Wind wheel blade with antiicing and deicing functions

A technology of wind rotor blades and capacity, applied in wind power generation, wind engines, wind turbine components, etc., can solve the problems of insignificant heating effect, low heat utilization rate, and inability to install airflow pipelines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

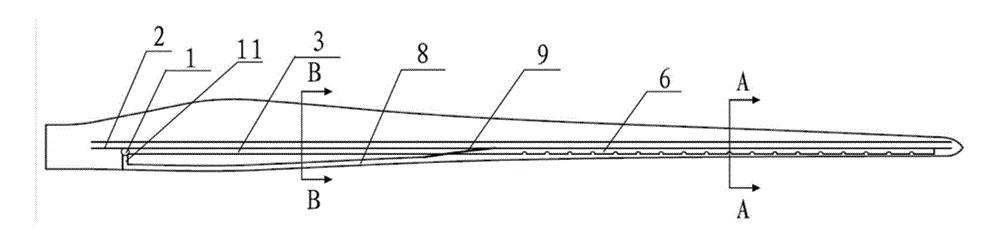

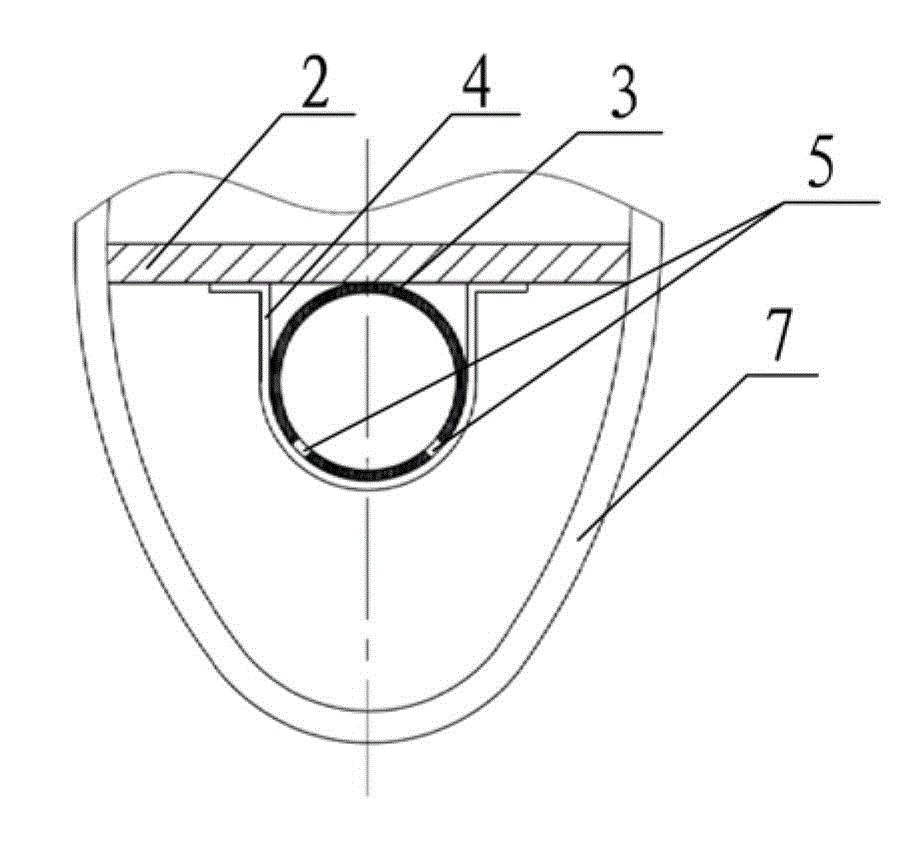

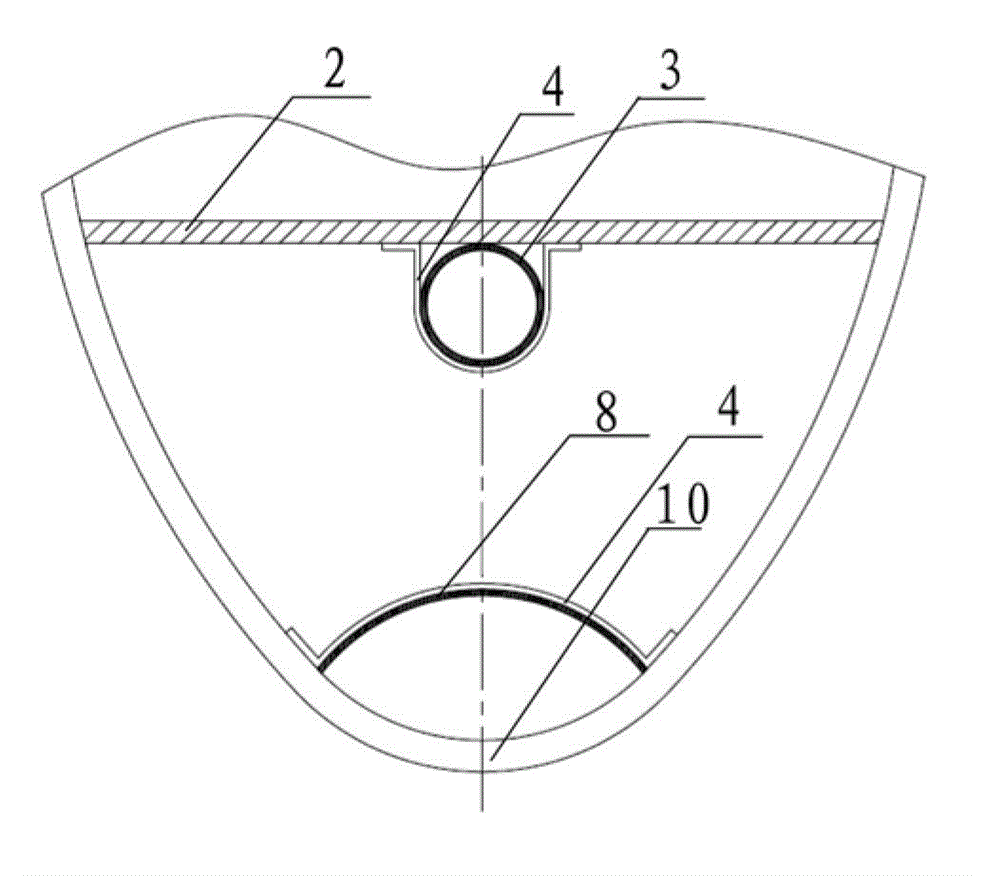

[0023] See Figure 1-5 As shown, the wind turbine blade usually includes a shell and a shear web 2 that divides the inside of the shell into front and rear edge cavities. The wind turbine blade with anti-icing and de-icing capabilities of the present invention is located in front of the blade. A heating device is added to the edge cavity.

[0024] Specifically, the heating device includes a heated blower 1 installed near the root of the blade, and an insulating pipe 3 connected to the air outlet of the heated blower 1. The insulation pipe 3 is located in the middle of the blade (approximately R / 2, where R is the length of the blade) to the corresponding area of the blade tip is a flute tube 6 with an air jet hole 5, and the opening direction of the air jet hole 5 faces the leading edge of the blade. 5 The discharged hot air is circulated to the air inlet of the heated blower 1.

[0025] The pipe diameter, nozzle aperture, hole number, hole spacing, spanwise spacing, hole layout ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com