Imitation brick producing and processing device for constructional engineering

A technology for construction engineering and processing devices, which is applied to supply devices, unloading devices, manufacturing tools, etc., can solve the problems of low cement content at the upper ends of imitation bricks, affecting installation operations, holes, etc., to eliminate air bubbles and save materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

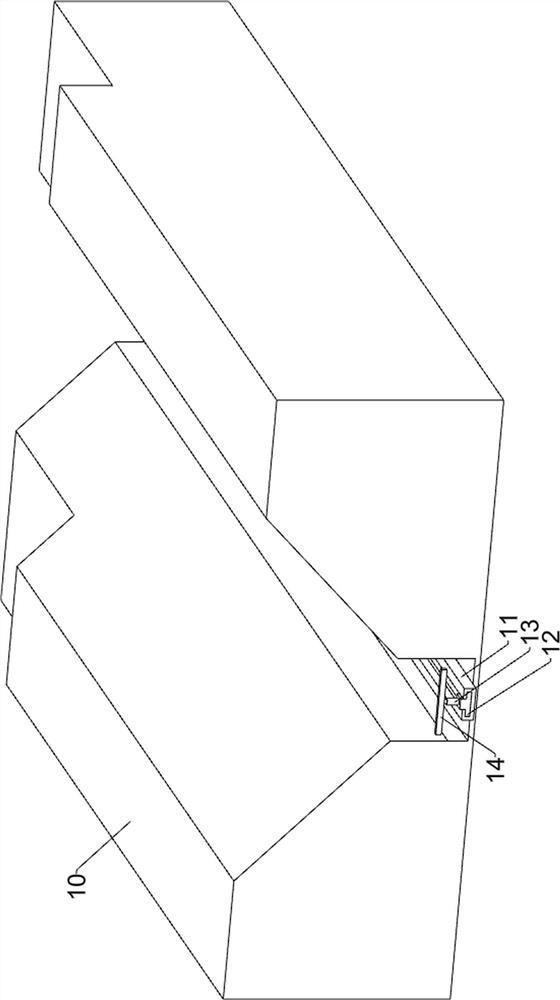

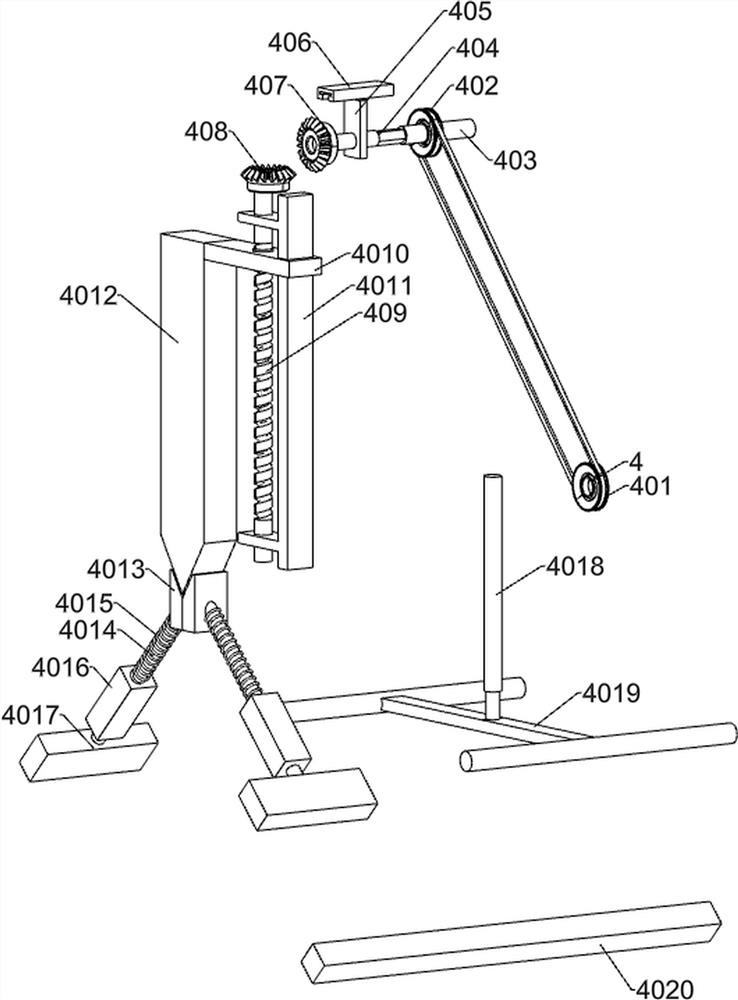

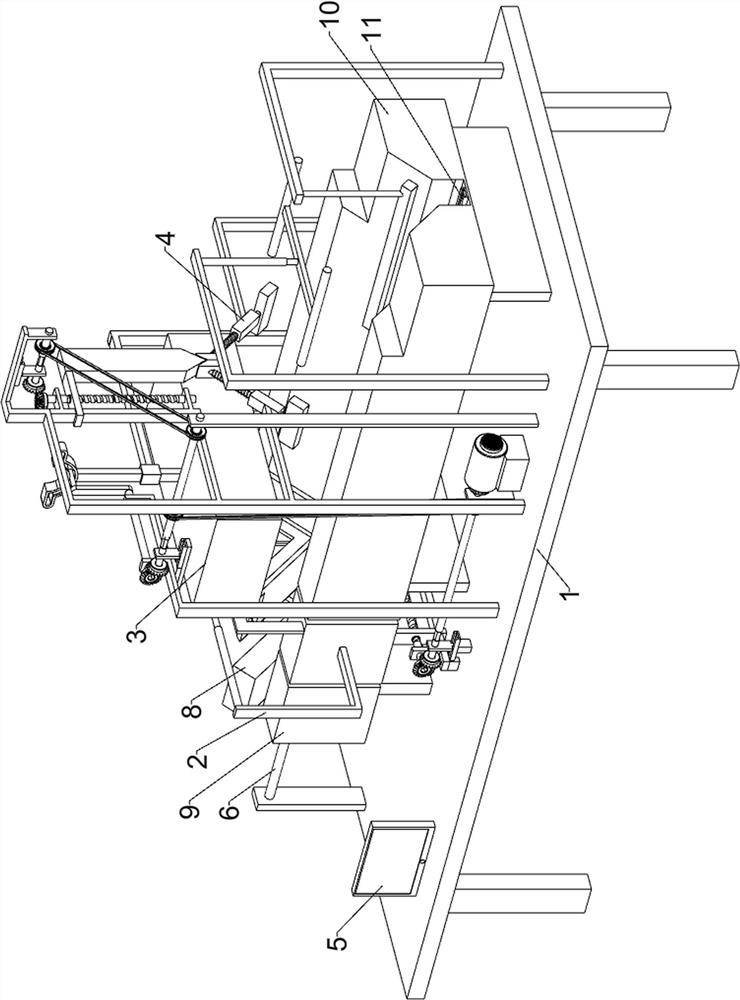

[0028] A kind of imitation brick production and processing device for construction engineering, such as Figure 1-8 As shown, it includes a bottom frame 1, a filling component 2, a drying component 3, a demoulding component 4, a control panel 5, a first electric push rod 6, a first push block 7, a first mold 8, a first receiving Block 9, the second receiving block 10, the first electric slide rail 11, the first sliding block 12, the second electric push rod 13 and the second push block 14; the bottom frame 1 is connected with the filling assembly 2; the bottom frame 1 is connected with the The drying component 3 is connected; the bottom frame 1 is connected with the demoulding component 4; the bottom frame 1 is connected with the control panel 5; the bottom frame 1 is connected with the first electric push rod 6; the bottom frame 1 is connected with the first receiving block 9 are connected; the bottom frame 1 is connected with the second receiving block 10; the filling assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com