Titanium alloy volute casing piece forming method

A forming method and a technology of volute parts, which are applied in the field of processing plate-made metal heterogeneous parts, can solve problems such as processing technology gaps, and achieve the effect of large springback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The invention has been used in the industrialized small-batch production of a certain type of titanium alloy volute for aircraft engines, and the quality, various shapes, sizes, performances, structures, etc. of the volute meet the requirements of design and use.

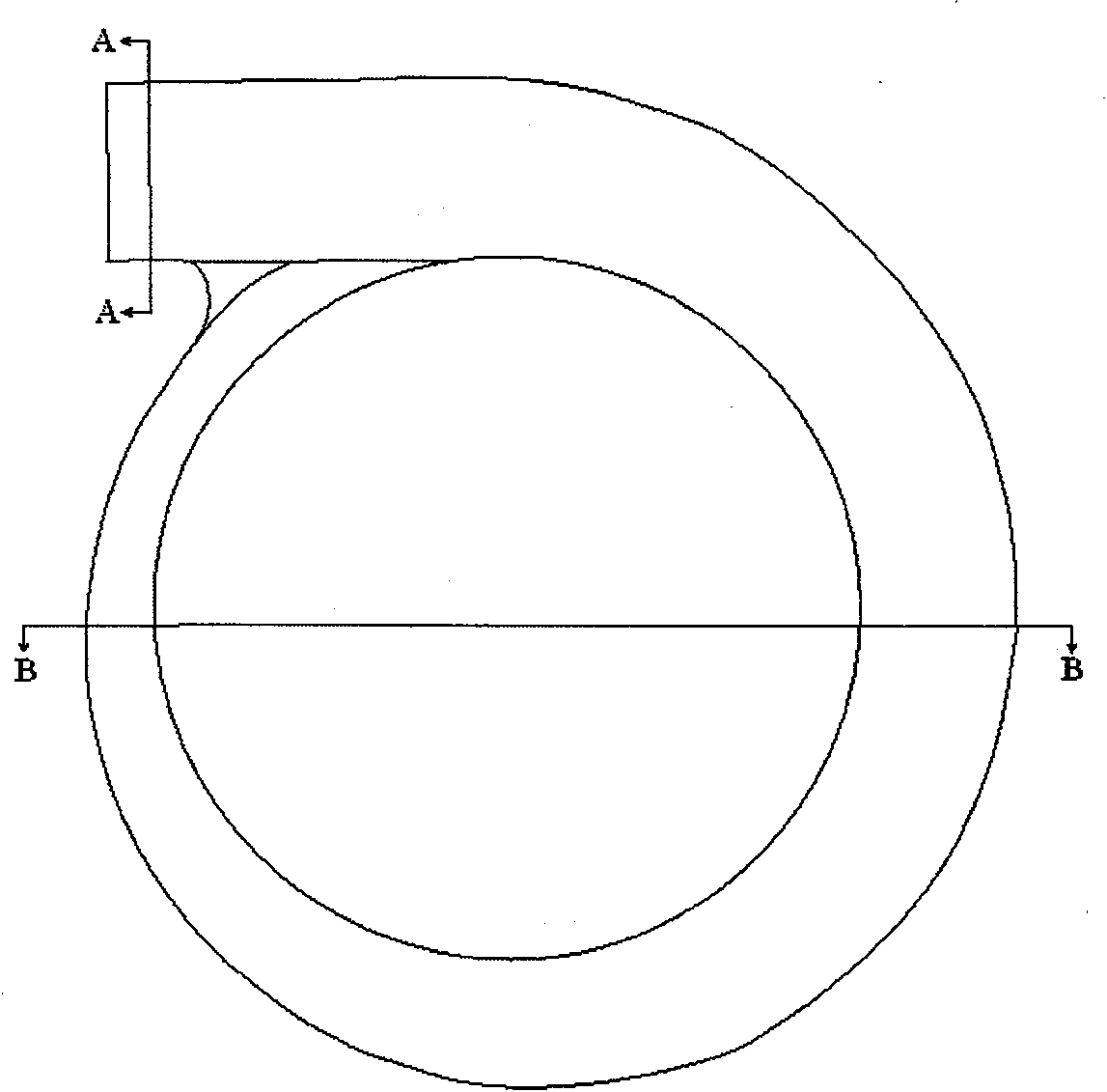

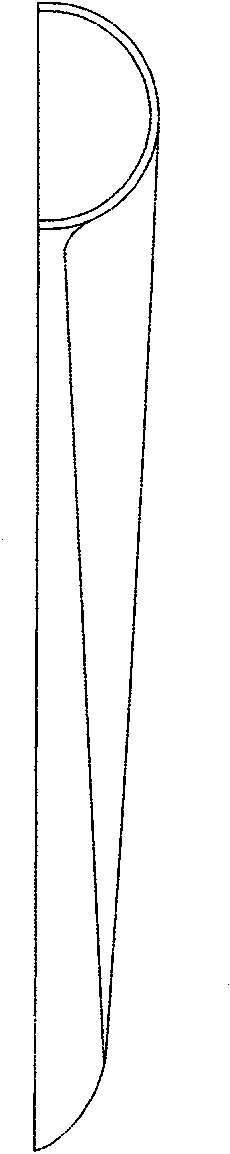

[0046] (1) Billet calculation: according to figure 1 As shown in a certain type of titanium alloy volute, the product design thickness is 2mm, choose 2mm TC4 thin plate as the blank, and then bring the corresponding parameters at different angles α of the volute into formulas 1 and 2 to calculate the outer circle and inner circle of the blank respectively. circle size. Billet diagram see Figure 6 .

[0047] Formula 1: R α =R α1 +π / 4D α +Δ

[0048] Formula 2: r α =R α1 -π / 4D α -Δ

[0049] R α ——Outer radius at angle α of billet; unit: mm

[0050] R α1 ——Central radius at angle α of the volute itself; mm

[0051] D. α ——the cross-sectional diameter of the volute itself at angle α; mm

[0052] r ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com