A kind of electroplating solution and method

A solution and copper electroplating technology, which is applied in the field of electroplating, can solve the problems of easy decomposition of inhibitors and limited inhibitory effect, and achieve the effects of improving filling conditions, improving stability, and improving deep plating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

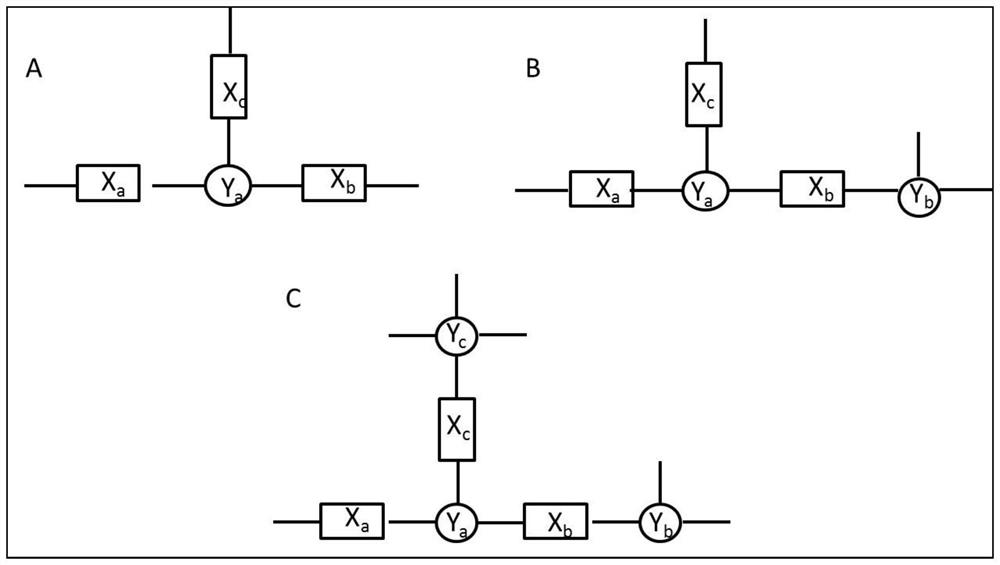

[0037]The molecular structure of the inhibitor in Example 1 includes a branch node cyclohexane and 3 linking units polyethylene oxide directly connected to the cyclohexane. The molecular weight of the inhibitor in Example 1 is 2000 to 4000. The molecular structure of the inhibitor in Example 2 includes a branch node cyclohexane. Cyclohexane is directly connected to 3 connecting units of polyethylene oxide and then connected to 3 polypropylene oxides respectively. Example 2 Inhibitor molecule relative molecule The quality is 5000 to 10000. The molecular structure of the inhibitor in Example 3 includes a branch node triphenylamine. Triphenylamine is directly connected to three connecting units of polyethylene oxide and then connected to three polypropylene oxides respectively. In Example 3, the relative molecular mass of the inhibitor molecule is 5000 to 10000. The molecular structure of the inhibitor in Example 4 includes a branch node, tetraphenylethane, and 4 connection units direc...

Embodiment 5

[0041]Embodiment 5 is a through-hole electroplating solution based on pulse electroplating prepared according to the foregoing embodiment 2. The specific components are shown in Table 2:

[0042]Table 2

[0043] Serial number Component content 1Inhibitor of Example 2 100mg / L 2Brightener SPS 1mg / L 3Copper sulfate pentahydrate 75g / L 4sulfuric acid 240g / L 5Chloride 50mg / L

[0044]The high aspect ratio electroplating solution prepared in Example 5 mainly adopts pulse electroplating. The electroplating parameters are: forward current density 2ASD, reverse current density 6ASD, forward current time 60ms, reverse current time 3ms, and electroplating time 90 minutes. The finally formed multi-layer board with a plating aperture of 10miI and a hole depth of 120mi1. After the through-hole is plated, the through-hole position is sliced, and the sliced inspection results are as followsfigure 2 As shown, the thickness of the surface copper is 26 μm, and the thickness of the through-hole copper ...

Embodiment 6

[0045]Example 6 is a hole-filling electroplating solution based on direct current electroplating prepared according to the foregoing Example 2. The specific components are shown in Table 3:

[0046]table 3

[0047] Serial number Component content 1Inhibitor of Example 2 150mg / L 2Brightener SPS 5mg / L 3Leveler Gena Green B 10mg / L 4Copper sulfate pentahydrate 230g / L 5sulfuric acid 100g / L 6Chloride 50mg / L

[0048]The hole-filling electroplating solution prepared in Example 6 adopts direct current electroplating. The electroplating parameters are: current density 1ASD plating HDI template with 4miI hole diameter and 2miI hole depth. The electroplating time is 60 minutes. The result isimage 3 As shown, the thickness of the surface copper is 14 μm, and the hole filling position is 0 μm.

[0049]Through the above embodiments, the electroplating solution of the present invention adopts a new type of branched inhibitor, which can be achieved by matching the inhibitor with the electroplating ion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com