Injection molding die of equal-diameter both-way plastic helical gear

An injection molding, helical gear technology, applied in the direction of gears, household appliances, other household appliances, etc., can solve the problems of difficult pilot hole processing, poor molding quality, large resistance to core rotation, etc., to achieve automatic demoulding, improve Forming efficiency and reliable action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

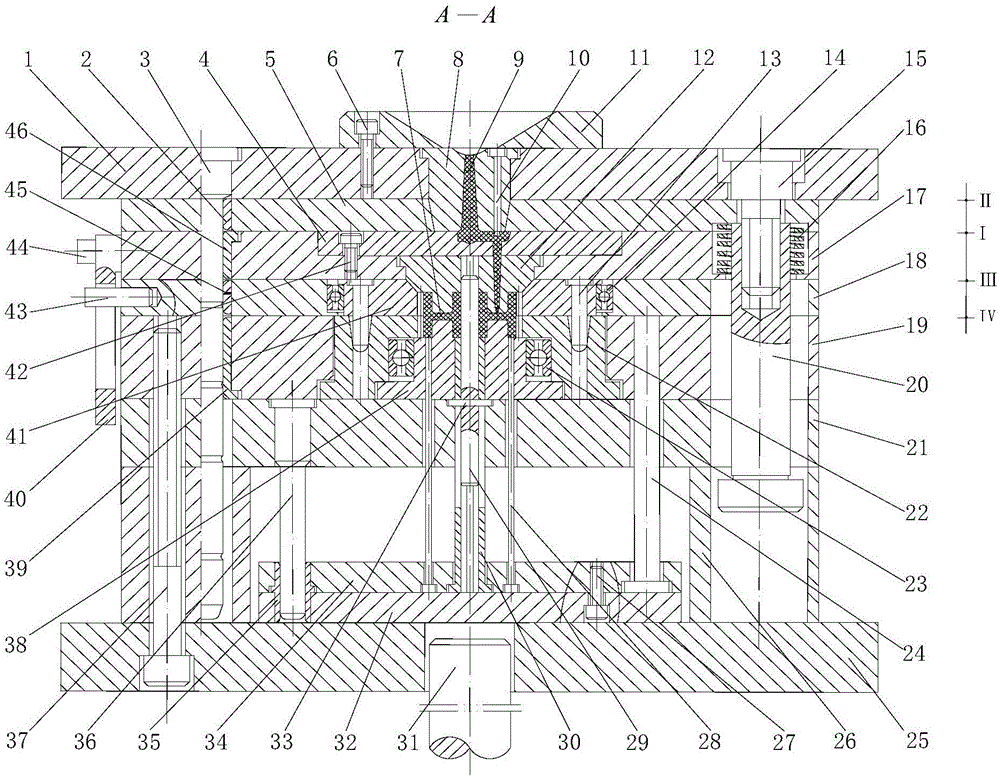

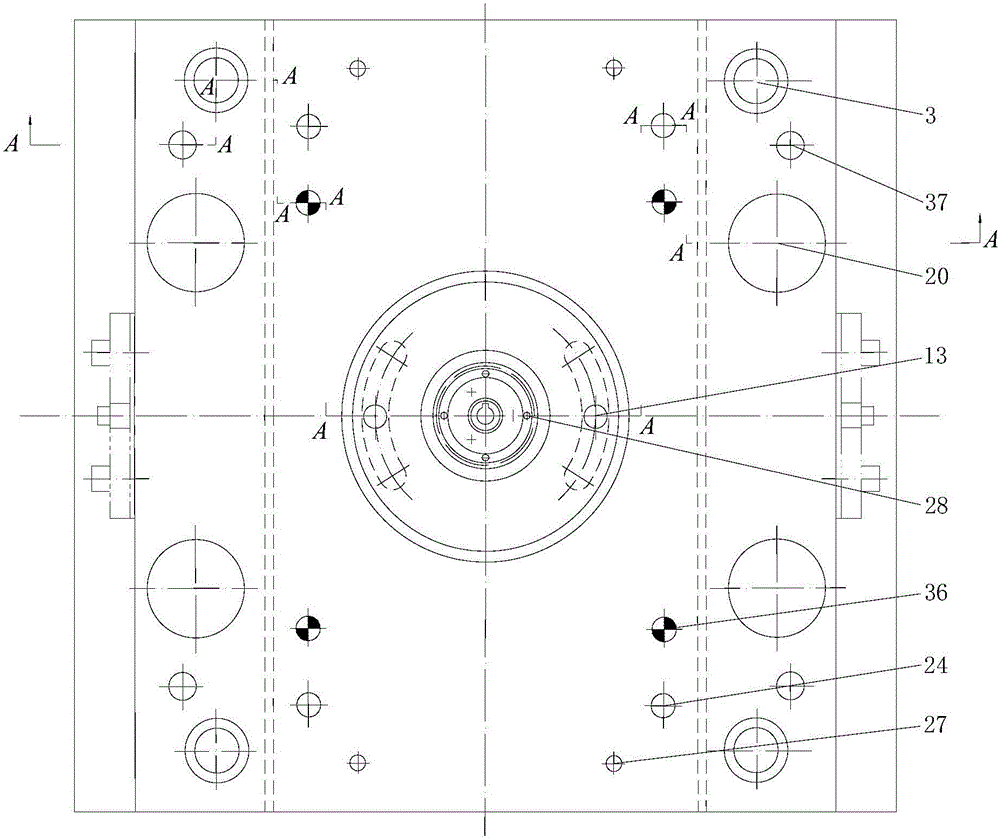

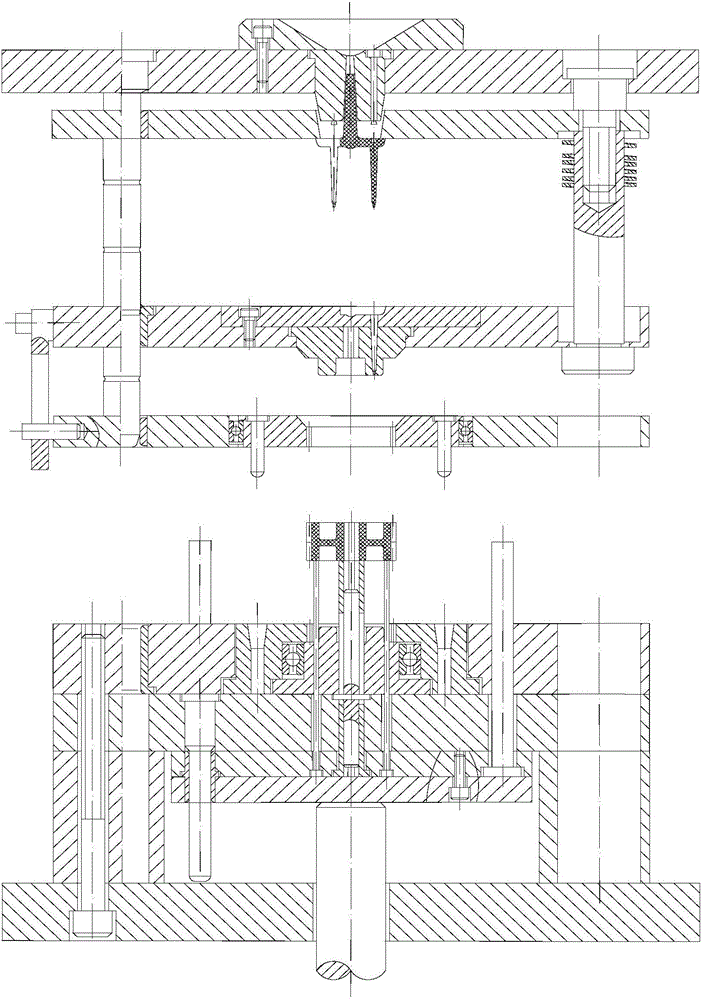

[0046] Such as figure 1 , figure 2 as shown, figure 2 It mainly reflects the distribution positions of parts such as guide post 3, hexagon socket head cap screw, ball guide pin 13, push rod 28, reset rod 24, push plate guide post 36, limit pull rod 20 and the like. From top to bottom, it includes: fixed mold seat plate 1, de-casting plate 5, core fixed plate 17, cavity fixed plate 18, movable template 19, support plate 21, cushion block 26, movable mold bottom plate 25;

[0047] There is a positioning ring 11 on the top of the fixed mold seat plate 1, and a pressure plate 4 is embedded in the upper surface of the core fixing plate 17. Below the pressure plate 4, a No. The core insert 12 and the No. I helical gear cavity insert 41 are arranged inside the cavity fixing plate 18; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com