A kind of preparation method of tin bronze welding wire

A tin bronze and welding wire technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of easy oxidation of the wire billet surface, poor fluidity and wettability of the molten pool, long production cycle, etc. Excellent wettability, excellent copper water fluidity and wettability, and low content of impurity elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

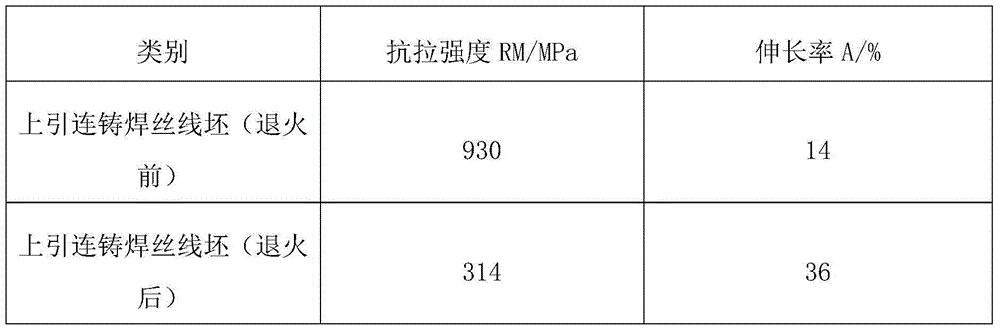

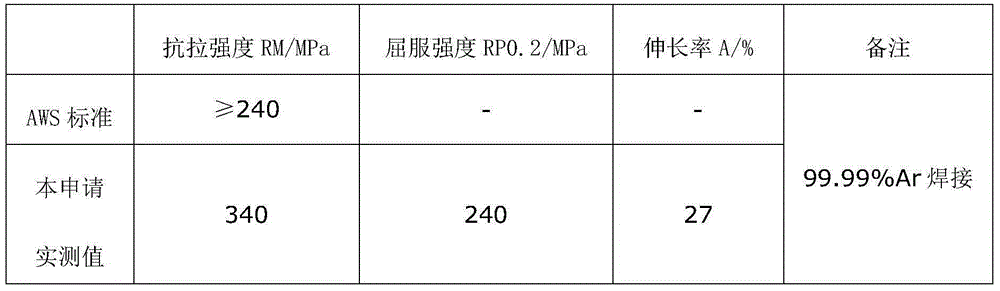

[0026] Taking the production of tin bronze welding wire SCu5180 in the standard of GB / T9460-2008 "Copper and Copper Alloy Welding Wire" as an example, the chemical composition of the welding wire is based on Zn: 0.010%, Sn: 4.50%, Fe: 0.02% based on the calculation of 1 ton of melting in one furnace , Al: 0.001%, Pb: 0.0006%, P: 0.01%, the balance is Cu for batching, determine the type and proportion of raw materials that need to be added, add them to the melting furnace in turn, then add charcoal to cover, stir evenly after the raw materials are melted, Sampling and analysis before the furnace is carried out, and the test results must meet the chemical composition requirements of tin bronze welding wire SCu5180 in GB / T9460-2008. After passing the test, raise the temperature to remove slag from the melt, then pour the melt into the holding furnace for heat preservation and refining, then remove the slag, and cover the melt with charcoal. The temperature of the melt in the holdi...

Embodiment 2

[0032] Taking the production of tin bronze welding wire SCu5410 in the standard of GB / T9460-2008 "Copper and Copper Alloy Welding Wire" as an example, the chemical composition of the welding wire is based on Zn: 0.050%, Sn: 12.3%, Fe: 0.10% based on the calculation of 1 ton of melting in one furnace , Al: 0.005%, Pb: 0.005%, P: 0.40%, the balance is Cu for batching, determine the type and proportion of raw materials that need to be added, add them to the melting furnace in turn, then add charcoal to cover, stir evenly after the raw materials are melted, Sampling and analysis before the furnace is carried out, and the test results must meet the chemical composition requirements of tin bronze welding wire SCu5180 in GB / T9460-2008. After passing the test, raise the temperature to remove slag from the melt, then pour the melt into the holding furnace for heat preservation and refining, then remove the slag, and cover the melt with charcoal. The temperature of the melt in the holdin...

Embodiment 3

[0034]Taking the production of tin bronze welding wire SCu5180 in the standard of GB / T9460-2008 "Copper and Copper Alloy Welding Wire" as an example, the chemical composition of the welding wire is based on Zn: 0.02%, Sn: 5.50%, Fe: 0.04% based on the calculation of 1 ton of melting in one furnace , Al: 0.003%, Pb: 0.002%, P: 0.1%, the balance is Cu for batching, determine the type and proportion of raw materials that need to be added, add them to the melting furnace in turn, then add charcoal to cover, stir evenly after the raw materials are melted, Sampling and analysis before the furnace is carried out, and the test results must meet the chemical composition requirements of tin bronze welding wire SCu5180 in GB / T9460-2008. After passing the test, raise the temperature to remove slag from the melt, then pour the melt into the holding furnace for heat preservation and refining, then remove the slag, and cover the melt with charcoal. The temperature of the melt in the holding f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com