Heating and refrigerating system applied to supergravity model test

A model test, refrigeration system technology, applied in the testing of machine/structural components, measuring devices, instruments, etc., can solve the problems of small footprint and the influence of supergravity, and achieve the elimination of air bubbles, precise control of structural temperature, and improvement of Effects of stability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

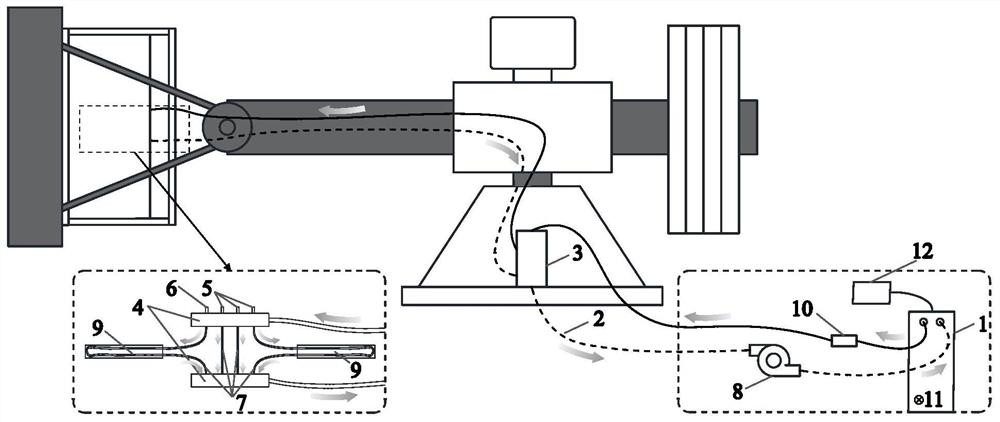

Image

Examples

Embodiment

[0033] Embodiment: design acceleration is 100g

[0034]The model of the cooling circulating water machine is F12-MA, the inner diameters of the nylon tube and the silicone tube are 10mm and 1.5mm respectively, the model of the centrifuge is C67, the maximum temperature of the water flow allowed by the rotary joint is 60°C, and the model of the diverter is 431 -7223, there are 4 branch ports, each branch port has an effective inner diameter of 3.175mm, the model of the temperature control valve and air valve is 17968, the effective outer diameter is 3.175mm, and the model of the three-stage centrifugal pump is D25-50*3( head 150m), the model of the flowmeter is MR3A16BVBN (range 2-30l / min), the model of the temperature sensor is SE028 (range -75—+250°C), the model of the temperature data collector is TC-08 (accuracy ±0.5°C ).

[0035] Specific steps are as follows:

[0036] S1. First, adjust the opening degree of the temperature control valve of each branch according to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com