High-quality welding wire steel wire rod and production method thereof

A production method and technology for welding wire steel, applied in the field of welding wire steel, can solve the problems of difficulty in effectively reducing welding spatter, inability to effectively reduce calcium content, and no removal of inclusions, so as to achieve gas shielded welding, reduce welding costs, and reduce arc combustion. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific embodiment:

[0023] Take the rolled wire rod with a diameter of 5.5mm as an example, which is drawn and processed into a welding wire of Φ1.0mm. During the welding test, keep the welding area clean, use the same welding current and arc voltage, the same welding torch angle, and the same welding wire elongation. Under the conditions of length and wire feeding speed, the comparative test of welding spatter rate was carried out.

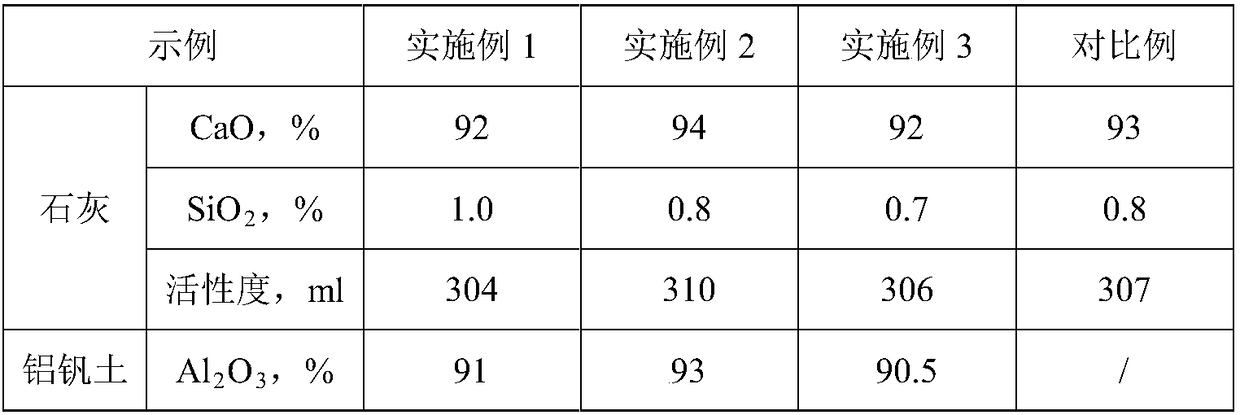

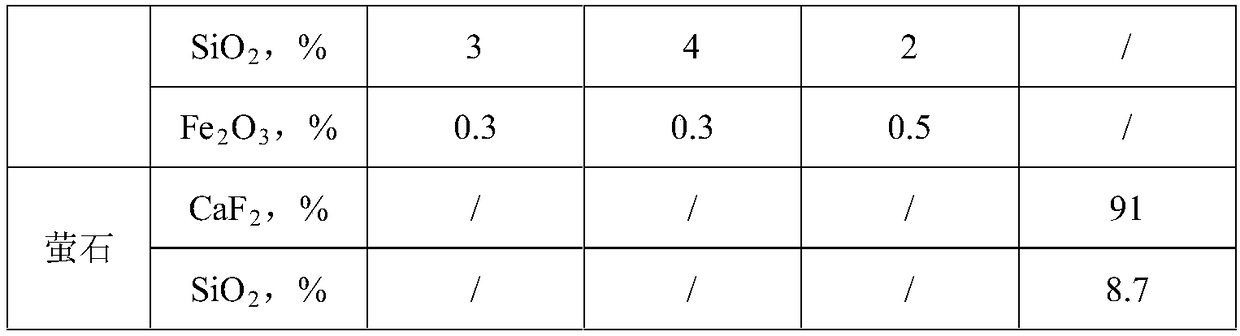

[0024] The present invention is further described. In the embodiment of the present invention, according to the component ratio of the technical solution, pretreatment of molten iron, converter smelting, LF refining, continuous casting, continuous rolling and wire rolling are carried out, and then processed into welding wire. The smelting composition of the embodiment of the present invention and the comparative example is shown in Table 1, the lime and bauxite c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com