Mixing device for canned painting pigment production

A technology for mixing devices and pigments, applied in mixers, mixers with rotary stirring devices, transportation and packaging, etc., can solve the problems of low mixing efficiency, large stirring force stirring and mixing, affecting the production efficiency and reliability of pigments, etc. , to facilitate uniformity, ensure mixing efficiency, and achieve the effect of efficient and automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

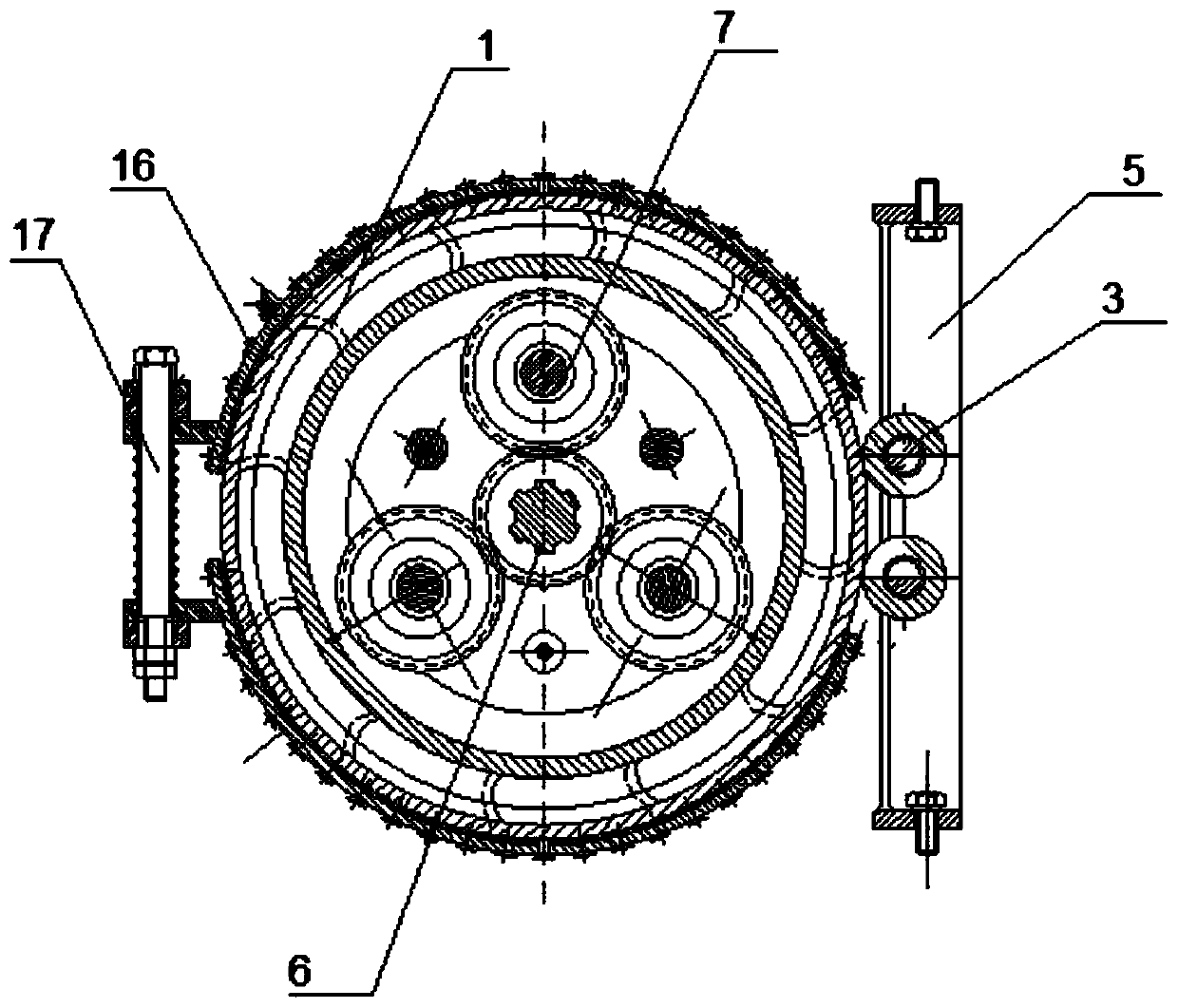

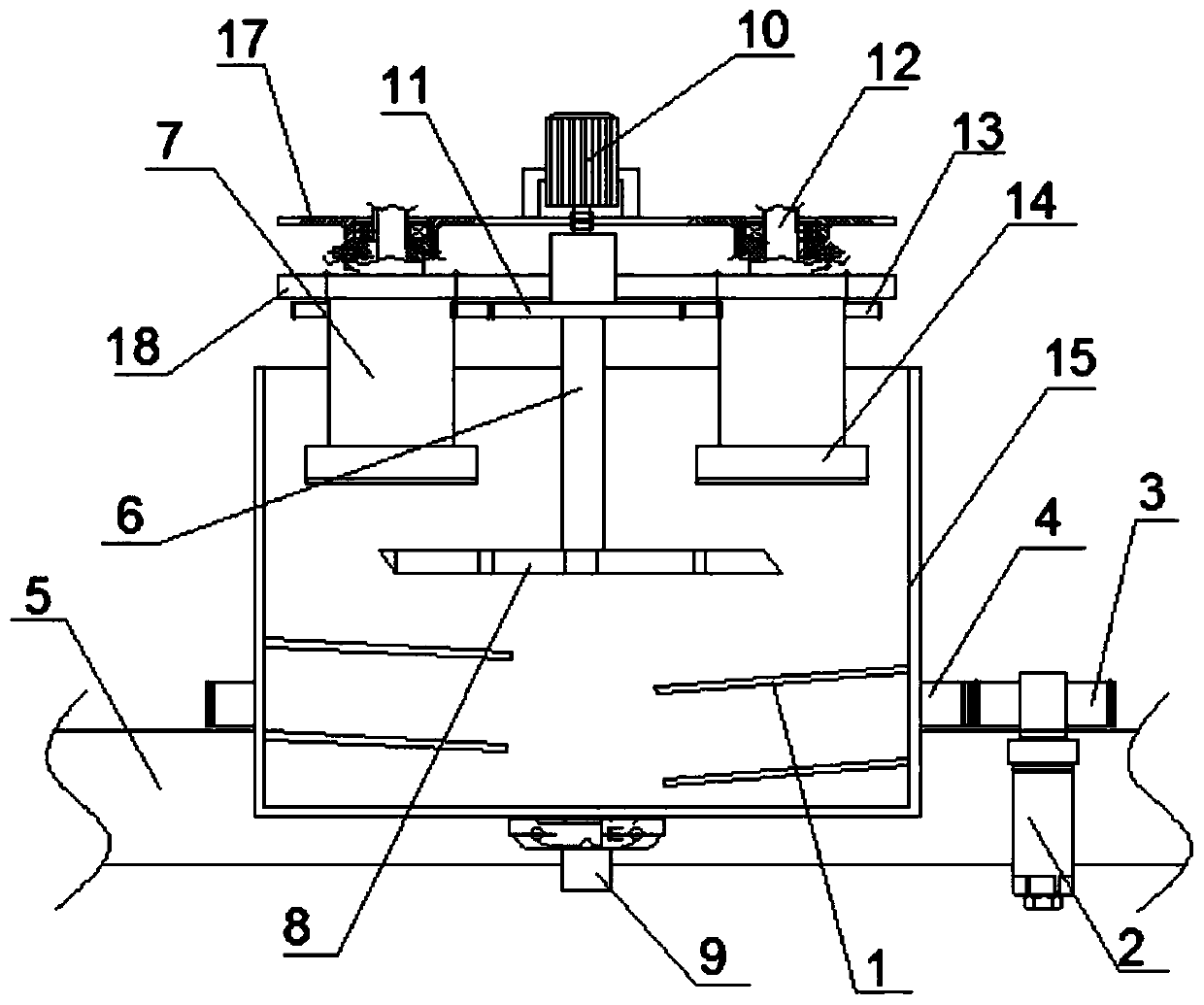

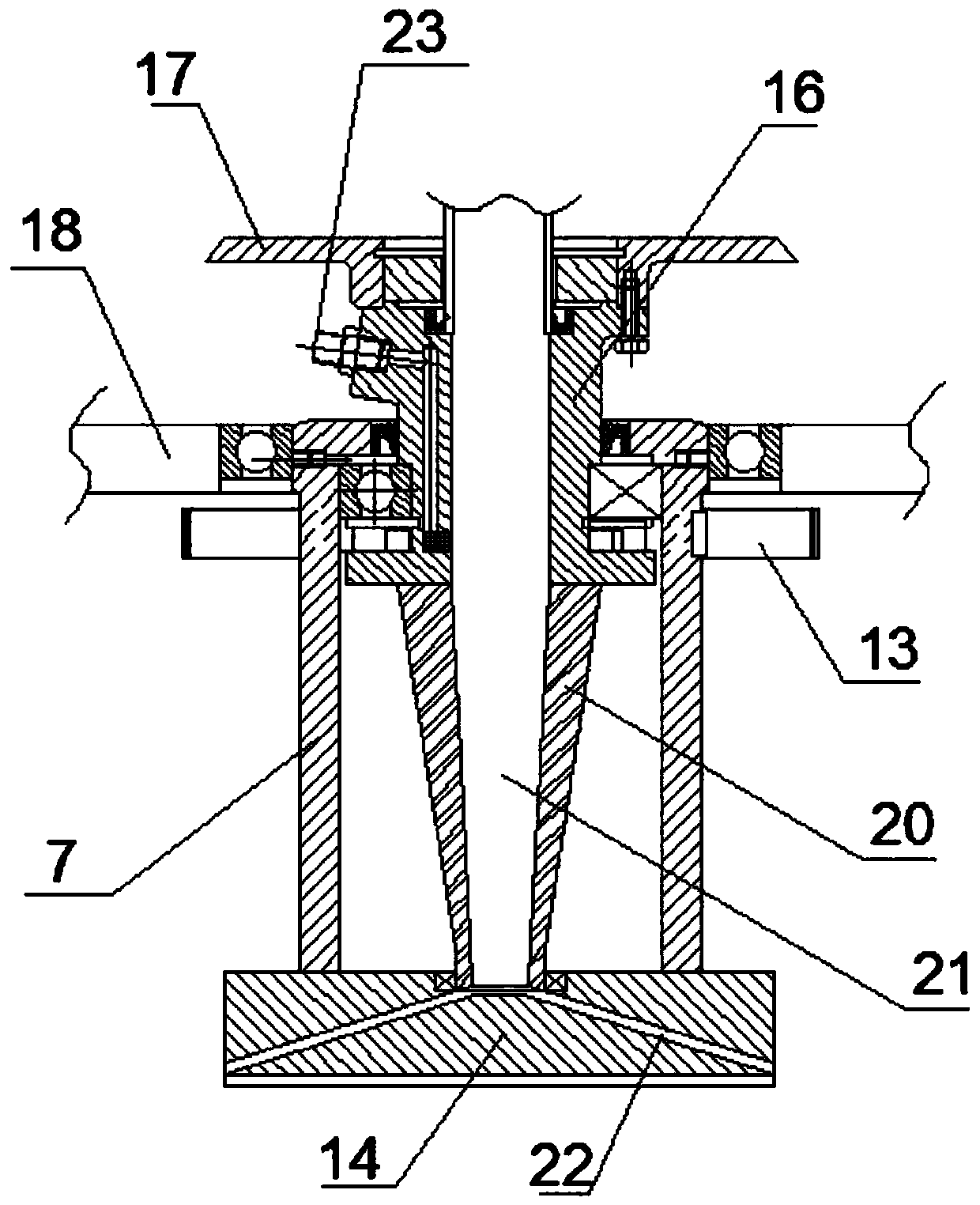

[0021] see Figure 1~3 , in the embodiment of the present invention, a kind of mixing device for the production of canned paint comprises a support base 5, a mixing cylinder 15, an upper fixed plate 17, a lower fixed plate 18 and a rotary feeding mechanism, and the support base can rotate The mixing tube is provided with a filling joint 9 at the bottom of the center of the mixing tube, and a lower fixing plate and an upper fixing plate above the lower fixing plate are fixedly arranged above the mixing tube, The rotary feed mechanism is supported and connected to the upper fixed plate 17 and the lower fixed plate 18, and is characterized in that the rotary feed mechanism includes multiple groups of feed spinners 14 that can rotate around their own vertical axes, each The group of said feed spinners rotates along the central axis of the mixing barrel, the upper end of said feed spinners is connected to the lower fixed plate through a rotating sleeve 7, each of said feed spinners...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com