Vibration-assisted nano rolling device

A vibrating device and rolling technology, applied in the field of hot embossing, can solve the problems of obstructing ultrasonic waves, low filling rate, pattern damage accuracy, etc., and achieve the effects of improving filling degree, uniform force and eliminating air bubbles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

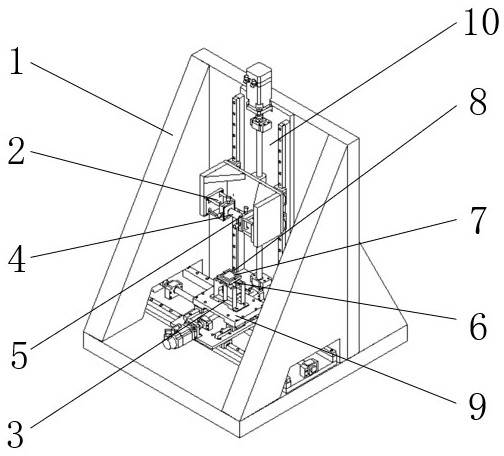

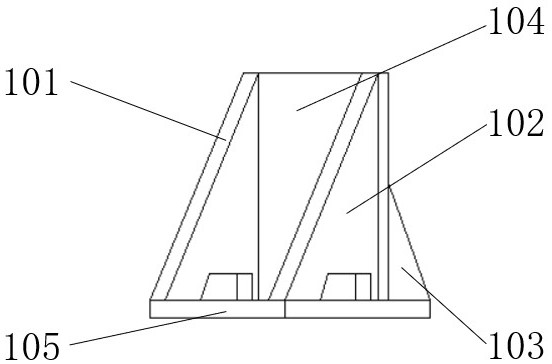

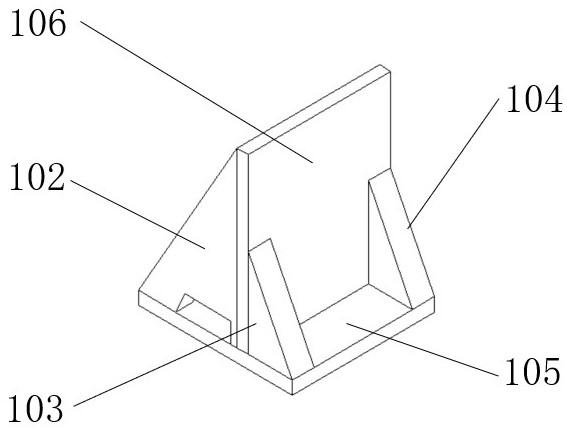

[0027] like figure 1 As shown, the vibration-assisted nano-rolling device includes a frame 1, a four-column connecting frame 2, a Z-direction vibration device 3, an embossing device 4, a fine-tuning device 5, a heating device 6, and a substrate chuck 7 , Cooling device 8, X-Y axis displacement platform 9, Z-axis displacement platform 10, wherein frame 1 is placed horizontally on the horizontal plane, Z-axis displacement platform 10 and X-Y axis displacement platform 9 are fixed on the frame 1 by screws, and the four-column connecting frame 2 is fixed on the Z-axis displacement platform 10 by screws, the imprinting device 4 is fixed on the four-column connecting frame 2 by screws, the Z-direction vibration device 3 is fixed on the X-Y axis displacement platform 9 by screws, and the heating device 6 is fixed on the Z-axis by screws. On the vibration device 3, the substrate chuck 7 is fixed on the heating device 6 by screws, the height of the placed substrate is higher than the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com