Residue-free curing machine and curing method of materials

A kind of curing machine and no residue technology, which is applied in the field of curing device, can solve the problems of excessive unqualified head material, waste of inorganic head material, residue in the curing device, etc., and achieve the goal of improving work efficiency, increasing filling degree, and increasing filling degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

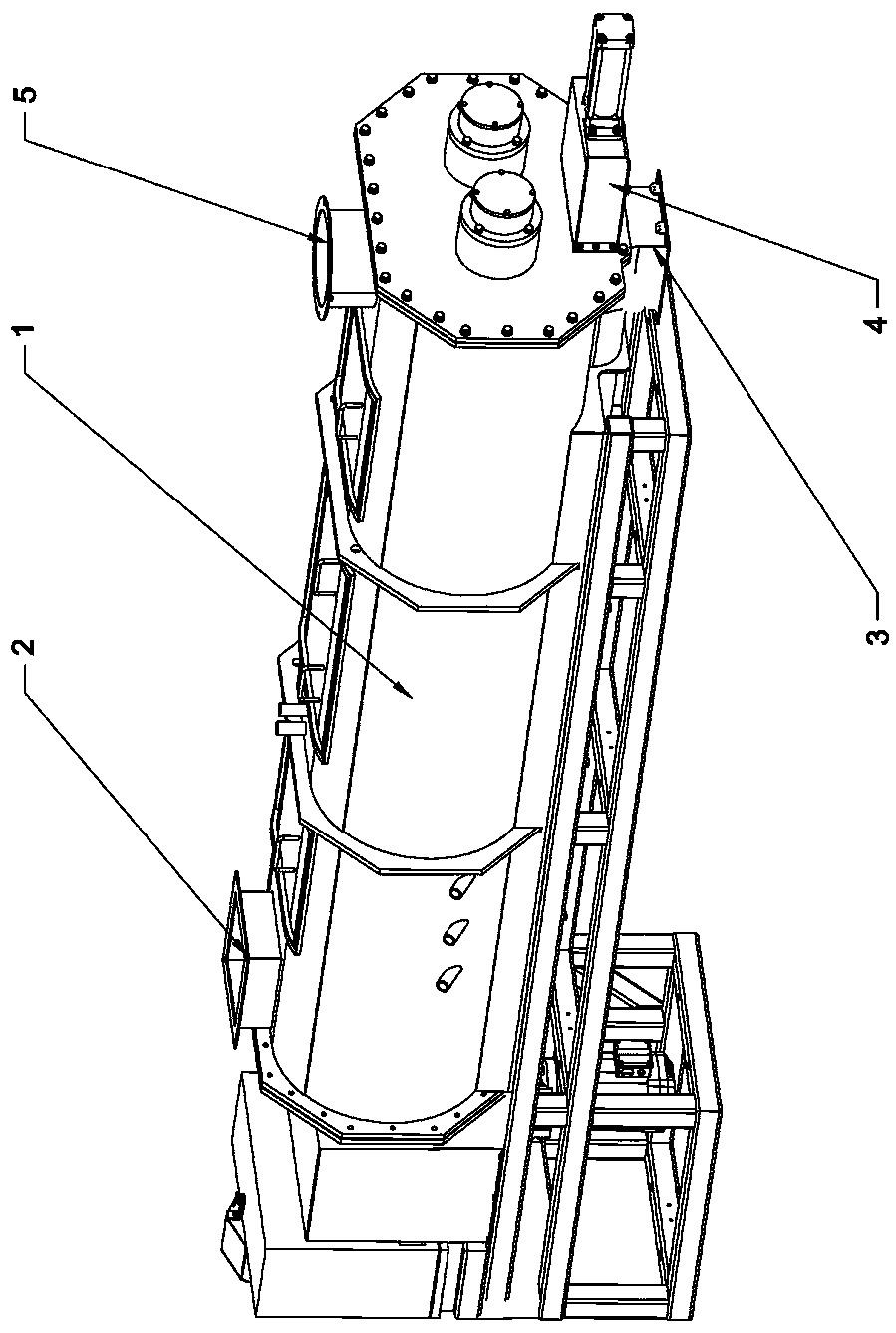

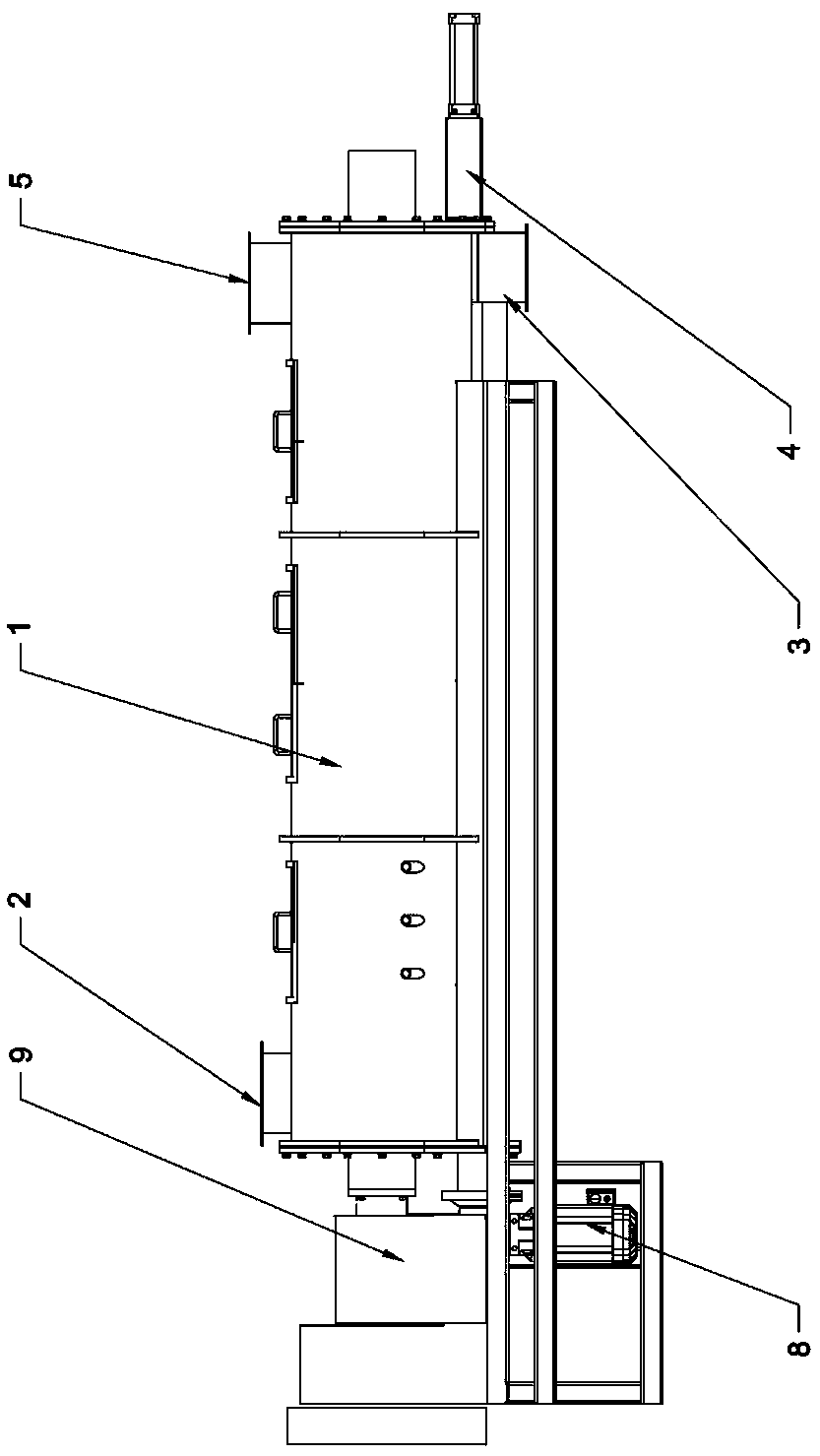

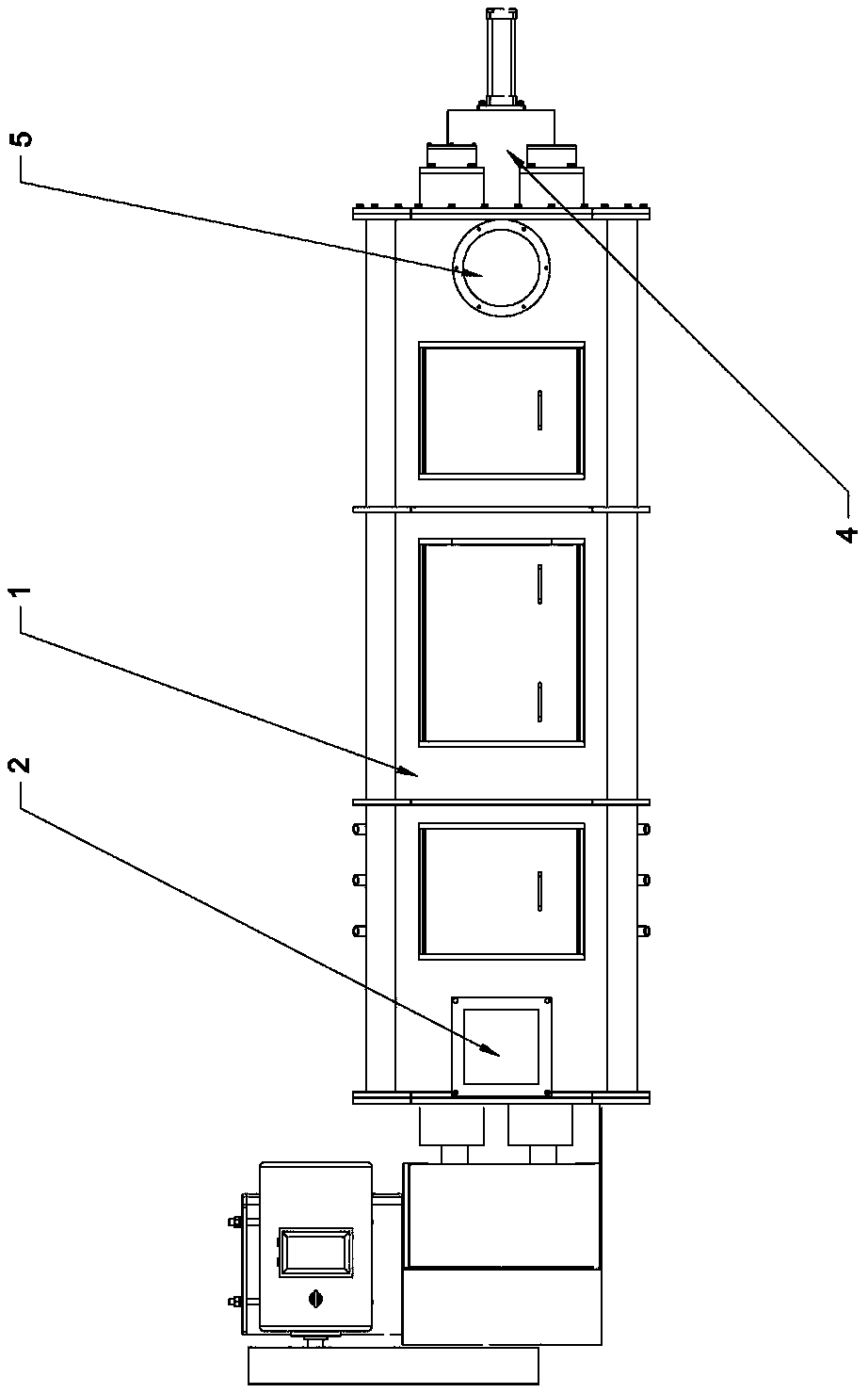

[0054] The purpose of the present invention is achieved as follows: a residue-free curing device, comprising a housing 1, one end of the housing 1 is provided with a feed port 2, the other end of the housing 1 is provided with a discharge port 3, the housing 1 A main rotor 10 is arranged inside, a plurality of propulsion blades 6 are installed on the main rotor 10, the main rotor 10 is in transmission connection with the main motor 9, the casing 1 is provided with a vent 5, and the casing 1 is also A water adding port and a steam port are provided; a spiral rotor 7 is provided under the main rotor 10, and the shape of the inner wall of the lower part of the housing 1 matches that of the spiral rotor 7, and the spiral rotor 7 is connected to the auxiliary motor 8 in transmission, A gate assembly 4 capable of opening and closing the discharge port 3 is installed at one end of the discharge port 3. The gate assembly 4 includes an insert plate 11 and an insert plate driving mechanis...

Embodiment 2

[0063] Another objective of the present invention is achieved as follows:

[0064] The main rotor 10 and the spiral rotor 7 in the cooker rotate in the same direction or in the reverse direction to reduce the headstock of the material, increase the fullness of the material inside the cooker and discharge without residue; the corresponding includes the initial working stage of the cooker , Intermediate work phase and shutdown work phase.

[0065] The initial work phase includes:

[0066] Step one, close the discharge port 3 of the cooker, start the main rotor 10, start the spiral rotor 7, open the feed port 2, feed into the feed port 2, and at the same time pass steam and water into the cooker;

[0067] Step two, the material continuously enters the cooker, and under the action of the advancing blade 6, the material is stirred and mixed and pushed to the direction of the outlet 3;

[0068] Step 3: The screw shaft 13 at the bottom drives the screw blade 14 in a reverse direction, that is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com