Semiconductor ceramic packaging shell

A ceramic packaging and semiconductor technology, which is applied to semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc. Into and other problems, to avoid the effect of not easy to deal with

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

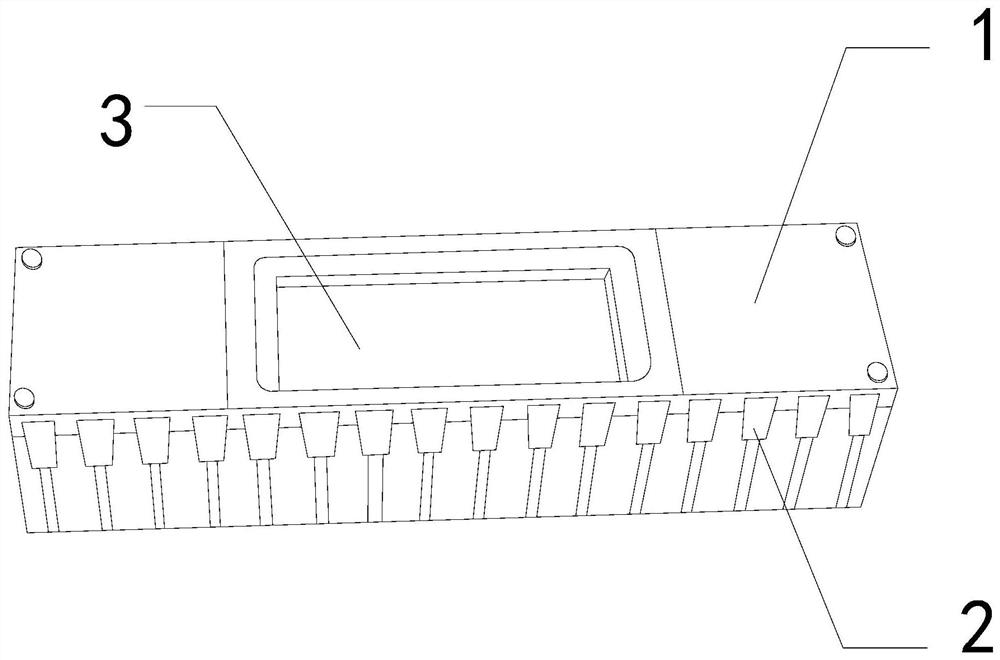

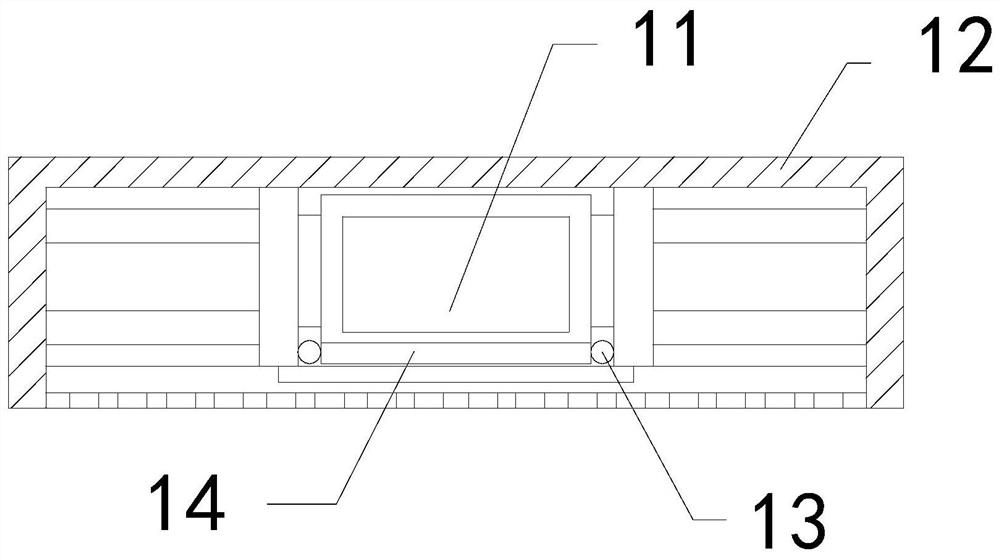

[0026] For example figure 1 -example Figure 5 Shown:

[0027] The present invention provides a semiconductor ceramic packaging shell, the structure of which includes a protective shell 1, an electrical terminal 2, and a chip cavity 3, the electrical terminal 2 is embedded in the front end of the protective shell 1, and the protective shell 1 and the chip cavity 3 is an integrated structure; the protective shell 1 includes a chip 11, a shell 12, a movable ball 13, and a contact plate 14, the chip 11 is embedded in the inner center of the shell 12, and the movable ball 13 is installed between the chip 11 and the contact plate 14. Between the inner walls of the housing 12 , the contact plate 14 and the chip 11 are integrated.

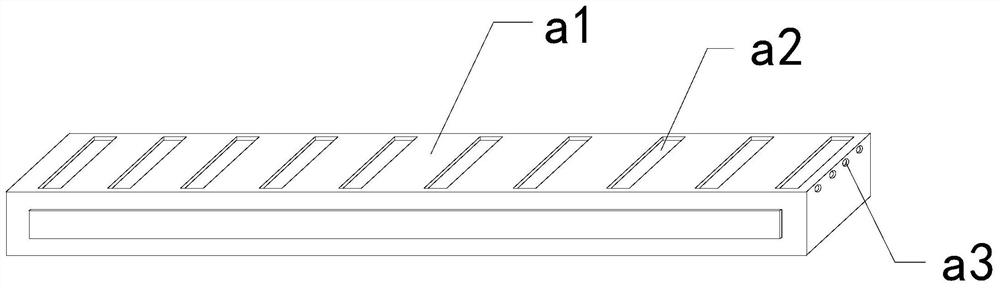

[0028] Wherein, the contact plate 14 includes a plate body a1, a concentration groove a2, and an outer row hole a3, the concentration groove a2 is embedded in the upper surface of the plate body a1, and the outer row hole a3 and the plate body a1 are an...

Embodiment 2

[0034] For example Image 6 -example Figure 8 Shown:

[0035] Wherein, the movable ball 13 includes an outer contact ring c1, a guide mechanism c2, a middle solid block c3, and a collection groove c4. The outer contact ring c1 is movably engaged with the middle solid block c3. c1 is an integrated structure, the collection groove c4 is embedded and connected with the middle solid block c3, the guide mechanism c2 is provided with four, and is evenly distributed in a circle on the outer contact ring c1, and the outer contact ring c2 can be guided by the guide mechanism c2 The ceramic debris is introduced between the outer contact ring c1 and the middle solid block c3.

[0036] Wherein, the guide mechanism c2 includes a fitting block c21, an outer sliding plate c22, an elastic strip c23, and a frame c24. The fitting block c21 is embedded and fixed at the front end of the outer sliding plate c22, and the elastic strip c23 is installed on the outer sliding plate c22. Between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com