Quantitative concrete wallboard pouring equipment for civil construction engineering

A technology of civil engineering and concrete, applied in the direction of manufacturing tools, ceramic molding machines, supply devices, etc., can solve problems such as inability to vibrate, affect pouring quality, and concrete air bubbles cannot be quickly eliminated, so as to improve vibrating efficiency and practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

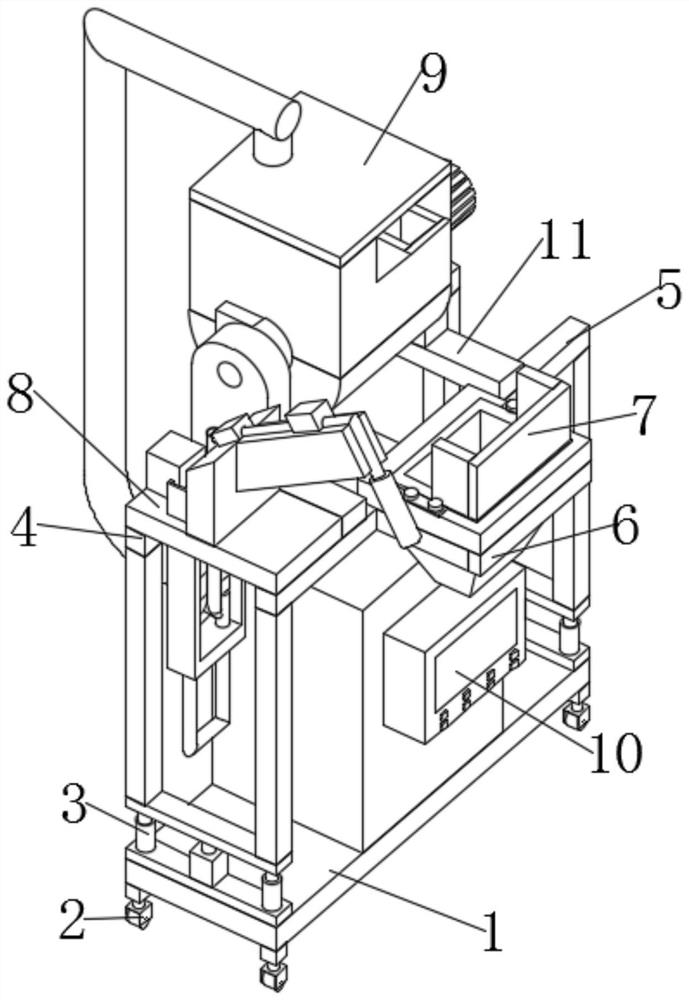

[0035] A kind of equipment for quantitative pouring of concrete wall panels for civil engineering, such as Figure 1-2 As shown, including the mobile base 1, the four corners of the lower end of the mobile base 1 are fixedly connected with the universal wheels 2, the upper front part of the mobile base 1 and the upper rear part are fixedly connected with the fine-tuning device 3, and the upper ends of the two fine-tuning devices 3 are fixedly connected together. There are a first connecting rod 4 and a second connecting rod 5, the middle part of the right end of the second connecting rod 5 is fixedly connected with a support frame 6, and a material guide device 7 is interspersed in the supporting frame 6, and the first connecting rod 4 and the second connecting rod 5 The front part of the upper end is fixedly connected with a vibrating device 8, and the middle part of the upper end of the first connecting rod 4 and the second connecting rod 5 is fixedly connected with two backi...

Embodiment 2

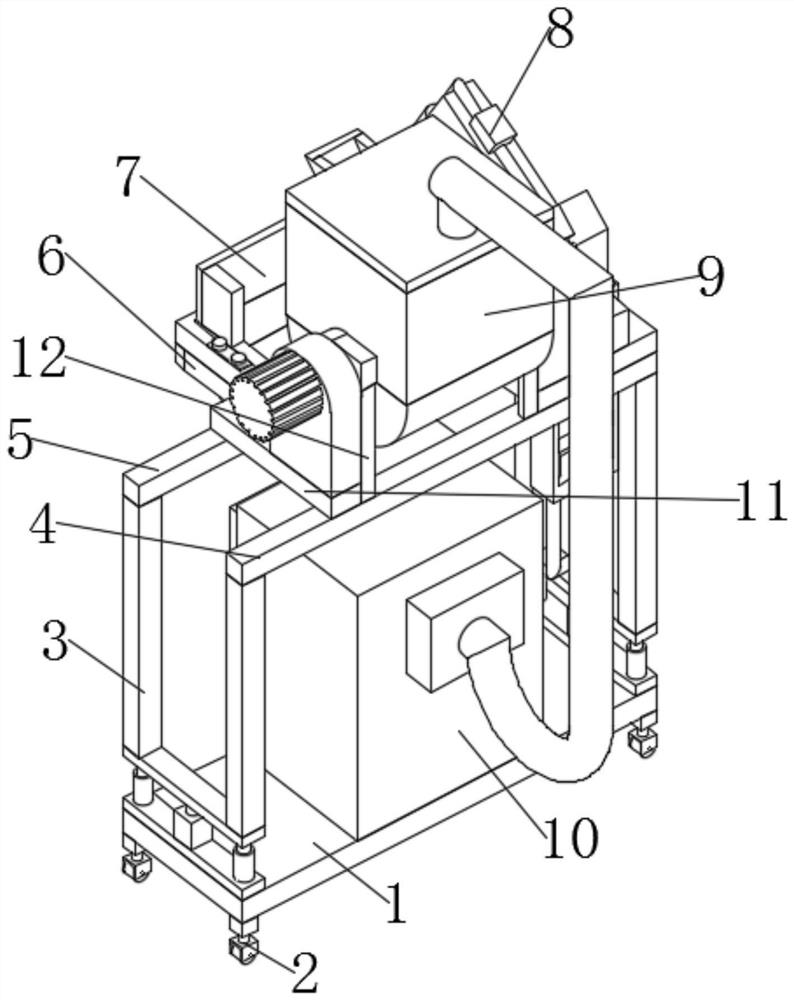

[0038] On the basis of Example 1, as Figure 3-4 As shown in the figure, a quantitative pouring equipment for concrete wall panels for civil and construction engineering, including a mobile base 1, the four corners of the lower end of the mobile base 1 are fixedly connected with universal wheels 2, and the upper front part and the upper rear part of the mobile base 1 are fixedly connected with fine-tuning Device 3, and the upper ends of the two fine-tuning devices 3 are fixedly connected with the first connecting rod 4 and the second connecting rod 5, the middle part of the right end of the second connecting rod 5 is fixedly connected with the support frame 6, and the support frame 6 is interspersed with a material guide device 7. The front part of the upper end of the first connecting rod 4 and the second connecting rod 5 is fixedly connected with a vibrating device 8, and the middle part of the upper end of the first connecting rod 4 and the second connecting rod 5 is fixedly...

Embodiment 3

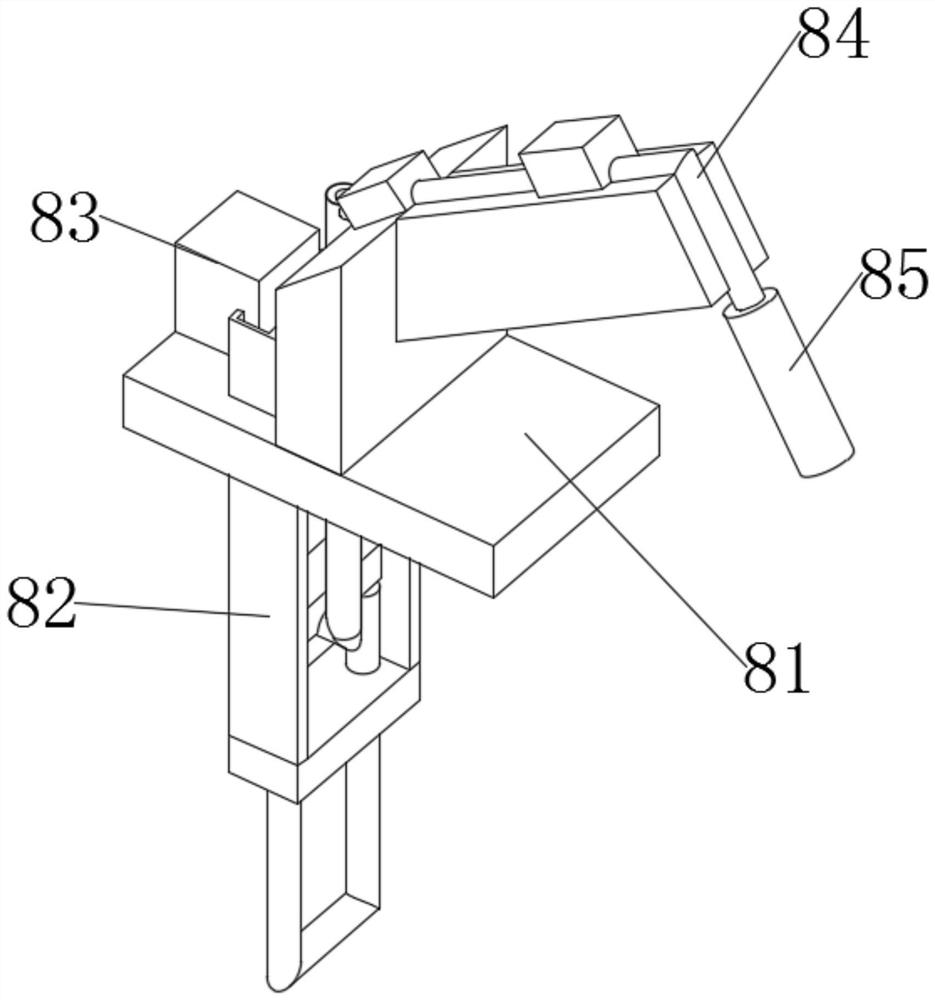

[0041] On the basis of Example 1, as Figure 5-9 As shown in the figure, a quantitative pouring equipment for concrete wall panels for civil and construction engineering, including a mobile base 1, the four corners of the lower end of the mobile base 1 are fixedly connected with universal wheels 2, and the upper front part and the upper rear part of the mobile base 1 are fixedly connected with fine-tuning Device 3, and the upper ends of the two fine-tuning devices 3 are fixedly connected with the first connecting rod 4 and the second connecting rod 5, the middle part of the right end of the second connecting rod 5 is fixedly connected with the support frame 6, and the support frame 6 is interspersed with a material guide device 7. The front part of the upper end of the first connecting rod 4 and the second connecting rod 5 is fixedly connected with a vibrating device 8, and the middle part of the upper end of the first connecting rod 4 and the second connecting rod 5 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com