Patents

Literature

40results about How to "Smooth wire feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Submerged arc welding wire of high tensile pipeline steel

ActiveCN101905391AHigh yield strengthQuality improvementArc welding apparatusPipeline systemsCrack resistanceSheet steel

The invention discloses a submerged arc welding wire of a high tensile pipeline steel. The welding wire material comprises the following chemical components in percentage by weight: not more than 0.10 of C, not more than 0.6 of Si, 1.3-1.8 of Mn, 1.4-2.5 of Ni, 0.25-0.55 of Mo, not more than 0.12 of Ti, not more than 0.05 of V, not more than 0.35 of Cr, 0.0005-0.005 of B, not more than 0.015 of S, not more than 0.015 of P, and the balance of Fe and other inevitable impurities. The submerged arc welding wire of the high tensile pipeline steel provided by the invention has the yield strength of deposited metals of more than 690MPa and the tensile strength of more than 785Mpa, has attractive welding formation, high intensity, high flexibility and high crack resistance without defects of cracking, undercut and the like, and has favorable matching effect with X100 level pipeline steel plates, and meets the requirement on the welding of oil-gas transmission pipelines under the condition of higher pressure.

Owner:YICHANG MONKEY KING WELDING WIRE

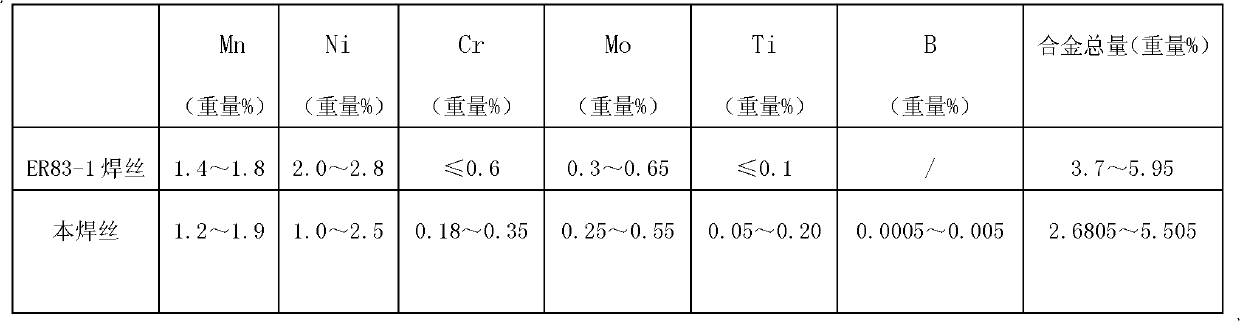

High-toughness low-alloy solid welding wire

ActiveCN101905392AQuality improvementReduced crack susceptibilityWelding/cutting media/materialsSoldering mediaSheet steelChemical composition

The invention relates to a high-toughness low-alloy solid welding wire which comprises the following chemical components in percentage by weight: not more than 0.10 percent of C, 0.4 to 0.8 percent of Si, 1.2 to 1.9 percent of Mn, 1.0 to 2.5 percent of Ni, 0.25 to 0.55 percent of Mo, 0.18 to 0.35 percent of Cr, 0.05 to 0.20 percent of Ti, 0.0005 to 0.005 percent of B, not more than 0.015 percent of S, not more than 0.015 percent of P and the balance of Fe and other inevitable impurities. The high-toughness low-alloy solid welding wire has the tensile strength of deposited metal more than 830MPa, the yield strength of the deposited metal more than 730MPa, and the reduced alloy content by near 50 percent compared with the welding wire ER83-1 on the premises of ensuring the strength and the impact toughness, can satisfy the welding of 830MPa-grade and 900MPa-grade steel plates and greatly reduce the cost and is suitable for large-scale popularization and application.

Owner:YICHANG MONKEY KING WELDING WIRE

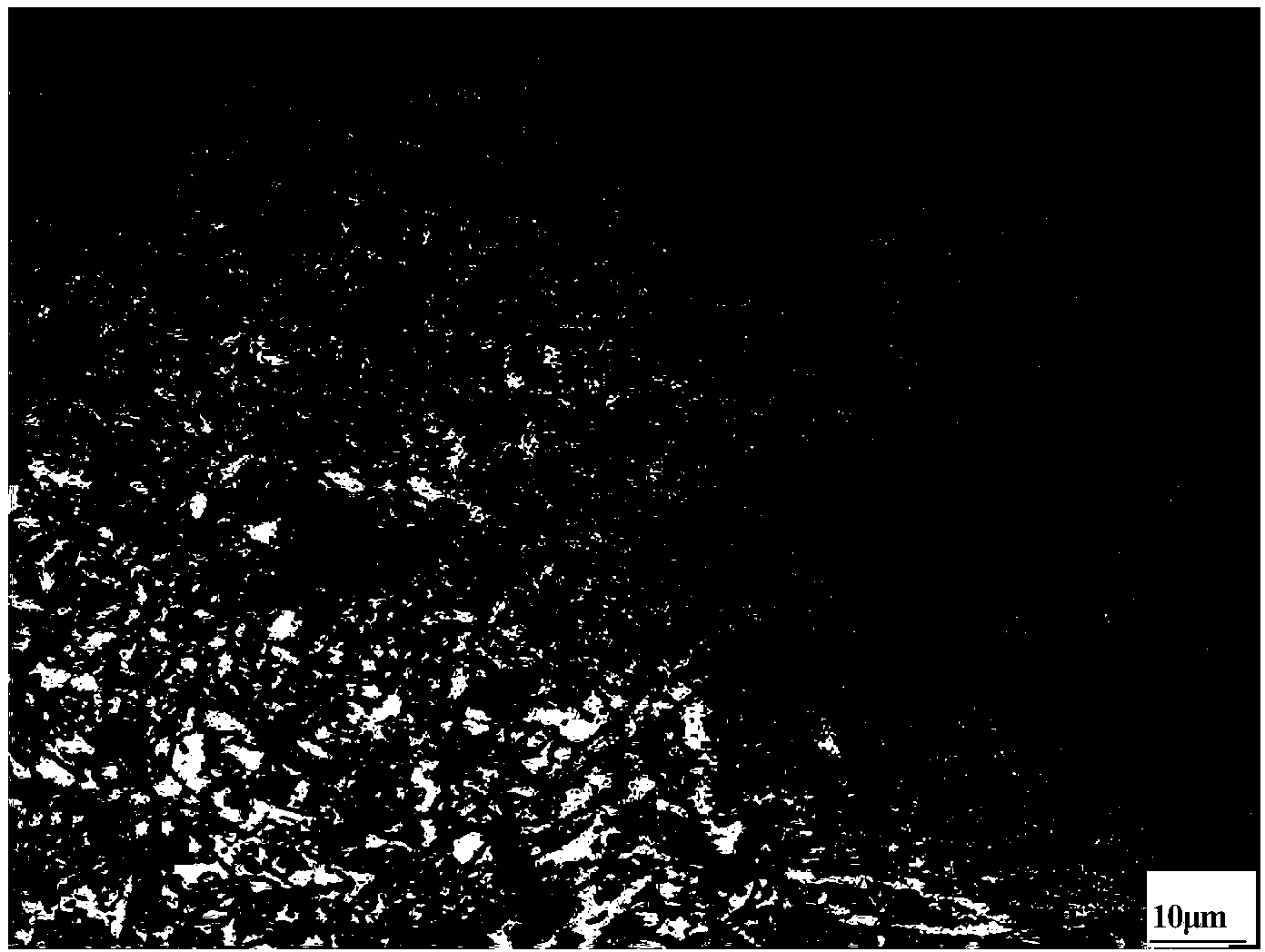

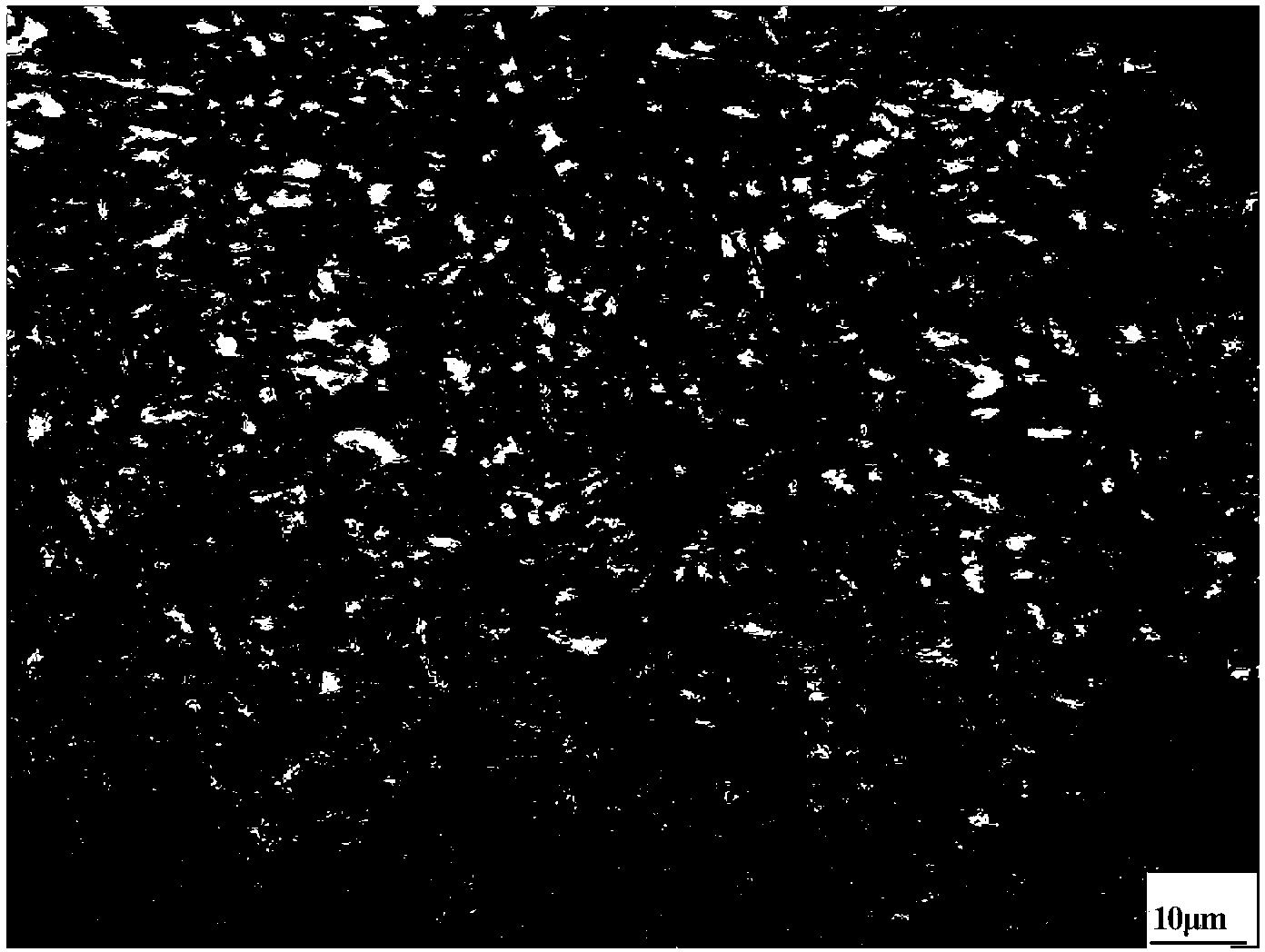

High-quality welding wire steel wire rod and production method thereof

ActiveCN108393614ALow splash rateReduce welding costsWelding/cutting media/materialsSoldering mediaElectric arcMetal

The invention discloses a high-quality welding wire steel wire rod and a production method thereof. The high-quality welding wire steel wire rod comprises 0.05-0.07% of C, 0.85-0.95% of Si, 1.45-1.65%of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.010% of S, smaller than or equal to 0.010% of Al, 0.0001-0.0004% of Ca, smaller than or equal to 0.0040% of N, smaller than orequal to 0.0030% of O and the balance Fe and inevitable impurities. The content of calcium in the produced wire rod is not larger than 0.0004%, and in the welding process, and the metal splashing ratedoes not exceed 1.0%; and after a welding wire steel wire rod produced by adopting a common process is machined into a welding wire, the metal splashing rate is 3.2% or so, and the splashing rate inthe welding process is remarkably reduced. The welding cost can be reduced easily, it is guaranteed that wire feeding is smooth, electric arc combustion is stable, and a gas protecting welding effectis achieved very well.

Owner:ANGANG STEEL CO LTD

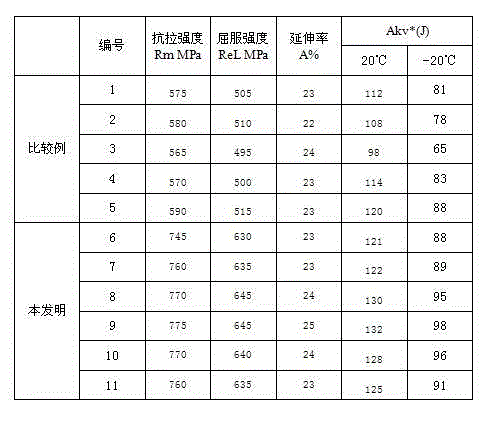

Welding wire for submerged-arc welding of high-efficiency X100 pipeline steel and application of welding wire

ActiveCN103846571ABeautiful shapeMeet welding requirementsArc welding apparatusPipeline systemsCrack resistanceWeld seam

The invention belongs to the field of a welding wire material, and particularly relates to a welding wire for submerged-arc welding of high-efficiency X100 pipeline steel and the application of the welding wire. The welding wire material comprises the chemical components in percentage by weight: 0.01-0.05 wt% of C, 1.4-2.1 wt% of Mn, 0.1-0.3 wt% of Si, 0.2-0.4 wt% of Mo, 0.05-0.1 wt% of Ti, 0.003-0.005 wt% of B, 0.1-0.4 wt% of Cr, 0.2-0.3 wt% of Cu, 0.3-0.6 wt% of Ni, 0.03-0.08 wt% of Nb, less than or equal to 0.005 wt% of S, less than or equal to 0.005 wt% of P, and the balance of Fe. The welding wire for the submerged-arc welding, disclosed by the invention is matched with an SJ101-100 welding flux deposited metal and has an excellent comprehensive mechanical property, the yield strength is greater than 690 MPa, the tensile strength is greater than 780MPa, and the impact work is greater than 108J in -20 DEG C; after welding, the forming of a welding seam is attractive, the defects of cracking, undercutting and the like do not exist, the strength is high, the toughness is good, the crack resistance is good, the welding seam has a good matching effect with the X100 pipeline steel, and the welding wire has a decisive function on performance of a weld metal as the welding wire is used as a main filling metal; according to the welding wire disclosed by the invention, the welding requirements of an oil and gas transmission pipeline under a situation of higher pressure are met.

Owner:JINZHOU SWAN WELDING CONSUMABLES

Rare earth aluminum alloy wire for 3D printing and preparation method thereof

ActiveCN110396627AImprove mechanical propertiesAvoid breakingAdditive manufacturing apparatusHigh densityRare earth

The invention relates to a rare earth aluminum alloy wire for 3D printing and a preparation method thereof. The rare earth aluminum alloy wire comprises the following materials: 3-5wt% of Mg, 0.4-1.2wt% of RE, 0.1-1.0wt% of Zr, 0.1-1.0wt% of Mn, 0.05-0.25wt% of Ti, less than or equal to 0.05wt% of O, less than or equal to 0.02wt% of N, less than or equal to 0.01wt% of H and balance of A1 and unavoidable impurities, wherein the ratio of the Mn content to the RE content is 0.5-1:1, and the ratio of the Zr content to the RE content is 0.2-1:1. The wire provided by the invention adds rare earth and zirconium element on the basis of the composition of the aluminum-magnesium alloy to refine crystal grains, and simultaneously produces Al3 (REZr) precipitation strengthening, which is used for smooth feeding on the 3D printer, is not easy to break, has high strength, and ensures the printing precision of a product; and the printed parts have high density, good mechanical properties and corrosion resistance.

Owner:HUNAN ORIENTAL SCANDIUM

Thin-layer slag protecting medicinal powder for welding high strength steel

InactiveCN102581520AReduce the cost of updatesEasy to getWelding/cutting media/materialsSoldering mediaSlagRare earth

The invention discloses a thin-layer slag protecting medicinal powder for welding high strength steel. The medicinal powder is prepared by uniformly mixing an alloy and a slag forming and arc stabilizing agent. The content of the alloy accounts is 88-92wt% (weight percent), and the content of the slag forming and arc stabilizing agent accounts is 12-8wt%. The alloy comprises the following elements by weight percent: 0.06-0.10% of C, 1.0-5.0% of Si, 1.2-3.4% of Mn, 0.72-1.4% of Mo, 0.5-1.4% of Cr, 1.4-5.2%Ni, 0.30-0.70% of Ti and the balance of Fe; the slag forming and arc stabilizing agent is prepared by mixing the following materials in parts by weight: 15-30 parts of rutile, 8-25 parts of potash potassium feldspar, 1-5 parts of magnesia, 2-10 parts potassium titanate, 2-8 parts of sodium fluoride, 0-8 parts of sodium fluosilicate, 5-12 parts of barium fluoride and 0-4 parts of cerium oxide rare earth. The medicinal powder can be used together with a welding torch with the powder and gas supplying double function, thereby overcoming the defects that the high-strength steel welding wire is hard to obtain from a wire rod, the welding wire is produced by multiple thermal treatment, and the cost is high.

Owner:SHANDONG UNIV

Solid welding wire for high-toughness structural steel

ActiveCN101905393AIncrease contentMeet welding requirementsArc welding apparatusWelding/cutting media/materialsChemical compositionSheet steel

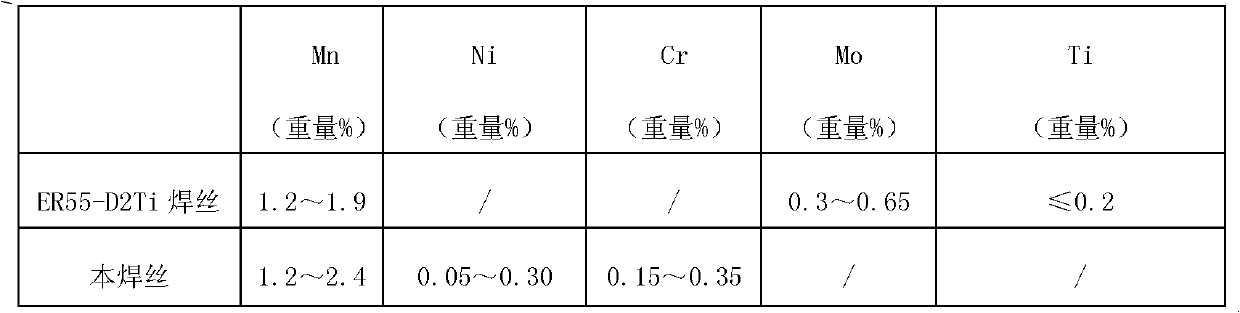

The invention provides a solid welding wire for high-toughness structural steel, which comprises the following chemical components by weight percent: C: 0.06-0.12, Si: 0.4-0.8, Mn: 1.2-2.4, Ni: 0.05-0.30, Cr: 0.15-0.30, S: not more than 0.015, P: not more than 0.020 and the balance of Fe and other unavoidable impurities. As for the solid welding wire for the high-toughness structural steel provided by the invention, yield strength for deposited metal is more than 500MPa and tensile strength is more than 600MPa; after welding, welding seams have beautiful shaping, little splash and low crack sensitivity, thus meeting the welding requirement for a low-alloy high strength steel plate; and relative to an ER55-D2Ti welding wire or a 60kg of welding wire containing Ni-Mo system, the solid welding wire of the invention lowers production cost and use cost on the premise of guaranteeing intensity and impact toughness, thus being suitable for large-scale popularization and application.

Owner:YICHANG MONKEY KING WELDING WIRE

A New Type of High Scandium Aluminum Alloy Welding Wire

ActiveCN103286471BGood electrical conductivityHigh strengthWelding/cutting media/materialsSoldering mediaManganeseWeld strength

The invention relates to the field of welding materials, in particular to a novel high-scandium aluminum alloy welding wire. The novel high-scandium aluminum alloy welding wire chemically comprises, by mass, 4.5-6.0% of Mg, 0.10-0.20% of Mn, 0.20-0.30% of Ti, 0.30-0.50% of Zn, 0.10-0.20% of Cr, 0.25-0.35% of Zr, 1.20-1.60% of Sc, not more than 0.20% of Fe, not more than 0.20% of Si, not more than 0.05% of Cu, not more than 0.0005% of Be, not more than 0.1% of other single impurity elements, not more than 0.15% of other impurity elements and the balance Al. The novel high-scandium aluminum alloy welding wire has the advantages of uniformity in texture, tiny grains, good electrical conductivity, excellent welding performance, high weld strength, good ductility and toughness, excellent mechanical property, low hot-cracking susceptibility and excellent corrosion resistance.

Owner:NORTHEASTERN UNIV LIAONING +1

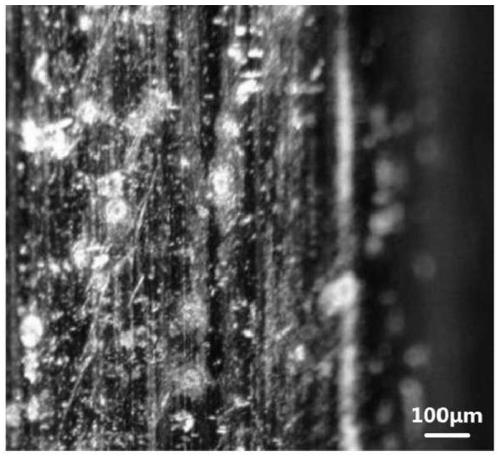

Lubricant for producing non-copper plating solid core welding wire and preparation technology of welding wire

InactiveCN101362980ASimple production processIncrease polarityAdditivesBase-materialsCopper platingCarbon dioxide

The invention provides a lubricant which is used in the protection of the production of solid-core welding wires by using non-copper-plating carbon dioxide gas and a production technology of the welding wires. The lubricant is formed by mixing graphite and ferrous oxalate. The production technology of the welding wires comprises: steel wires with the diameter of Phi 5.5mm for welding are firstly drawn to the semi-finished welding wires with the diameter of Phi 1.865mm; the semi-finished welding wires with the diameter of Phi 1.865mm are drawn to the finished welding wires; the production technology is characterized in that: the lubricant which is formed by mixing the graphite and the ferrous oxalate is added in a mould box of the final two or three-channel mould during the drawing process into the finished welding wires; or the mixture of water-soluble dry wire drawing lubricant and triethanolamine stearate is added in the mould box of the former one or two-channel mould before adding the lubricant. When in welding of the non-copper-plating welding wires which are manufactured by the technology, the spatter is less and the metal coating performance is good. The rust-proof period of the welding wires which are packaged by thermoplastic thin films can reach more than three years.

Owner:张俐

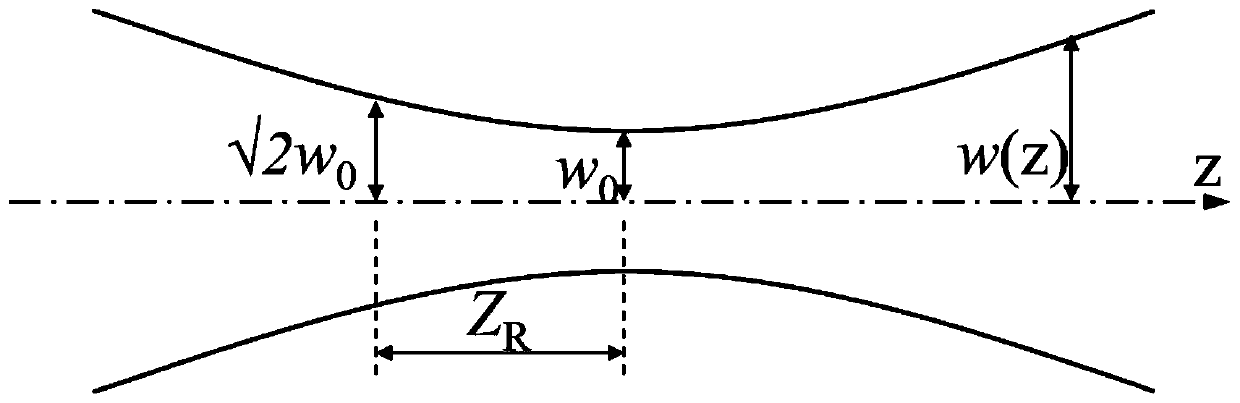

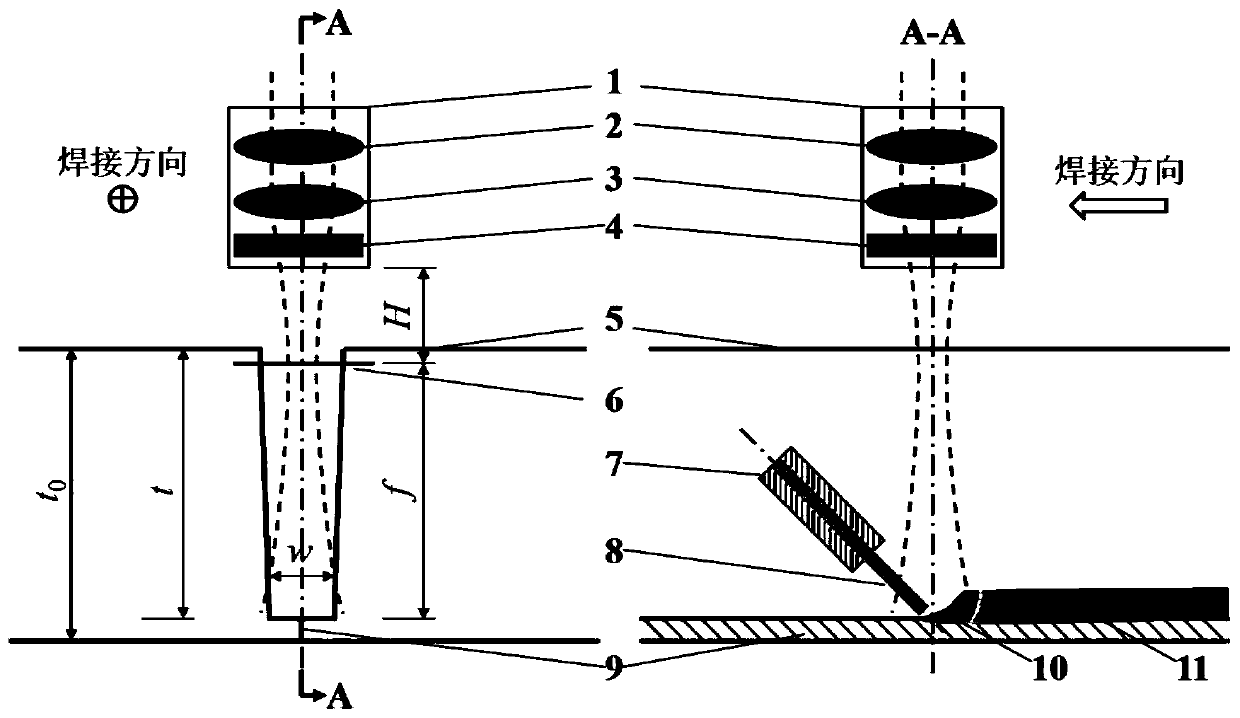

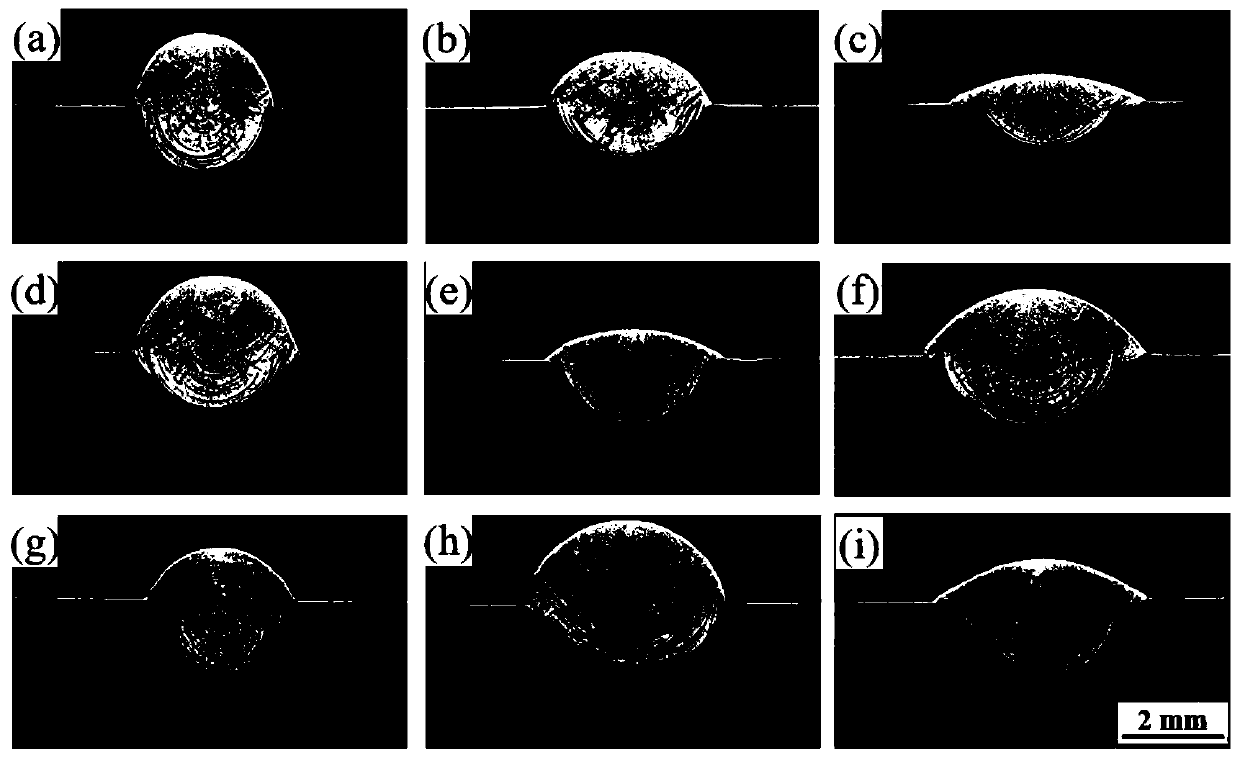

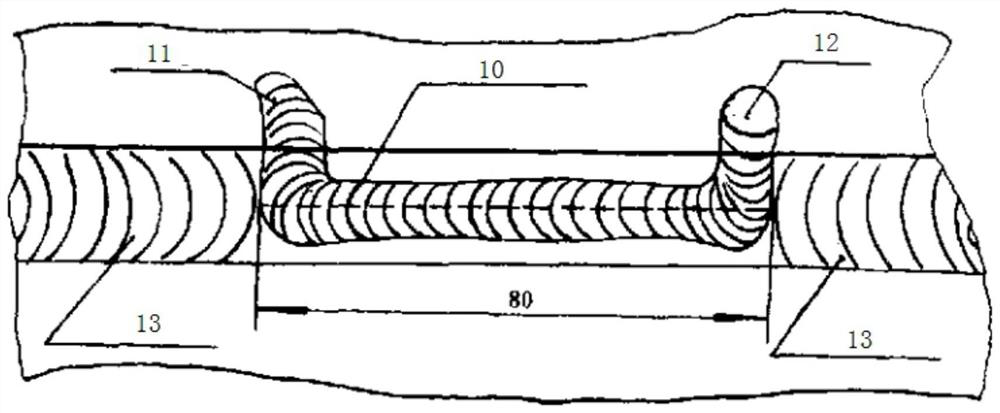

Method for calculating groove width of narrow gap laser filler wire welded plat

ActiveCN110340529AShorten application cycleReduce the number of trialsLaser beam welding apparatusProcess optimizationGroove width

The invention discloses a method for calculating the groove width of a narrow gap laser filler wire welded plate. According to laser beam transmission characteristic parameters, a proper laser defocusamount range for the thickness of a to-be-welded plate can be obtained; according to the defocus amount range, a well-formed laser filler wire single-pass surfacing process parameter window and the welding bead width variation range are obtained on a flat plate of the same material; the expected well-formed groove width is obtained according to the sidewall melting condition and spatial interference analysis; and a groove is machined in a to-be-welded test plate, and narrow gap laser filler wire welding is completed. The well-formed ultra-thick plate narrow gap laser filler wire welding process parameters can be quickly calculated, and the number and cycle of experiments required for process optimization are greatly reduced. According to the specified characteristic parameters of laser filler wire welding equipment, whether narrow gap welding of the corresponding thick plate can be completed or not is judged, the process parameter window is given, and the application period of the narrow gap laser filler wire welding technology is greatly reduced.

Owner:XI AN JIAOTONG UNIV

High-strength heat-resistant steel gas shielded solid welding wire

ActiveCN103056548BReduce embrittlementImprove performanceWelding/cutting media/materialsSoldering mediaHeat resistanceRoom temperature

Owner:CHENGDU XINDAYANG WELDING MATERIAL

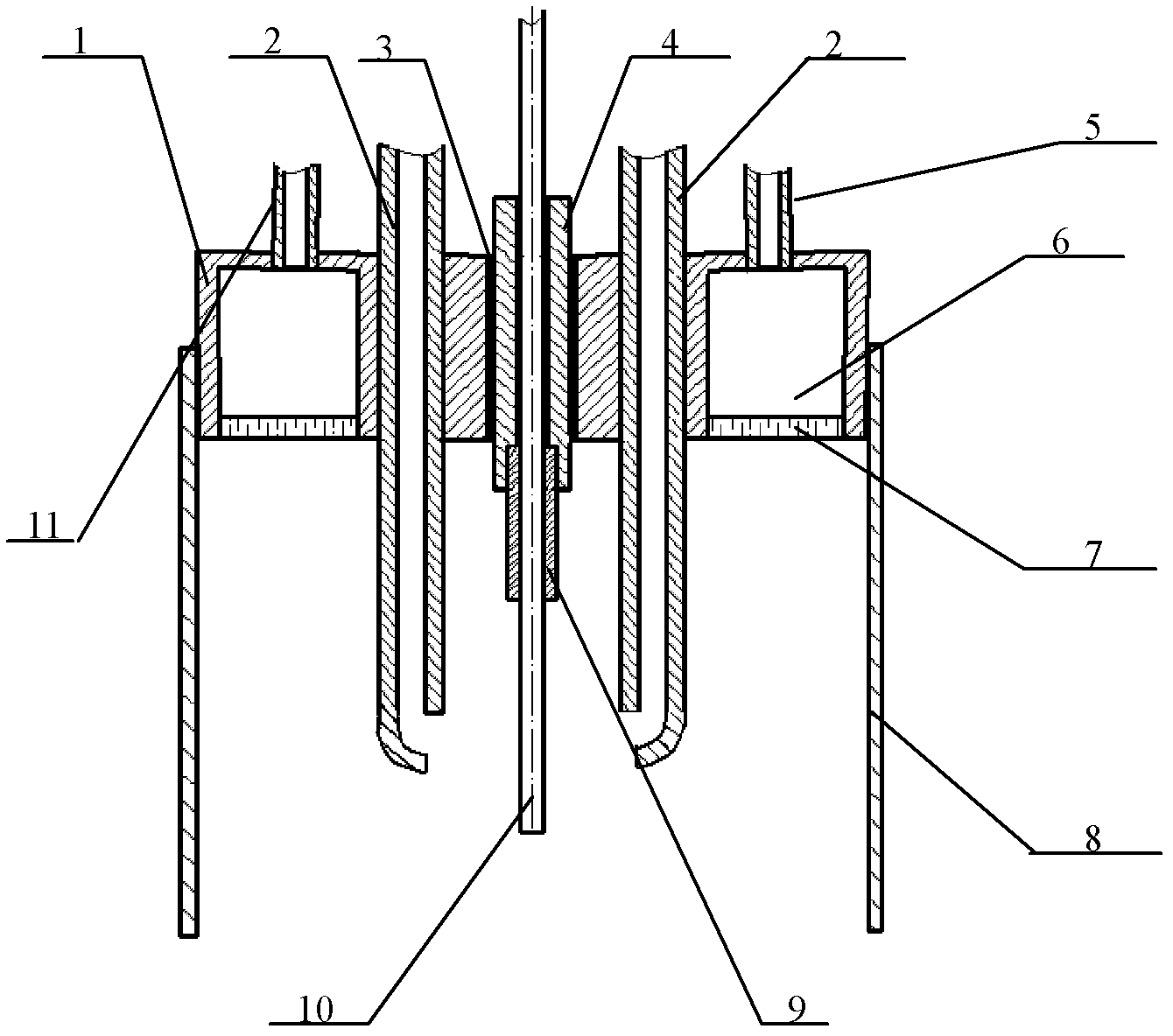

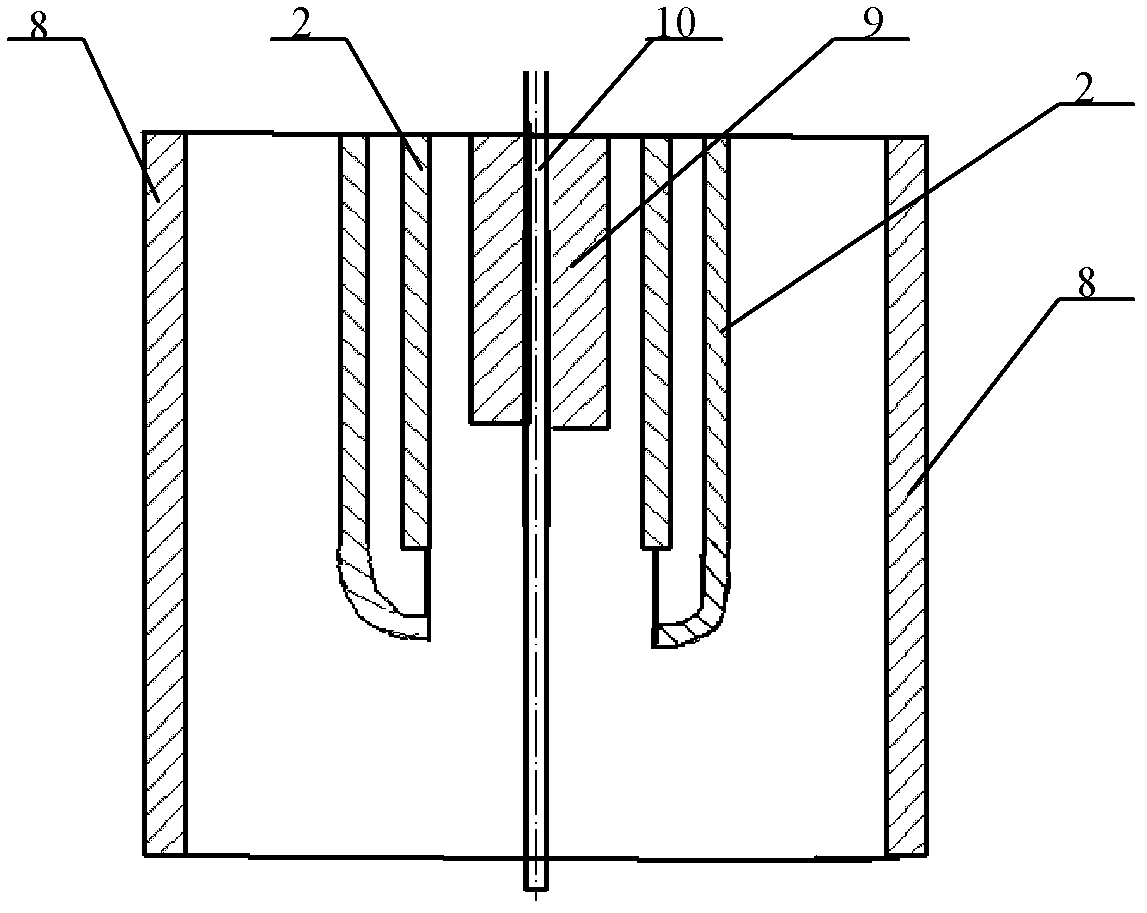

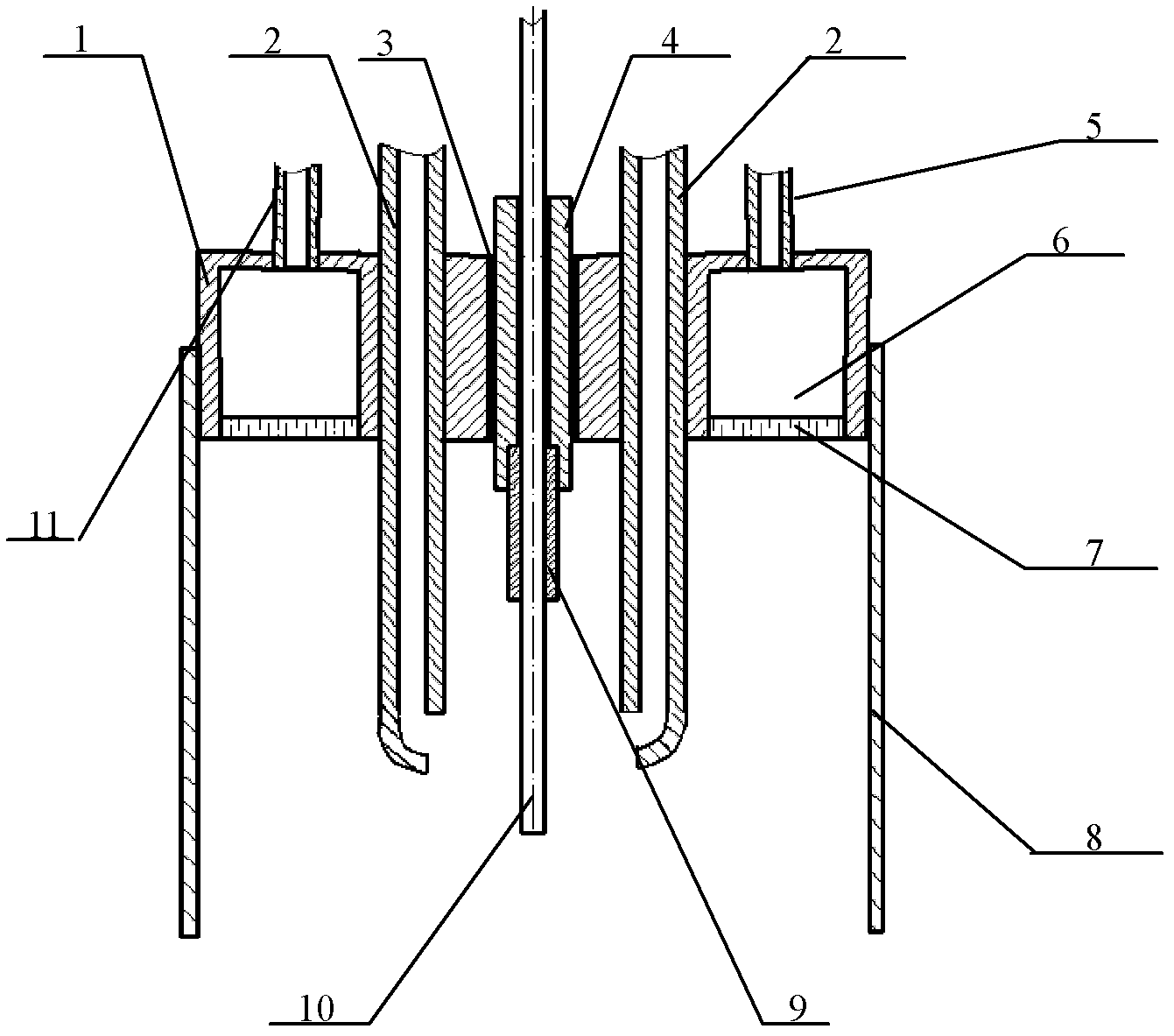

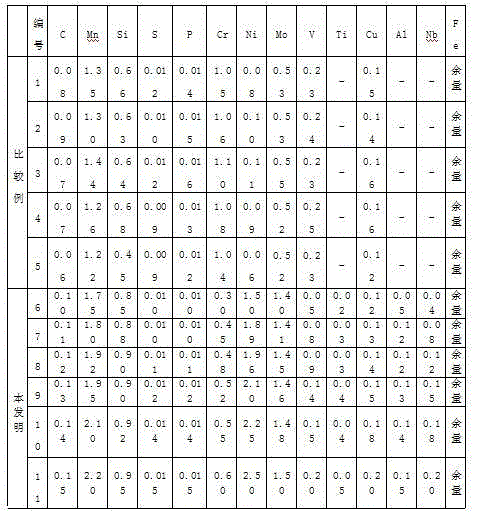

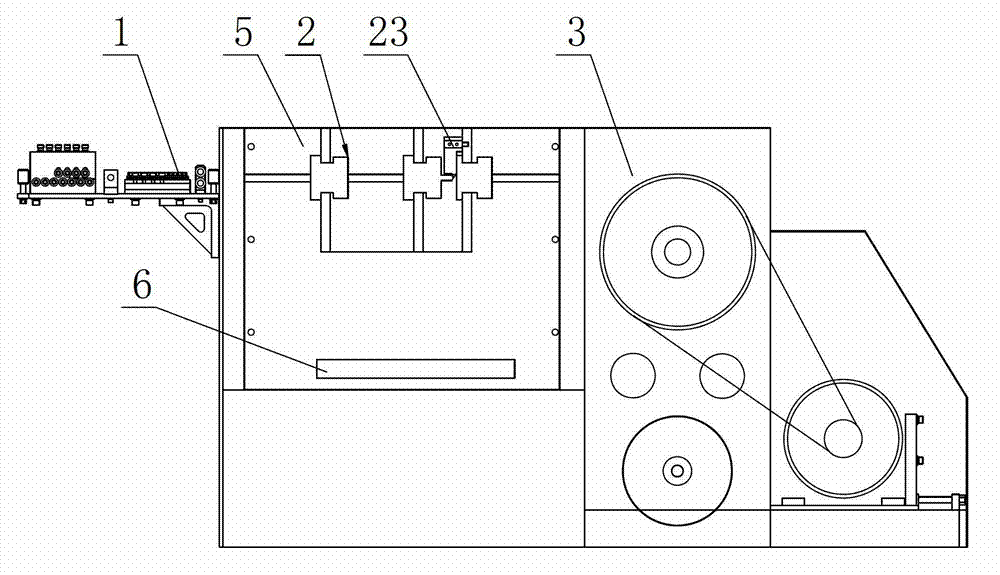

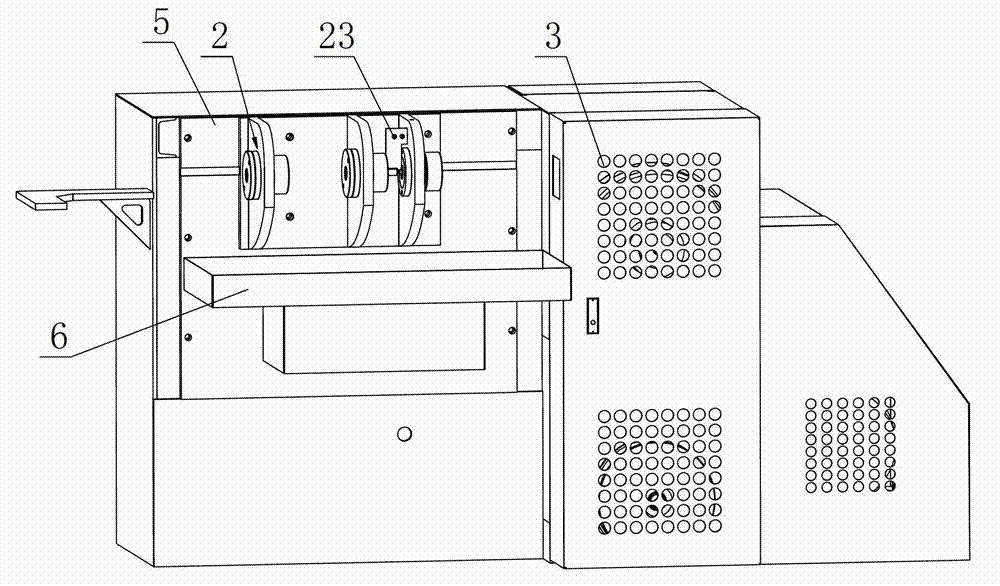

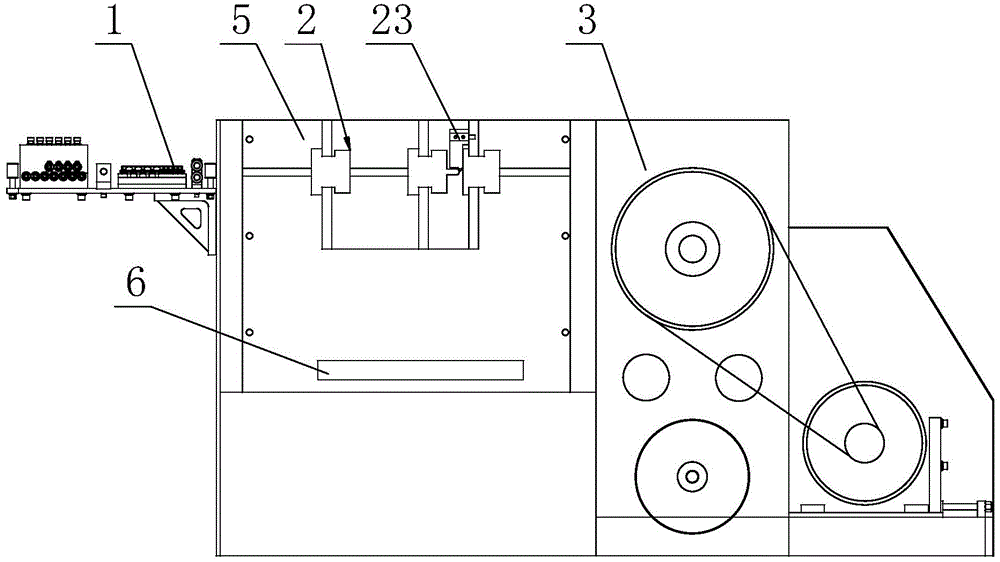

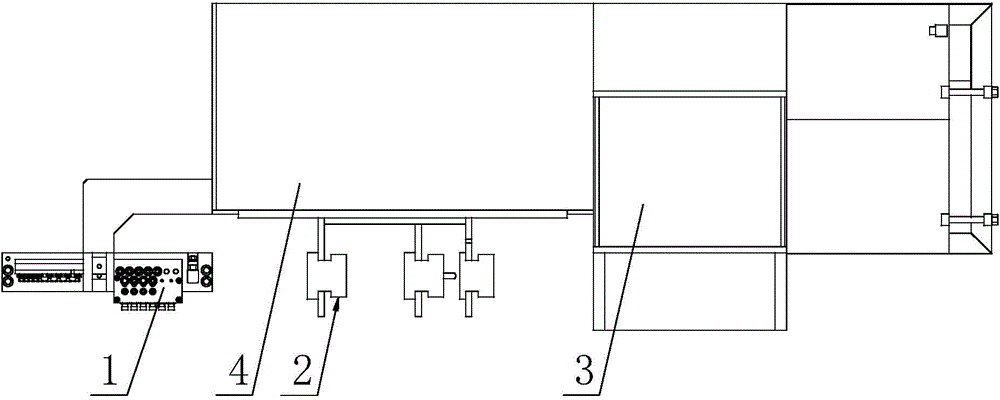

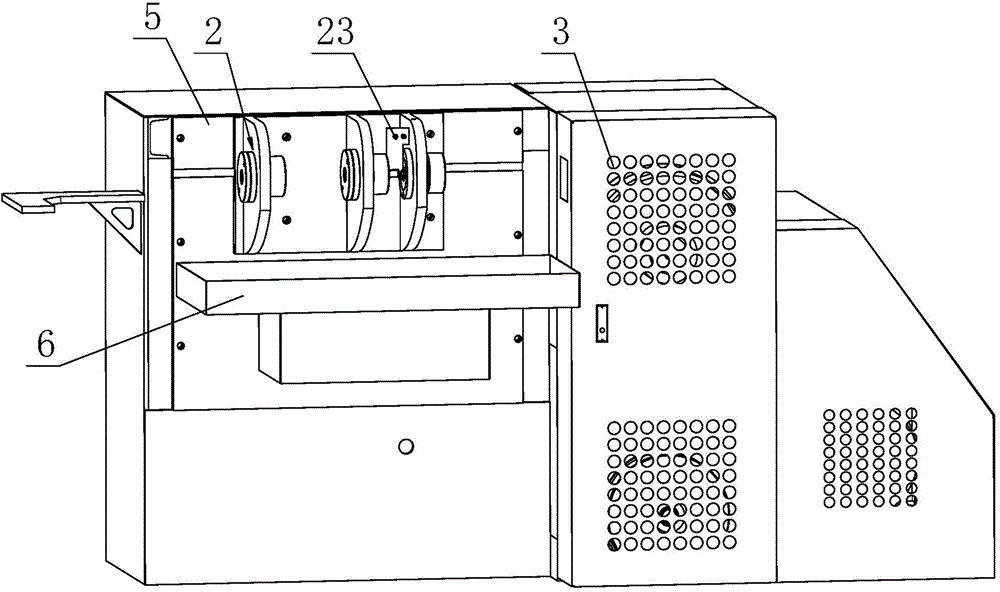

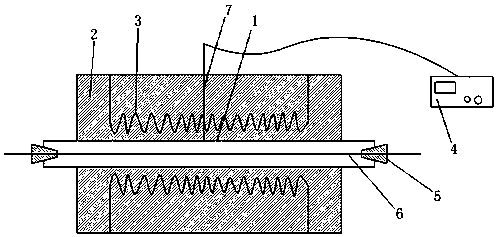

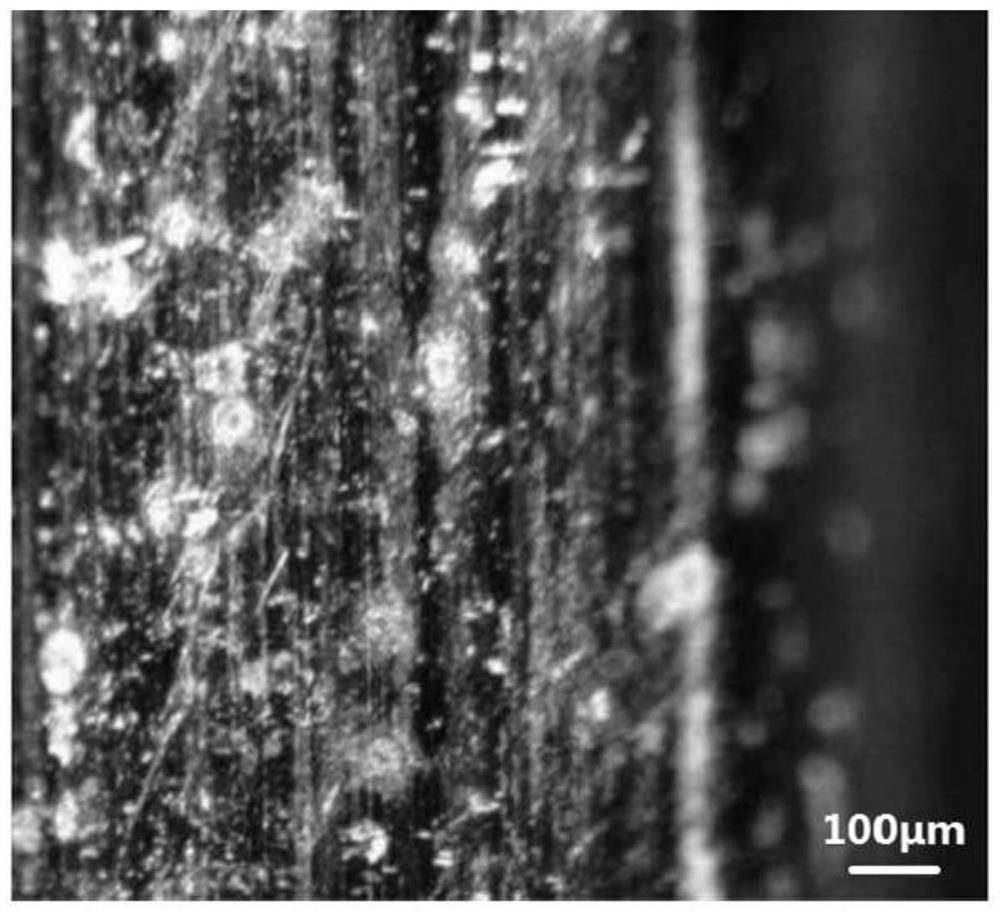

Equipment for scraping surface of aluminum soldering material

ActiveCN102784969ASimple structureEasy to manufactureWelding/cutting media/materialsSoldering mediaSoldering processPetroleum engineering

The invention relates to equipment for scraping the surface of an aluminum soldering material. The equipment comprises a rack; a straightening wheel assembly, a scraping assembly and a rolling-drawing assembly are sequentially arranged on the rack; the scraping assembly comprises a compression part, a scraping part and a cutting tool for cutting sweeps located between the compression part and the scraping part; the compression part comprises a compression die and a compression die fixing device; the compression die is provided with a compression hole; the scraping part comprises a scraping die and a scraping die fixing device; a scraping hole is arranged in the scraping die; and the compression hole and the scraping hole are coaxially arranged. The equipment for scraping the surface of the aluminum soldering material provided by the invention has the advantages of simple structure and easiness of manufacturing; and the defects of surface hollows, surface scraps and the like, caused by the aluminum soldering material in production, can be overcome, so that the surface of the soldering material is smooth. Therefore, wires can be enabled to be fed smoothly in a soldering process, and the welding quality is improved.

Owner:哈焊所华通(常州)焊业股份有限公司

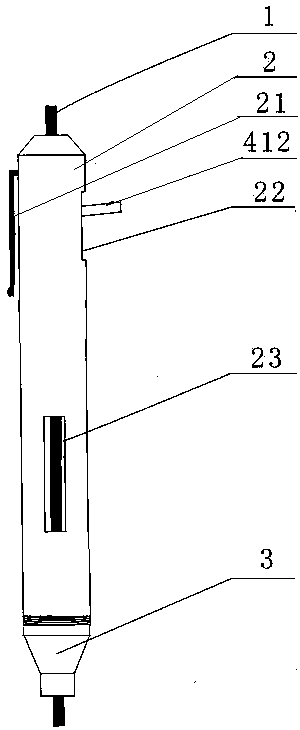

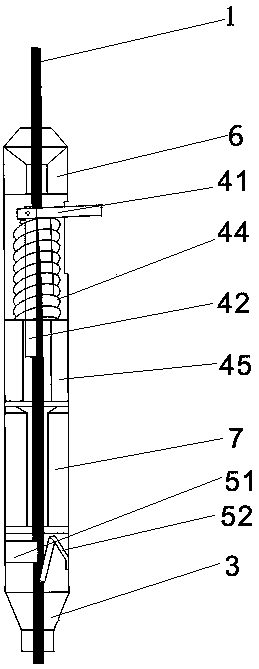

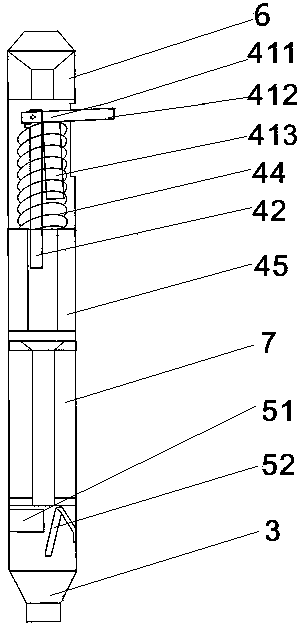

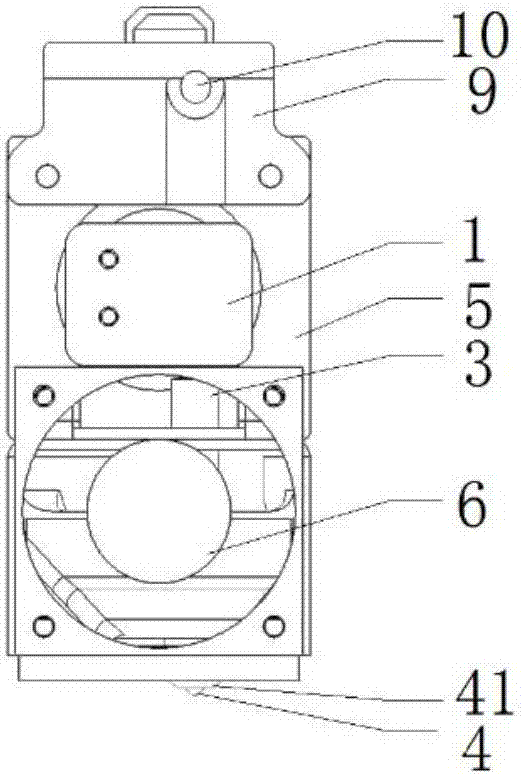

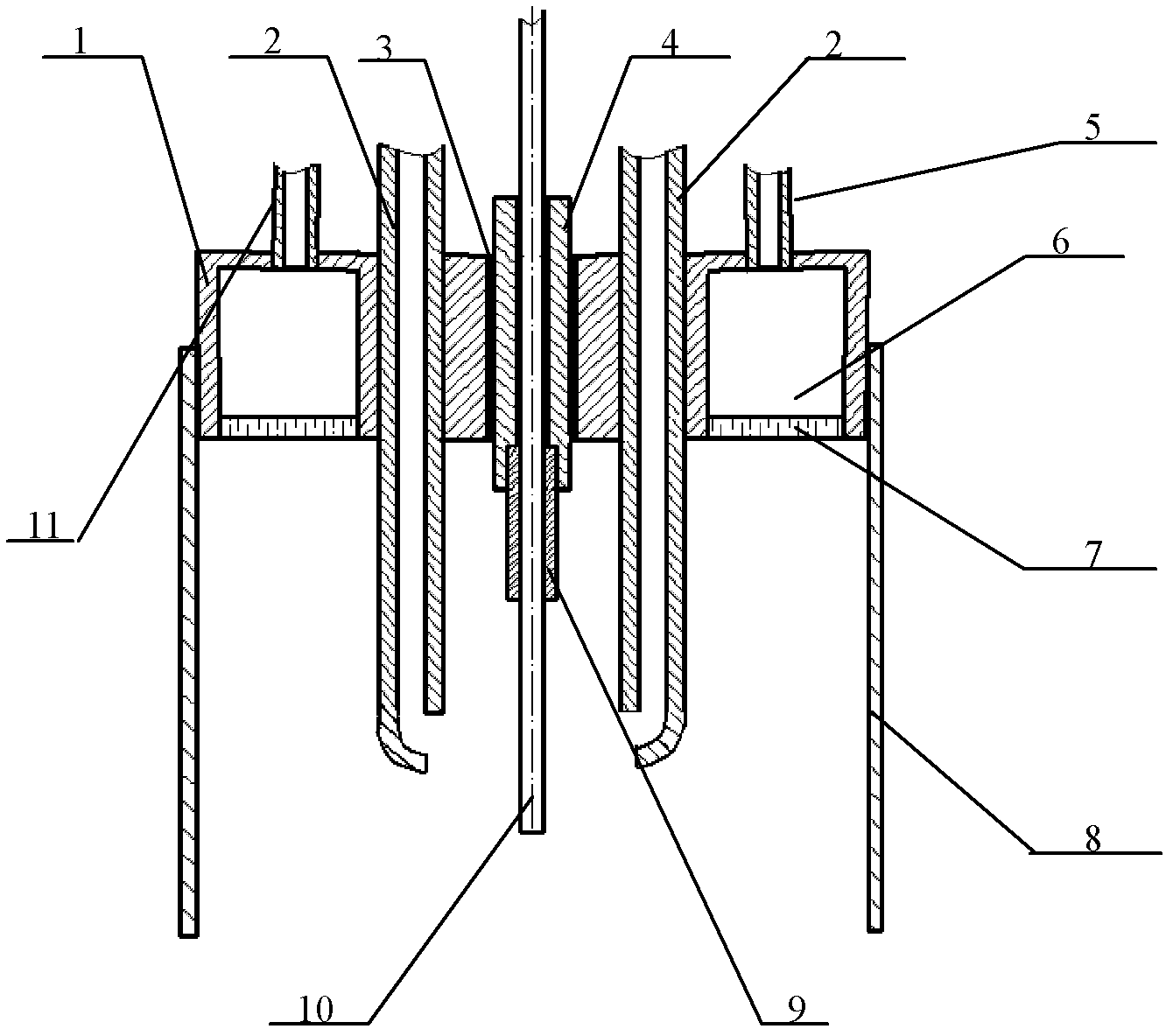

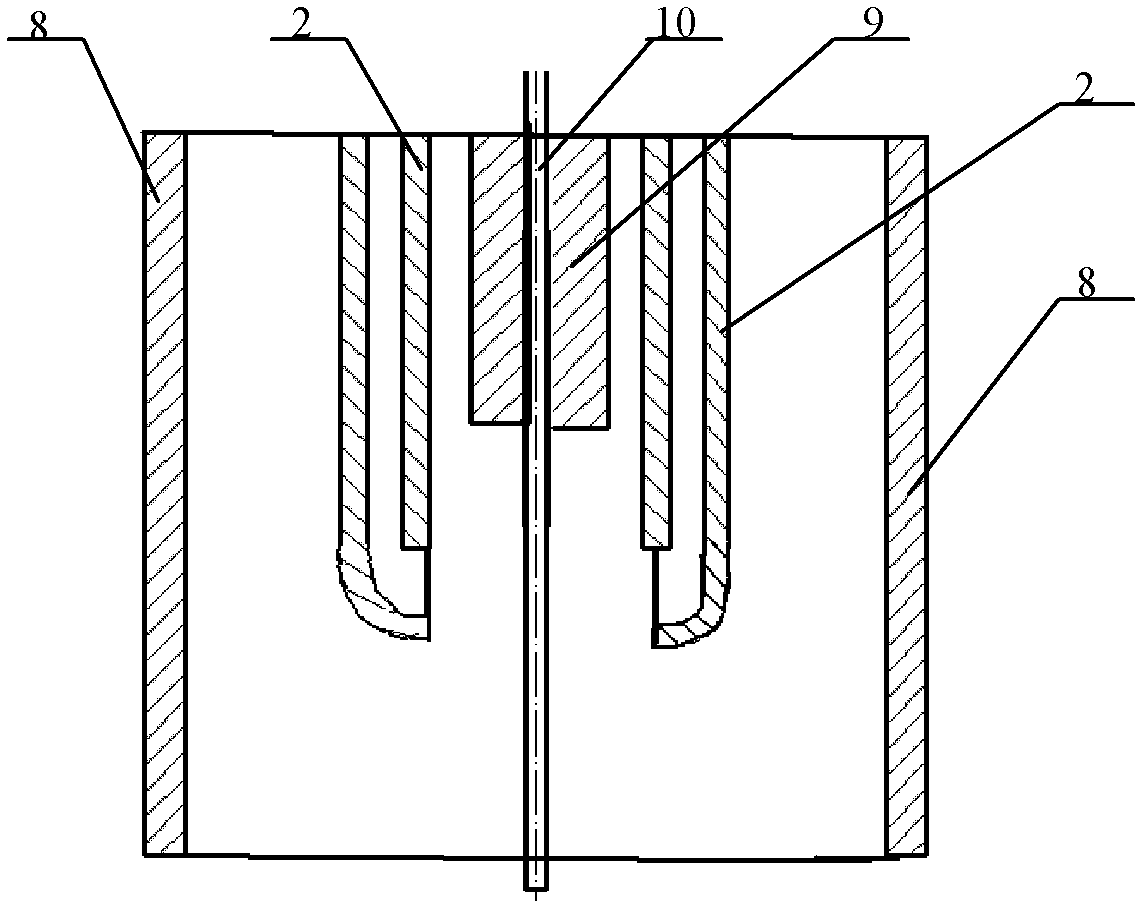

Wire feeding pen for TIG welding of argon arc welding

PendingCN111085757ASmooth wire feedingGuaranteed accuracyArc welding apparatusEngineeringMaterials science

The invention discloses a wire feeding pen for TIG welding of argon arc welding. The wire feeding pen comprise a wire feeding pen body, a ceramic nozzle, a first wire feeding guiding pipe, a pressingwire feeding mechanism, a damping check device and a second wire feeding guiding pipe, the wire feeding pen body is of a hollow rod-shaped structure, a wire installation hole is formed in the upper end of the wire feeding pen body, the ceramic nozzle is arranged at the lower end of the wire feeding pen body, the first wire feeding guiding pipe is arranged in the upper end of the wire feeding pen body, the pressing wire feeding mechanism is arranged below the first wire feeding guiding pipe in the wire feeding pen body, the damping check device is arranged at the lower end in the wire feeding pen body, and the second wire feeding guiding pipe is arranged between the pressing wire feeding mechanism and the damping check device in the wire feeding pen body. The wire feeding pen is simple in structure, simple in operation and convenient to carry, effective control of wire feeding length can be achieved, convenient control of wire feeding angle is achieved, the operation difficulty of operators is reduced, the welding quality is ensured, and the welding efficiency is improved.

Owner:孙栋波

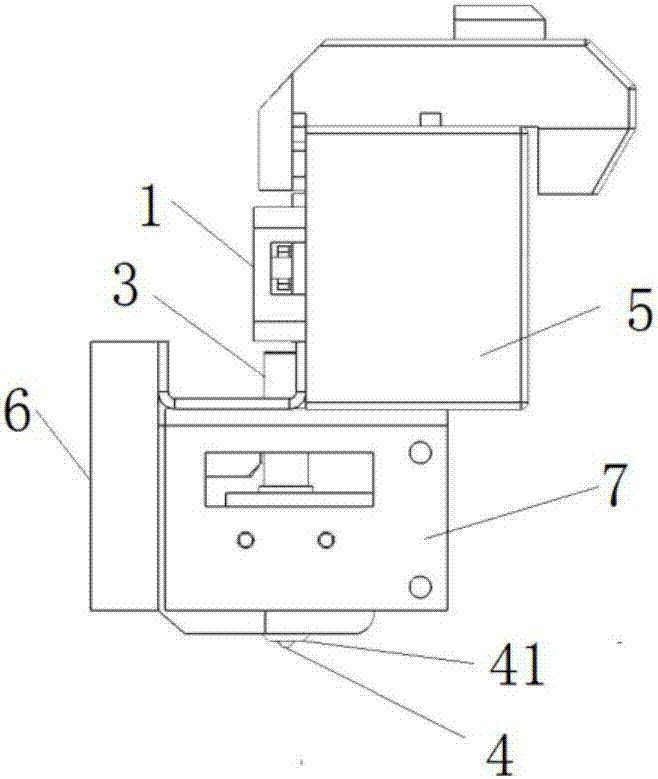

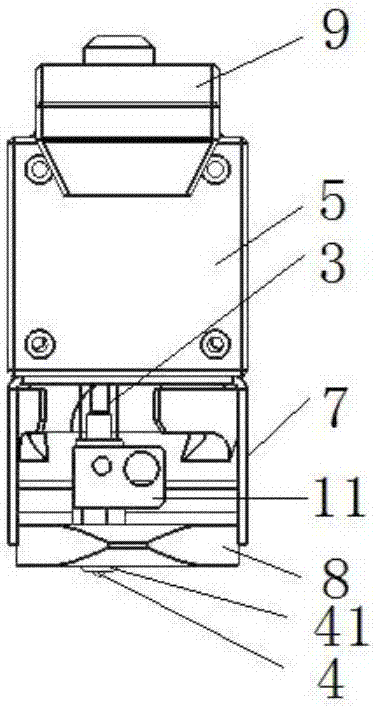

Spray head of 3D printer

PendingCN107244067AControl heat transferSmooth wire feedingManufacturing heating elements3D object support structuresProcess engineeringElectrical and Electronics engineering

The invention relates to the technical field of 3D printing, in particular to a spray head of a 3D printer. The spray head comprises a feeding structure, a liquefier and a shower nozzle, wherein the feeding structure is connected with the liquefier by means of a transfer passage; the lower part of the liquefier is connectd with the shower nozzle; and a protection nozzle sleeves the shower nozzle. Through adoption of the design that the feeding structure is connected with the liquefier by means of the transfer passage, heat conduction is effectively controlled, and smooth wire feeding is ensured; the spray head is simple in structure and convenient to use; and by combination between the protection nozzle and the shower nozzle, after the shower nozzle works for a long time for printing, the condition that materials are stuck and carbonized on the spray head is effectively reduced.

Owner:WUXI TIERTIME TECH CO LTD

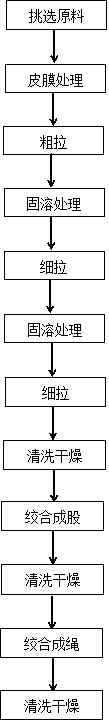

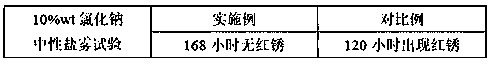

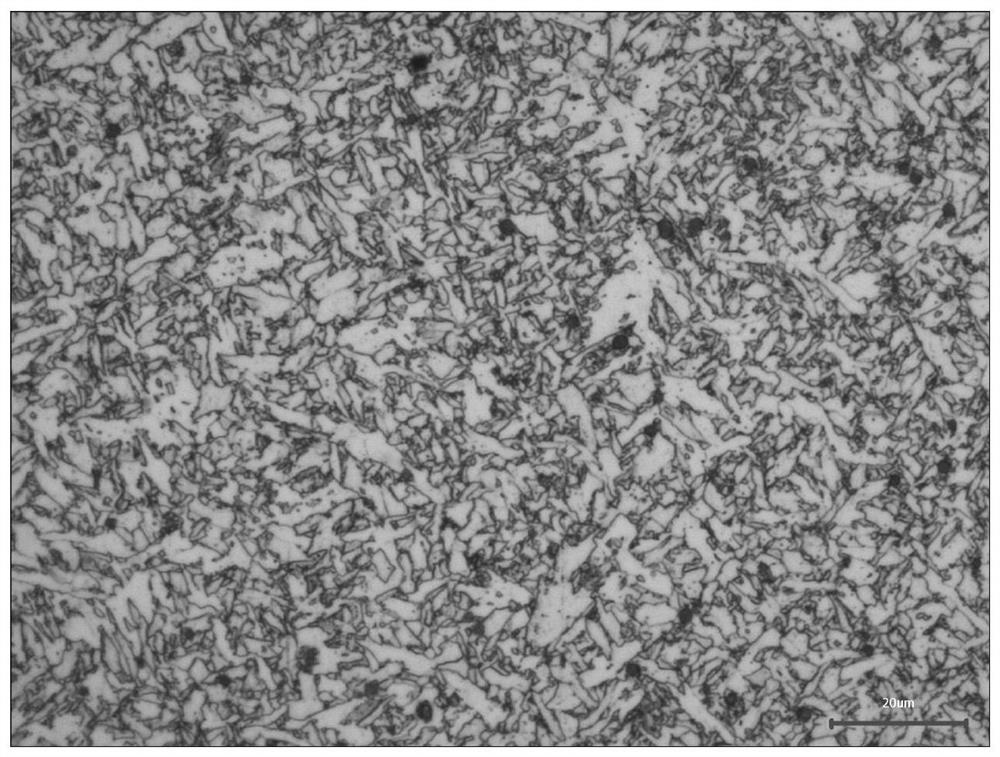

Production process for multiple stranded electrodes for maritime work

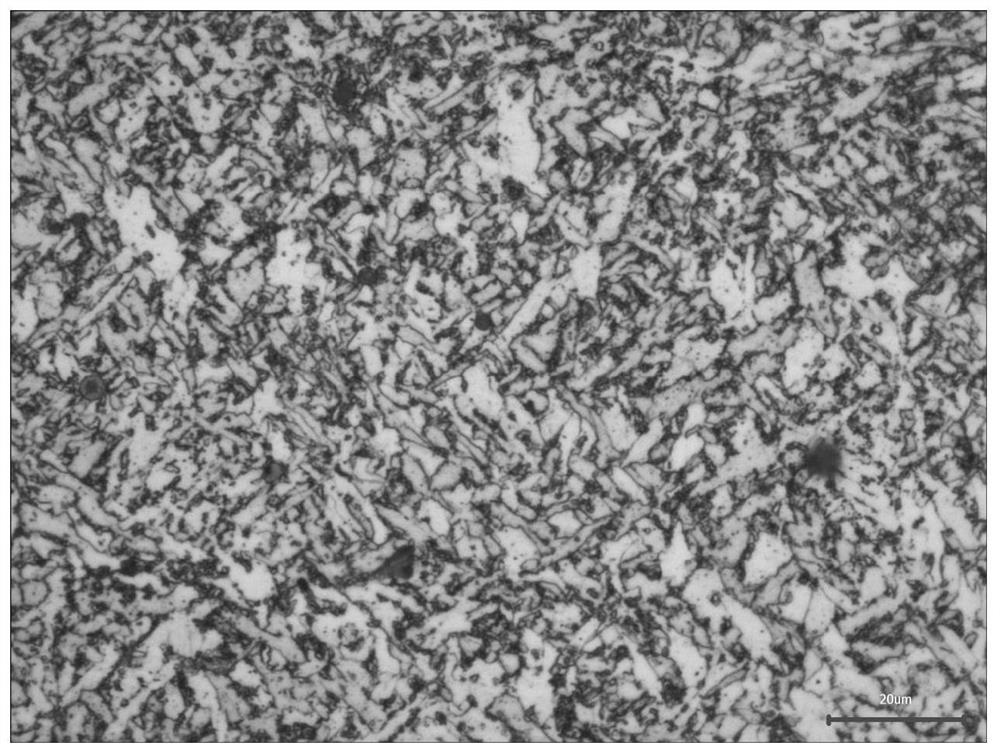

ActiveCN111015018AHigh welding process matchingConsistent qualityWelding/cutting media/materialsSoldering mediaSolution treatmentManufactured material

The invention relates to a production process for multiple stranded electrodes for maritime work. The production process comprises the following steps: skin film treatment, rough drawing, solid-solution treatment, fine drawing, cleaning and drying, stranding, and rope twisting, wherein single strand of the multiple stranded electrodes is formed by spirally twisting multiple peripheral monofilaments around a central filament, and multiple stranded electrodes are spirally twisted from single strands around the center; in a welding process, the multiple stranded electrodes, compared with a singlestranded electrode, can feed filaments to a weld pool quicker, so that a spiral arc is formed by automatic rotation, and therefore, the weld pool is stirred in real time, and refining of welding seamcrystal and escape of gas in welding seams are facilitated. Meanwhile, on the basis of controlling chemical components of a welding wire raw material, the surface quality and cleanliness of the multiple stranded electrodes produced by the process are basically consistent with those of single stranded electrode, so that use requirements of a marine environment can be met.

Owner:JIANGYIN FASTEN STAINLESS STEEL PROD CO LTD +1

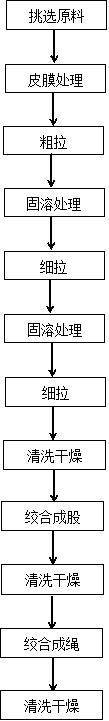

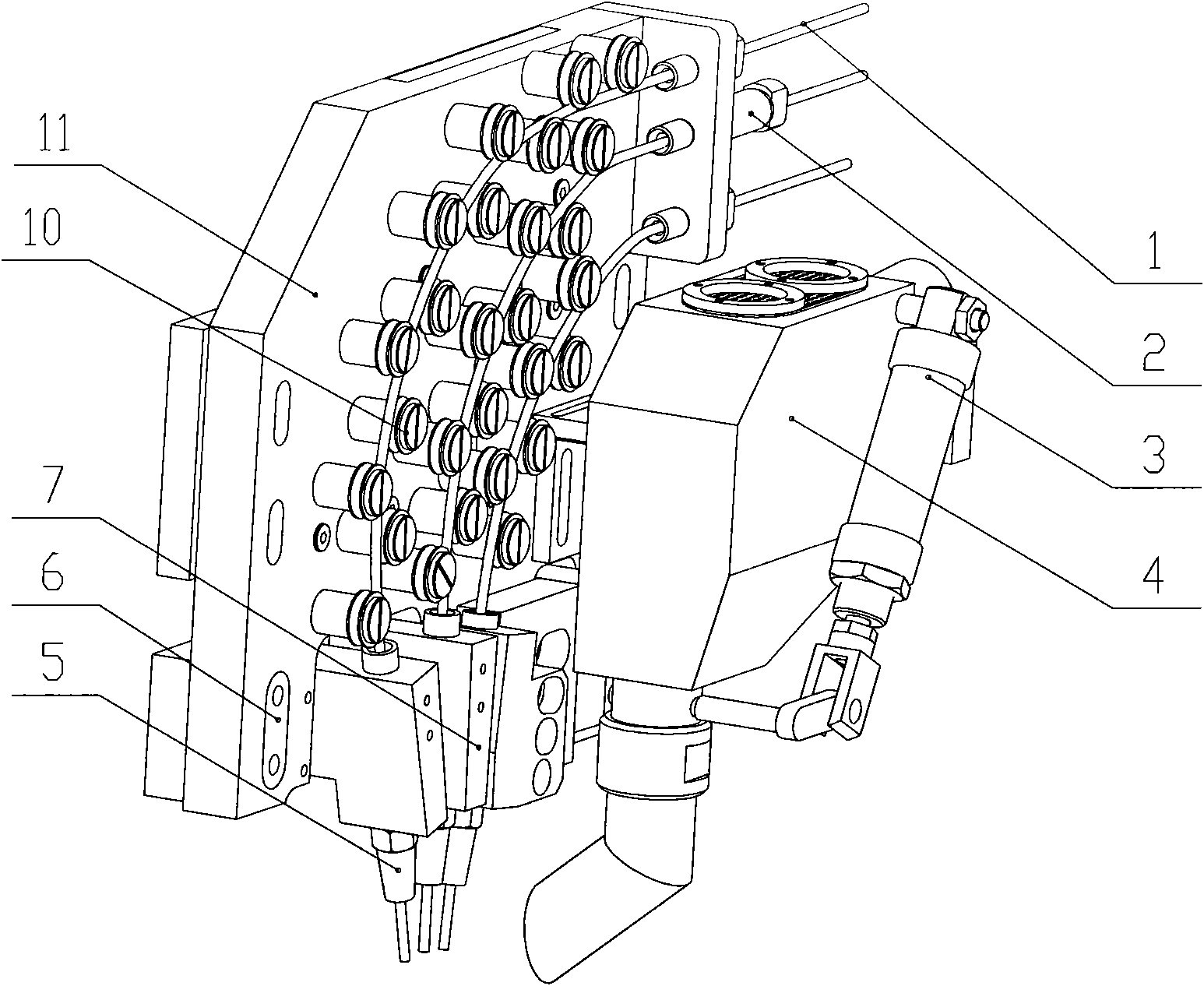

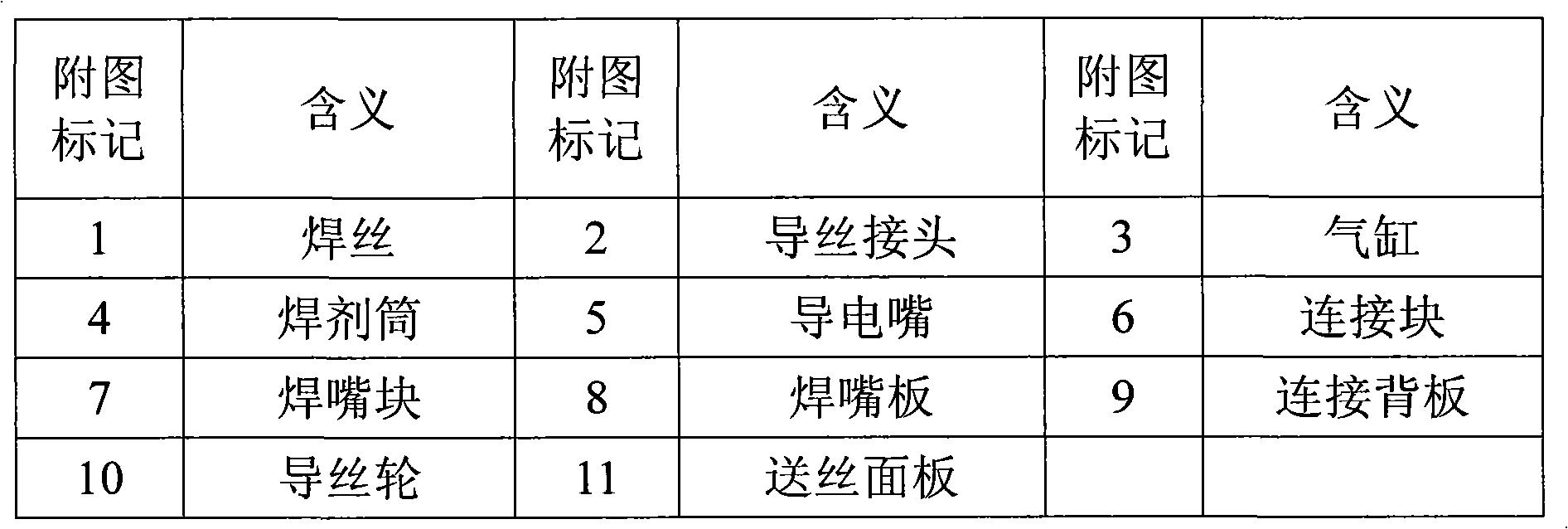

Steel tube multiple-wire internal welding machine nose

InactiveCN101837532AShorten the lengthSolve the problem of internal weldingWelding/cutting auxillary devicesAuxillary welding devicesButt jointEngineering

The invention provides a steel tube multiple-wire internal welding machine nose comprising a soldering flux cylinder, a wire feeding panel, wire guide wheels and contact tubes, wherein a plurality of wire guide wheels are regularly distributed on the front side of the wire feeding panel to form a plurality of wire guide channels, a connection rear panel is lined at the back side of the wire feeding panel, and the wire guide wheels are fixed with the connection rear panel after passing through the wire feeding panel; a wire guide connector is arranged on the wire feeding panel, a welding nozzle plate is connected under the wire feeding panel, the welding nozzle plate is respectively welded with welding nozzle blocks, each welding nozzle block is internally connected with a contact tube by threads, and the upper port of each contact tube is in butt joint with the wire guide channels. In addition, the soldering flux cylinder is arranged on the wire feeding panel, a discharging hole of the soldering flux cylinder just faces to the lower ports of the contact tubes. The device can realize large straight seam welding of a small internal diameter steel pipe and is worthy of being widely popularized and applied in the industry.

Owner:SUZHOU WEIDA WELDING & CUTTING TECH

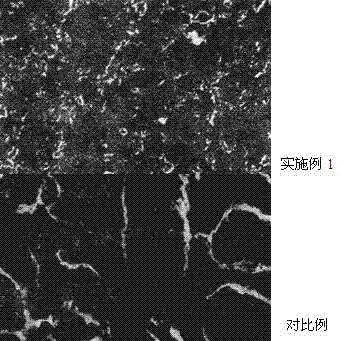

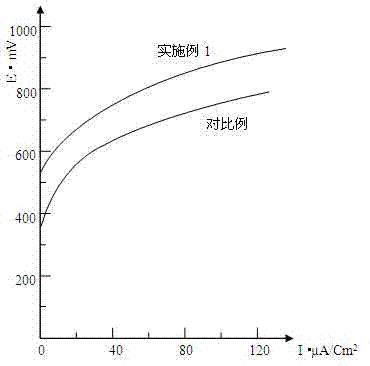

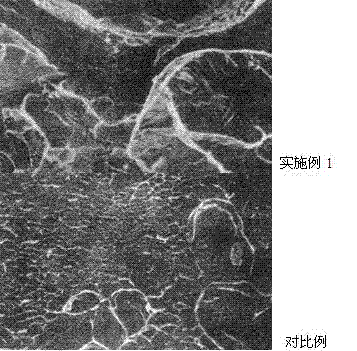

Austenitic stainless steel

InactiveCN102732803AStable mechanical propertiesImprove pass rateWelding/soldering/cutting articlesWelding apparatusCrazingSS - Stainless steel

The invention provides an austenitic stainless steel, which comprises the following components by mass percent (wt%): no greater than 0.08 of C, 0.5-1.0 of Si, less than or equal to 0.80 of Mn, less than or equal to 0.030 of P, less than or equal to 0.018 of S, 19-21 of Cr, 10.0-12 of Ni, 2.5-3.0 of Mo, 0.6-1.0 of Ti, 0.6-0.9 of Nb and the balance of Fe; according to the austenitic stainless steel, 0.6-0.9 of Nb, 0.6-1.0 of Ti and 2.5-3.0 of Mo are added, thereby the intergranular corrosion resistant ability can be effective improved, the satisfied pitting corrosion resistance performance is difficult to obtain even the Cr content is high if the stainless steel contains no Mo, Mo can perform the effect only in the Cr steel, The capability for increasing the pitting corrosion resistance performance by Mo in the austenitic stainless steel is 3 times than that of Cr, and the strength and the high temperature mechanical property of the stainless steel can be enhanced and improved. The flyer energy welding, the rapid cooling and multilayer welding with low interlayer temperature are used for ensuring the welding line to contain a proper amount of ferrite, thereby the generation of the hot crack can be prevented.

Owner:JIANGSU XINGHAI SPECIAL STEEL

Equipment for scraping surface of aluminum soldering material

ActiveCN102784969BSimple structureEasy to manufactureWelding/cutting media/materialsSoldering mediaSoldering processPetroleum engineering

The invention relates to equipment for scraping the surface of an aluminum soldering material. The equipment comprises a rack; a straightening wheel assembly, a scraping assembly and a rolling-drawing assembly are sequentially arranged on the rack; the scraping assembly comprises a compression part, a scraping part and a cutting tool for cutting sweeps located between the compression part and the scraping part; the compression part comprises a compression die and a compression die fixing device; the compression die is provided with a compression hole; the scraping part comprises a scraping die and a scraping die fixing device; a scraping hole is arranged in the scraping die; and the compression hole and the scraping hole are coaxially arranged. The equipment for scraping the surface of the aluminum soldering material provided by the invention has the advantages of simple structure and easiness of manufacturing; and the defects of surface hollows, surface scraps and the like, caused by the aluminum soldering material in production, can be overcome, so that the surface of the soldering material is smooth. Therefore, wires can be enabled to be fed smoothly in a soldering process, and the welding quality is improved.

Owner:哈焊所华通(常州)焊业股份有限公司

Flux-cored welding wire for steel welding for large heat input welding, its preparation method and welding method

ActiveCN110773905BImprove welding effectGrain refinementArc welding apparatusWelding/cutting media/materialsShielding gasCarbon steel

Owner:北京奥邦新材料有限公司

Roller overlaying powder with thin-layer slag protection

InactiveCN102615449BReduce the cost of updatesLow costWelding/cutting media/materialsSoldering mediaSlagThin layer

The invention discloses a roller overlaying powder with thin-layer slag protection. The roller overlaying powder is prepared by uniformly mixing an alloy with a slagging arc stabilizer, wherein the content of the alloy is 88-92 wt% and the content of the slagging arc stabilizer is 12-8 wt%. The powder provided by the invention is applied to a welding cabinet with double functions of powder feeding and air supply, so that a layer of thin slag with a thickness which is not more than 0.5 mm is formed on the surface of a furnace hearth to improve the effect of forming a weld joint. Multilayer welding can be carried out in a welding process without cleaning slag, so that the welding efficiency is improved.

Owner:SHANDONG UNIV

A kind of high-quality welding wire steel wire rod and its production method

ActiveCN108393614BRealize the role of protective weldingPrevent splashWelding/cutting media/materialsSoldering mediaWire rodMaterials science

The invention discloses a high-quality welding wire steel wire rod and a production method thereof. The high-quality welding wire steel wire rod comprises 0.05-0.07% of C, 0.85-0.95% of Si, 1.45-1.65%of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.010% of S, smaller than or equal to 0.010% of Al, 0.0001-0.0004% of Ca, smaller than or equal to 0.0040% of N, smaller than orequal to 0.0030% of O and the balance Fe and inevitable impurities. The content of calcium in the produced wire rod is not larger than 0.0004%, and in the welding process, and the metal splashing ratedoes not exceed 1.0%; and after a welding wire steel wire rod produced by adopting a common process is machined into a welding wire, the metal splashing rate is 3.2% or so, and the splashing rate inthe welding process is remarkably reduced. The welding cost can be reduced easily, it is guaranteed that wire feeding is smooth, electric arc combustion is stable, and a gas protecting welding effectis achieved very well.

Owner:ANGANG STEEL CO LTD

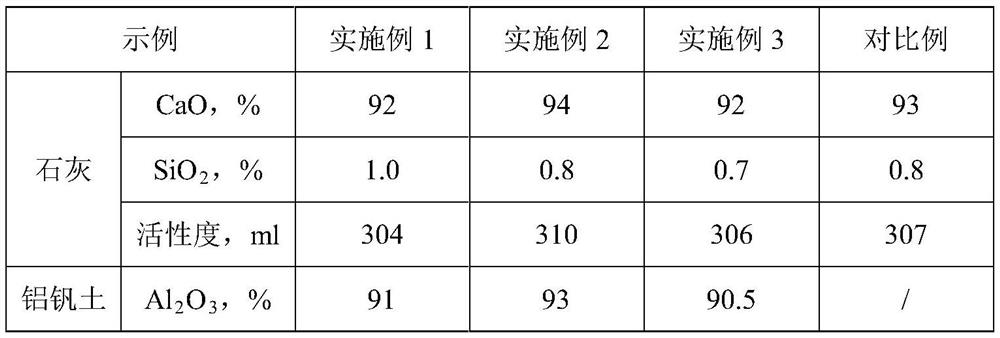

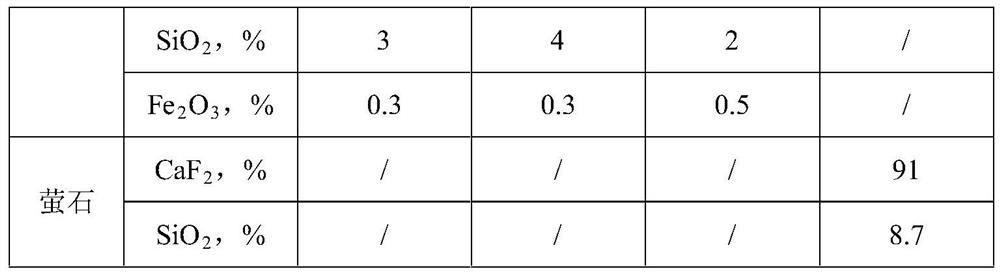

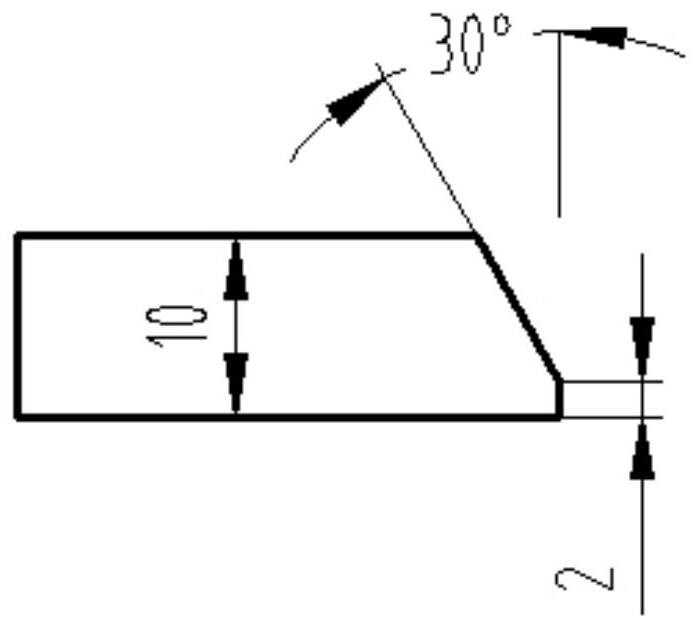

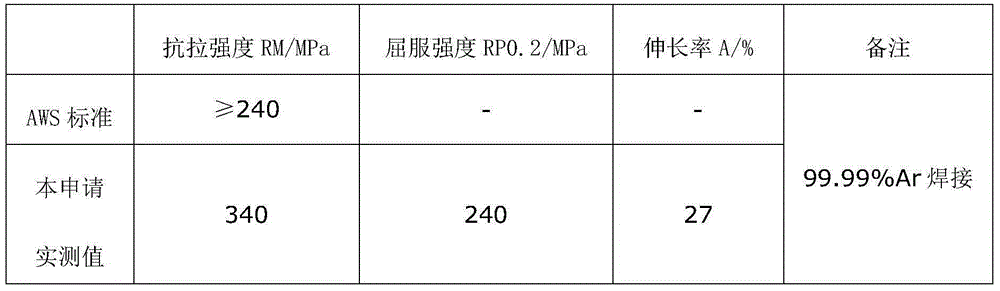

Welding method of thin-wall high-strength steel plate

The invention relates to a welding method of a thin-wall high-strength steel plate. The welding method comprises the steps that 1) welding materials are selected, specifically consumable electrode gasshielded welding materials are adopted; 2) the preheating temperature is determined through a Y-groove cracking test, wherein the reference standard is CB / T4364-2013; 3) the steel plate is cut and blanking is performed; 4) groove machining is conducted, specifically, the cutting parts of base metal are polished to remove cracks or heat affected zones left after cutting, and then regular Y-shapedgrooves are machined in the two pieces of base metal, wherein the regular Y-shaped grooves are 60-degree grooves, and the truncated edges are 2 mm; 5) the base metal is preheated before welding, specifically, steel is preheated according to the preheating temperature determined in the step 2); 6) test pieces are spliced, specifically, a truncated edge gap is controlled to be 0-0.2 mm; 7) welding is conducted, specifically, the temperature of the base metal is uniformized through a cooling device, welding is conducted in a front-back face welding mode, back gouging is conducted thoroughly in acarbon arc gouging mode after front-face welding is completed, and then back-face welding is conducted; 8) postweld heat treatment is conducted, specifically, hydrogen elimination is conducted; and 9)flaw detection of a welded joint is performed. According to the welding method of the thin-wall high-strength steel plate, the problems that the thin-wall steel plate is prone to deformation in the welding process, and the heat affected zones are prone to softening when high heat input welding is adopted are solved.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Steel welding flux-cored wire used for high heat input welding and preparing method and welding method of steel welding flux-cored wire

ActiveCN110773905AImprove welding effectGrain refinementArc welding apparatusWelding/cutting media/materialsShielding gasCarbon steel

The invention belongs to the technical field of welding machining materials and particularly relates to a steel welding flux-cored wire used for high heat input welding and a preparing method and a welding method of the steel welding flux-cored wire. The flux-cored wire comprises a flux-cored material and a carbon steel belt sheath wrapping the flux-cored material. The flux-cored material comprises C, Si, Mn, Ni, B, Ti, Nb, N and the balance Fe and inevitable impurities. The preparing method includes the steps of material mixing, wet mixing and heat treatment, drying and smashing and welding wire forming. The welding method includes the step that CO2 and Ar mixed gas is adopted as welding shield gas. Single-substance materials are adopted in the flux-cored wire to serve as the components of the flux-core material, before welding operation, stability of the flux-cored material is better, and the welding effect is more stable.

Owner:北京奥邦新材料有限公司

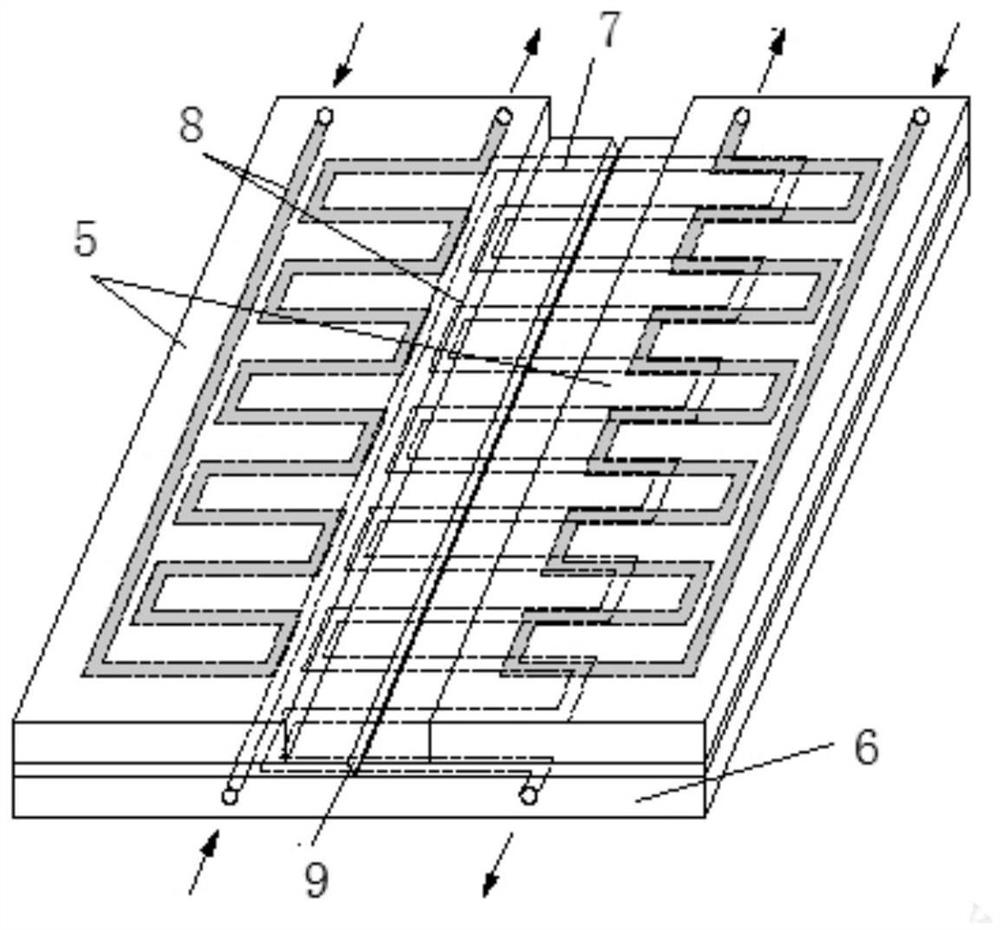

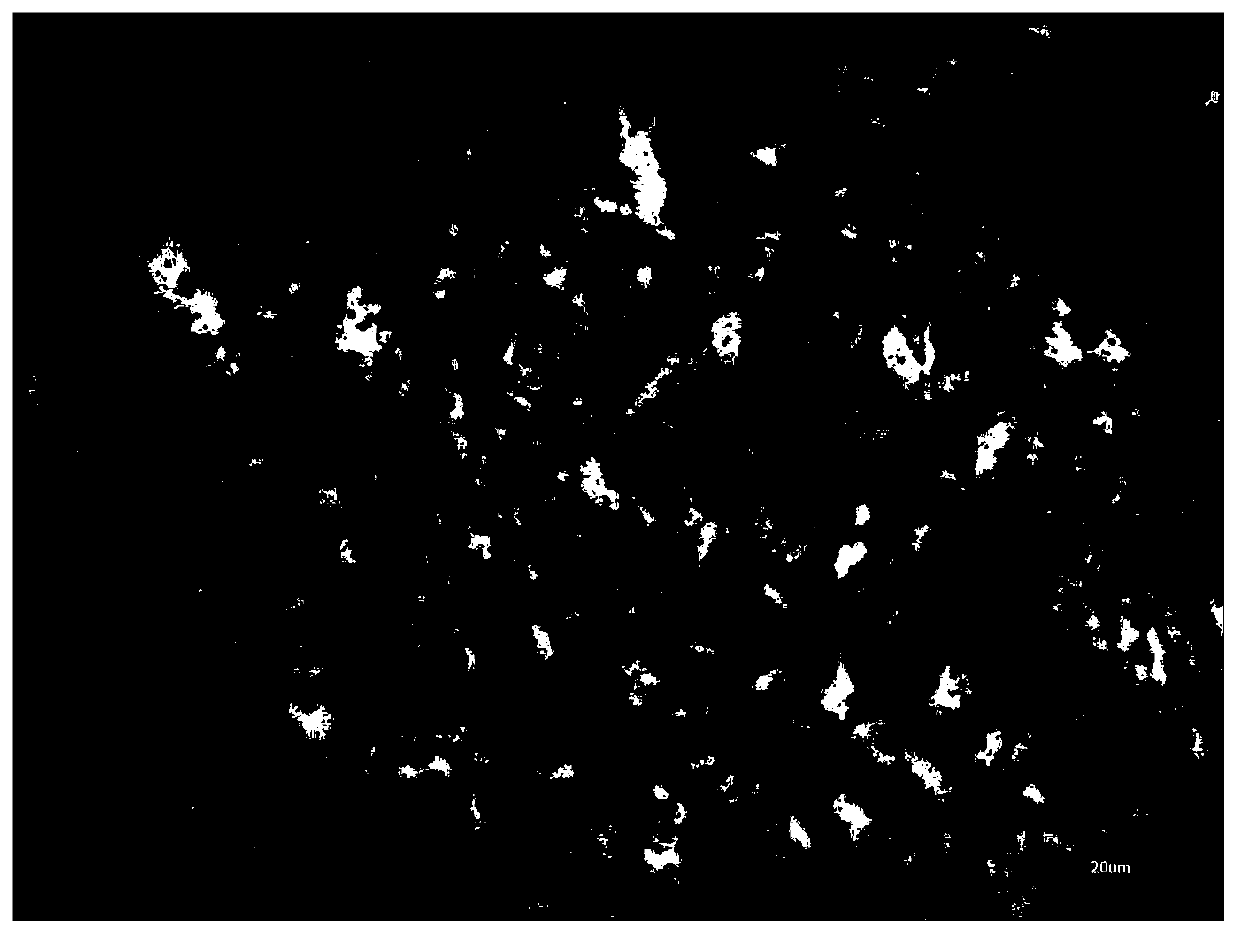

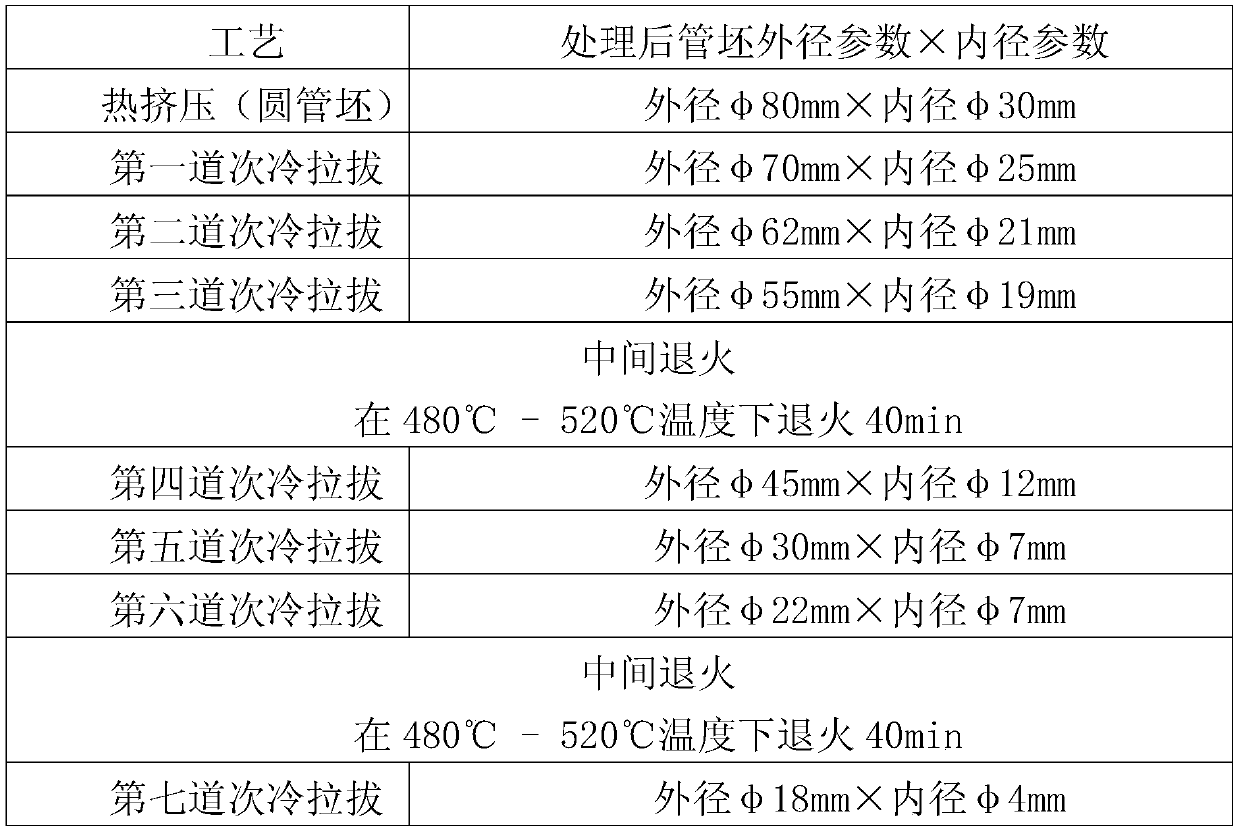

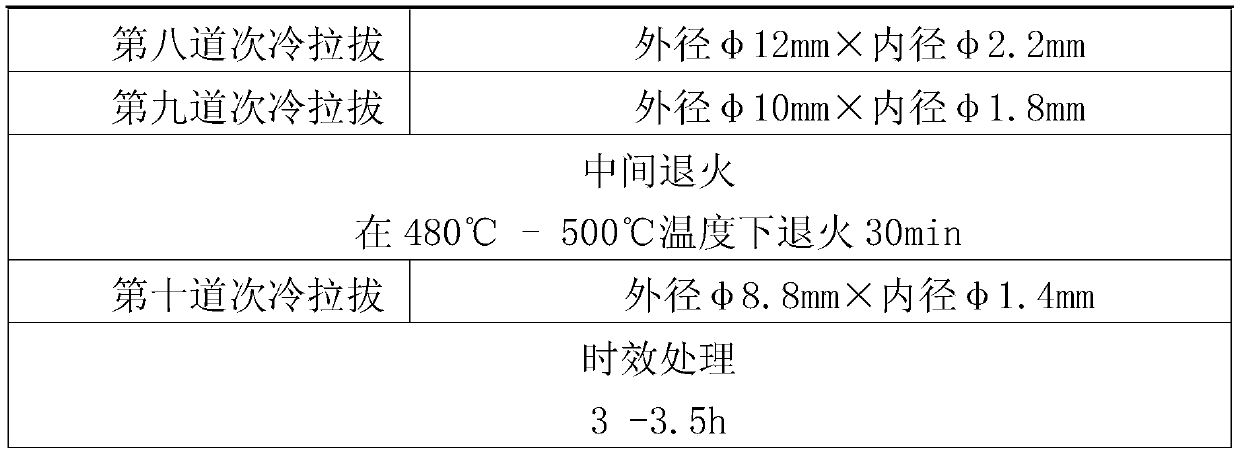

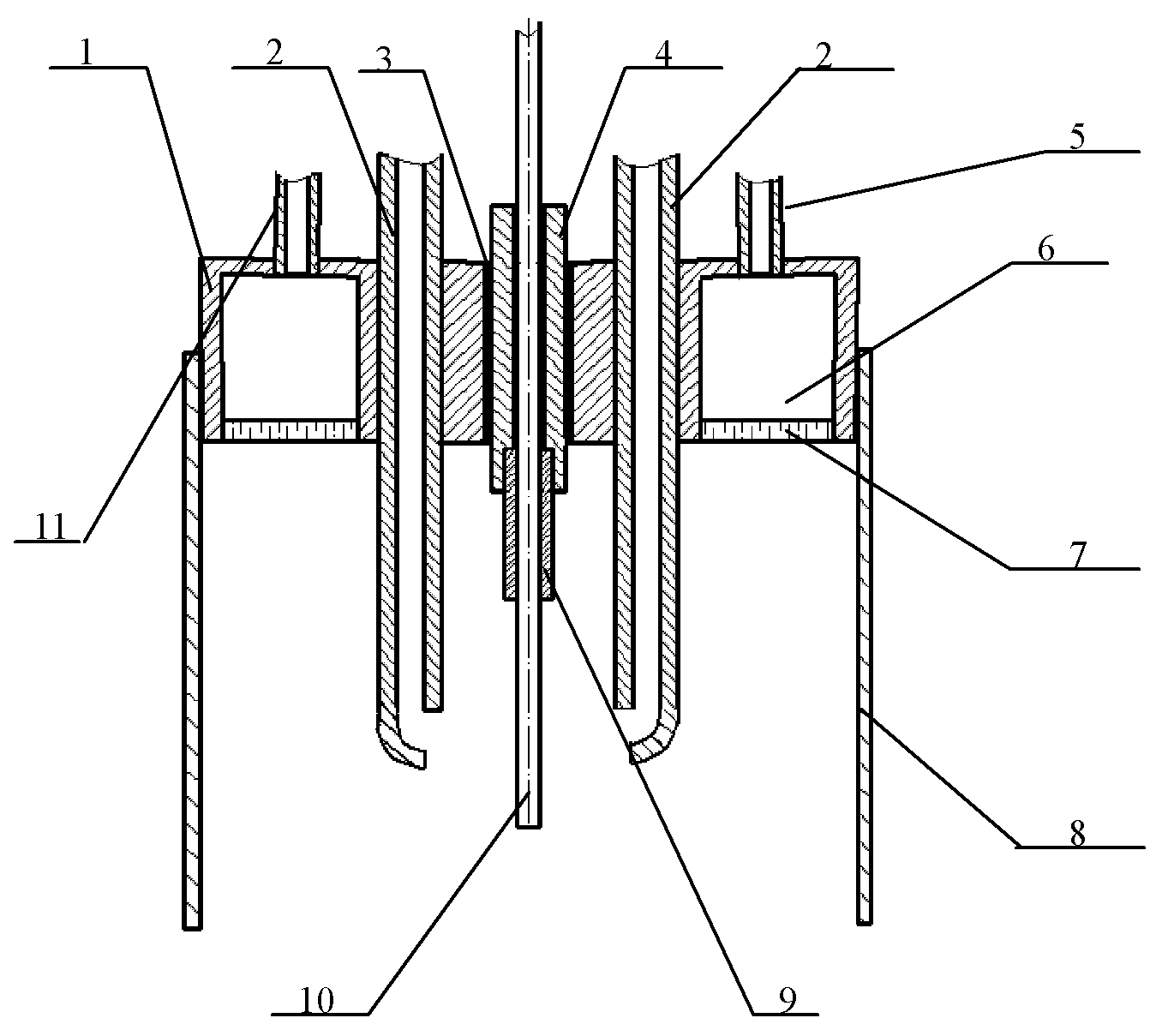

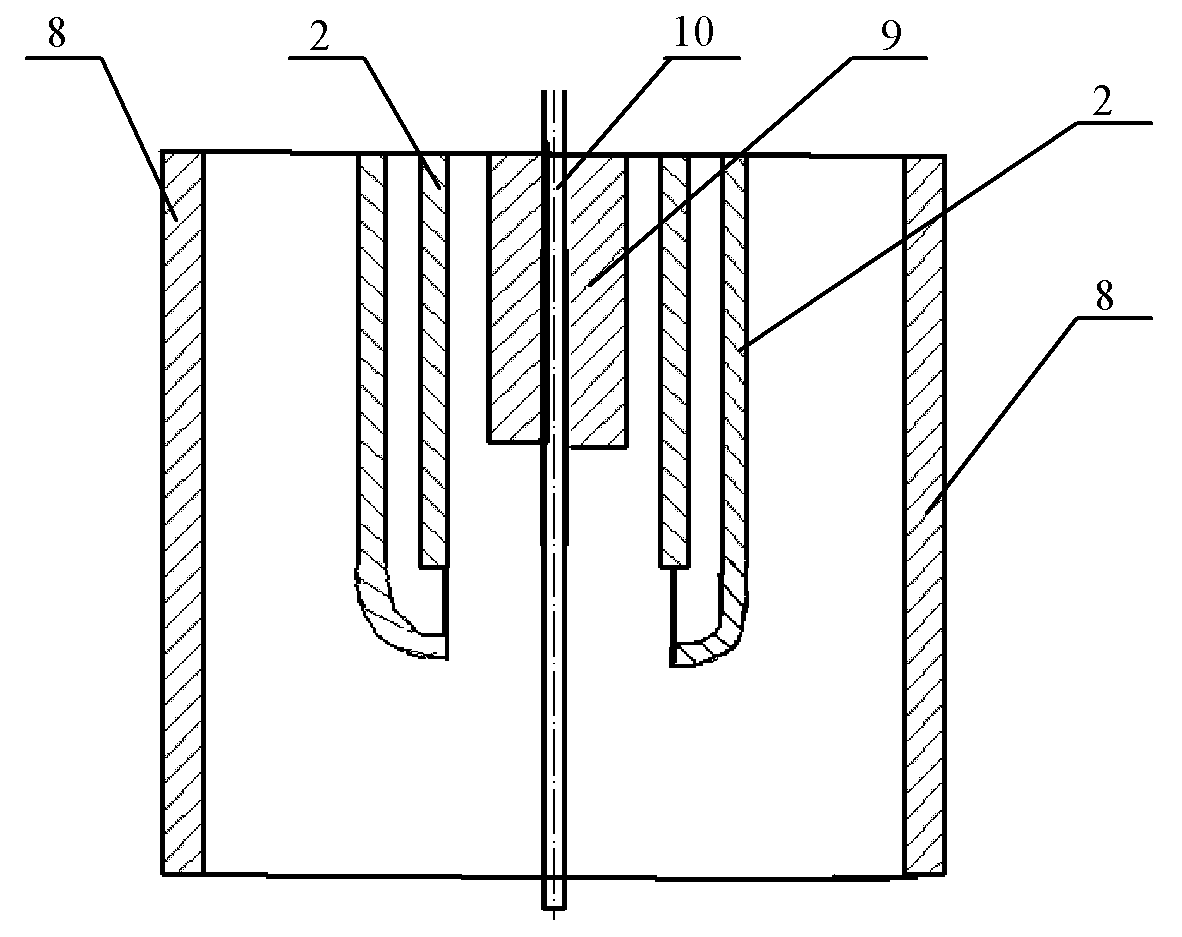

A processing method of chromium-zirconium copper microporous tube and chromium-zirconium copper microporous tube

ActiveCN109201769BSimple processReduce manufacturing costFurnace typesHeat treatment furnacesShielding gasIngot

The invention relates to a machining method of a chromium-zirconium-copper microporous tube. The machining method comprises the following steps that S1, copper, chromium and zirconium are mixed according to chemical composition requirements, smelting is conducted after preparation, and a solid circular ingot is formed by casting, the solid circular ingot is subjected to component testing, metal defect detecting and surface detecting, and the solid circular ingot is sawed into sections when qualified; S2, the sawed solid circular ingot is subjected to hot extrusion to obtain round tube blanks with the outer diameter of 80mm and the inner diameter of 30mm; S3, the round tube blanks are stretched for 10 times through a straight drawing machine to form microporous tube blanks, and each stretching has a matching external drawing die and internal drawing die; and S4, the microporous tube blanks are loaded in a furnace pipe of a horizontal annealing furnace, the furnace pipe of the horizontalannealing furnace is vacuumized, and is filled with protection gas to conduct aging treatment to the microporous tube blanks, wherein the aging treatment temperature is 420-450 DEG C, and the aging treatment time is 3-3.5 hours, and the material temperature of the microporous tube blanks is lower than 60 DEG C when the microporous tube blanks are taken out of the furnace.

Owner:HEBEI OUTONG NONE FERROUS METAL PROD

Special powder for welding torch with functions of conveying powder and delivering gas

InactiveCN102601545BReduce splashArc stabilizationElectrode supporting devicesWelding/cutting media/materialsPotassiumRare earth

The invention discloses special powder for a welding torch with functions of conveying powder and delivering gas. The special powder comprises powder materials including, by weight, from 20 to 35 parts of rutile, from 5 to 8 parts of potassium feldspar, from 0 to 3 parts of potassium titanate, from 0 to 5 parts of sodium fluorosilicate, from 0 to 2 parts of sodium fluoride, from 0 to 8 parts of ferrotitanium and from 0 to 6 parts of cerium oxide rare earth (CeO2), wherein the powder materials are uniformly mixed to prepare the powder. By means of using the powder with the welding torch with the functions of conveying powder and delivering gas and delivering the shielding gas to a welding zone, purposes of stabilizing electric arc during welding and reducing splashing during high-current gas shielded welding can be realized. Besides, the raw materials of the powder can be obtained easily, cost is low, and the special powder can be prepared and popularized easily.

Owner:SHANDONG UNIV

Submerged arc welding wire of high tensile pipeline steel

ActiveCN101905391BHigh yield strengthQuality improvementArc welding apparatusPipeline systemsCrack resistanceHigh intensity

The invention discloses a submerged arc welding wire of a high tensile pipeline steel. The welding wire material comprises the following chemical components in percentage by weight: not more than 0.10 of C, not more than 0.6 of Si, 1.3-1.8 of Mn, 1.4-2.5 of Ni, 0.25-0.55 of Mo, not more than 0.12 of Ti, not more than 0.05 of V, not more than 0.35 of Cr, 0.0005-0.005 of B, not more than 0.015 of S, not more than 0.015 of P, and the balance of Fe and other inevitable impurities. The submerged arc welding wire of the high tensile pipeline steel provided by the invention has the yield strength of deposited metals of more than 690MPa and the tensile strength of more than 785MPa, has attractive welding formation, high intensity, high flexibility and high crack resistance without defects of cracking, undercut and the like, and has favorable matching effect with X100 level pipeline steel plates, and meets the requirement on the welding of oil-gas transmission pipelines under the condition of higher pressure.

Owner:YICHANG MONKEY KING WELDING WIRE

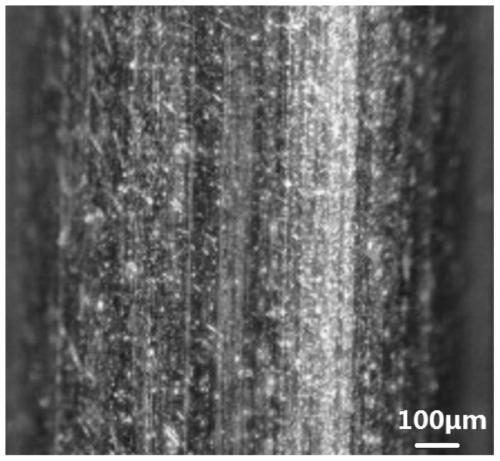

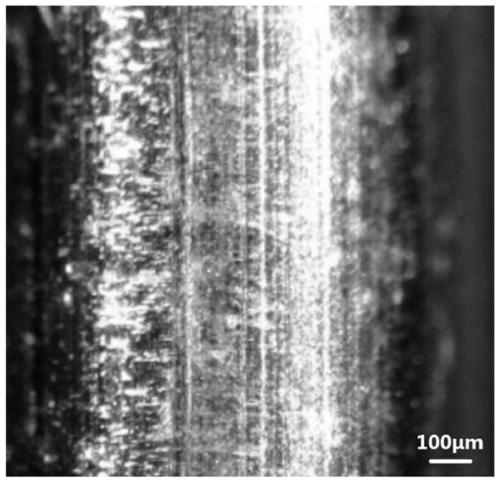

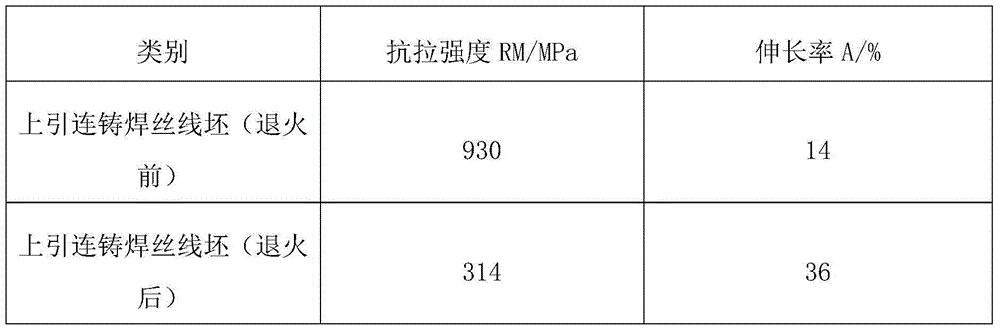

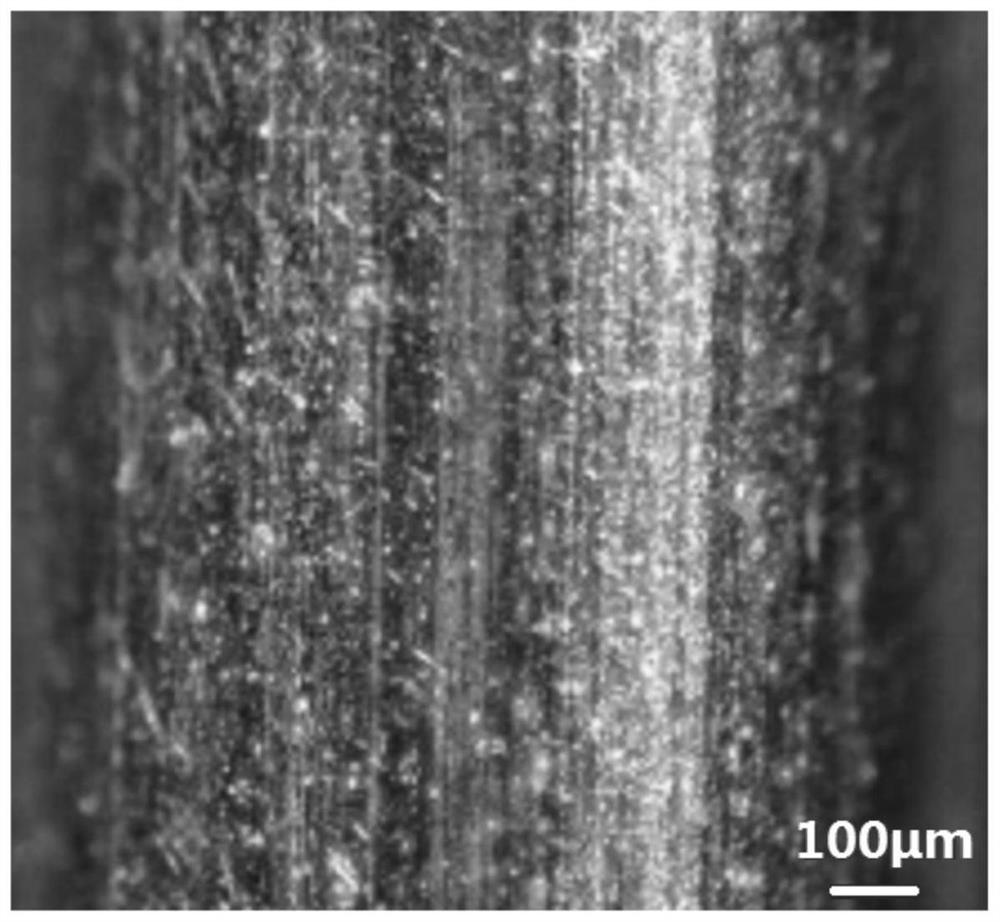

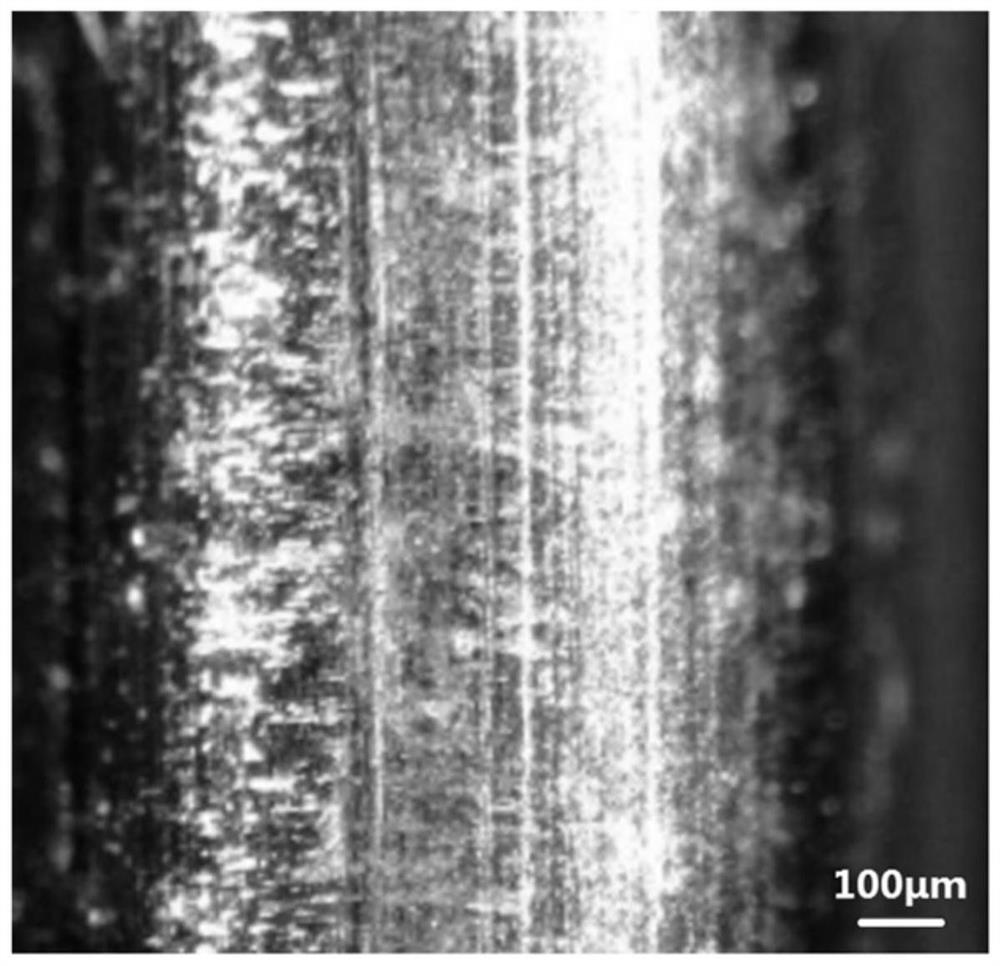

A kind of preparation method of tin bronze welding wire

ActiveCN102941417BQuality improvementLow impurity oxygen contentWelding/cutting media/materialsSoldering mediaWeld seamMechanical property

The invention discloses a tin bronze welding wire and a preparation method thereof, which belong to the field of nonferrous metallurgy and processing. The welding wire comprises the following components of Zn, Sn, Fe, Al, Pb and P, and the remaining component is Cu. The preparation method comprises the following steps in sequence that the components are prepared in accordance with the proportion, and a welding wire blank is manufactured through up-drawn continuous casting; annealing treatment is performed on the welding wire blank, and then the welding wire blank is air cooled to room temperature; cold rolling is performed on the welding wire blank; the annealing treatment is performed again; pickling and drawing are performed; and post-treatment is performed to prepare a finished product. According to the preparation method, the efficiency of producing the welding wire blank is greatly increased; the surface of the produced welding wire blank is smooth and cannot be oxidized; internal structures are uniform; the chemical components are stable; the content of impurity elements is low; the wire blank has good mechanical property; energy consumption is reduced; the difficulty in subsequent drawing of the wire blank is reduced; additionally, smooth wire feed is protected by produced tin bronze gas in the welding process of the welding wire; the liquidity and the wettability of a molten pool are good; welding seams are not split; and the mechanical property is good.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

A surface treatment process for stainless steel flux-cored wire

ActiveCN106181135BPlay the role of moisture-proofAdapt to weldingWelding/cutting media/materialsSoldering mediaWater vaporMolecular level

The invention discloses a stainless steel flux-cored wire surface treatment process, and belongs to the field of production of welding materials. A stainless steel flux-cored wire is instantly heated firstly to remove oil dirt and wire drawing powder on the surface of the wire, and then the surface of the stainless steel flux-cored wire is coated with existing special lubricating oil for smooth wire feeding. The stainless steel flux-cored wire is instantly heated, and therefore the oil dirt and the wire drawing powder which are left on the surface of the stainless steel flux-cored wire are burnt off without damaging the flux core powder ingredients of the stainless steel flux-cored wire. The surface of the stainless steel flux-cored wire is coated with an oil film with the molecular-level thickness to achieve the aim of normal and smooth wire feeding. Due to the fact that the oil film is evenly smeared to the surface of the wire, and especially a joint of the stainless steel flux-cored wire is also coated with a small quantity of oil film, a channel allowing water vapor to enter flux core powder is thoroughly closed; and a moisture preventing function can also be achieved, and therefore the stainless steel flux-cored wire can be suitable for all-weather welding.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

A rare earth aluminum alloy wire material for 3D printing and preparation method thereof

ActiveCN110396627BImprove mechanical propertiesAvoid breakingAdditive manufacturing apparatusHigh densityComputer printing

The invention relates to a rare earth aluminum alloy wire material for 3D printing and a preparation method thereof. In the rare earth aluminum alloy wire material, the Mg content is 3-5wt%, the RE content is 0.4-1.2wt%, and the Zr content is 0.1-0.1wt%. 1.0wt%, Mn content is 0.1‑1.0wt%, Ti content is 0.05‑0.25wt%, O content≤0.05wt%, N content≤0.02wt%, H content≤0.01wt%, the balance is Al and unavoidable impurities; wherein, the ratio of the Mn content to the RE content is 0.5-1:1, and the ratio of the Zr content to the RE content is 0.2-1:1. The present invention adds rare earth and zirconium elements on the basis of the aluminum-magnesium alloy composition, refines the crystal grains, and produces Al 3 (REZr) precipitation strengthening, used for smooth wire feeding on 3D printers, not easy to break, high strength, to ensure the accuracy of product printing; printed parts have high density, good mechanical properties and corrosion resistance.

Owner:HUNAN ORIENTAL SCANDIUM

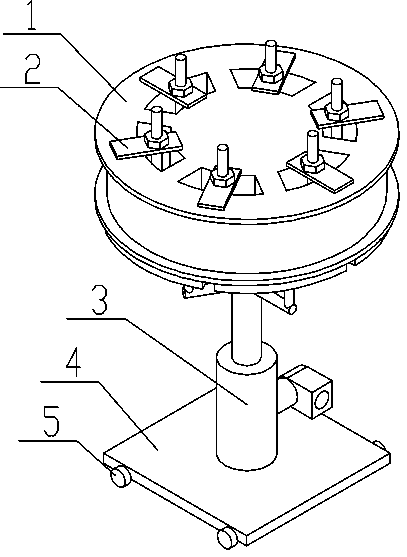

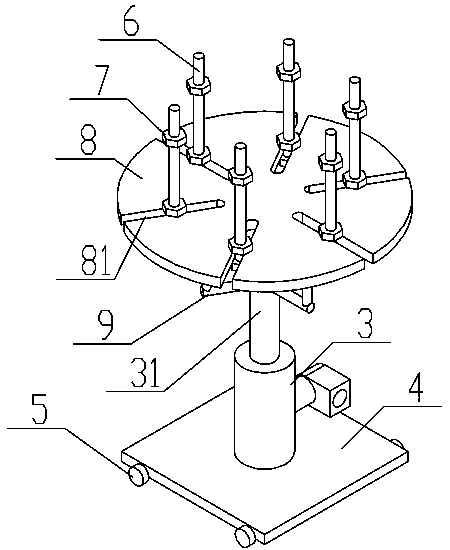

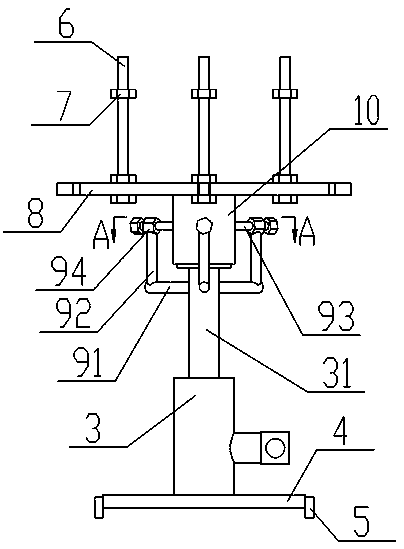

Welding wire reel frame

InactiveCN110653523AFlexible useFlexible rotation without stagnationWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsStructural engineering

The invention relates to the technical field of welding, in particular to a welding wire reel frame. The frame comprises a base, wherein a jack is arranged on the base, the top of a piston rod of thejack is provided with a sleeve through a pivotal bearing, a rotary disc is fixedly connected to the top of the sleeve, a plurality of elongated through holes are uniformly formed in the rotary disc inthe radial direction, supporting columns are mounted in the elongated through holes through bolts, and a pressing nut is arranged on each supporting column. The welding wire reel frame is smoother inwire feeding and more flexible to use.

Owner:湖北新冶金属表面处理科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com