Welding wire for submerged-arc welding of high-efficiency X100 pipeline steel and application of welding wire

A pipeline steel, submerged arc welding technology, applied in the direction of application, arc welding equipment, welding medium, etc., to achieve the effect of improving electrical conductivity, increasing strength, and easy realization of welding wire drawing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Among the present invention, the preparation method of welding wire for submerged arc welding of high-performance X100 pipeline steel, the specific steps are as follows:

[0032]Desulfurized molten iron is used to control the sulfur content of molten iron entering the furnace. Raw materials with low S and P content are selected. Converter steelmaking and top-bottom composite blowing process are used to control the C, S and P at the end of smelting at a low level. After deoxidation After alloying, use LF furnace and other refining process outside the furnace to add trace elements to smelt molten steel whose composition meets the requirements. The molten steel is fully protected and cast into continuous casting slabs by variety casting machines, and the continuous casting slabs are rolled into Φ5mm by high-speed twist-free rolling mill Wire rod, mechanical shelling of wire rod → pickling and rust removal → drying → dry wire drawing → coiling → heat treatment → dry wire dra...

Embodiment 1

[0034] In this embodiment, the welding wire steel of the present invention is smelted by an electric furnace. After smelting, the welding wire steel is drawn into a welding wire with a specification of Φ5mm, and its chemical composition (by weight percentage) is: C: 0.03wt.%, Mn: 1.6wt. %, Si: 0.2wt.%, Mo: 0.35wt.%, Ti: 0.08wt.%, B: 0.0035wt.%, Cr: 0.3wt.%, Cu: 0.25wt.%, Ni: 0.4wt.% , Nb: 0.06wt.%, S: 0.0036wt.%, P: 0.0044wt.%, and the balance is Fe. The welding wire mentioned above is used after copper plating on the surface (the thickness of the plating layer is not less than 1.25 μm).

[0035] In this embodiment, the welding wire is used in conjunction with SJ101-100 flux and X100 pipeline steel. The thickness of the X100 pipeline steel is 15mm, and the chemical composition is shown in Table 2 (the balance is Fe). The welding process parameters are: welding voltage 30V, welding current 550A, welding speed 44cm / min.

[0036] Table 2 Chemical composition of X100 pipeline st...

Embodiment 2

[0050] The difference from Example 1 is:

[0051] In this embodiment, the welding wire steel of the present invention is smelted by an electric furnace. After smelting, the welding wire steel is drawn into a welding wire with a specification of Φ5mm, and its chemical composition (by weight percentage) is: C: 0.02wt.%, Mn: 1.8wt. %, Si: 0.12wt.%, Mo: 0.35wt.%, Ti: 0.06wt.%, B: 0.0045wt.%, Cr: 0.33wt.%, Cu: 0.25wt.%, Ni: 0.48wt.% , Nb: 0.04wt.%, S: 0.0025wt.%, P: 0.0033wt.%, and the balance is Fe. The welding wire mentioned above is used after copper plating on the surface (the thickness of the plating layer is not less than 1.25 μm).

[0052] In this embodiment, the mechanical properties and impact properties of the welding wire deposited metal are shown in Table 6 and Table 7.

[0053] Table 6 Mechanical properties of welding wire deposited metal

[0054]

[0055] Table 7 Impact properties of welding wire deposited metal / J

[0056]

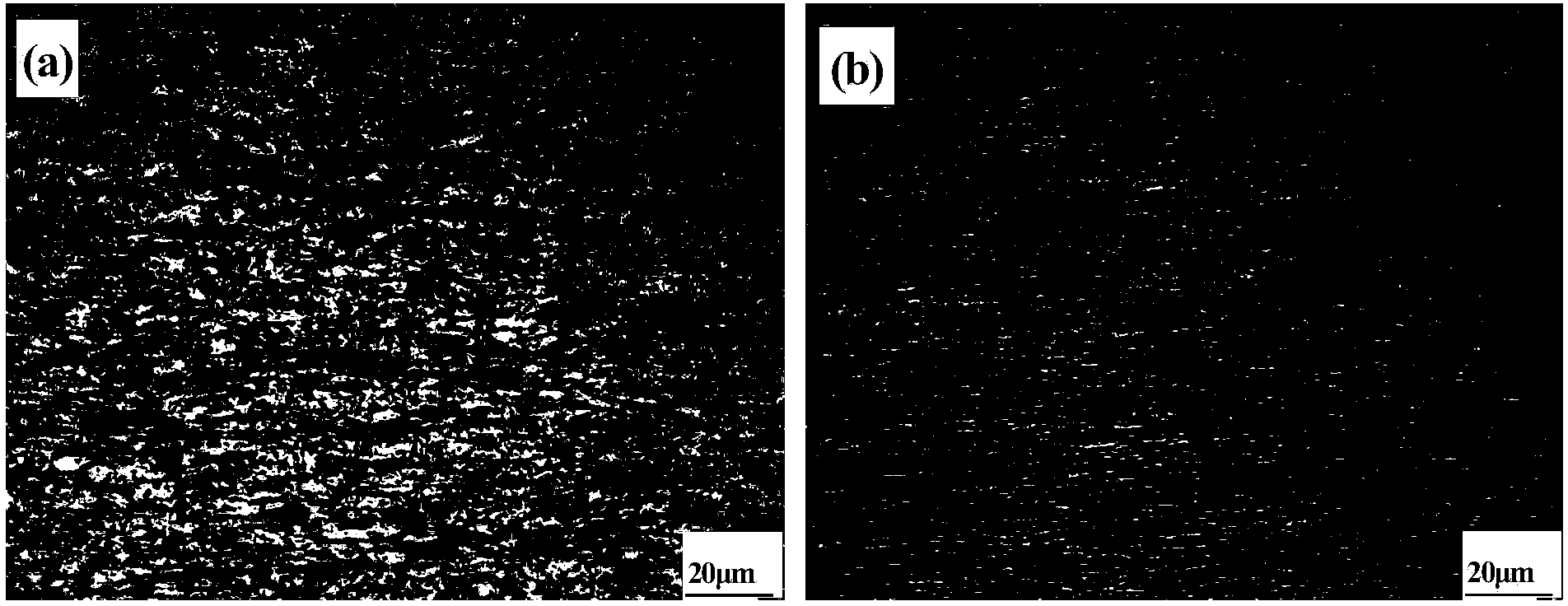

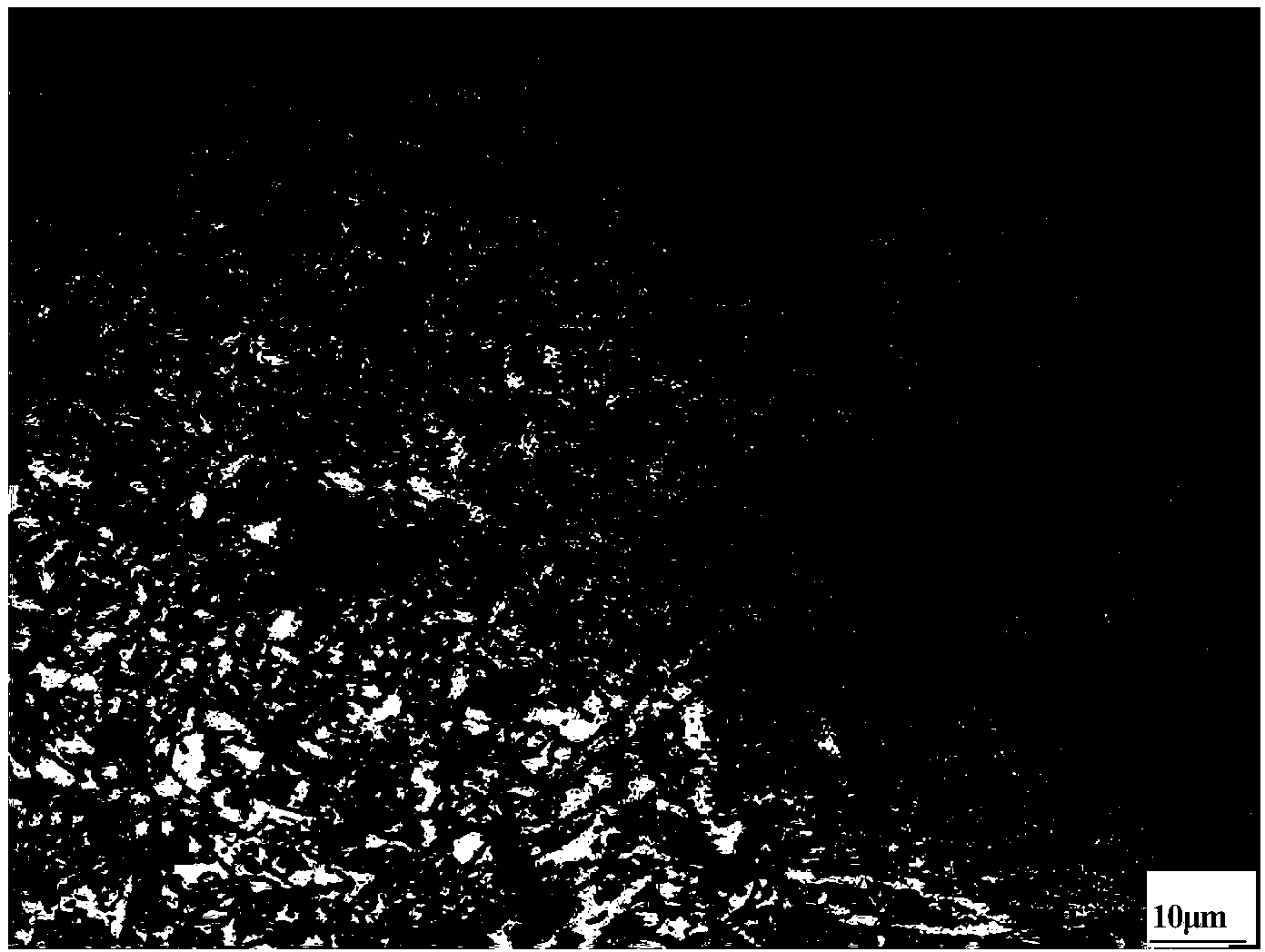

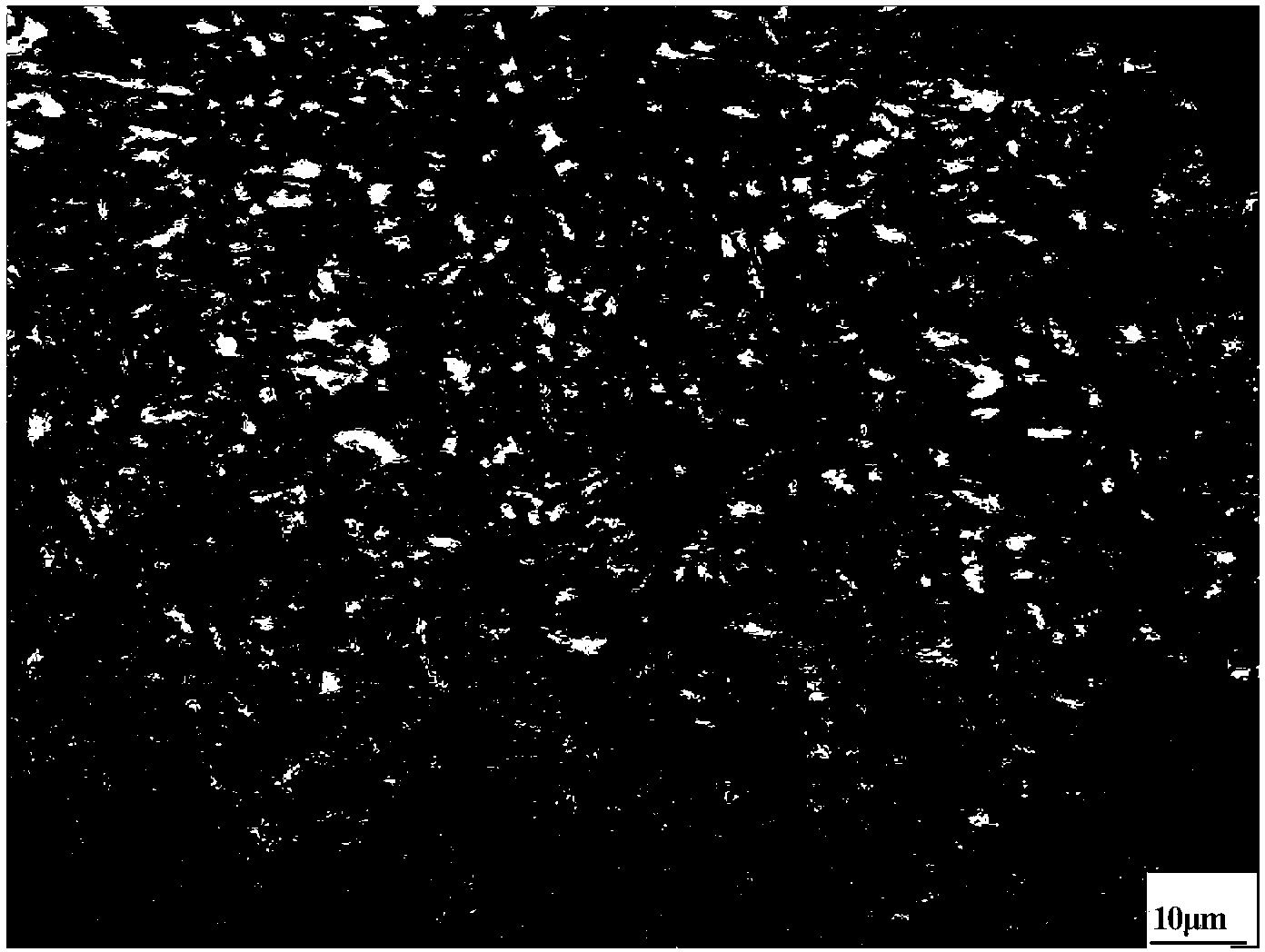

[0057] Such as image 3 As show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com