Fuel tank capable of achieving precise air-dropping and application method of fuel tank

An oil tank, precise technology, applied in container handles, containers, cans/barrels/barrels, etc., can solve the problems of low efficiency, inaccessibility, long transportation distance of large oil transportation vehicles, etc., to ensure effectiveness, avoid injury, high The effect of strength combined with mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

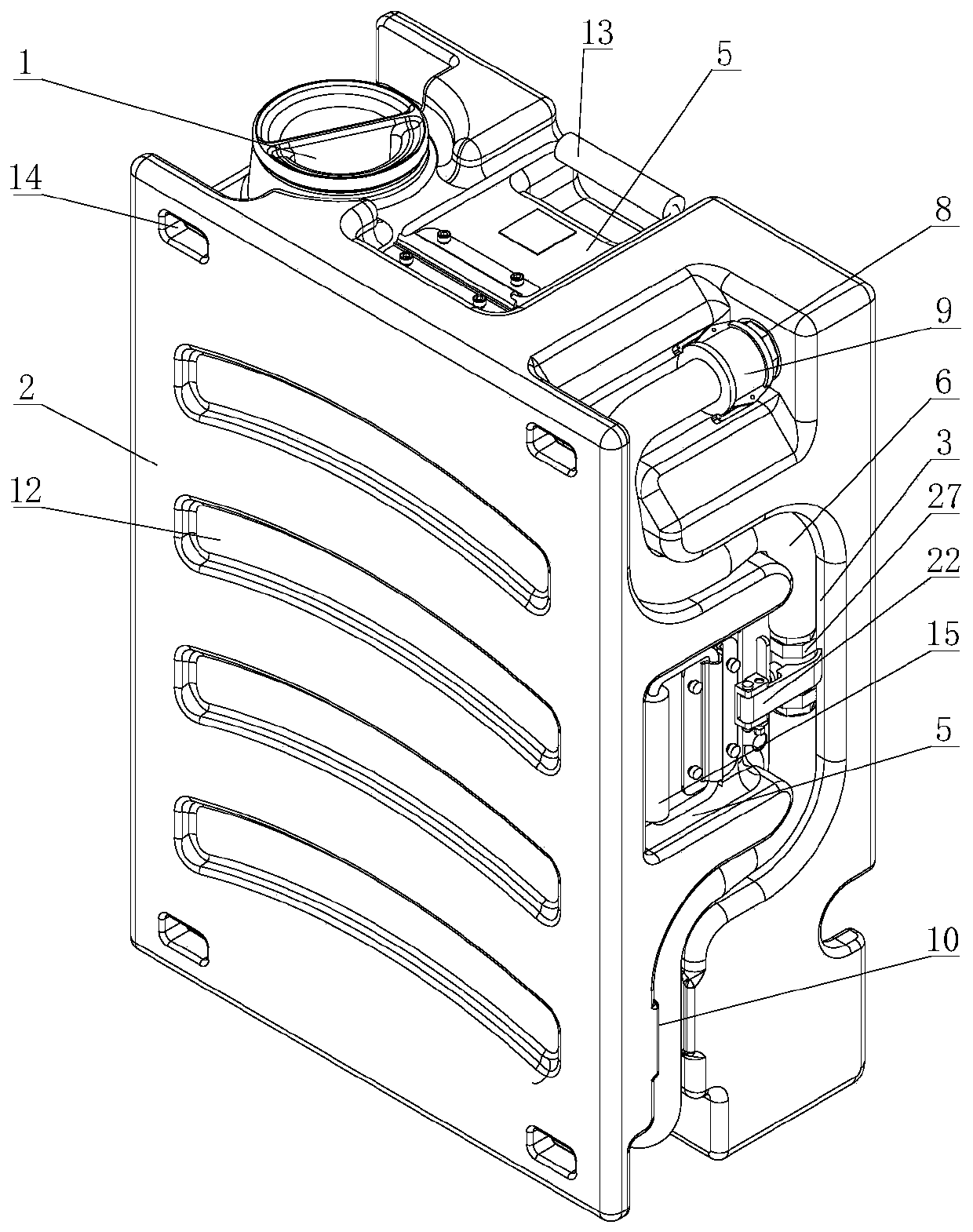

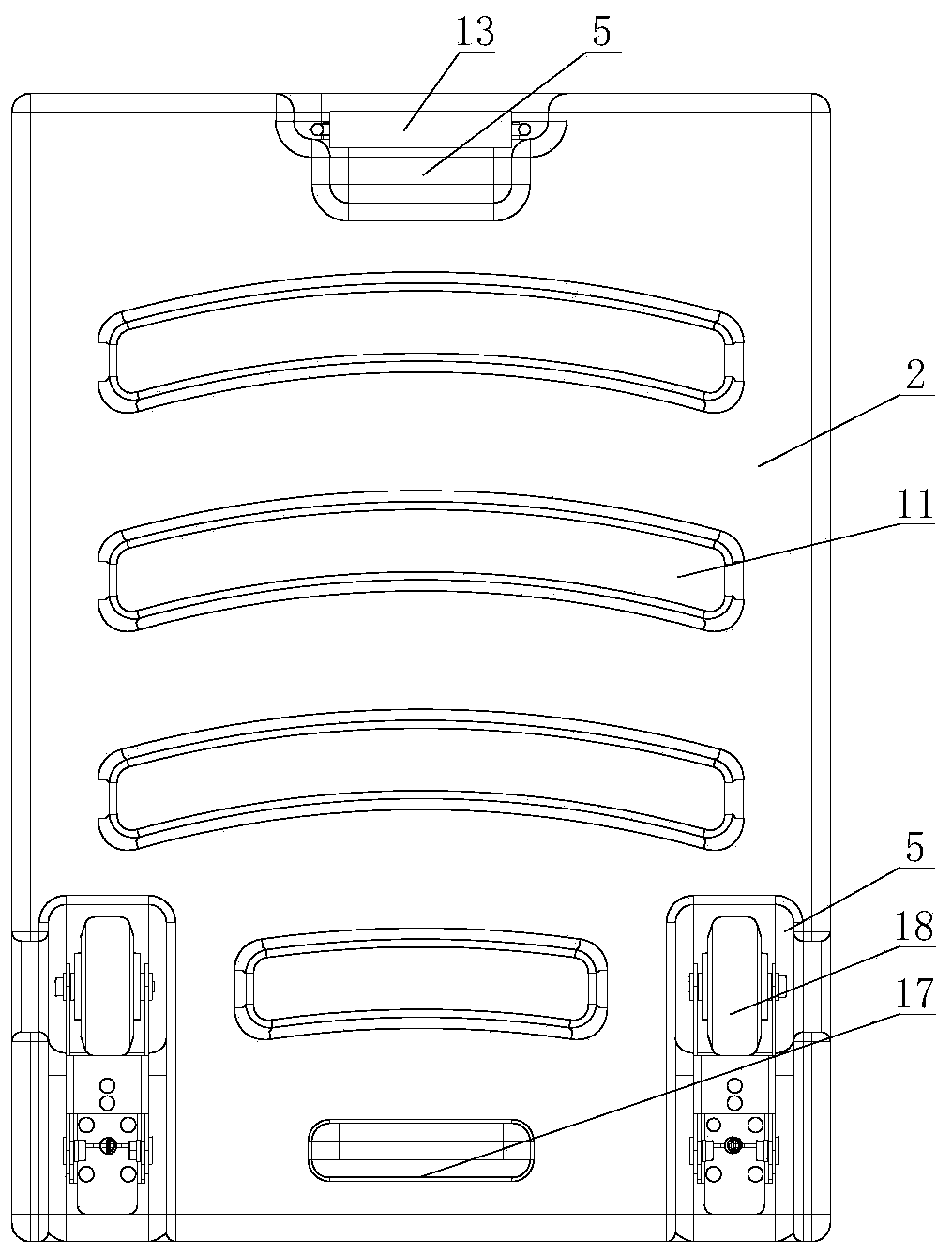

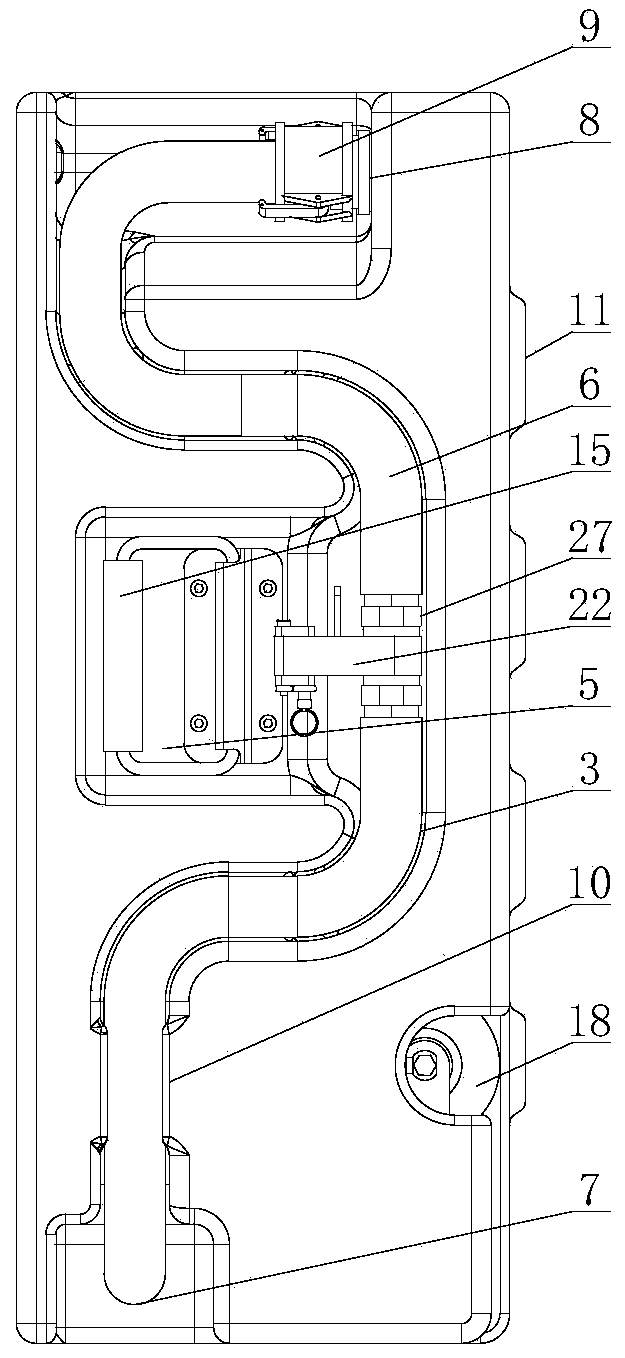

[0045] Example 1, such as Figure 1-14 As shown, the fuel injection port 1 is provided with a fuel tank cover 32, the front and rear sides of the box body 2 are respectively provided with a set of mutually matched stacking positioning ribs 11, stacking positioning concave ribs 12, stacking positioning convex The ribs 11 cooperate with the stacking positioning concave ribs 12 to form a stacking limiting structure of adjacent boxes 2. The stacking positioning convex ribs 11 and the stacking positioning concave ribs 12 between adjacent two boxes 2 can improve storage and The stacking stability of the box 2 during transportation; the box adopts a rectangular flat shape and a regular appearance structure, which can facilitate flexible and diverse stacking, storage and transportation, and can effectively improve the storage and transportation space utilization.

[0046] The first through opening 7 and the second through opening 8 are respectively provided at a set of diagonally opposit...

Embodiment 2

[0141] Example 2 is basically the same as Example 1, such as Figure 15 As shown, the difference is that the box 2 is also provided with an automatic force output unit and a second groove 4 for embedding the automatic force output unit. The second groove 4 and the automatic force output unit are located in the box 2 On the left, the automatic force output unit includes a compressed gas cylinder 30 arranged in the second groove 4 by means of a fixing plate 29, the compressed gas cylinder 30 is arranged vertically upwards, and the air outlet of the compressed gas cylinder 30 is connected to the box 2 The upper end is connected, and the upper part of the compressed gas cylinder 30 is provided with a knob. When the oil needs to be drained outwards, the upper port of the quick connection pipe 6 is connected with the equipment to be supplied, and the knob is rotated, and the compressed gas cylinder 30 is removed from the box 2 The upper end inputs compressed air into the tank 2, under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com