Rare earth aluminum alloy wire for 3D printing and preparation method thereof

An aluminum alloy wire and 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of high operating environment requirements, low strength of printed products, low material utilization rate, etc., achieve simple process flow, ensure molding accuracy and appearance Effect, good fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A preparation method of rare earth aluminum alloy wire for 3D printing is carried out according to the following steps:

[0054] (1) Raw material smelting: In a vacuum furnace, the smelting composition is Al-4%Mg-0.3%Mn-0.7%Er-0.3%Zr-0.05%Ti, controlling Fe-3 Pa. (Each percentage is mass percentage)

[0055] (2) The ingot in the step (1) is subjected to homogenization annealing at 480°C / 12h, the skin is cut and the head is removed.

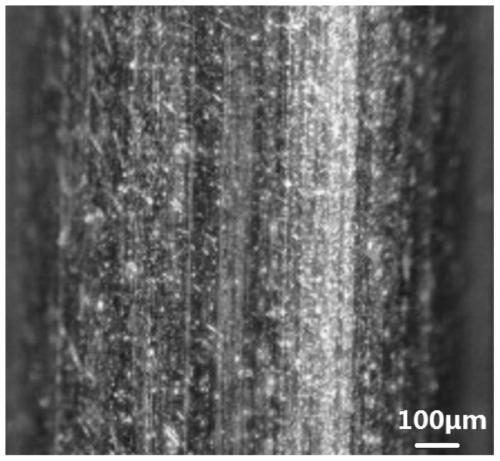

[0056] (3) The ingot in the step (2) is continuously extruded at 500°C, and after rough drawing, intermediate drawing, annealing, and fine drawing, the wire is stripped to obtain a wire with a diameter of 1.2 mm, according to GB / T 228- 2010 standard for mechanical performance test, wire tensile strength σ b =356Mpa, yield strength σ 0.2 =325Mpa; the microscopic appearance of the wire is like figure 1 Shown.

[0057] (4) The wire material in the step (3) is printed with a laser fuse 3D printing device for sample printing, and processed into a test ...

Embodiment 2

[0059] (1) Raw material smelting: In a vacuum furnace, the smelting composition is Al-5%Mg-0.3%Mn-0.4%Sc-0.2%Zr, controlling Fe-3 Pa. (Each percentage is mass percentage)

[0060] (2) The ingot in the step (1) is subjected to homogenization annealing at 350° C. / 10 h, the skin is cut, and the head is removed.

[0061] (3) The ingot in the step (2) is continuously extruded at 500°C, and after rough drawing, intermediate drawing, annealing, and fine drawing, the wire is stripped to obtain a wire with a diameter of 1.2 mm, according to GB / T 228- 2010 standard for mechanical performance test, wire tensile strength σ b =347Mpa, yield strength σ 0.2 =312Mpa, 9% elongation.

[0062] (4) The wire material in the step (3) is printed with a laser fuse 3D printing device for sample printing, and processed into a test piece after heat treatment. According to GB / T 228-2010 standard for mechanical performance test, tensile strength σ b =457Mpa, yield strength σ 0.2 =415Mpa, elongation rate 10%.

Embodiment 3

[0064] (1) Raw material smelting: In a vacuum furnace, the smelting composition is Al-5%Mg-0.3%Mn-0.5%Sc-0.25%Zr control Fe-3 Pa.

[0065] (2) The ingot in the step (1) is subjected to homogenization annealing at 350° C. / 10 h, the skin is cut, and the head is removed.

[0066] (3) The ingot in the step (2) is continuously extruded at 500°C, and after rough drawing, intermediate drawing, annealing, and fine drawing, the wire is stripped to obtain a wire with a diameter of 1.2 mm, according to GB / T 228- 2010 standard for mechanical performance test, wire tensile strength σ b =414Mpa, yield strength σ 0.2 =382Mpa, elongation rate 12%.

[0067] (4) The wire material in the step (3) is printed with a laser fuse 3D printing device for sample printing, and processed into a test piece after heat treatment. According to GB / T 228-2010 standard for mechanical performance test, tensile strength σ b =492Mpa, yield strength σ 0.2 =458Mpa, elongation rate 11%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com