Universal bilateral composite mold integrated circuit pin forming mechanism of nesting structure

A nested structure, integrated circuit technology, applied in the direction of electrical components, electrical components, etc., can solve the large operating error and cumulative error, it is difficult to achieve the precision of molding processing, the consistency of molding pins, and the absolute adjustment cannot meet the requirements of the molding mechanism and Problems such as the connection conditions of the automatic control system, to ensure the forming accuracy and consistency, realize the effect of automatic forming equipment, high-precision automatic forming equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0023] The specific embodiment of the present invention is set forth below in conjunction with accompanying drawing as follows:

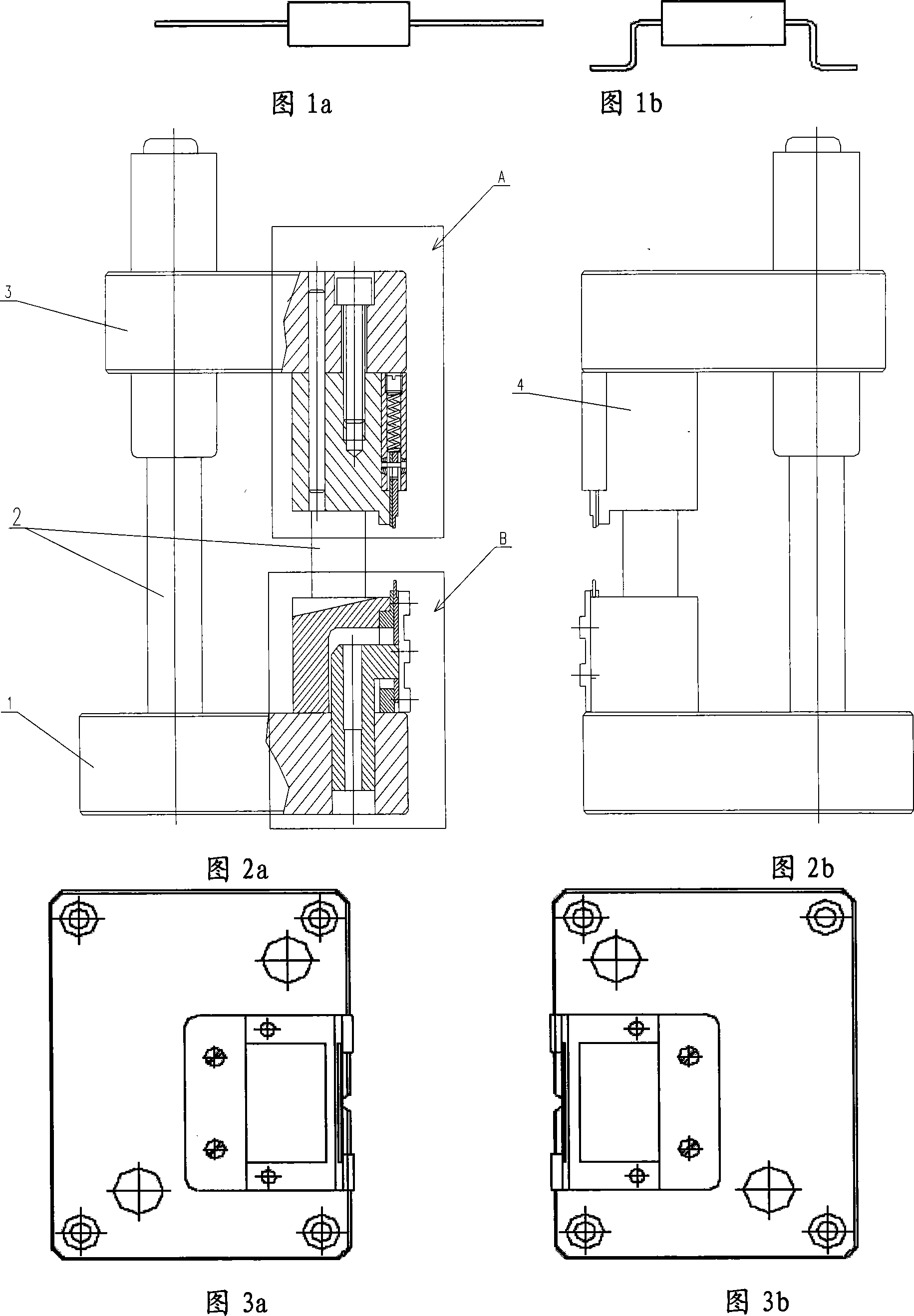

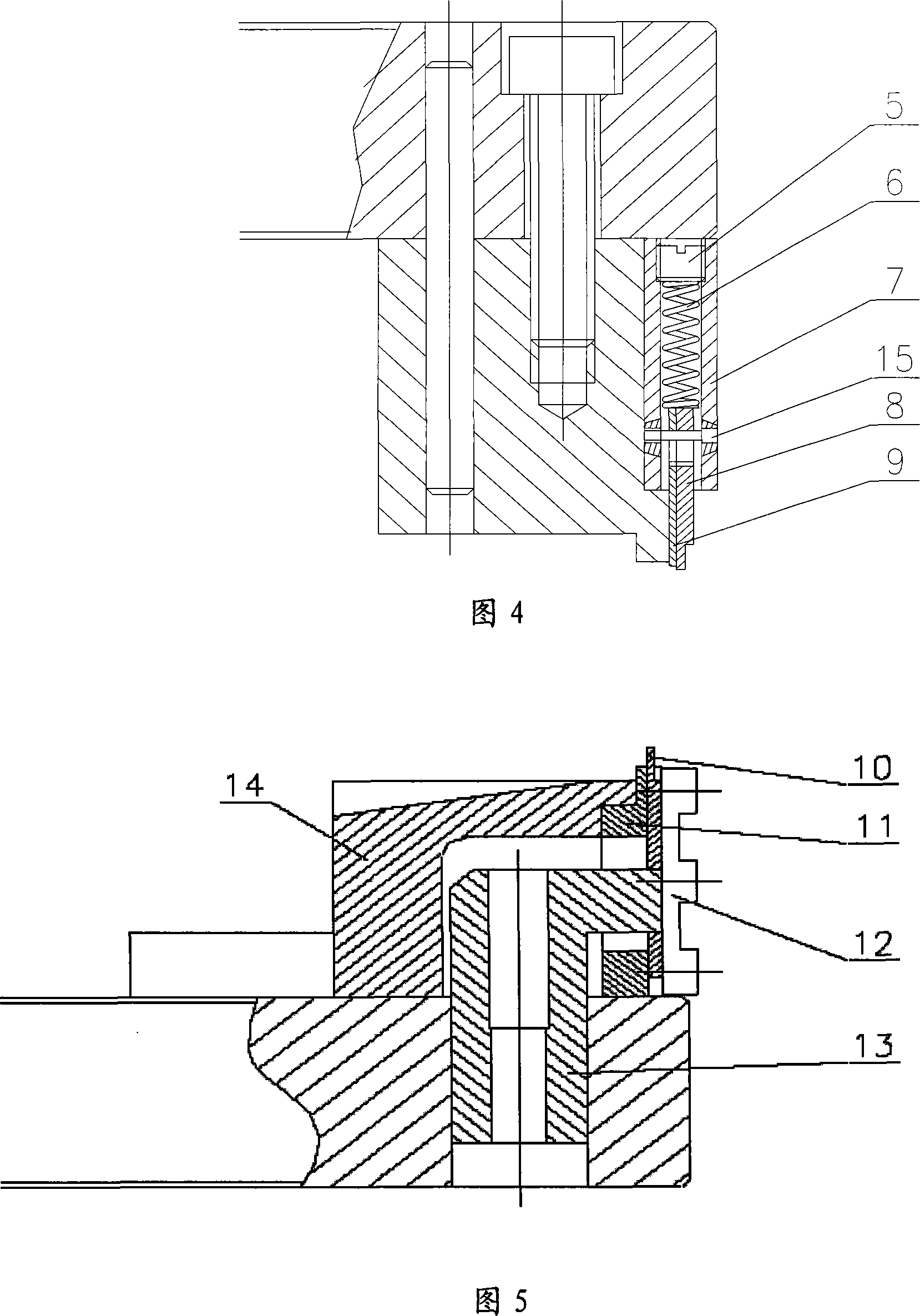

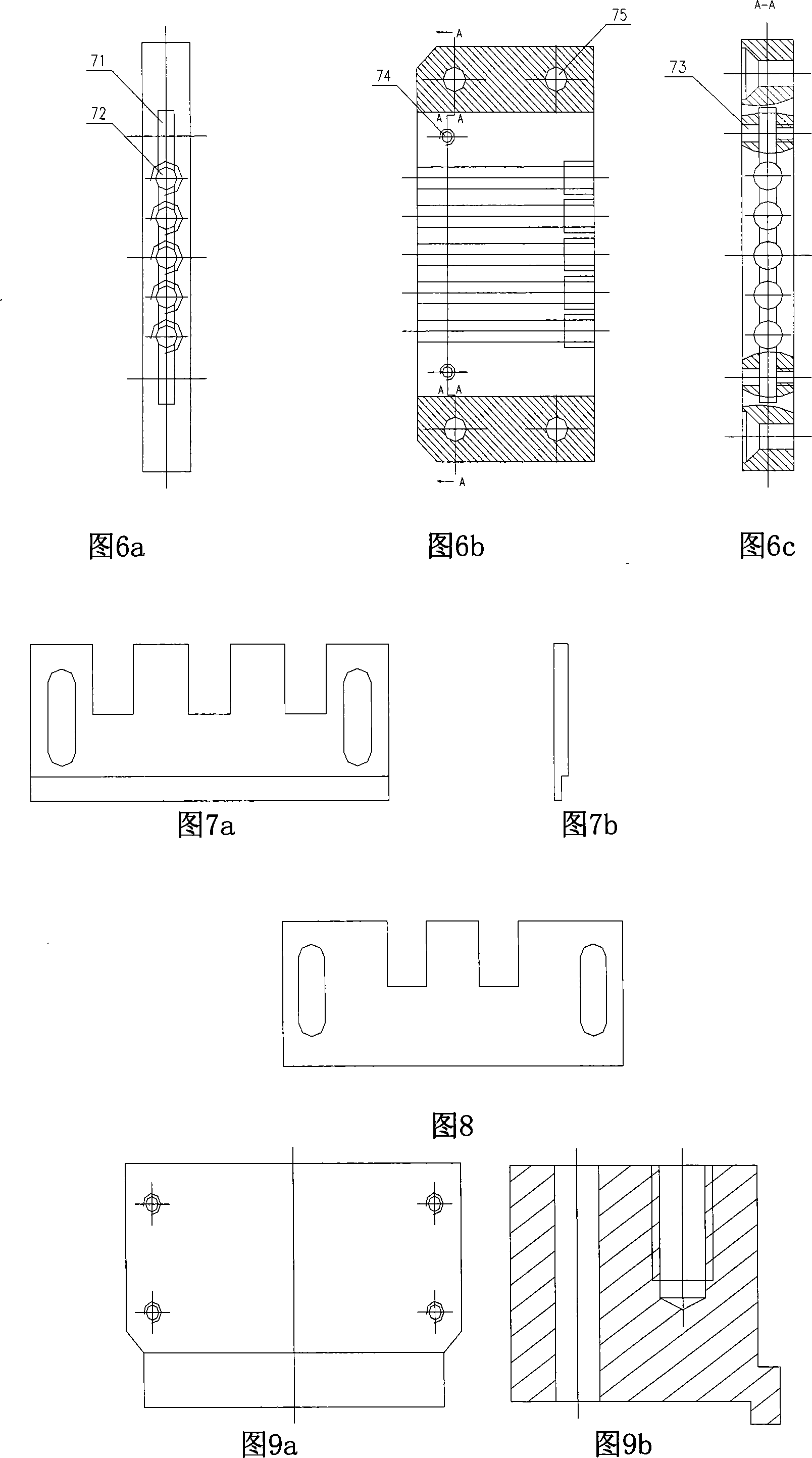

[0024] As shown in Figures 1 to 5, the main structure of the forming mechanism of the present invention is left-right symmetrical, including a left half mold and a right half mold, and each half mold forming mechanism includes a composite mold base 1, a guide post 2, an upper support 3, The upper mold and the lower mold, the lower mold and the guide post 2 are fixed on the composite mold base 1, and the upper mold is fixed on the upper bracket 3, and the upper mold is mainly fixed by the shearing mold 4, the screw 5, the spring 6, and the upper mold plate 7, pressing plate 8 and upper molding die 9, the upper molding die 9 and pressing plate 8 are fitted together and nested in the upper die fixing plate 7, and the screw 5 and the spring 6 installed in the upper die fixing plate 7 will The upper forming die 9 and the pressing plate 8 are ejected outw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com