Pre-embedded full hole plugging method of printed circuit board

A technology for printed circuit boards and plug holes, which is used in printed circuits, printed circuits, and printed circuit manufacturing. Foaming problem, the effect of eliminating foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

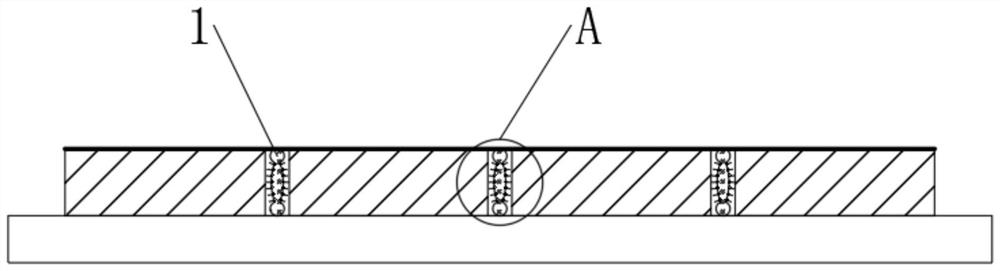

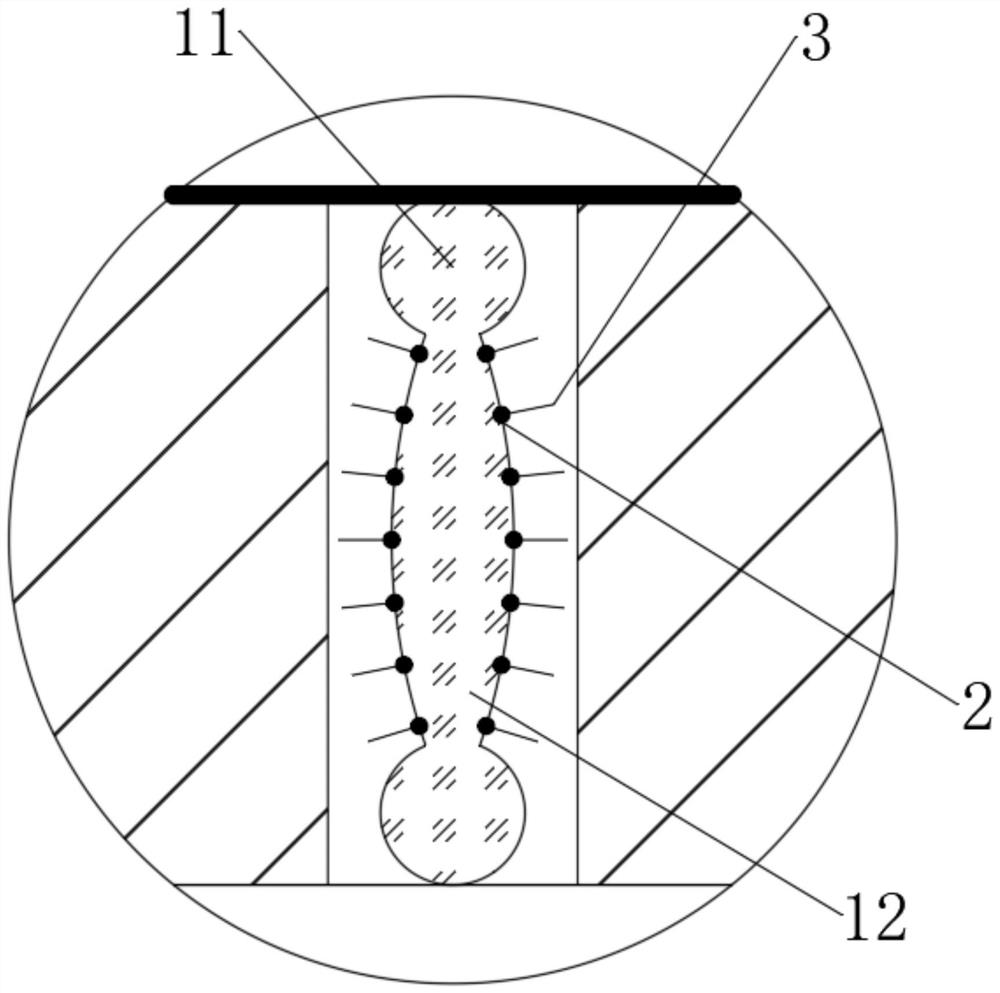

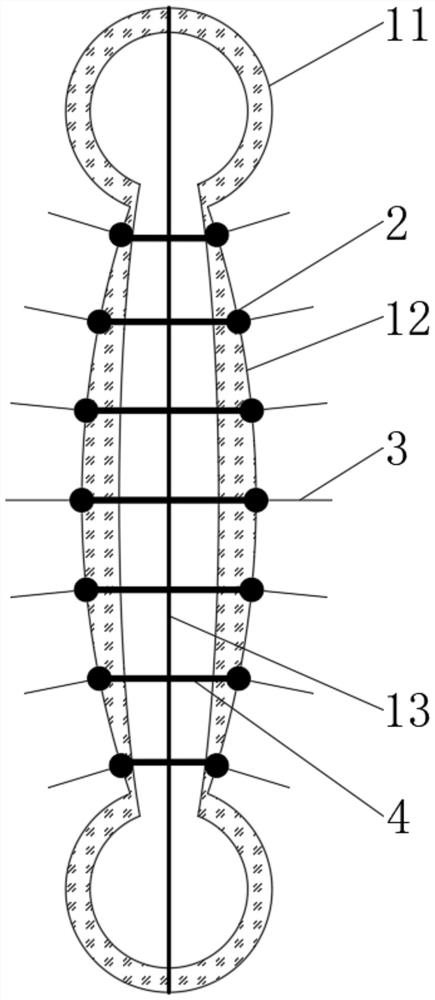

[0043] see figure 1 A method for pre-embedded full plugging holes of a printed circuit board, wherein the printed circuit board is provided with at least one through hole to be plugged, comprising the following steps:

[0044] S1. Pre-embed the plugging rod 1 into the through hole of the printed circuit board, and keep the vertical state after adjusting the position;

[0045] S2. Carry out film-sticking treatment to one end surface of the printed circuit board, and cover with a protective film;

[0046] S3. Print the plug hole material on the printed circuit board where the protective film is exposed, and ensure that the plug hole material completely covers the through hole;

[0047] S4. After the plugging is completed, the printed circuit board is heated and solidified, and the plugging rod 1 expands in the through hole to seal the through hole, and performs local fretting to eliminate air bubbles;

[0048] S5. After the plug hole material is completely cured, the protectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com