[0032] Such as Figure 1-8 , a 3D printer with a dual-cycle heating constant temperature molding space, including a constant temperature box 2; a printing workbench 3 and a print head 4 are arranged in the constant temperature box 2; the side wall of the constant temperature box 2 is provided with Two oppositely arranged circulating air ducts 5 with heating function, of course, it is also possible to set four in practical applications; said constant temperature box 2 is provided with a door 6; said circulating air duct 5 is provided with a temperature sensor , the frame 1 is arranged outside the thermostat box 2 .

[0033] The printing platform is driven by the first drive mechanism 7 to move along the Z axis; the print head 4 is driven by the second drive mechanism 8 to move along the X and Y axes; the first drive mechanism 7 and the second drive mechanism 8 are all arranged on the outside of the constant temperature box body 2.

[0034] Due to the existence of the circulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com