Caster emitting device

A technology of injection molding machine and piston, which is applied in the field of injection device of injection molding machine to achieve the effect of stable operation, sensitive injection and stop, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

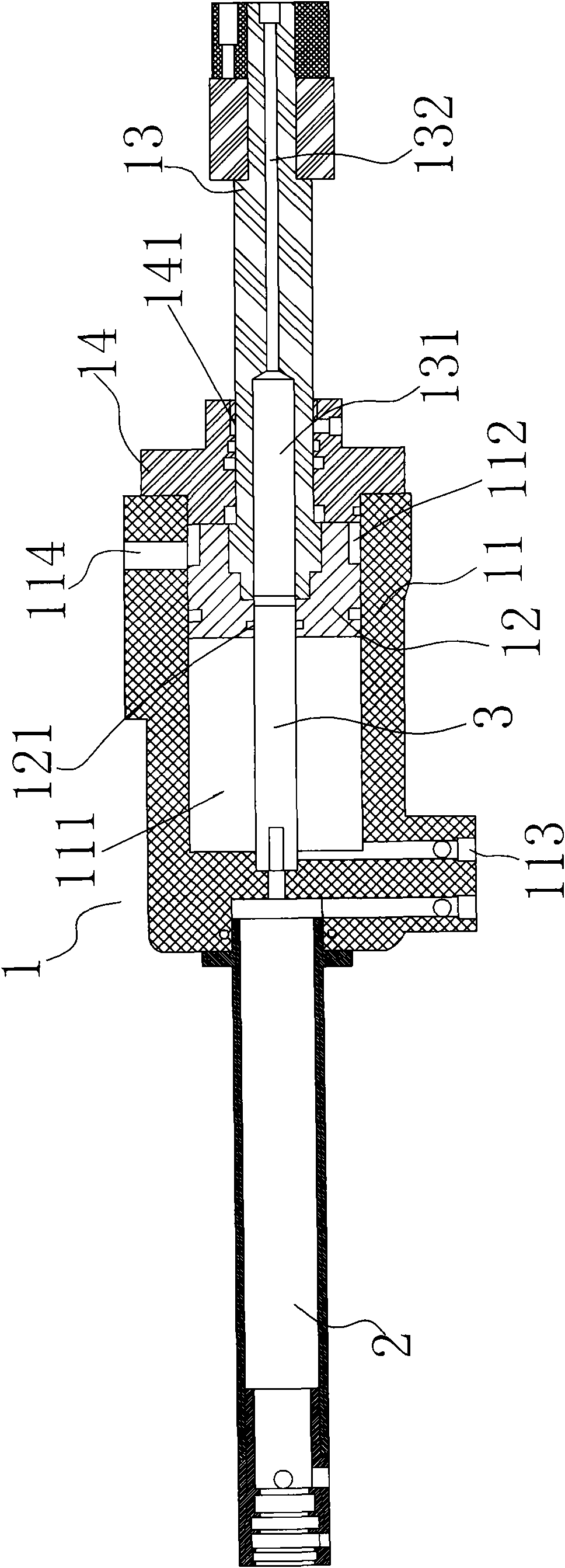

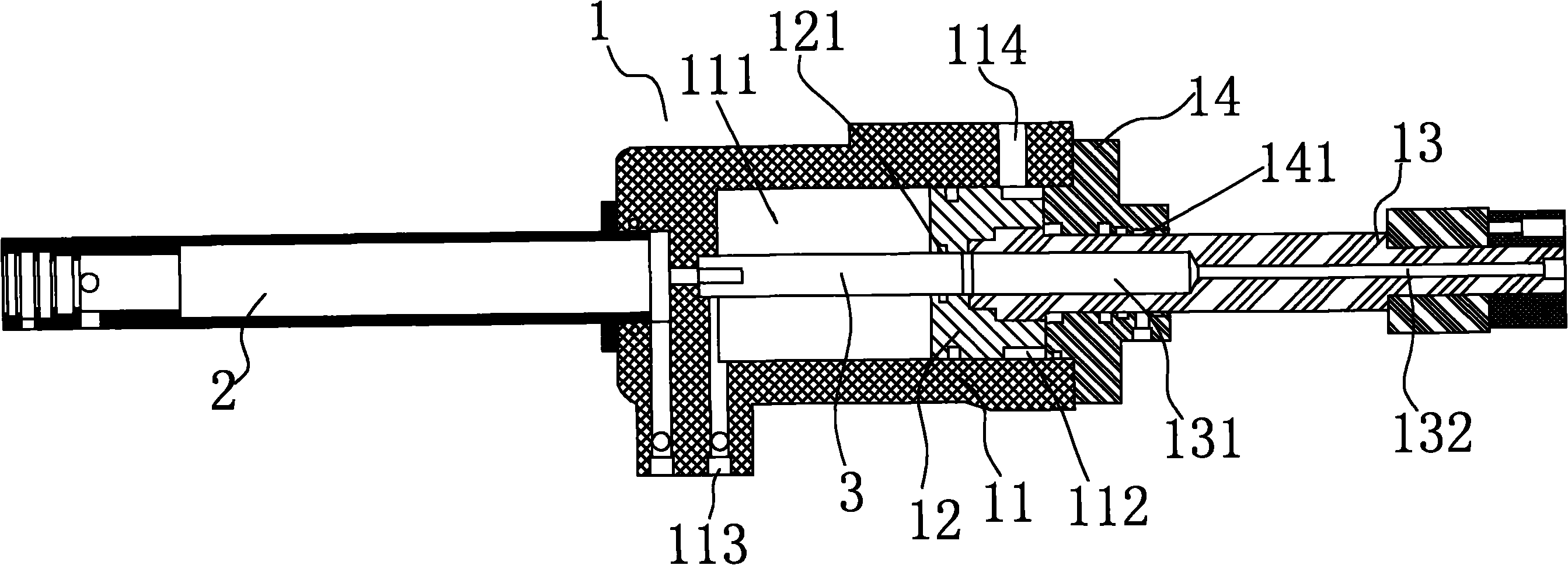

[0012] Below in conjunction with accompanying drawing, the present invention will be further described:

[0013] Such as figure 1 As shown, the present invention includes: an injection cylinder 1 , a hydraulic motor for pumping oil, and a guide rod 3 .

[0014] The injection cylinder 1 includes: a cylinder barrel 11 , a piston 12 installed in the cylinder barrel 11 , a piston rod 13 fixedly connected with the piston 12 , and a cylinder cover 14 . The cylinder head 14 covers the opening of the cylinder barrel 11 , and the cylinder head 14 is provided with a through hole 141 for the piston rod 13 to move left and right.

[0015] The piston 12 divides the cylinder 11 into an air chamber 111 and an oil chamber 112, wherein the air chamber 111 has an air hole 113 communicating with the outside, and the oil chamber 112 has an oil hole 114 communicating with the outside; There is an ejection oil cylinder 131 corresponding to the piston guide hole 121 and cooperating with the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com