Pretreatment method and device for circuit board heat dissipation ink

A technology of pretreatment device and circuit board, which is applied in transportation and packaging, foam dispersion/prevention, chemical instruments and methods, etc., can solve the problems of a large number of tiny bubbles, and the distribution of graphene is not uniform enough, so as to reduce production costs and eliminate the Bubble, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

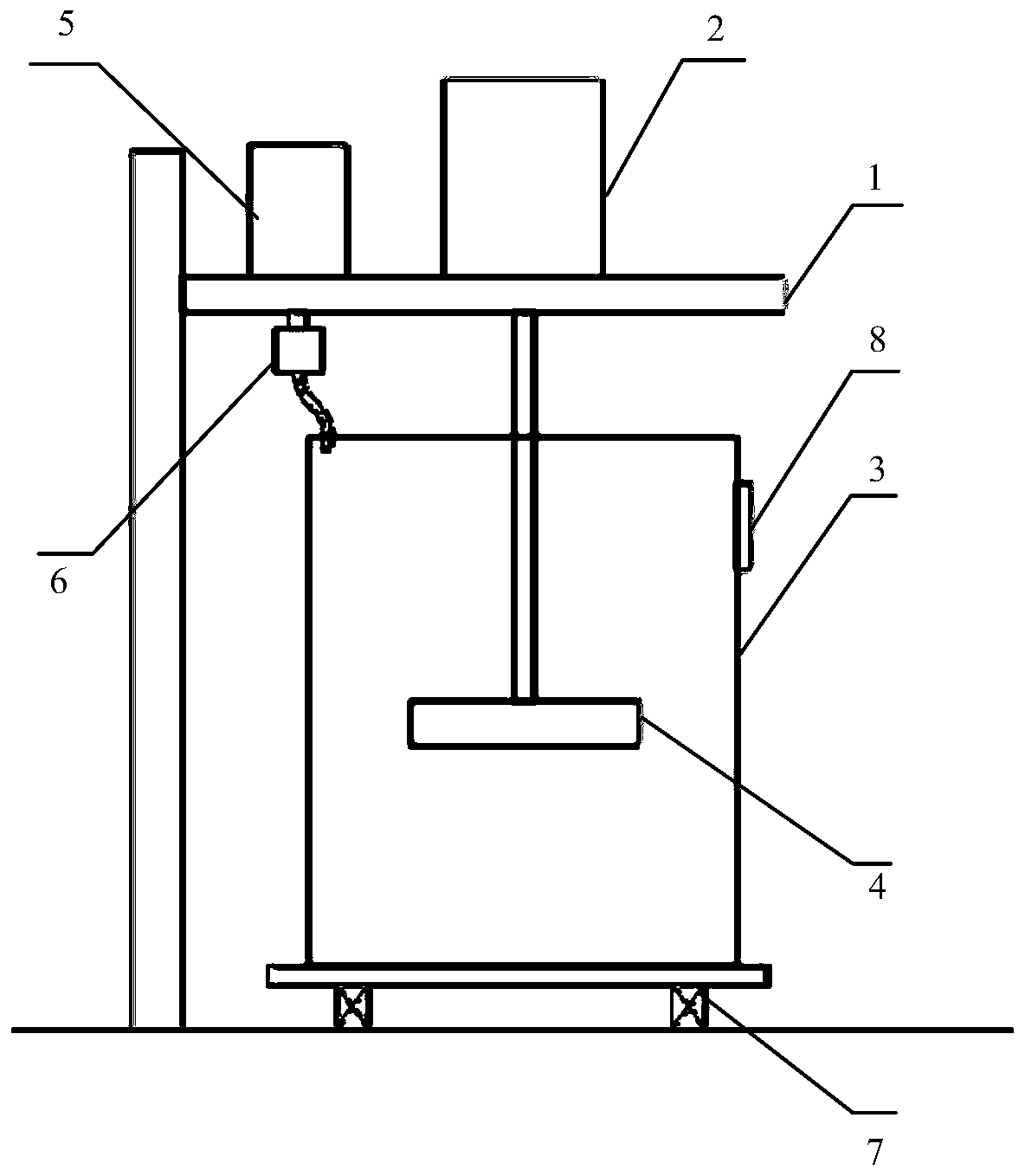

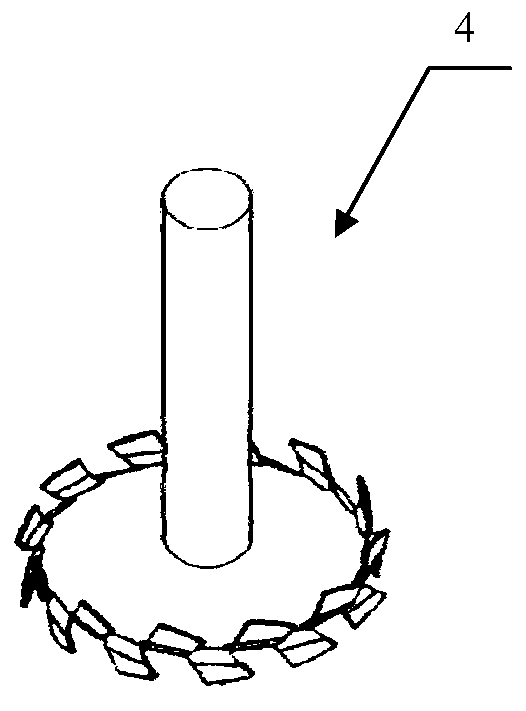

[0025] The above description is only an overview of the technical solution of the present invention. In order to better understand the technical means of the present invention, it can be implemented according to the contents of the description, and in order to make the above and other purposes, features and advantages of the present invention more obvious and understandable , the following preferred embodiments are specifically cited below, and are described in detail as follows in conjunction with the accompanying drawings.

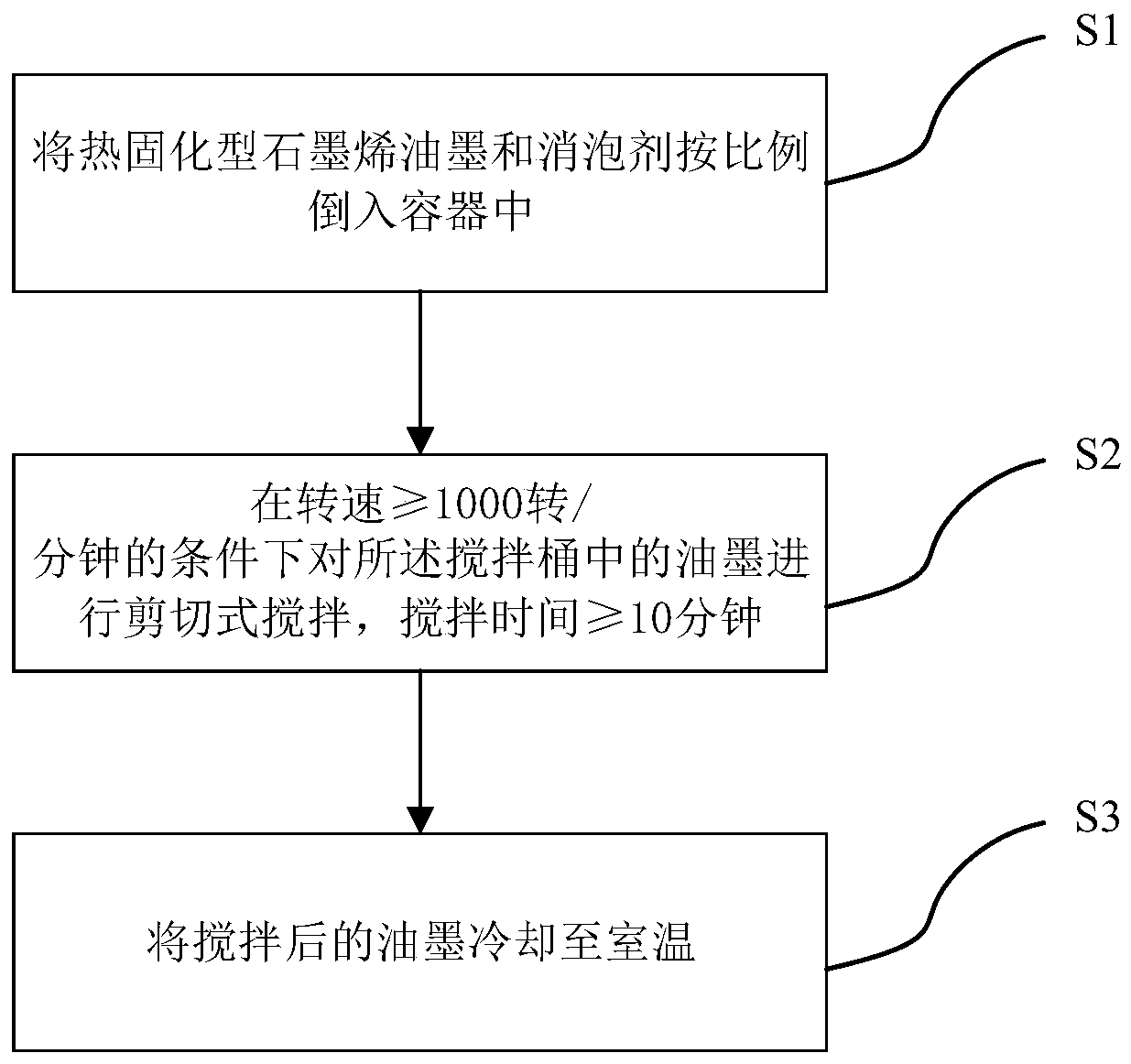

[0026] Please refer to figure 1 , the pretreatment method of a kind of circuit board heat-dissipating ink disclosed in this embodiment, comprises the following steps:

[0027] S1. Pour the thermosetting graphene ink and the defoamer into the mixing tank in proportion, and add the defoamer when stirring the thermosetting graphene ink, which is beneficial to eliminate the bubbles in the ink;

[0028] S2. Under the condition of rotating speed ≥ 1000 rpm, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com