Anti-swelling steel sheet casting equipment for aluminum piston

A casting equipment and piston technology, applied in the field of anti-expansion steel sheet casting equipment, can solve the problems of poor use effect of anti-expansion steel sheet, easy generation of bubbles in casting liquid, affecting processing effect, etc., and achieve good use effect and long service life , The effect of high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

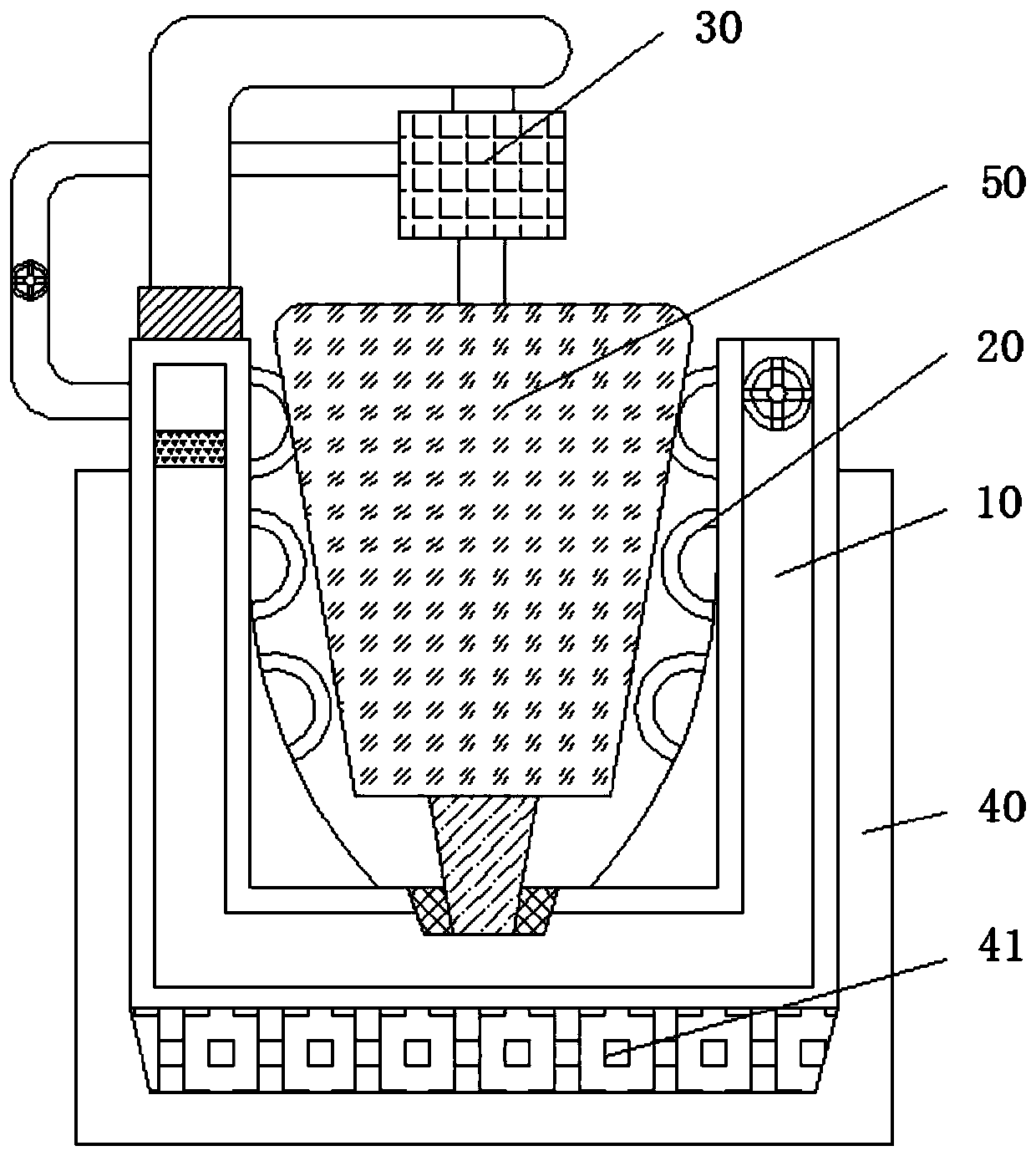

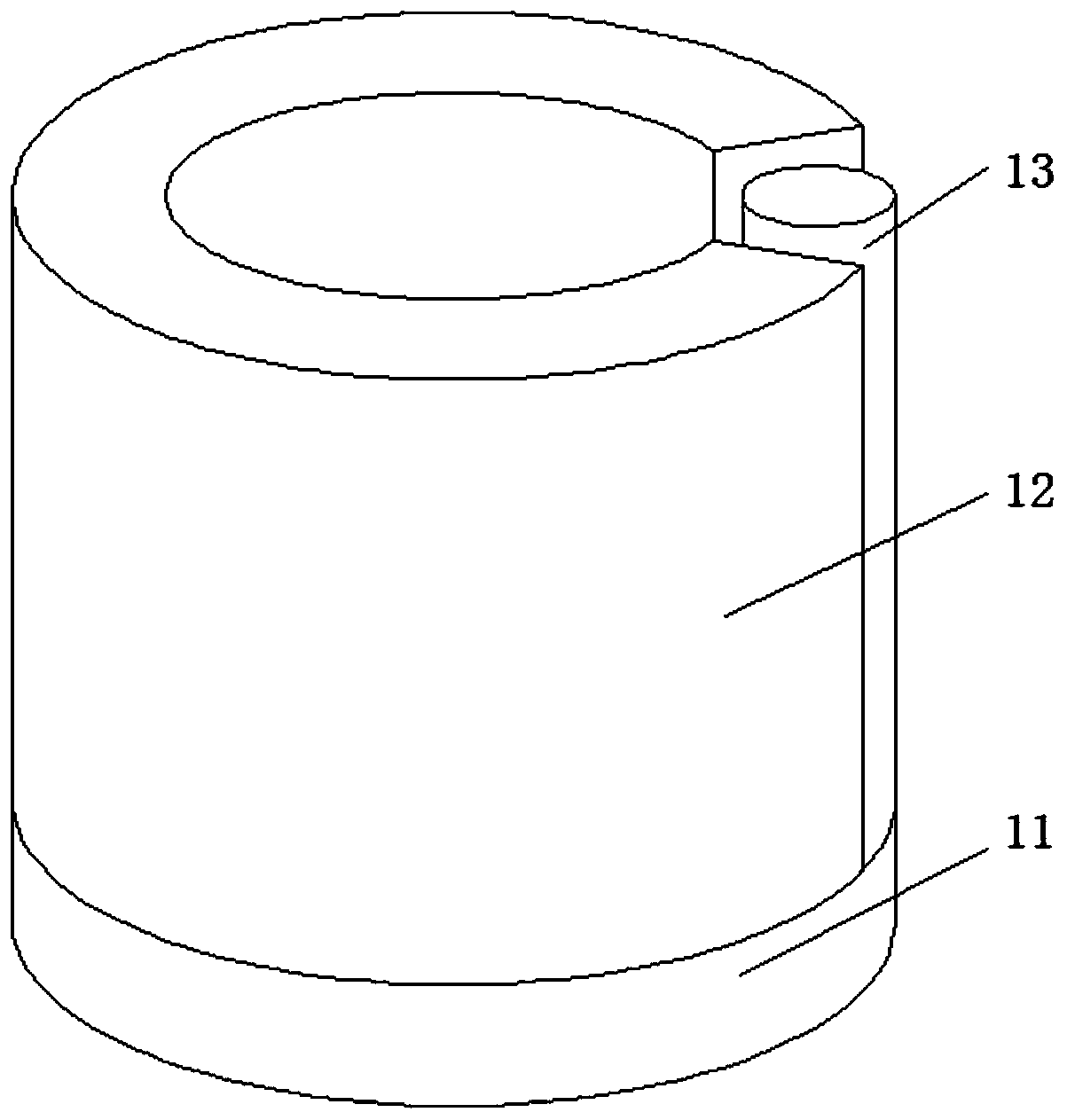

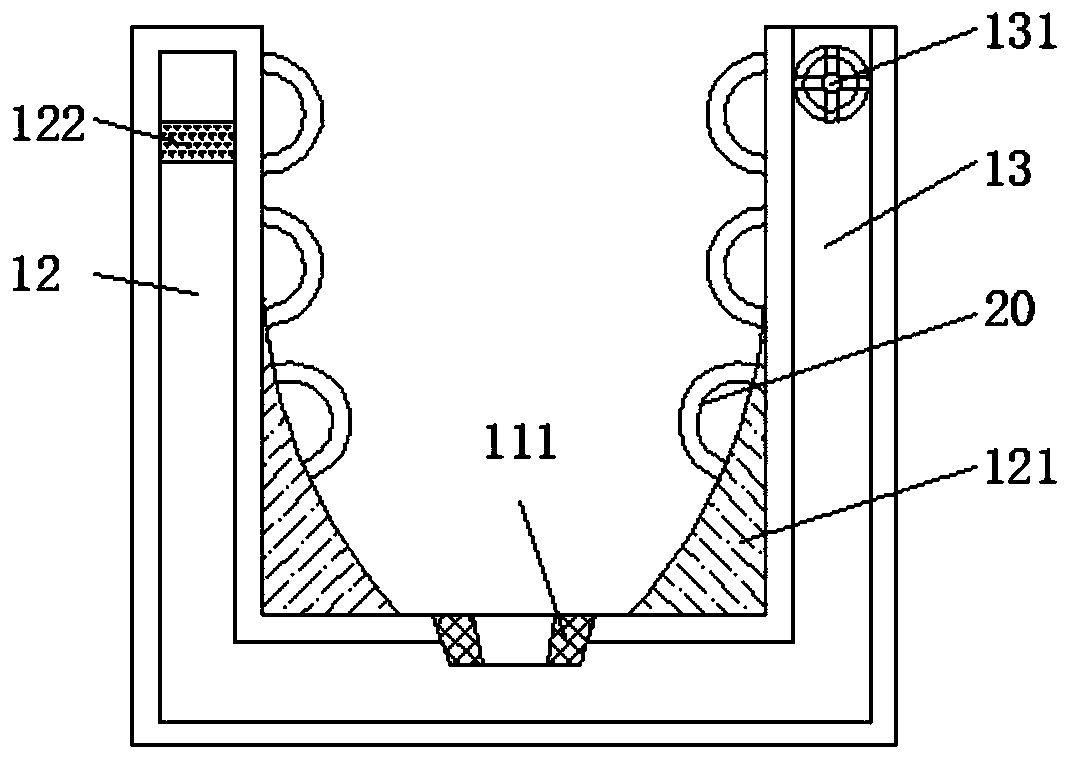

[0024] Such as figure 1 As shown, the anti-expansion steel sheet casting equipment for aluminum pistons described in this embodiment includes a casting liquid storage bin 10, a negative pressure mechanism 30 and a casting cavity 50, and the top of the casting liquid storage bin 10 is provided with a negative pressure A mechanism 30, the casting liquid storage bin 10 is provided with a casting cavity 50, and the negative pressure mechanism 30 is used to negatively absorb the air inside the casting cavity 50 so that the casting cavity 50 is filled with casting liquid;

[0025] The air inside the casting cavity 50 is absorbed by the negative pressure mechanism 30, so that the liquid inside the casting liquid storage bin 10 slowly flows into the casting cavity 50. In this way, the liquid can be eliminated from pouring into the casting cavity 50 from top to bottom. Bubbles are generated inside, which makes the casting effect of the anti-expansion steel sheet better.

[0026] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com