High-strength heat-resistant steel gas shielded solid welding wire

A gas-shielded, solid-core welding wire technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problem of difficulty in reducing the embrittlement of weld metal in power station equipment, the effect is not significant, deposited metal and welded joints The parameters such as creep strength, permanent strength, permanent plasticity and high-temperature microstructure stability are not ideal, so as to achieve the effect of good welding process performance, reducing embrittlement phenomenon and beautiful molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

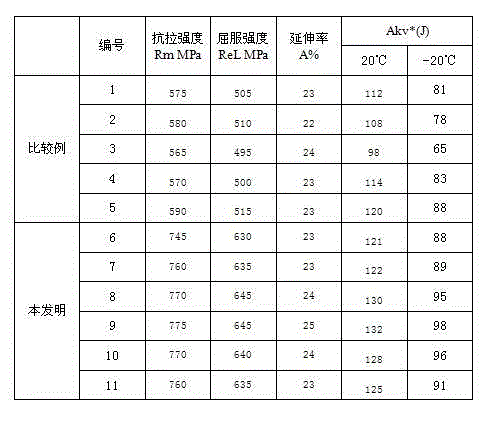

Examples

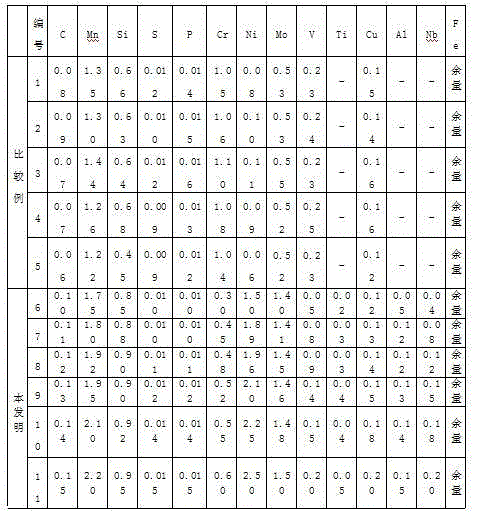

Embodiment 1

[0018] High-strength heat-resistant steel gas-shielded solid welding wire, the chemical composition and mass percentage of the high-strength heat-resistant steel gas-shielded solid welding wire are C: 0.10-0.15%, Mn: 1.75-2.20%, Si: 0.85-0.95% , S: 0~0.015%, P: 0~0.015%, Cu: 0~0.20%, Cr: 0.30~0.60%, Ni: 1.50~2.50%, Mo: 1.40~1.50%, V: 0.05~0.20%, Ti: 0.02~0.05%, Al: 0.05~0.15%, Nb: 0.04~0.20%; the balance is Fe. Si is a good alloying agent. Adding an appropriate amount of silicon to the steel can improve the yield strength, elasticity and acid resistance of the steel; if the content is too high, the plasticity and toughness will be reduced. In the present invention, the preferred content of Si doped is 0.90%. During the welding process, Si also has good deoxidation ability and forms silica with oxygen, but it will increase the viscosity of slag and easily promote non-metallic inclusions. Generated, which improves the stability when welding.

[0019] The mass percentage of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com